Engine ready to lift out ...

Very badly scored friction surface on the cover-plate, a deep groove from the friction plate rivets as well as significant wear across the full width of the friction surface.

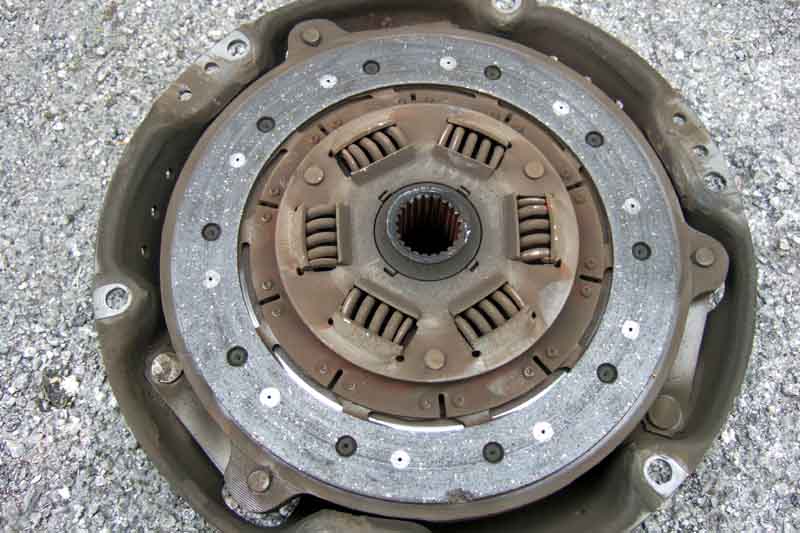

Friction-plate down to the rivets, fortunately only on the cover-plate side (facing upwards here)

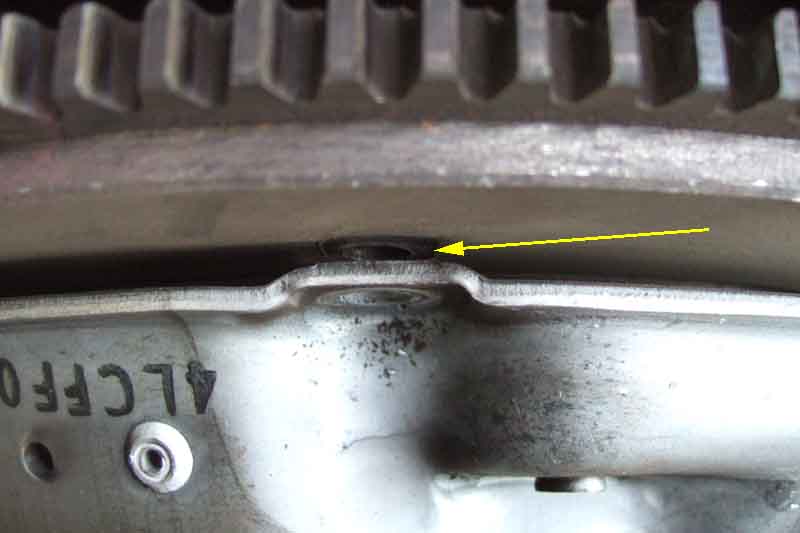

Flywheel fortunately sound. Only a very slight depression across the full width, what looks like a groove from rivets is actually only a polish mark as can be seen by the reflection of the screwdriver. No blueing from the slipping or sign of oil from the crank seal.

Old and new friction plates - the old has the pads completely worn away both sides plus about half the base material on the cover-plate side. Quite a difference in thickness between old and new, together with the wear on the cover plate it's not surprising it was slipping and the springs wouldn't push the cover-plate off the dowels. Note the centre section containing the damper springs and splined boss projects much further from the face of the friction surface on one side than the other, uppermost on both these. This side faces the cover plate, if incorrectly fitted it prevents the friction surface from reaching the flywheel. So offer up the new one first to double-check, and triple check any 'flywheel side' legend on the new friction plate.

New and old release bearings - plenty of meat left on the old, perhaps only 1/3rd worn, as the boss on the cover plate can go right down inside the release bearing casting.

... and engine out (wish it were as easy as that). Gunky oil in the bell-housing, around the release arm rather than straight down from the first-motion shaft and cleaner oil if it had been the oil seal. I would very strongly advise freeing-up the connection between the clutch hydraulic pipe and the end of the hose, and the locknut securing the hose to the bracket on the chassis rail while the engine is out even if you don't think you will be removing it later. It's an absolute pig when the engine is in.

No visible seepage from the seal itself, so just checked the nuts on the seal plate for tightness. Check the release arm does not wobble on its pivot, but still moves freely. If the arm wobbles the release bearing can be off-set to the cover plate which causes premature failure.

Another clutch change June 2013

Cover plate pushed off by the diaphragm spring ...

... indicating plenty of life in the friction plate

Witness marks as the rivets pass by, but no grooves on the flywheel, which could have happened with any previously worn-out clutch

New cover plate

Friction plate fitted the wrong way round, miles away from the flywheel

Fitted correctly, no gap

Back together, gearbox harness fitted, ready to go back in. However the harness should go under the remote change housing from the reverse switch to the OD switch, not over as here.