Prior to UK emissions limits setting the mixture on SU carbs involved adjusting the mixtures independently to get the highest idle speed, then on one carb at a time using the lifting pin to raise the piston 1/32" while listening for a slight and momentary increase in idle speed. If the idle speed just falls the mixture is too weak, and if it rises and stays up whilst you are holding the piston up by that 1/32" it is too rich.

However this should only be attempted with the engine, carbs, distributors including points, condenser, rotor, cap, leads and spark plugs in good physical condition, after all the other running adjustments have been made correctly such as valve clearances, ignition points gap/dwell, timing, spark plug gaps, and carb air-flow balance, and the engine is up to running temperature, then for a further five minutes, then run at 2500 rpm for 30 secs. Until you get all that right you may never get the carbs set correctly.

The only thing that is done after mixture adjustment is setting the correct idle speed by altering both idle screws in the same direction by the same amount, and after that the choke. This involves setting the enrichment point to be the same on both carbs with the control pulled by 1/2" to 5/8", using the choke spindle clamps, and after that setting the fast-idle screws to give the correct speed and equal air-flow.

During carb adjustment if you cannot complete it in 3 minutes you need to run the engine at a raised idle for a few seconds (the WSM again says 2500 rpm for 30 secs) to 'clear their throats'. HSs in particular can get fuel pooling which affects the mixture and hence idle speed, and you can get this when stuck in traffic unless you periodically blip the throttle. Less noticeable in HIFs as they have a bypass port immediately downstream from the jet to under the butterfly which clears this pooling, but still advisable.

Lifting pin use is easier written than done, they have a lot of movement before they start to raise the piston - you have to feel for the slight increase in weight as they do so when the piston is already 'floating' on the air flow, then judge moving the pin and hence piston another 1/32" with a finger-tip when you can't see it!

John Twist shows an easier method of raising the piston with the air-cleaners off using a flat-blade screwdriver of a suitable width in the carb throat - placed under a piston then twisting it to raise the piston the required amount, which you can see to judge the distance, and will be the same every time:

Adjusting the HS jet nuts may well need a special spanner even with the air-cleaners off, even more so with them in-situ, this made from a bit of steel square tube, shaped to fit round a bolt-head the same size as the jet nuts:

The jet adjusting nuts on HS carbs - these are 'unscrewed' to lower the jet to enrich the mixture and vice-versa to weaken:

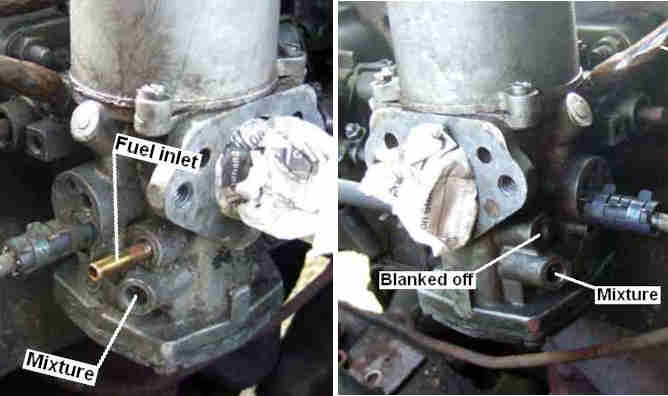

HIF mixture screws on the front (left) and rear (right) carbs - these are screwed in to enrich the mixture and unscrewed to weaken:

That still leaves detecting the slight and momentary change in idle which many have problems doing when not familiar with setting-up these carbs, but you can 'train your ear' as follows:

- Turn the mixture nut or screw one way or the other to get the highest idle.

- Weaken the mixture bit by bit until the idle speed just starts to fall - HS carbs by raising the jet, HIF by unscrewing the screw.

- Now enrich the mixture, again bit bit, noting how many flats or quarter-turns you are moving the nut or screw, back to the highest idle.

- Continue enriching noting the flats/quarter-turns until again the idle speed just starts to fall.

- Now weaken the mixture by half the number of flats/quarter-turns you counted.

