I said several times that you can measure components and do calculations until the cows come home but until you get an installed system with no air (which he had problems getting out anyway) you cannot get an accurate measurement of slave travel, but he didn't do that. His installation is further complicated by him having a Ford Type 9 gearbox so I wondered if the release arm could be a factor, but apparently the MGB release arm is used so unless the bell-housing or other parts of the gearbox are badly out of line it cannot be a factor. I know others use the Type 9, and also that others use the plastic-bodied master, but I don't know if anyone has both. I suggested he ask on the forum, but he didn't do that. The plastic-bodied cylinders do seem have less depth than the tin reservoirs - 120mm as opposed to the 125mm I measured on an old one, but I still couldn't see that making the difference as by my calculations he should still get more than 26/27mm of master piston movement when the pedal hits the carpet. I'm sure it was discussed at the outset that 'difficulty selecting gears' could mean a multitude of things, lack of clutch disengagement being just one of them. The type 9 does not have synchro on reverse so that is the first test - does it grind selecting reverse? No. Where is the biting point? Not answered. With the off-side rear wheel raised, engine running and in gear, does the wheel stop turning when the clutch is fully depressed? And it should do that without being fully depressed? Not done. With just the reverse test the conclusion has to be it's not the clutch but the gearbox, and then he said the difficulty is changing up or down between 2nd and 3rd. You shouldn't need a clutch at all changing from 2nd to 3rd (as long as you give it a moment in neutral ...). When he started talking about gear sets with different metal synchro rings having different effects I left him to it, he has repeatedly got bogged down in irrelevant minutiae on a number of topics in the forum.

Practising what I was trying to preach, I removed the roadster pedal cover and took a number of measurements there of my standard tin master, as well as down at the slave.

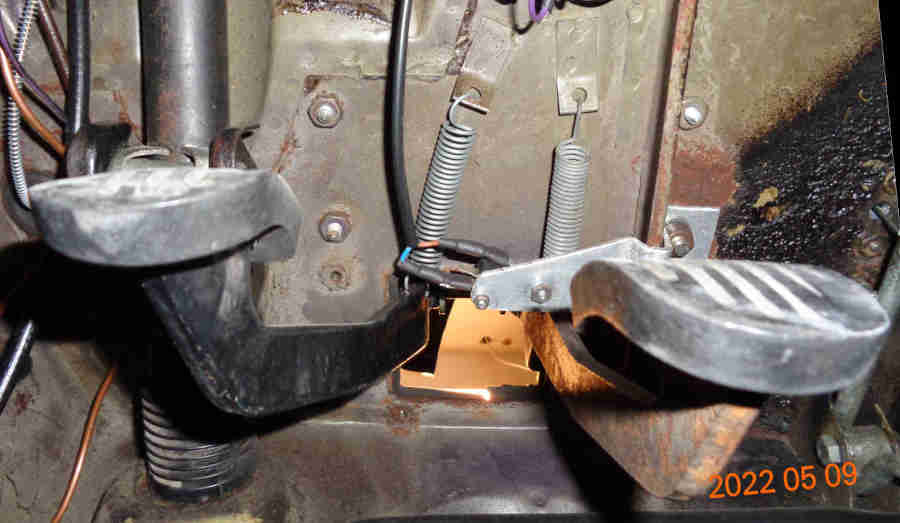

Standard pedal and push-rod, centre-point of the clevis pin at an arbitrary 65mm:

Pedal foot-pads equal:

Clevis pin removed, the pedal can come back a further 5mm. Previously I had modified a pedal and push-rod in this manner to give more travel:

Clutch foot-pad now about 1" higher than the brake. One might imagine this would make things really awkward, but using one leg for the clutch and a different leg for the brake I drove it for a while like this with no problems, and the ZS 180 pedals are like that from the factory!

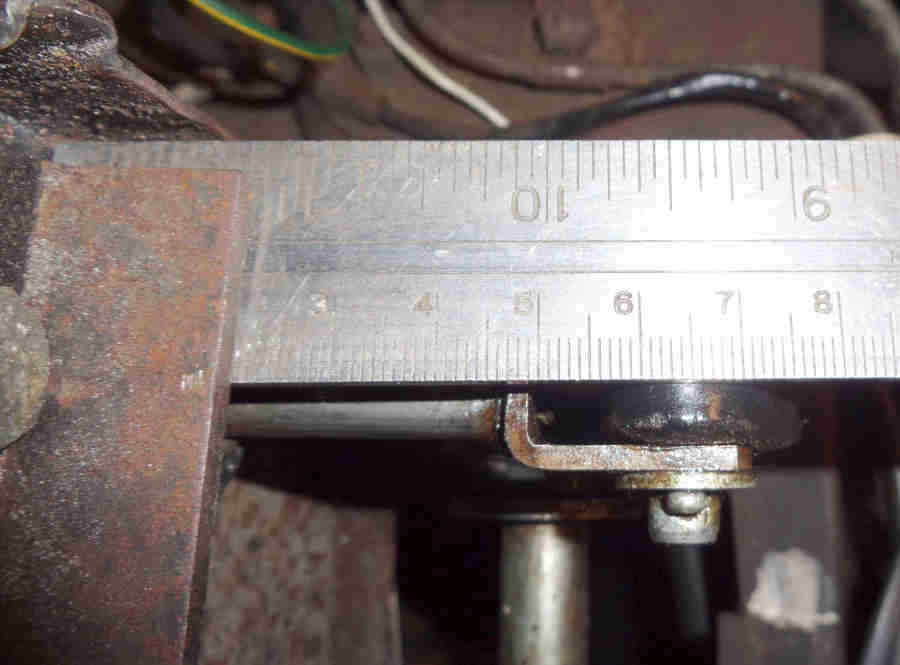

Clevis pin back in (minus split-pin at this point) and pedal jammed down to the carpet - centre-point of the clevis pin now at about 32mm, therefore giving about 33mm of master piston travel:

Clutch pedal fully depressed, push-rod fork still about 3/4mm from the dust cover. With the modified pedal and push-rod it was hard up against the dust cover:

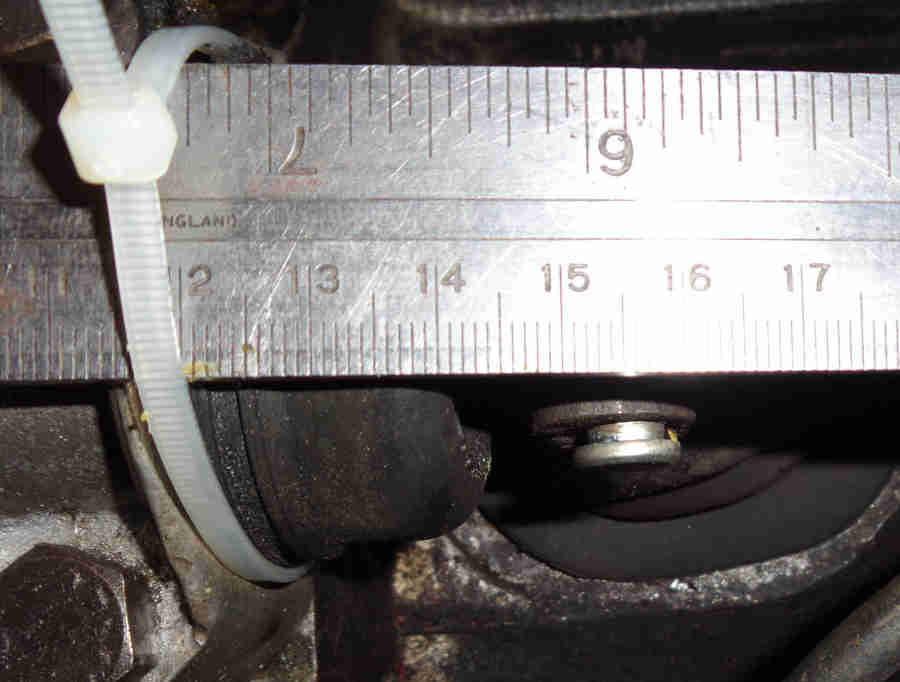

Slave cylinder, pedal released, convenient mark on the push-rod fork at an again arbitrary 154.5mm:

Pedal fully operated, mark now at 166mm. This means there has been 11.5mm of slave push-rod travel, or 0.453". That's between 7/16" and 15/32", so as near as dammit 1/2", and makes the biting point slightly higher than I would like so no shortage of travel there.

I've just noticed that the two pictures of the slave are 'upside down' to how they are on the car, but the camera flash gave a clearer picture that way up, and I didn't think to reverse the ruler. I could flip it over but then the numbers would be upside down.