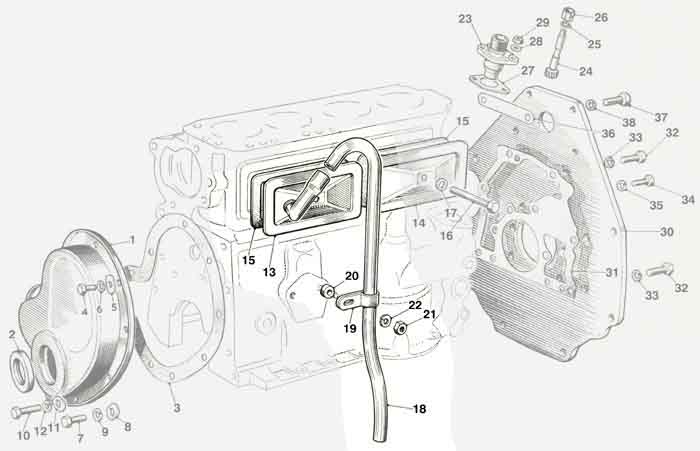

Early unrestricted and unfiltered cover 12H950 for the 'road draught tube' used on non-positive ventilation systems. (Auto-Part.com)

Cover with internal filter and oil separator 12H1399 for PCV-ventilated systems. (Moss Europe) However despite the drawing showing it as being box-shaped one corner was flattened as per the top one here.

Cover with external filter and separator 12H3684 used when carburettor ventilation was introduced with 18GG engines (69 model year), and used until the 18V779/780 engines were introduced during the 74 model year. However the Parts Catalogue states that rebuilt engines used the cover below, as is the case on Bee's Gold Seal engine. Image from William Revit in Tasmania via the MG Enthusiasts forum.

The later front cover 12H4395 ...

... with internal oil separator/flame trap steel 'pan scourer'. However at least one person has found this resulted in excessive oil burning via the cover and replaced it with the earlier PCV version 12H1399. With one corner flattened and the opposite corner changed in shape as per the lower one here.

12H1399 above, 12H4395 below. (Chris Howells)

12H1399 above, 12H4395 below. (Chris Howells)

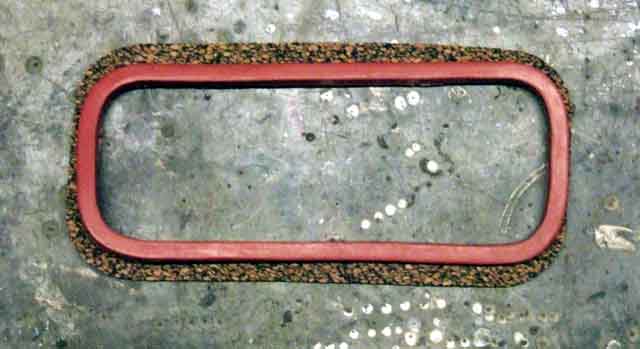

Rubber gasket quite a bit smaller than cork

It's possible the rubber would stretch to fit the front cover, but it would be very difficult to keep it in place. The cork is an easy fit, but note how it has to seal against a 'rippled' surface where the inner and outer plates have been attached together. Note also the very long bolt, cup washer and rubber bush. The pre-September 76 Parts Catalogue indicates a copper washer (or two) was used here with only this cup and bush on the rear cover, the September 76 on catalogue shows cup and bush being used on both covers. My 1973-spec Gold Seal engine had them on both.

When fitted the bush is pushed into the cup washer, and compressed as the bolt is tightened. The bush wants to squeeze outwards, but is constrained by the cup, so squeezes onto the bolt threads instead, as well as being pressed onto the face of the cover.

The cork gasket would never fit the rear cover, being too large and thin to fit in the channel. As it is the rubber gasket is slightly too small. This has a flat face and a slightly rounded face, the rounded face fits in the channel.

Lightly clamping it in place overnight stretches it. Note the round-edged pieces of wood so the face of the gasket isn't distorted.

When the clamps were released the gasket stayed in place, but leaving it unclamped for a while allowed it to regain its former size and pop back out.

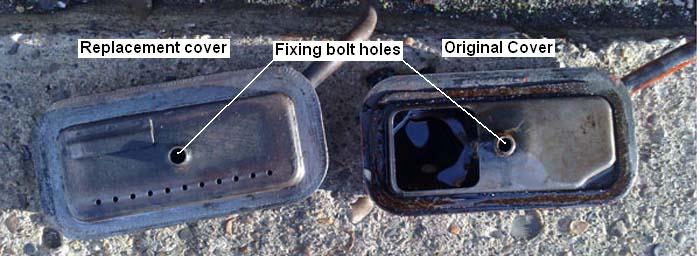

Oil burning via the breather: Adam's original (12H4395) and replacement (12H1399) covers. The strip of metal near the top left corner of the replacement cover is positioned over another set of holes. I suspect these are nominally the inlet, with the strip of metal acting as a shield preventing oil running down the walls from trickling in. The holes at the bottom draining any oil mist converted to liquid drops by the wire wool.

If you have the problem and can't lay your hands on one of these alternative covers it seems to me you could weld a plate over the hole and drill your own holes along the bottom, although I'd remove the wire wool first, drill the holes in the right-hand half of the cover and be sure I had got all the swarf out, replace the wire wool, cut the plate to size, drill that before welding (to keep swarf out of the cover), then weld it to the cover. Or maybe weld a plate over the hole leaving just a narrow slot at the bottom.

Peter Donlan's neat catch-bottle installation