The 8000 mile release bearing. Not a trace of carbon left in it, or any pieces in the bell-housing, just a fine dust spread all round the inside. Note the roll-pin on the bottom left-hand side, is this the pin that causes the problem? (This and the next two photos by David Bolton)

Two more pictures of the roll-pin in the old bearing. Is it supposed to be sticking out like this or flush?

The inner end of the roll-pin. Part shows obvious signs of wear, but there is a recessed part that doesn't. It's not possible to determine whether the pin projected into a hole in the carbon ring and so has had quite a bit ground off by the boss on the cover plate plus some broken away, or whether the pin only bears on the side of the carbon ring (so holding it slightly off-centre) so very little has been ground away:

An NOS AP/Borg&Beck release bearing I've had since 1994, no sign of a roll-pin, protruding or flush:

Graphite face 5mm above the casting face giving at least that amount of wear before replacement because of noise or vibration:

In theory if the clutch-cover release-ring is exactly concentric with the release-bearing (rare!) more wear could take place with the release ring moving down inside the casting without causing noise or vibration.

These four photos by Bob Muenchausen: Badly broken-up bearing but still a ring of carbon seems to be left. Probably once the boss on the cover plate had worn down the carbon to the top of the carrier there was a mis-match that meant it was bearing on the casting rather than the carbon ring, wearing that down instead, note the upper piece of the outer ring of casting is much thinner than the lower piece. Eventually it go so thin it couldn't take the force of the clutch and it broke suddenly, further operations of the clutch pedal pushing the slave piston out of the end of the cylinder. This is very similar to what happened to the clutch on my roadster many years ago (mileage unknown), although on that the offset was worse and towards one of the pivots which snapped off leaving the rest of the bearing relatively undamaged:

Inside of the bell-housing liberally coated with carbon:

Friction plate with the lands worn away but still well clear of the rivets, not bad for 75k:

Deep wear groove in the cover-plate, although Bob reports that the flywheel itself was fine. I found much the same on the clutch change I did, perhaps deliberately dissimilar strength metals?

A claimed release bearing failure having caused the release ring to have been ripped off the diaphragm springs of the cover plate, rather than the release ring having come off and damaged the bearing: (Name withheld to protect the naive ...)

Peter King's showing the edges breaking away most of the way round, and further cracking elsewhere:

But the off-setting of the bearing to the first-motion shaft is very low:

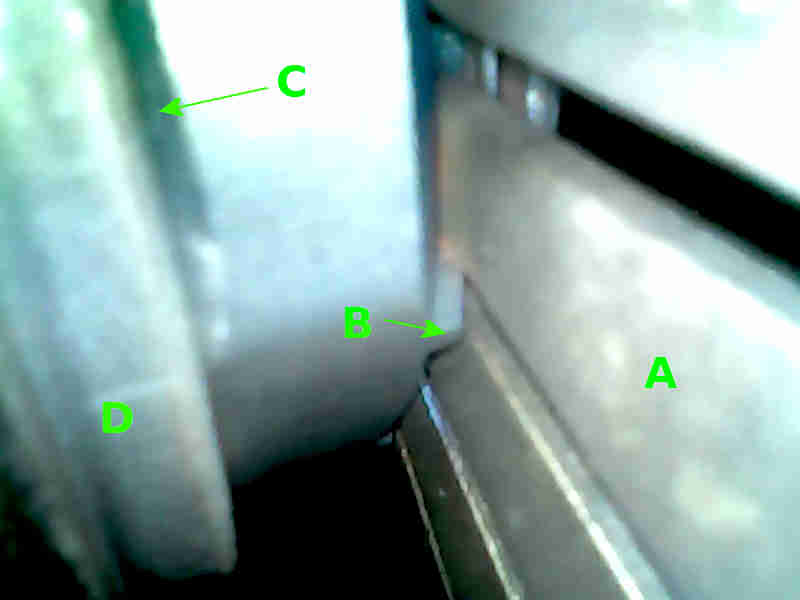

Looking up through the release arm hole, gaiter pulled back - 'A' are the diaphragm spring 'fingers' on the cover plate; 'B' is the release ring with 'teeth' (arrowed) that locate the ring in the slots between the spring fingers. The ring is retained to the cover plate with a flanged sleeve (see below); 'C' is probably the graphite ring on a new release bearing; 'D' is the release bearing casting. As the graphite wears down the casting will get closer to the release ring and the graphite vanish from view, but that will happen some time before the bearing needs replacement: (Mike Dixon)

