There are two types of locking process - one that responds to sudden changes of speed and direction i.e. inertia or at severe angles from the horizontal, and another that responds to 'snatch' i.e. if the belt is suddenly yanked out of the reel. Vee's originals only had the inertia function i.e. didn't respond to snatch, but Bee's (retro-fitted) and the ZS respond to snatch as well as inertia. The snatch function can be checked with the car stationary, but the inertia function can only be tested under harsh braking or by tilting the car significantly.

Vee's original mechanism is very similar to these pictures from Justin Mercier on the TR6-pack forum. Remove one of the screws and slacken the cover, then by swivelling the cover round you can expose the spring to be able to re-tension or de-tension it, without it sproinging all over the place. Nevertheless eye protection should be worn, just in case, as it can be pretty violent and has near-razor sharp corners.

The reel has many turns of a 'clock' spring which is tightened as the belt is withdrawn, and retracts the belt when unfastened. When Vee's first replacement belt arrived above initially I had great difficulty when checking it to get the belt to come out at all. Eventually I realised that even though I was holding it at the correct orientation the little bit of movement while hand-held was enough to cause it to lock. It was only when pressing it down onto a flat surface to keep it still that I could get it to reel out consistently.

But by that time I'd decided to investigate. Two covers on the sides secured with cross-head screws, one of the covers was embossed 'DO NOT REMOVE', but when did that stop me? Undid the screws, carefully lifted the cover a bit ... and SPROING!!! ... out spills a 'clock' spring. That's all there is that side so it didn't need removing anyway, and I pondered how to put it back. If it does sproing out care is needed to untangle it without buckling it.

Looking at the spring, it started spiralling out from what had obviously been the tightly wound middle for about a quarter of its length, then it turned back on itself to spiral in the other direction for the remainder of the length to the outside! Eh? The spindle has a slot for the inner end of the spring, and when I was able to pull the belt out that spindle was turning in a clockwise direction, so that obviously has to tighten the spring and so determines which way round the spring fits at that end. Looking at the other end of the spring there is a cut-out on one edge about 1/2" from the end, and was a corresponding projection in the slot in the cover, so again the spring can only fit that way round. However slotting that end into the cover and curling the spring into the cover, I realised that would put the inner end the wrong way round in the spindle, i.e. pulling out the belt would try and unwind the spring, not wind it up! It's not helped by the outer end being held in the cover and the inner end on the spindle, and trying to look at both halves at the same time and work out the 'logic'. At the same time I came to the conclusion that the bulk of the spring was curved the 'wrong' way when it was out of the cover. But even then, it meant that the outer end instead of following the curve of the bulk of the spring, must fit in the slot in the cover, then turn back on itself, as well as being wound into the cover against its natural curve, as that was the only way that the inner end would be the correct way round for the spindle. The spring has a natural reverse curl like this as it is a way of increasing the tension once fitted, a clever bit of lateral thinking.

Fortunately the spring was well-behaved and could be fed back into the cover quite easily, and stayed there once complete.

Note that with both this earlier grey-bodied reel and the later black-bodied, as it is withdrawn the belt rotates the spindle clockwise to tighten the spring. If it needs retensioning there are two possible ways, and that is either to turn the inner end of the spring clockwise relative to the spindle to add tension, or to rotate the outer end of the spring anti-clockwise relative to the body. On the face of it this should be easier on the grey-bodied reel as both inner and outer ends are retained by the body when the cover is removed, whereas on the black-bodied type the inner is in the spindle in the body, and the outer is retained in the cover. However with the grey-bodied it does mean that one either has to grasp the inner end of the spring, remove it from the spindle slot, and rotate it clockwise relative to the spring, or remove the outer end from its slot and rotate it anti-clockwise, neither of which sound particularly easy. Theoretically one could pull the belt out a certain amount, detach the spring from the spindle and hold it there, then rotate the spindle anti-clockwise to reel the belt in, then refit the spring, but that sounds even less easy. With the black-bodied by careful lifting of the unscrewed cover the minimum amount, it can be rotated anti-clockwise relatively easily to add tension.

That done I wound the belt all the way back in manually, and refitted the cover with the inner end of the spring in the spindle slot. By this time I had discovered the cover had a section over the end of the spindle that could be removed to help refit and remove the inner end of the spring to the slot in the spindle. I then pulled the belt all the way out, and released it, but of course it only retracted about a quarter of the way even being 'helped'. So removed the cover again this time careful to pull the inner end out of the spindle slot so it didn't sproing out again, and manually wound the belt the rest of the way back in counting turns of the spindle, and got to ten full turns. So the spring needs to be pre-tensioned by something approaching that amount, to retract in use. It doesn't need to retract all the way under its own efforts as there is still a couple of feet of belt from the reel to my belt-guide, and from there to the sill, in normal 'use' when not fastened. I refitted the cover, then very carefully lifted it up as little as possible leaving the inner end engaged ion the spindle slot while I turned it anti-clockwise (the spindle turns clockwise when the belt is pulled out remember) through a series of half-turns to pre-tension it. After five full turns I refitted the cover and tried it, but even helping it retract there was still a couple of feet or so that wouldn't go in. So unscrewed the cover again, carefully turned it another full turn. Better, but still some left, and another full turn plus me helping it got all the belt in, I reckon that will do.

Justin Mercer describes pulling a pin out from the other side, which is what locks the belt to the spindle, and at that point one could turn the spindle independently of the belt to add tension, however it needs complete dismantling of the locking mechanism to do that. With the later black-bodied it's just a case of turning the cover relative to the body, which keeps both ends of the spring firmly in place. On the other hand his mechanism was more straightforward than mine in that if dismantling is required, conventional circlips are used. This enables removal of the webbing from the reel, and is something I pondered doing to both old and new belts to enable me to change the tongues over. But my new one has one of those 'single-use' Spire clips which I was reluctant to break, lose or damage, hence decided to use the new belt complete.

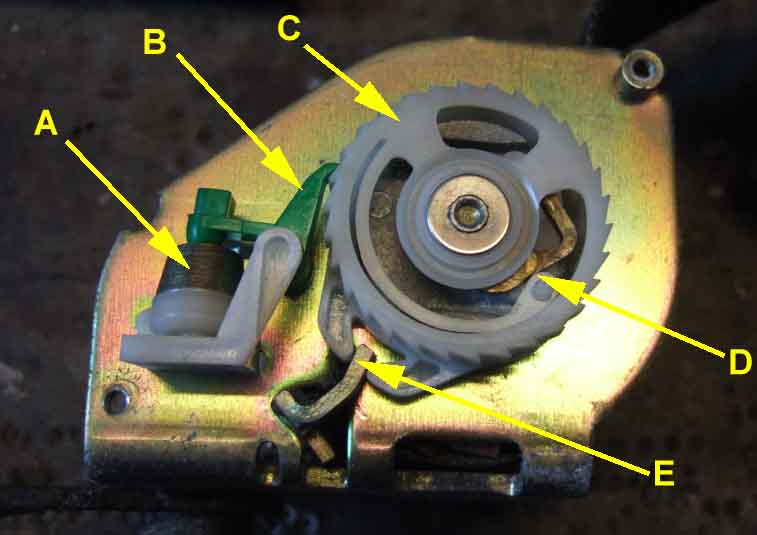

On the other side is the locking mechanism, a much safer area to investigate. Basically a pendulum hangs vertically and is free to swing in any direction. As it does so it pushes a latch into engagement with a toothed wheel that initiates the locking action. On the later reels there is also a friction mechanism that performs the same function if the belt reel spins at more than a certain speed i.e. if the belt is yanked. Vee's original belts - a single-action locking mechanism: On the left in the locked position, A is the pendulum that responds so sudden changes in speed, direction or car orientation; B is pushed up as the pendulum moves from the vertical; C is the initial locking lever; D is the toothed wheel that pulls C into the fully-engaged position, lifting E which is the main locking latch, into engagement with the main locking wheel F, to lock the belt. On the right unlocked - B is retracted, C is clear of D, and E is clear of F to allow the belt to be withdrawn. Circlips allow the mechanism to be completely dismantled and reassembled.

