When I tried to bleed the clutch on my MGB, I would open the bleed on the slave, press the pedal down. Result: the fluid comes out, the pedal stays down, so no pumping is possible (I always detach the pedal return spring, during bleeding, as it may give the false impression that the master cylinder piston has returned, where in fact it is just the pedal that has returned) it seems like the return spring inside the master is not strong enough to push back the piston. First thought: has the master return spring failed? No, on removal it is working properly.

I had spent several hours trying to bleed the clutch without success, so I looked on the internet and was comforted to see that it is a nightmare job for everyone including professional garages. While planning my next attempt, I thought I would bleed the clutch on my Triumph GT6. I filled up the master cylinder, opened the bleed. Fluid came out, pumped the pedal a few times, checked for bubbles, tightened bleed. Job completed in about 10 minutes.

Why were the two tasks so different?

This bit of information found at: mgparts.co.nz: The lack of a return valve means the air in the pipe and slave cylinder is not isolated from the master cylinder so the suction generated by the master cylinder piston stroke, is dissipated right through the system rather than confined to the master cylinder. The amount of suction remaining is not enough to draw new fluid in.

Clearly the problem lies with the master cylinder design. Taking a close look at the master cylinders in the early MGBs, there is very little room in the pedal box, the brake master cylinder takes up most of the room. It looks like MG had to use the thinnest reservoir clutch master available, and even then, they couldn't mount it straight (see the slanted mounting flange). On later cars with servo there is more room, but they kept with the Lockheed cylinder.

The Girling master cylinder was installed in most Triumphs, Land Rovers and the MGC. There are various bores available including 3/4inch (0.75") the same bore as the MGB. The pedal box mounting bolt holes match up perfectly, but unfortunately the centre hole is a few mm too small, but a few minutes with a hand file on the master cylinder solves this:

Just swap the push rod, circlip and the retaining washer (this needs to have a notch cut out to be fitted onto the push rod):

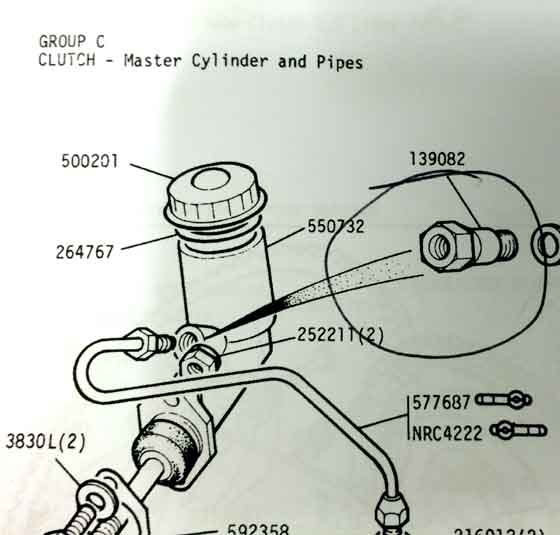

The MGB uses a larger diameter solid pipe, so the adaptor, (as used on Land Rovers) is required to convert 3/8 to 7/16:

I had considered replacing the whole solid pipe with smaller diameter pipe, however the slave cylinder are also the larger 7/16 union.

Gently bend the solid pipe to attach to the adaptor and master cylinder. Reconnect clevis pin etc.:

Bleed clutch in normal way (as you would do the brakes) now takes about 10 minutes instead of several days.

Land Rover Master cylinder: STC500100 & Adaptor: 139082

This Girling clutch master is original equipment on the MGC, which has a completely different pedal frame again, and this picture shows masses of clearance for the clutch - which is just as well given the height of the brake master. I'm wondering if the MGC frame positions the master cylinder mounting face forwards of both MGB positions, or is just lower:

Ray Leborgne's RHD installation, alongside the original single-circuit brake master. The clutch cap is pretty close to the brake master but otherwise clearance looks OK. Ray is contemplating using a Girling brake master as well, but as can be seen from the MGC installation above the MGC brake master almost certainly won't fit in an MGB pedal frame. That's maybe why a second clutch master has been mentioned as an alternative, but with significantly reduced fluid capacity:

The 'ink' is hardly dry on the above and Ray has fitted a Girling brake master:

He writes:

The top unscrews to fill it up, however the top cannot be removed, and it can only slide back. It just means I cannot use my Eezibleed, not the end of the world.

Although I used the old push rod from the old MC (as the clutch instructions) what I did not see (until it was too late) was that the overall length from the pedal box to the pedal was very slightly longer, thus it locked the brakes on. This was overcome by grinding down the edge of the pedal and inserting spacers on the MC.

It may work better with a Mk1 pedal box as this looks like the MC fixings a lower which means more space between the cap and bulkhead.

I was hoping to replace the plastic cap of the clutch MC for the metal version, I purchased a cap which was stated as 44mm (the ID of the Girling MC) but alas it was too big, I suppose that what you get with aftermarket. So I'm reluctant to keep trying, the plastic will stay.

Subsequently Ray had further problems with the push-rod causing the brakes to lock on:

I transferred the old push rod from the Lockheed (as per the clutch) and used the retaining washer from the Girling. But what was happening was as the pedal was on its return stroke the push rod was catching the retaining washer and not fully returning thus locking the brakes.

The reason (in my view) is twofold, the shape of the old push rod and the size of the hole in the retaining washer.

The Girling is on the left, Lockheed on the right. As the Lockheed is more pointed it would move around on the end of the cylinder's piston and because the retaining washer had a large hole the push rod would move to one side and catch the retaining washer on its return stroke. It's done this a number of times when driving, just flick the brake pedal and they would unlock.

So went back to the Girling push rod, made a new retaining washer (smaller hole) and adapted the old Clevis (drilled and tapped) to fit on the Girling push rod with locking nut. Having a locking nut (half nut) does not interfere with the overall travel of the push rod.

Converted the clutch to match.

Going by this picture of Mk1 and Mk2 single-circuit pedal boxes side by side from Dave O'Neil the Mk1 does seem to position the master cylinders lower. The covers also changed which tends to support that:

Note that the pedals also changed from Mk1 to single-circuit Mk2 and matching items may be necessary to maintain the geometry of the pedal, push-rod and master cylinder. The box (and cover) changed again for single-circuit rubber bumper, but the pedals didn't.

Mk2 Lockheed master cylinders for comparison: