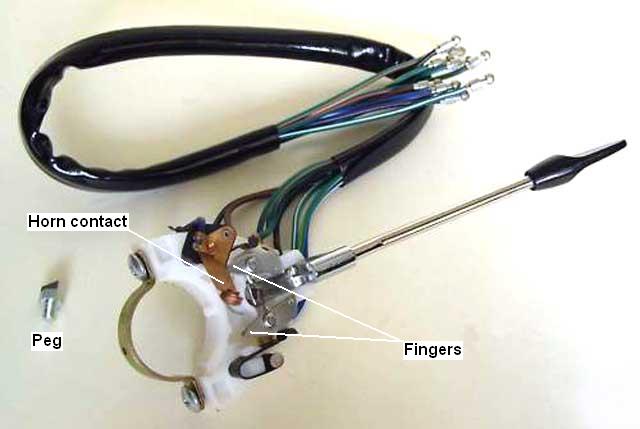

1970-76: Plastic bodied switch used for 1970 for RHD and Mk2 to 1970 for North America, having the horn-push on the stalk: Motaclan/Leacy

Very similar used for 1971 until the 1977 model year, the only difference being that the purple/black horn wire is a 'flying lead' to be connected to the separate horn brush that bears on the slip ring on the back of the steering wheel: Motaclan/Leacy

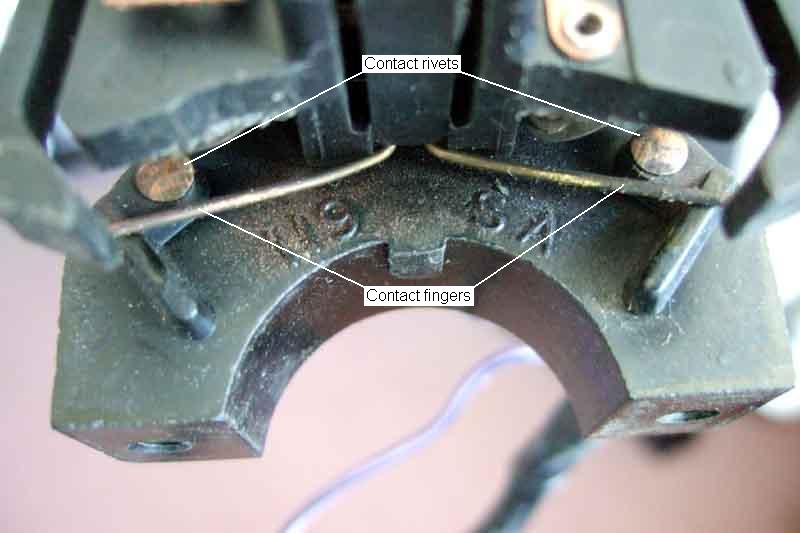

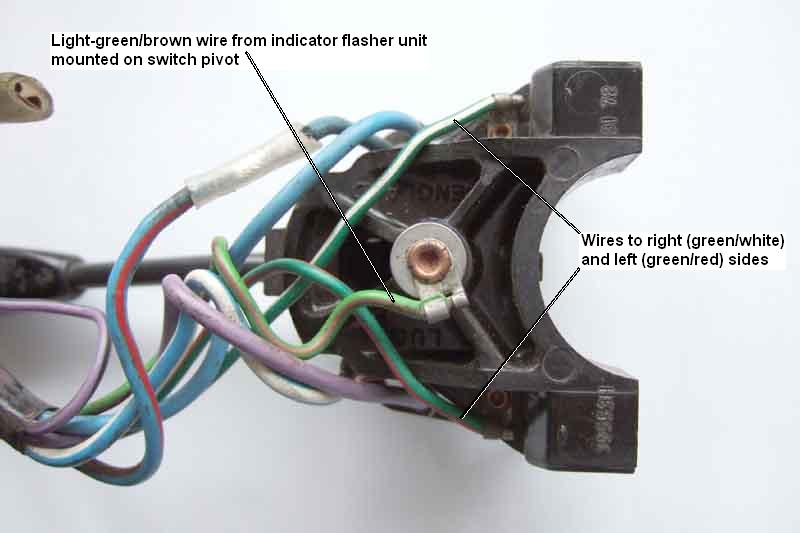

The following pictures show the detail of a switch from a 1973. Switch in the cancelled position showing the contact fingers clear of the contact rivets. The fingers are the 'common' contact with the light-green/brown wire coming from the flasher unit, the rivets are connected to the green/red and green/white wires going to the left and right respectively corners of the car

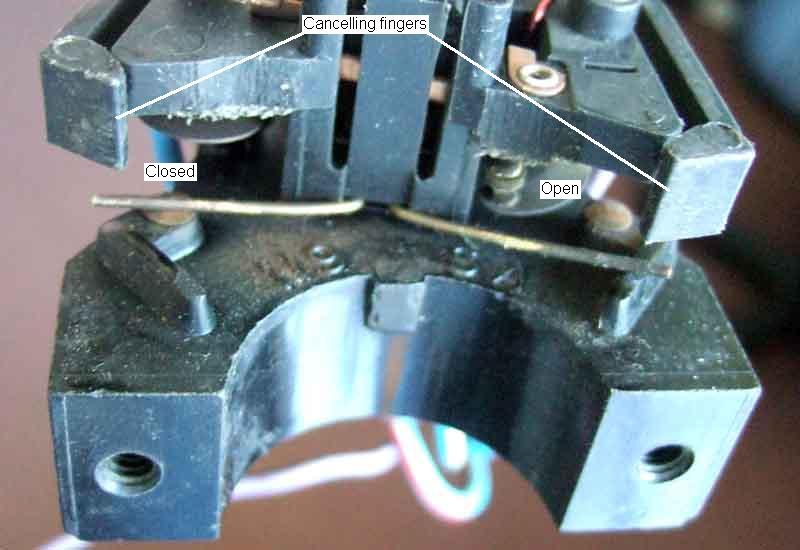

Switch turned to the right, stalk down and upper contact (when installed) closed. Also showing the cancelling fingers. When the switch is operated one of the cancelling fingers is moved closer to the column and the other further away. When the wheel is turned far enough from the straight-ahead a peg or cam on the steering column brushes under the finger lifting it and dropping it back with an audible click. When the wheel is turned back towards the straight-ahead position the peg or cam hits the tip of the finger pushing the switch back to the central position. In this position both fingers are clear of the peg or cam:

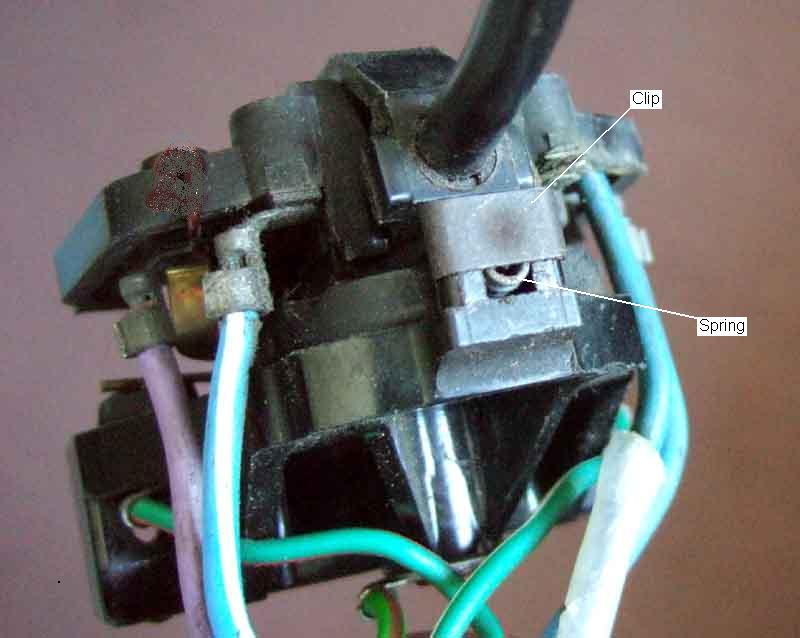

Clip partially removed showing the spring that latches the switch in each of the three positions:

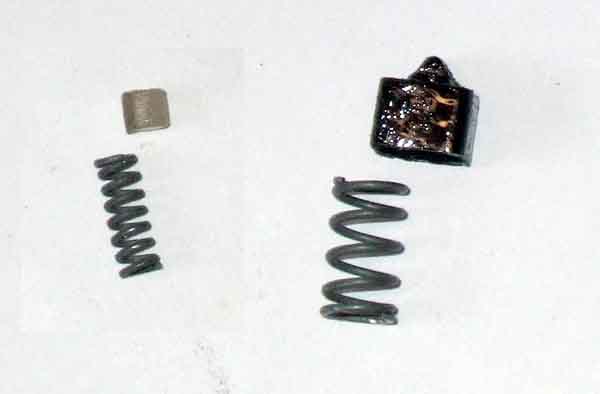

Originally this pressed a nylon cylinder which rolled into one of three notches in the fixed part, but on a replacement for my 73 that has been replaced with a plastic wedge which is nowhere as near as smooth in operation. I had the idea of swapping the wedge for the cylinder but the two are very different sizes so the cylinder wouldn't have sat in the correct position:

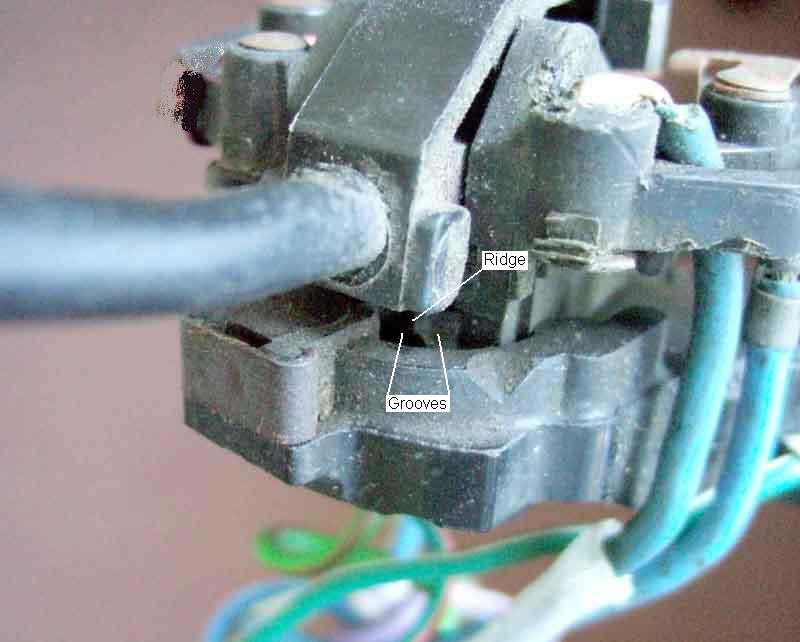

Switch turned to the left just showing one of the two ridges and two of the three grooves that are part of the latching mechanism:

The connection of the common wire from the indicator flasher and the wires to the right and left sides:

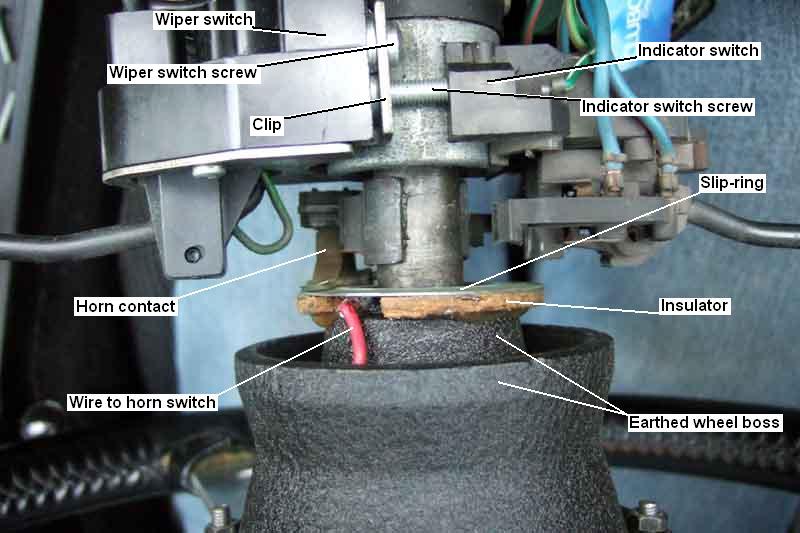

The rubber bumper prior to 1977 arrangement - the indicator switch clamps to the top of the column, and the wiper switch is screwed to the indicator switch bracket:

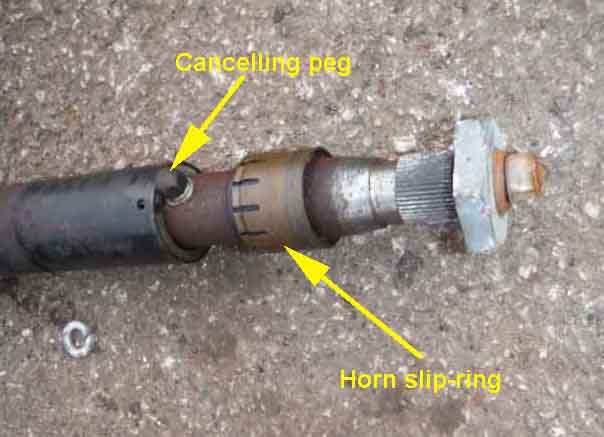

Showing the early cancelling peg screwed into the column, also the horn slip-ring. If the peg is in the wrong place the steering has to be split at the column UJ and the relative positions of the two shafts adjusted, then the position of the wheel corrected on the column:

Later indicator/turn switch in the cancelled i.e. central position, wheel straight-ahead, which puts the cancelling cam between the cancelling fingers. Unlike the earlier peg this cam can be slid around the column (it's a tight fit, obviously):

Indicator not operated, wheel turned to the left, cancelling cam under the cancelling finger but clear of it:

Indicator operated to the left, wheel being turned left, the cancelling cam lifting the finger as it passes it:

Indicator operated to the left, wheel has been turned left past the cancelling finger, now being straightened-up again. The cam hits the end of the finger and pushes the switch back into the central position again:

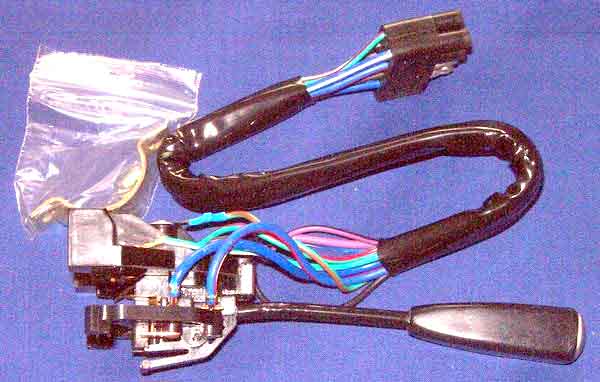

General views of the later 4-cylinder CB arrangement:

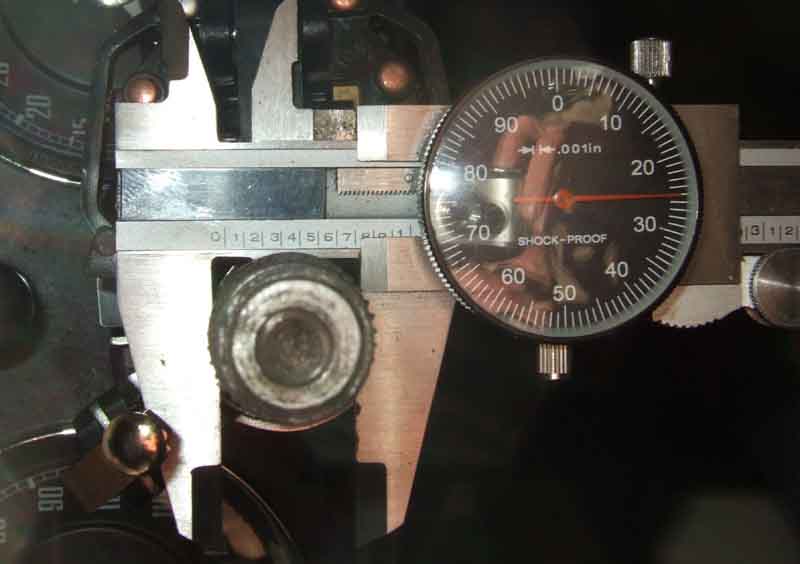

The top of the cam a fraction over 10mm from the side of the column:

The column is 0.725" (18.4mm) in diameter):

General views of the V8 and pre-77 RB:

The top of the cam is 13mm from the side of the column:

The column is 0.7475" (19mm) in diameter. So as well as the later cam being 'taller' it's also on wider column:

The RHD 77 and on indicator/dip/horn switch AAU4991, with provision to mount the wiper/OD switch AAU4992: (Motaclan/Leacy).

In case you are tempted to remove the indicator switch from its mounting plate that goes over the steering column be warned that there are many small parts which are then exposed and fall and spring out all too easily. This is a 77/78 switch with purple/black and black wires on the stalk putting out an earth to the horns which had a purple 12v supply from the fusebox. For 79 and 80 there were purple and purple black wires putting out 12v to the horns which picked up earths from their mountings:

The three indicator wires:

Contacts embedded in the plastic housing flush with the surface, the little copper cylinder two pictures above probably bridges them. 'A' is the common, 'B' the right-hand side and 'C' the left-hand, about the only thing you can do with these is squirt some contact cleaner in:

Click these links for info on dip/flash and horn functions.

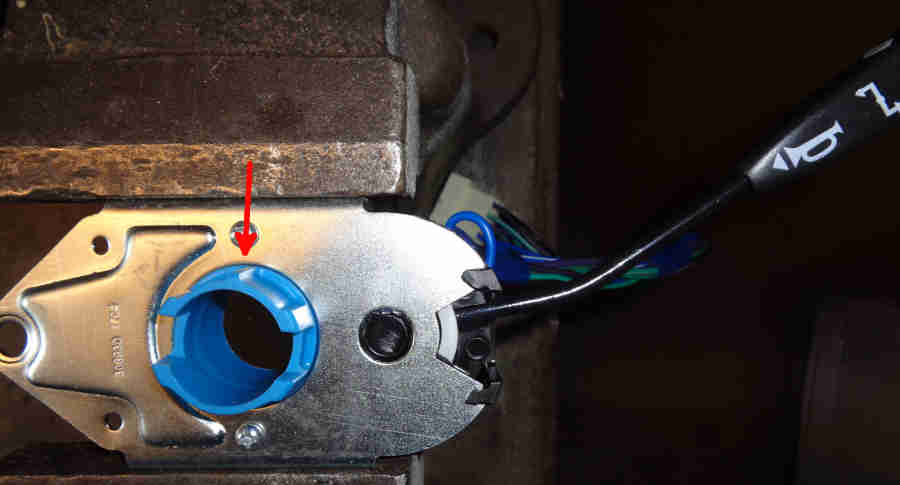

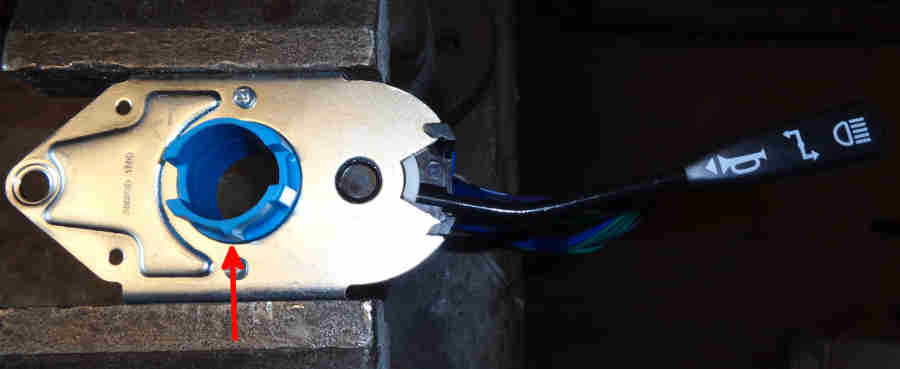

This type have no cancelling peg or cam on the column, instead a rotating collar (blue here) that is part of the indicator switch assembly performs the cancelling function inside the switch. It has two cut-outs (green arrows) that the steering wheel engages with and an identification rib (red arrow) which faces the switch in the straight-ahead position:

With the rib facing the switch in the straight-ahead position only a 1/4-turn of the wheel is needed for self-cancellation as the wheel is straightened, if it faces the other way a 3/4-turn is needed. Here the stalk has been lifted to indicate left, the wheel has been turned a 1/4-turn to the left (cut-outs horizontal, rib facing up) and straightening the wheel from there will cancel the indicators:

Here the stalk has been pushed down to indicate right, and the wheel turned 1/4-turn to the right (cut-outs horizontal as before but this time the rib is facing down) and again straightening the wheel will cancel the indicators:

The wheel has projections that fit the cut-outs in the rotating collar and continually rotate it as the wheel is turned:

An example of an after-market wheel boss. In this case it has two holes that I can utilise for a linking piece that will also engage with the cut-outs in the switch cancelling collar. Another possibility is to use a rod in a through-hole (arrowed), and see if that engages with the slots in the switch:

The metal linking piece that will engage with the two holes in the steering wheel boss and the two cut-outs in the switch cancelling collar:

The linking piece slid over the steering shaft and engaged with the slots in the switch cancelling collar. In fact it was easier to fit the linking piece to the steering wheel first, then carefully slide it on to the steering column:

August 2023: Helping Geoff who has a 78 initially with electrical stuff which necessitated getting the steering wheel and indicator switch off as the switch was faulty. He wanted a smaller steering wheel and had found a Mountney one that said it was specifically for 'post 76'. I wondered about indicator cancelling, and the advert referred to a 'wheel centre horn push', but 1977 and later have no provision for getting horn wiring onto the wheel as well as needing a special arrangement at the wheel itself to perform cancelling. So said pal contacted the vendor and asked questions about those two aspects, and got a completely meaningless response. I wondered if they had got the advert wrong and it was really for a pre-77 RB car. But the columns are the same and having made an adapter as above, the horn business being irrelevant as the horn push is on the column stalk, he was keen to go ahead and ordered the wheel.

On arrival the instructions talked about 'two scroll pins (if provided) item D' for indicator cancelling, but as there was no picture labelled 'item D' unlike all the other parts I assumed it did not have them. However looking closely at the boss there were two small holes on the back, and in the small packet of nuts, screws and washers I did espy two small roll pins. The wall of the collar on the indicator switch that the cancelling part of the wheel has to engage with is only a few mm thick, but partially inserting the pins and positioning the new switch over them they do overlap OK. The diameter of the pins is much smaller than the width of the cut-outs in the cancelling collar on the switch, which will create quite a bit of lost-motion, but that doesn't matter:

So far so good but the boss protrudes a good inch further from the end of the column than the factory wheel hence an inch closer to the driver. Being an inch less diameter, and with the column angle, it does mean the rim on this wheel has a greater clearance to the seat if thigh size is the issue.

The next down-side is that whereas the factory wheel closes the gap to the column shroud this wheel leaves a gap of approaching half an inch. The effect of that is the back of the boss with the roll pins to effect indicator cancelling is much the same distance away from the cancelling collar on the switch, and if the pins are pushed too far into the boss they will not reach the cancelling collar. However after resolving a problem where the indicator switch wouldn't seat on the column properly, and the two halves of the cowl wouldn't fit together properly, when the new wheel was fitted it is virtually flush with the cowl leaving a minimal gap, and cancelling works as it should. In fact you have to be careful the opposite problem doesn't occur which is the roll pins not tapped in far enough so their ends press against the cancelling collar of the indicator switch instead of just rotating it. I checked the depth of the holes but it seemed to me they would allow the pins to be pushed in too far, so I only tapped them in far enough to turn the collar without pressing against it.