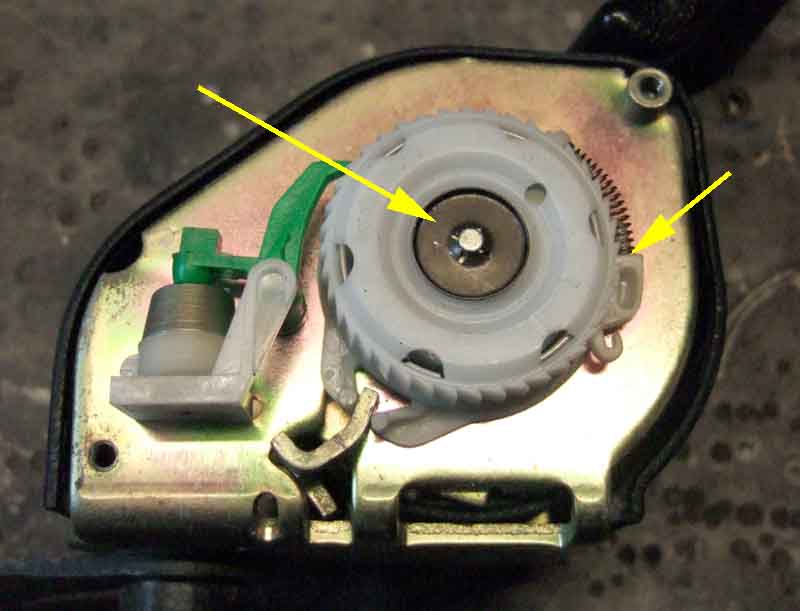

Later belts with a dual-action mechanism: A is the pendulum that responds so sudden changes in speed, direction or car orientation; B is the wedge lifted by the pendulum to lock the wheel C; D is the friction mechanism that responds to the belt being yanked out of the reel which also locks C; With C locked any attempt to withdraw the belt moves the main latch E in the direction of the arrow to engage with teeth on both sides of the reel (not shown) to lock the belt. This has a washer trapped under a peened-over shaft to retain the inertia mechanism, which make dismantling inadvisable if you want to reuse the belt.

Other versions of the externally identical reel have a spire-clip (A) securing the inertia mechanism, and a different way of triggering the locking action if the belt is yanked out (B). Despite being a spire-clip it's probably inadvisable to attempt removal of this as well in case it does not retain the parts as securely as previously.

Showing how the Securon adjustable reels have a large additional 'lump' on one end, which means the right-hand reel can't be positioned correctly on the GT arch without a second bracket at right-angles to the first, as on the right. If ever the belt is used in 'anger' the locked reel will almost certainly be pulled forwards a certain amount, allowing the occupant the travel further forwards than otherwise than otherwise would be the case. Absolutely pointless buying this adjustable belt, and Securon don't seem to do a non-adjustable reel where the belts exits forwards as is required for the GT arch-top mounting position, or the roadster, unless they are mounted so the belt exist vertically and has to twist through 90 degrees between reel and shoulder.

Non-adjustable belts are available from some sources, but many come with a floppy tunnel belt which would be a pain for single-handed fastening. The MGOC M061 (available singly) come with the stiff stalk (not shown, but they have confirmed it) and fitting kits for roadster and GT are available. Watford Classics shows a kit (pair with brackets) for the GT, and Chase MG one for the roadster (pair with brackets, albeit with red belts), both with stiff stalks.