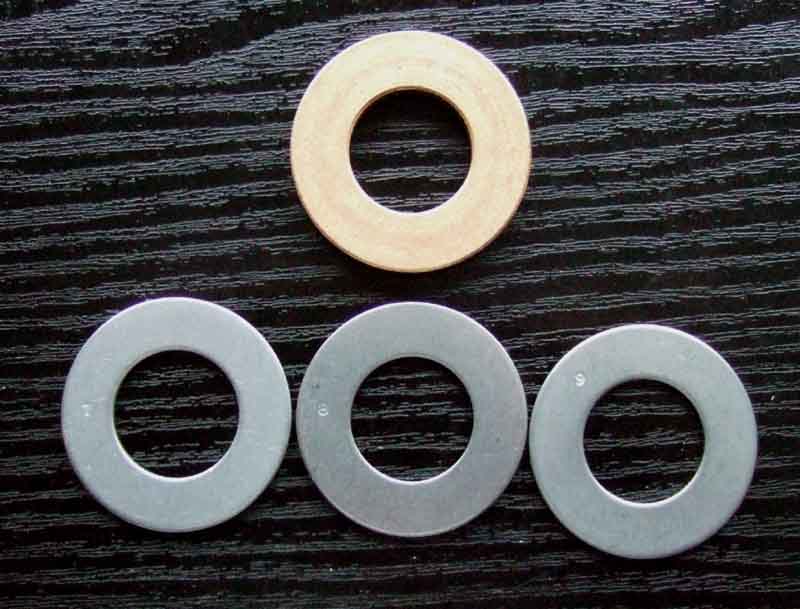

New phosphor bronze thrust washer and three selective sizes of shim. At least that is what the numbers stamped into the shims purport to be, five of the six I got from Moss were all the smallest size!

The recess in the king-pin for the bushes ...

... and the cut-out in the trunnion (shown with the threaded part of the king-pin in the cut-out for clarity):

Ironically I laid in a top-link repair kit for the side I hadn't had apart before, but didn't need it (for that ...). The Motaclan/Leacy repair kit. Ironically the 'original' (i.e. I hadn't had it off before) top trunnion pin came out easily with just a bit of tapping (on the threaded end of the pin with a lump-hammer behind the opposite damper arm):

Just as well as the pin I'd replaced a few years earlier (which also came out just fine) stripped its thread when re-tightening the nut!

Contrary to rumour, these bushes (described as 'barrel' type, and you can see why) have a steel sleeve in them, which acts as a distance tube to leave the correct clearance between damper arms and upper trunnion. This sleeve rusts to the pin meaning you have to hacksaw through the pin either side of the trunnion, then drill/chisel the remains out of the trunnion. There is talk of a poly 'top-hat' type which also have a sleeve, but the rear shackles use a top-hat type and neither rubber nor red (at least) poly have sleeves, which may be where the confusion comes from:

Hub supported. Either behind the bump/rebound bracket, or the anti rollbar drop-link if replacing the bracket at the same time (note the missing bump rubber!):

A plain nut and/or a spacer makes life easier when trial-fitting shims (not so much doing up and undoing) and protects the Nyloc (on my king-pins, not castellated) insert from wearing out:

Nut and bolt squeezing the bushes into the trunnion, daub with Waxoyl. Note the king-pin hole is inboard of the bushes and pin ...

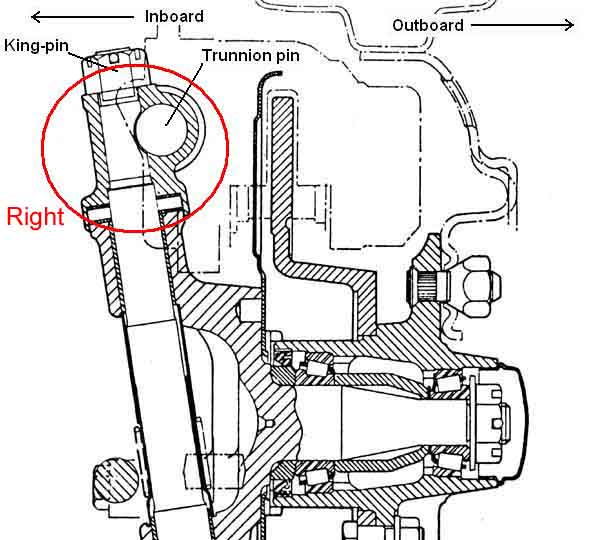

... the Leyland Parts Catalogue and Workshop Manual exploded drawings are incorrect (note this shows a top-fill damper but MGBs are side-fill) ...

... however the Workshop Manual assembled drawing (mirror-image for comparison with the above drawing) is correct:

Damper cross-bolt slackened, arms wedged apart ...

... and a paint scraper used as a guide to wedge the bushes between the arms. Again daub the faces of the bushes with Waxoyl, have the king-pin slack at this point so you can turn the trunnion a bit to get one face in, then push on the trunnion and the other face will slide along the paint scraper in to position: