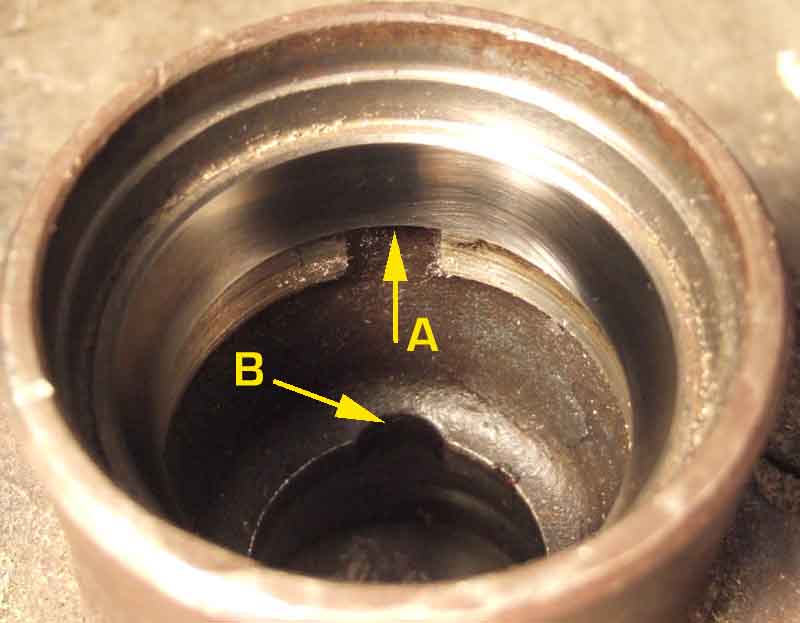

Cut-out revealing the face of the outer race of the outer bearing, for drifting out the old races. Above it is the cut-out for the outer race of the inner bearing which has already been removed.

From the other side - insert a drift through the hub along the line of A to drift this inner bearing race out. B shows the cut-out for the outer bearing race.

Looking down the 4" tube of a wire-wheel hub, down which the outer race of the outer bearing has to be fitted.

1 5/16" socket is a nice fit on the narrow face of the outer race of the outer bearing. OK on a stud-wheel hub, but it's not easy to control down the tube of a wire/wheel hub.

Outer race of the inner bearing. Would need a very large socket, or the old race can be used to spread the load. Note this thinner face of the two faces outwards, on both outer races.

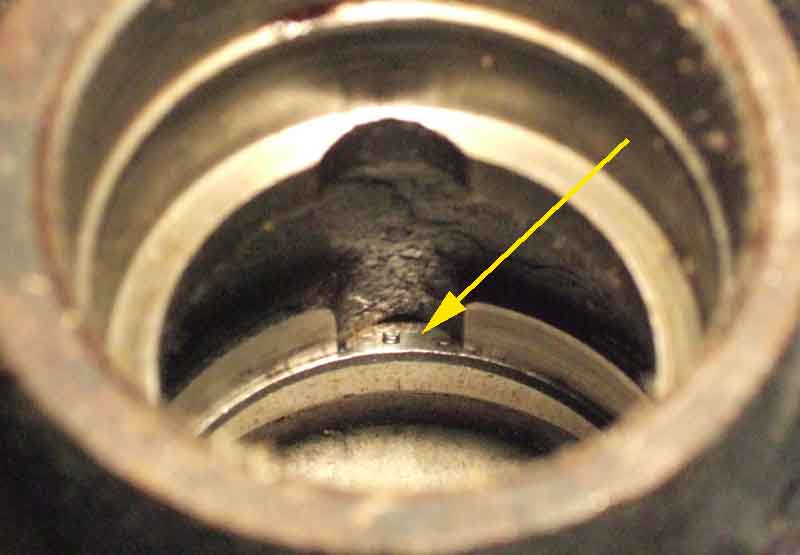

It's important to get the races fully seated. When drifting them in there is a definite change in the sound when they 'bottom', but peering in from the opposite end at the cut-outs used for drifting the old races out you can also inspect them. This is not quite seated and shining a light in shows a shadow on the seating face of the race:

Fully seated and no shadow:

Also fully seated you should be able to see the top of the slightly reduced diameter of the hub as a bright ring (arrowed) at the outer edge of the race:

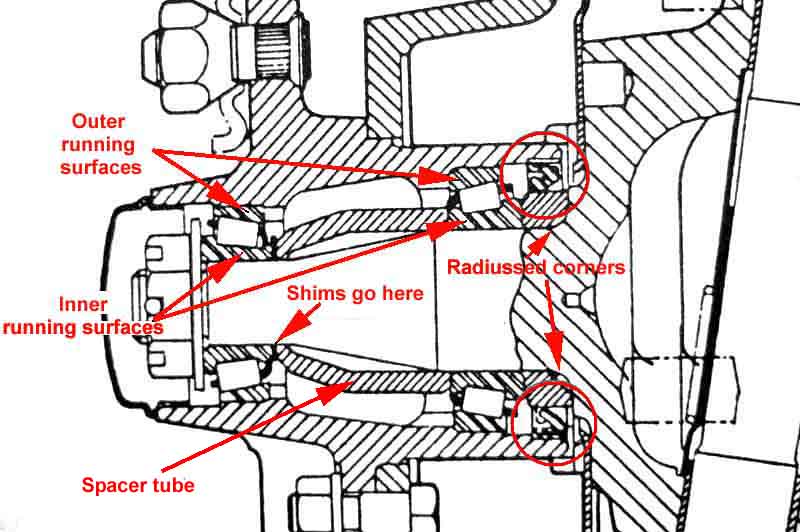

Oil seal (circled) correctly fitted with the flat side facing outwards (to the right) and the lip and groove facing inwards. Also note that the collar it rides on has the inner radiused corner facing the hub, if it's fitted the other way round you won't be able to set the end-float correctly:

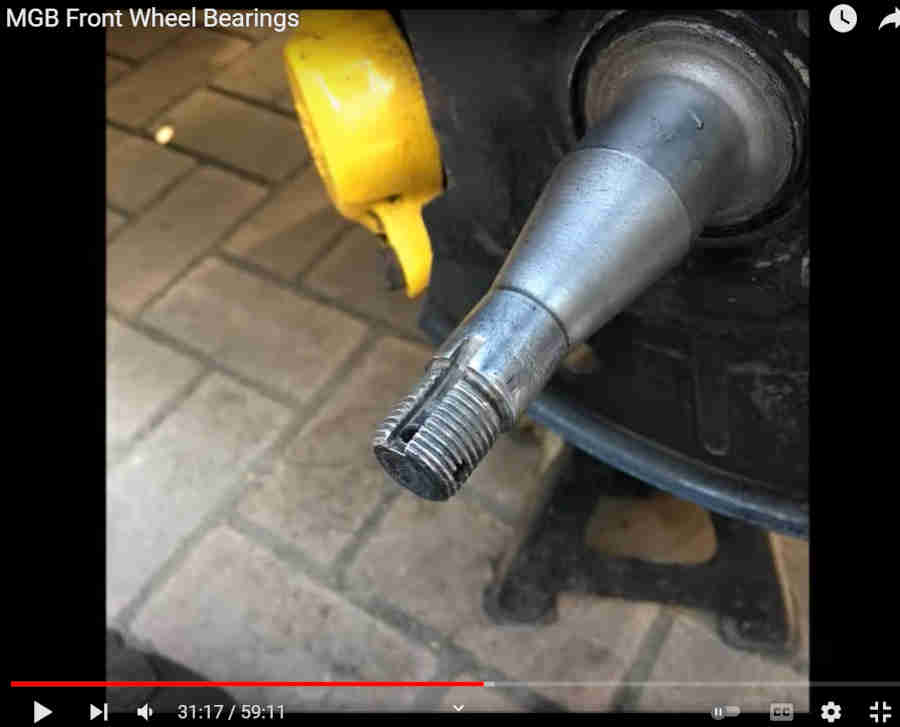

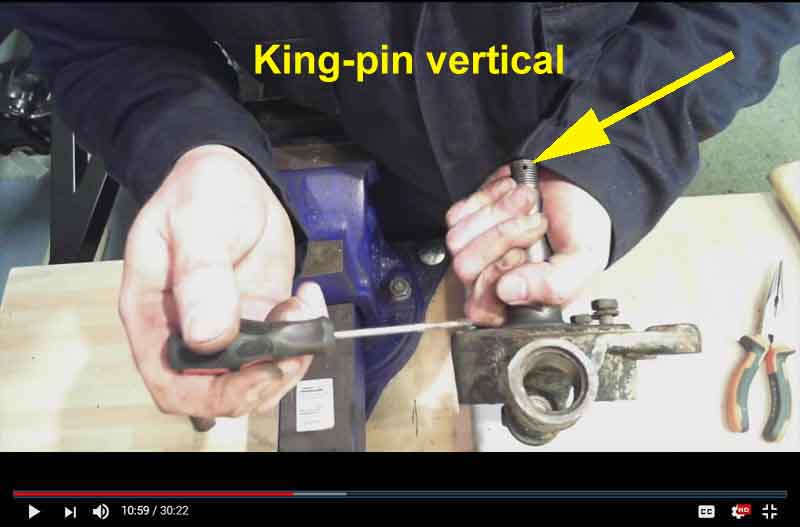

Some have said their stub axle only has one split-pin hole. Mine have two, and these two frames from this YouTube video also show two - one in-line with the king-pin and the other at right-angles. Check the previously unused hole isn't full of grease and muck:

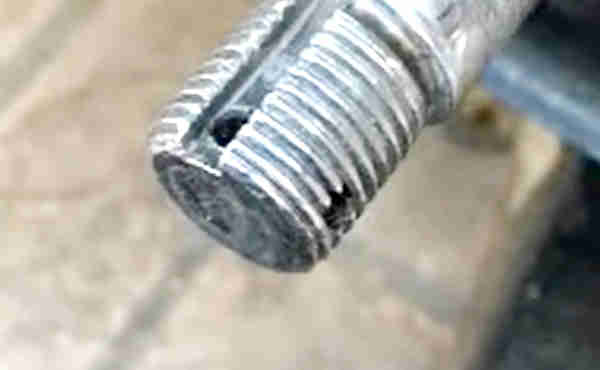

This still from another video shows both holes in the same shot: