Although LED front parking lights probably will be brighter and whiter than the originals the stop/tail versions can be very variable. A pal fitted them front and rear a while ago but they have failed an MOT by being 'adversely affected by the operation of other lamps' (e.g. MOT Manual Section 4.2.3 Defect c. but applies to all lamps) aka 'Discoing'. When the indicators (incandescent in this case) were going one side there was a very clear effect on the front lights and the tail and the stop lights on the other side. Three effects - one was visible slight dimming of the tail or stop lights while the indicators were lit, but the other was a very apparent momentary additional dimming of the tail or stop light at the instant the indicator bulbs were powered. This momentary dimming was also apparent every time the fuel pump clicked, although that is less of an issue. But the biggest problem was that when the brighter brake lights were already lit, turning on the parking lights dimmed the brake down to tail light level, and if the tail lights were already on powering the brake lights did not increase the brightness at all - totally unfit for purpose. A second set of a different type from another source had didn't do that but had their own problems.

This second set did not have the major defect of the stop lights not working when the tail lights were on, but to 'compensate' (I jest) for that they had their own major defect if you should happen to get a short-circuit on the stop-light wiring. This would blow the green circuit fuse as expected, but it also completely extinguishes the tail lights! Both these major defects are almost certainly due to the way the LEDs are wired inside the plug-in unit. LEDs need a resistor in series to limit the current and reduce the voltage down to the 2v that each element typically needs, and in both sets this has obviously been done in such a way - even though the two sets differed - to cause these unwanted interactions between stop and tail.

March 2020: Dave Birkby has tried three different sets of stop/tail LED and all of them cause the parking lights to glow every time the brakes are applied. He had the same problem when refitting incandescent bulbs, which turned out to be a problem with the earth contact in one of the dual-filament bulb holders, but even with this fixed the three sets of LEDs had the same problem (which didn't happen with the two sets above), so he gave up and has left standard bulbs there.

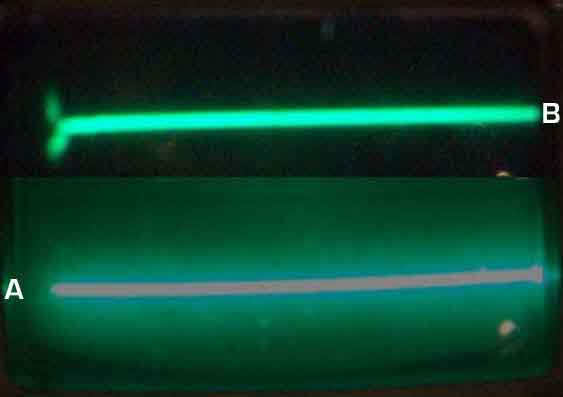

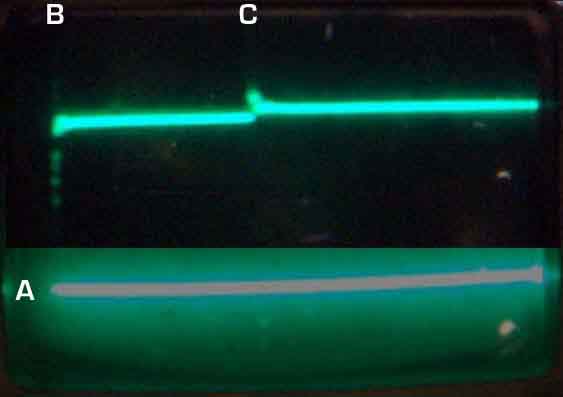

But even when everything is working 'normally' the second set are not all they are cracked up to be regarding brightness. Neither tail nor stop are any brighter than tungsten, with stop noticeably dimmer in a side-by-side comparison with a tungsten bulb that is at least 26 years old. But the biggest difference is the greatly reduced radial output, as can be seen in the images.

But even when everything is working 'normally' the second set are not all they are cracked up to be regarding brightness. Neither tail nor stop are any brighter than tungsten, with stop noticeably dimmer in a side-by-side comparison with a tungsten bulb that is at least 26 years old. But the biggest difference is the greatly reduced radial output, as can be seen in the images.

