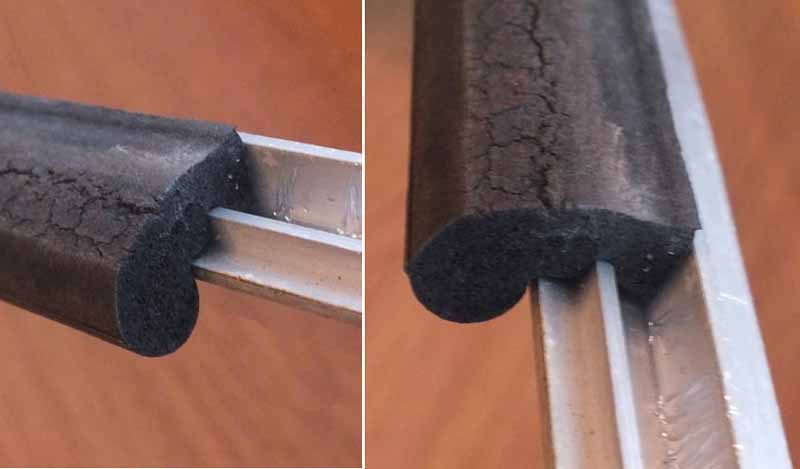

The current hollow seal from the usual suppliers, stiffer and less compressible than the original

The sponge seal from other sources, much denser than the original. The foot is also thicker making it more difficult to slot into the channel.

Placing the two side by side and pinching them you can see that the hollow seal has collapsed to about half its thickness whereas the sponge seal has barely moved.

February 2024: From March 76/chassis number 40100-on a different seal was used fitted to the boot opening rather than the lid - I presume with the small projection upper right on the inset facing the lid, this may work with earlier models: (Moss Europe)

The boot lid itself changed at that time - probably deleting the slot for the seal - but suppliers only have the later lid now, saying to use the later seal with it, so the two together at least must be compatible with the earlier opening. Given the difficulties with the lid seal, at £11 it would be no big deal to get the later body seal and try it with the earlier lid without its seal.

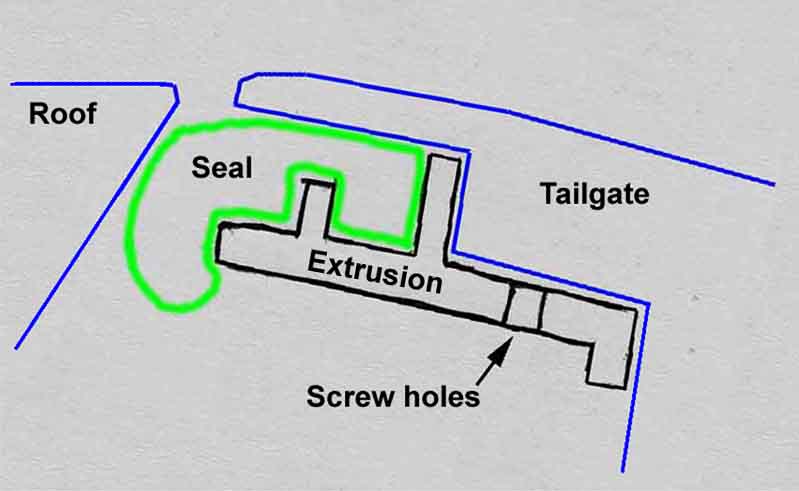

Detail of the tailgate seals from the Gaydon cutaway. The full-length seal (A) slots into a channel, and the part-seal (B) is clamped by an alloy extrusion (painted body-colour here but bare alloy ordinarily) screwed into the top edge of the tailgate. The sides of this seal are retained by gluing to the panel, and by the full-length seal.

How the seals sit in the extrusion channels Graham Barker

Graham's sketch of the extrusion, with additions.