- Use the lifting pin and see if you can detect the slight and momentary change in idle.

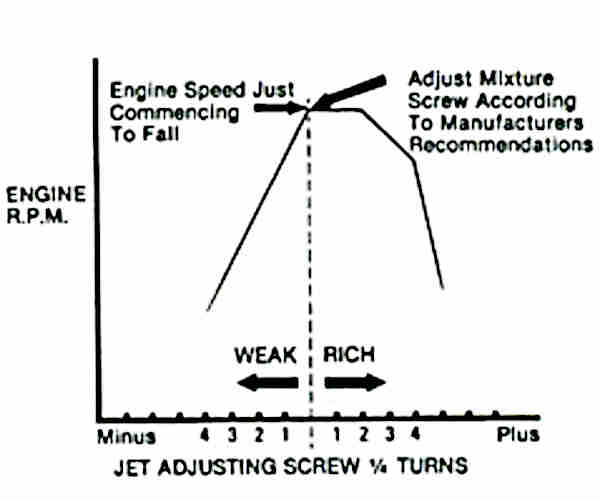

However with the introduction of emissions levels the process from SU changed, to finding the highest idle then weakening till the idle just starts to fall ... and that's it! If that's good enough for HIFs then it's good enough for HSs, easier than using the lifting pins, as long as you get both carbs at the 'just commencing to fall' point.

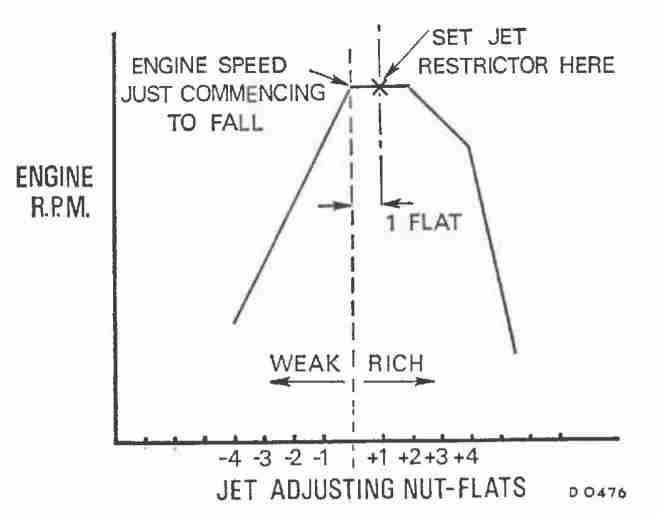

But for emissions-controlled HSs Haynes instructions are to detect where the idle speed just starts to fall then enrich by one flat. No indication as to how this varies from setting using the lifting pins but another source has this drawing:

So if struggling with the lifting pins but can detect the start of the fall you could settle for that.

The drawings do over-simplify things a bit by implying there is a flat top to the range of 'highest idle' movement and a sudden transition to starting to fall. It's a curve (as evidenced by the lifting pins giving different results at different points through the 'highest idle') but there is a range over which you won't be able to detect a change in the idle speed by adjusting the mixture, and that is effectively the . Also being controlled by screw threads there is bound to be an element of lost motion where changing direction does not change the actual position of the jet, hence the recommendation to tap the carb body with the wood or plastic handle of a screwdriver to 'settle' the piston and jet.

Remember that with the 4-cylinder inlet manifold there is a balance tube extending across both carbs and all three inlet ports on the head so changing one carb will have an effect on the 'other' two cylinders as well as it's own cylinders. For that reason after setting the second carb to have to go back to the first and recheck, re-adjusting if necessary,and if so then going back to the second carb and rechecking that. Only a couple of iterations should be needed.

When both carbs are done you can use an exhaust sniffer and if it is exceeding the limit then weaken both carbs by the same amount until you are just inside the limit. You can use the Gunson's Gastester for this but it's nowhere near as sophisticated as MOT station testers, so prior to an MOT I would recommend going inside the limit by at least half a percent, even if you note how much you have altered the carbs and then put them back afterwards ...