Other people have found that although some versions do have brighter tail lights than tungsten, the stops were much the same, which means there is less of a step change from tail to stop. I can remember this complaint from when I first started reading about LEDs in MGBs quite a few years ago now. As this makes the stop lights easier to miss unless a following driver is looking towards the back of the car, which has to be balanced with LEDs coming up to full brightness noticeably quicker than tungsten, although later MGBs with the pedal-operated brake light switch come on very significantly quicker (except when panic-braking) than hydraulic switches. With all the other problems, my pal refitted tungsten and gave the whole idea up as a bad job. See also these comments: Video 1, Video 2, Alfa forum and Land Rover forum legal opinion.

September 2018: Another type mentioned on an MGOC forum uses radial white LEDs and what is described as a 'wide-angle high-power Cree' red LED pointing straight back. A comparison using a motorbike rear light does show a significant increase in brightness in 'tail' mode, but tested on an MGB the increase over incandescent was only slight. 'Stop' isn't shown on the site, and on an MGB was not as bright as incandescent. They are described as lighting up the whole of the lens, but no matter how wide-angle an LED is it is never going to be as wide-angle as a dual-filament bulb. At £13 each I'll leave you to judge whether they are worth it or not.

But back to the first set and the 'discoing'. The first thought was bad earths or other connections even though when incandescent bulbs were substituted these effects were barely noticeable - had it been bad connections incandescent bulbs should have been much worse as they are much more sensitive to even small amounts of unwanted resistance. Also some time later these lights were fitted to another car and had the same problems. Despite that, some time was spent measuring voltage and volt-drops through the ignition and lighting circuits. But comparing with my car with incandescent bulbs at the corners of the car there was nothing out of the ordinary, which confirmed the suspicion that it was nothing to do with bad connections. However I also noticed on my car that when I turned on any incandescent lights, or the fuel pump clicked, the LED DRLs also appeared to dim momentarily. This got me thinking, and I have come to the conclusion that although the very low current consumption of LEDs makes them relatively insensitive to resistance from bad connections, they are at least as sensitive to voltage changes as incandescents, and probably more so.

Let me explain. A given resistance in series with an incandescent bulb on the one hand, and an LED on the other, is going to have a much greater visible effect on the light output from the incandescent than it is from the LED. This is because the higher current of the incandescent will cause more voltage to be 'lost' across the additional resistance than the low current of the LED will, therefore there is going to be significantly less voltage left for the incandescent than there is for the LED. But, if you reduce the voltage to both bulbs by the same amount, even a small amount, they both visibly dim.

Secondly even the best of circuits, and especially our 40 year-old classics with the connector technology of the day, will have very small but finite resistances at each connection point throughout the circuit, each 'losing' it's own little bit of voltage. Where these are lost in parts of the circuit common to two or more bulbs, i.e. indicators and brake lights, turning the indicators on will slightly reduce the voltage going to the brake lights, and vice-versa, hence reducing the current flowing through them, hence reducing their brightness. This is why, with the original type of indicator flasher unit, your flashers probably slow down slightly when you apply the brakes. However this was not the cause of the problem.

There is another significant difference between incandescent and LED lamps: Incandescent lamps have a filament that has to heat up when they are switched on, and the resistance of the filament varies very significantly between cold and hot, being very low when cold, and relatively high when hot. In the case of a pair of 21w bulbs as used for indicators and stop lights for example, they will draw about 3.5 amps when glowing, which implies a resistance of 3.4 ohms. However if you measure the resistance when cold you will see only a few tenths of an ohm. When 12v is first applied to these cold bulbs, they will try to draw 40 or more amps. You might think that would be enough to blow the fuse and you would be right - if that was the steady-state current. But just like bulbs, our fuses have to heat up and melt before they can blow. And as soon as any current starts flowing in the bulb filaments they heat up quicker than a fuse, so their resistance rapidly starts going up, which rapidly reduces the current through the fuse to its 'normal' level. But at the instant voltage is applied to the bulbs, the many various very small contact resistances all through the circuit mentioned above lose a significant amount of voltage going to those bulbs, both incandescents and LEDs. This drop in voltage affects everything else fed by that circuit, including tungsten bulbs and LEDs that are already lit. However whilst you will see a momentary flicker in the LEDs, you will not on a tungsten bulb as it takes time for it to 'cool down', and before it has done so enough to be visible the voltage has gone back up again. You will not see this voltage dip on a meter either as it is so brief - you need an oscilloscope. I do happen to have one - albeit very old and not of the highest quality, but even on that the dip in voltage is of the order of 4 volts or so for about 5 milli-seconds. By contrast LED bulbs take the same very low current when they are initially powered as subsequently. This means that turning on LED lamps doesn't produce a momentary current surge and consequent loss of voltage, and hence has no visible effect on other lamps - either incandescent or LED.

There is a third difference between incandescent bulbs and LEDs: As explained above incandescent lamps have a filament that has to heat up when they are switched on, and that takes a visibly finite time. Likewise when they are turned off they have to cool down, and again that takes a visibly finite time. By contrast, LEDs are at full brightness the instant they are powered, and extinguish the instant power is disconnected. This difference is very easily seen on cars with an LED third brake light but incandescent stop lights, as the third light coming on quicker and going off quicker, even though both types are powered from the same switch. And this brings us to the main reason why said pal's car failed it's MOT.

Because he was using incandescent indicator bulbs, but LED stop and tail, all the effects of the differences between the two types came into play. The momentary but very high current pulse when first powering the incandescent indicators each time they came on, and the resultant momentary but significant reduction in the supply voltage (3v in my tests), was clearly visible on the LED stop and tail lights. When incandescent bulbs are fitted all round, because the stop and tail filaments take a finite time to dim, this momentary voltage reduction (a few milli-seconds in my tests) is barely visible. You can see the same effect on incandescent lamps when cranking, as even though the voltage drop is less (typically from 12v to 10v with a good battery) the reduced voltage occurs for significantly longer each time a piston is rising on its compression stroke, long enough for an incandescent lamp to visibly dim. But that effect is, of course, not a problem in normal use.

Because he was using incandescent indicator bulbs, but LED stop and tail, all the effects of the differences between the two types came into play. The momentary but very high current pulse when first powering the incandescent indicators each time they came on, and the resultant momentary but significant reduction in the supply voltage (3v in my tests), was clearly visible on the LED stop and tail lights. When incandescent bulbs are fitted all round, because the stop and tail filaments take a finite time to dim, this momentary voltage reduction (a few milli-seconds in my tests) is barely visible. You can see the same effect on incandescent lamps when cranking, as even though the voltage drop is less (typically from 12v to 10v with a good battery) the reduced voltage occurs for significantly longer each time a piston is rising on its compression stroke, long enough for an incandescent lamp to visibly dim. But that effect is, of course, not a problem in normal use.

All this explains the very brief but significant dimming of the LED stop and tail lights (and DRLs) each time the indicators light up, but what about the visible dimming of the stop lights when the parking lights were turned on?

If you look at incandescent stop and tail bulbs they actually brighten very slightly when you switch on the parking lights with the brake lights already illuminated, as you have an additional filament being powered and glowing, albeit only 5w in addition to the already glowing 21w. If you look at a typical stop and tail LED unit and power first the tail contact, you may well find that all the LED elements light up - not perhaps what you might expect. Now take the power off the tail contact and apply it to the stop contact, and again you see all the elements light up, but this time brighter. That is deliberate as it results in the greatest illuminated surface area in each case, which gives better visibility than having one section illuminated for tails and another section for stops. It is achieved by having different resistors from each lamp contact to the LED elements - a higher value resistor giving the lower level of brightness for the tail lights compared to the stop lights. So now we have the situation that once the stop lights are powering all the LED elements brightly, when additionally powering the tail contact nothing should happen. And if you test the LED unit away from the car with a separate voltage supply, that is probably what you will see. So why do you see a difference when it is fitted to the car? Probably because quite a few other lamps are switched on with the parking lights, and taking current, and in the case of the car in question this included four 5w incandescent number plate lights. And why isn't this effect as visible on incandescent stop and tail lights? Probably because the additional filament being powered by the tail lights is masking the overall slight reduction in supply voltage caused by the additional load.

And what about when the fuel pump causes a similar dimming? That just involves applying power to a solenoid, which doesn't have the cold inrush current of incandescent bulbs. In fact a solenoid (like an ignition coil) is effectively an inductance, and one of the properties of an inductor is that it tends to oppose the current and delay its rise to a peak value i.e. the opposite of the inrush current in a cold bulb. However the solenoid on a pump measures about 2 ohms, giving a current of 6 amps at 12v, which is near double that of a pair of indicators. And looking at that on the scope although the duration of the reduction in voltage is quite a bit less than when the indicators are going, the voltage itself reduces by much more, at 6 or 7 volts, i.e. momentarily the 12v supply has dropped to 5 or 6v!

And what about when the fuel pump causes a similar dimming? That just involves applying power to a solenoid, which doesn't have the cold inrush current of incandescent bulbs. In fact a solenoid (like an ignition coil) is effectively an inductance, and one of the properties of an inductor is that it tends to oppose the current and delay its rise to a peak value i.e. the opposite of the inrush current in a cold bulb. However the solenoid on a pump measures about 2 ohms, giving a current of 6 amps at 12v, which is near double that of a pair of indicators. And looking at that on the scope although the duration of the reduction in voltage is quite a bit less than when the indicators are going, the voltage itself reduces by much more, at 6 or 7 volts, i.e. momentarily the 12v supply has dropped to 5 or 6v!

If you had LED lamps everywhere - indicators, number plate lights, instruments as well as all four corners of the car you may well not see these effects (apart from the pump). But LED indicators have a significant safety issue in that they are incapable of letting you know that one, or even both, of the corners has failed, unlike conventional flashers and incandescent bulbs. Ironically these dimming and brightening effects could be 'designed out' of LED units, and 'failure warning' designed in, but it would increase the cost so is probably why it isn't done. As stated above all LEDs need a series resistor to operate off 12v, as each LED element has a limit of typically 2v. A series resistor is a cheap way of doing this, but as shown it does mean that any change in supply voltage causes the light output to change. But if a voltage regulator of, say 5v was fitted internally, together with a different resistor to reduce 5v to 2v instead of 12v to 2v, then the LED unit would be able to ignore these changes in the system voltage. As long as the supply voltage remained above 5v, the light output would remain constant. But as I say, there is a cost implication, and these days (for utility items anyway) price is everything.

The LED tail light (right) is slightly brighter then the incandescent on the left, the stop light only very slightly brighter:

Note that this does not show the true differentiation between tail and stop as the auto aperture has taken account of the brighter stop lights, indicated by the number plate and other features at the back of the car being darker.

What is more noticeable is that the incandescent (left) has a small very bright area concentrated in the middle of the lens where the filament is with a more normal level of light around it, whereas the LED (right) has a more even and wider spread lit area. These are the tail lights, with as close as I could get to an equal exposure:

But the main difference is that there are none of the drawbacks associated with the older types I'd tried i.e. the two serious fault conditions, and no flickering when other circuit operate even when cranking. So together with the instant full glow with LEDs, and my conversion to a mechanical switch on the roadster there is no reason not to use this type - subject to insurance company approval. I'll still not use LED indicators though until I come across a flasher unit that indicates corner failure.

But note that when retro-fitting LEDs to front position markers, rear position markers, stop lamps and registration plate lamps all have different dates as to when they are legal and when they are not. Direction indicator conversions are not legal at all.

Incidentally if you find LEDs are significantly brighter than incandescent then you probably have bad connections in the circuit. Whilst these have less impact on LEDs they are still there, and could get worse, so you should be looking to find and fix them.