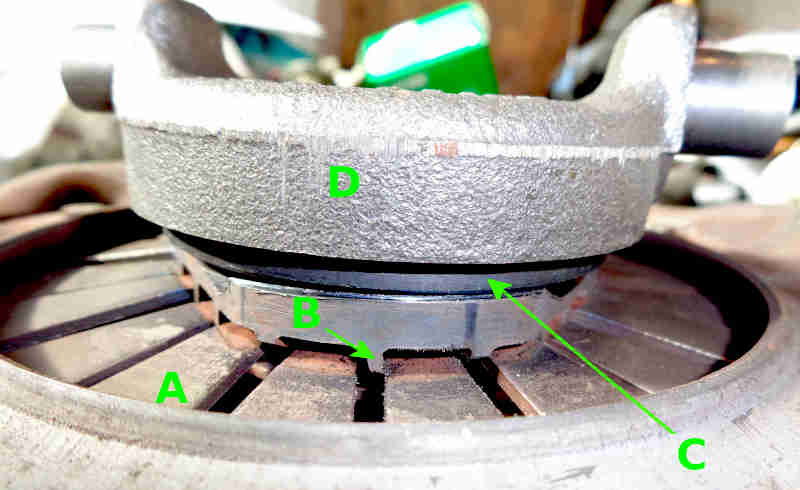

As above 'A' are the diaphragm spring fingers on the coverplate, 'B' is the release ring with its location teeth, 'C' is the graphite on e new bearing, and 'D' is the bearing casting:

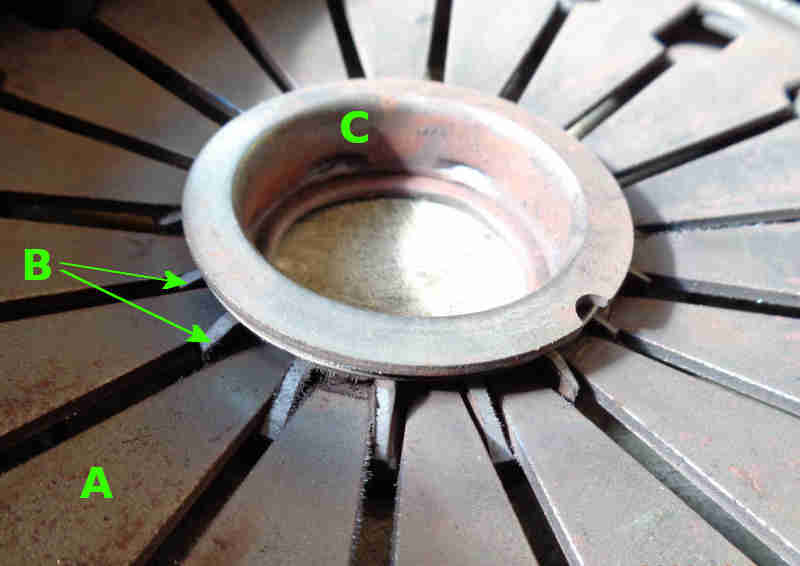

The 'back' of the cover plate with 'A' and 'B' as above, 'C' here is the flanged sleeve that retains the release ring on the spring fingers:

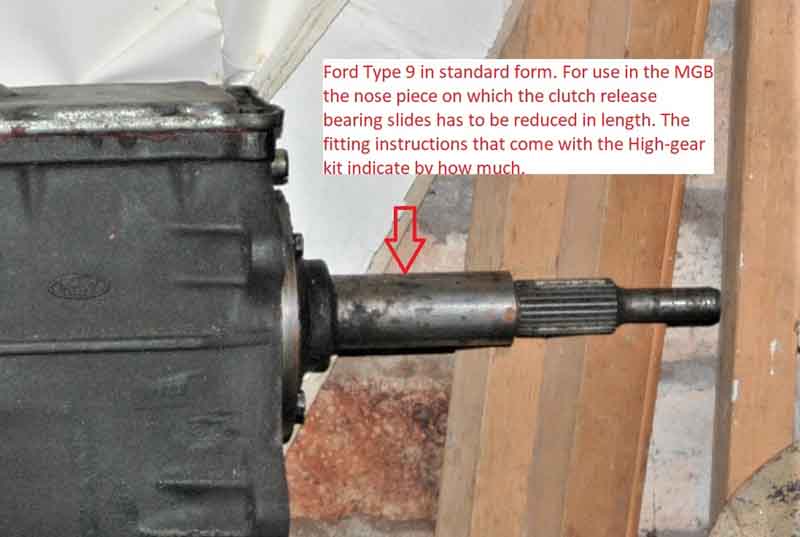

Richard's Ford Type 9 gearbox showing the guide tube for the release bearing (as per the V8), and also how it has to be cut back to fit to the MGB engine: (Richard)