Capacitor quenched pump (in this case installed to a rubber bumper), showing the beige wire-ended capacitor connected between the points and a earth screw, i.e. effectively connected across the points.

Stepped end-cover of the capacitor quenched pump

Diode-resistor with red and black wires connected between the points and the 12v supply, i.e. effectively across the solenoid winding. This is a negative earth pump, a positive earth pump would have the red and black wires reversed. Diodes do seem to be more effective at quenching, I can still see very slight spitting on the capacitor quenched, but nothing at all on the diode quenched. However having refurbished both types the physical erosion seems to be exactly the same! The diode is in series with a resistor so that if the pump is reverse connected no damage will occur to the pump or the car's wiring. A simple diode would burn out giving no quenching, and possibly damage wiring. The resistor limits the diode current to about 1 amp, which together with the normal pump current of 1.5 amps is well within the capacity of the wiring. The irony is that reverse connection will result in exactly the same quenching effect as correct connection!

Diode-resistor end-cap with a half-cylindrical raised portion instead of the step. Bear in mind the end-caps are interchangeable, and I see no reason why they could not be swapped over between pump types, so you really need to look under the cap to see if there is a diode and which way round it is connected to be sure what you have.

Metal-oxide varistor of the type giving dual polarity quenching in the later version of AZX1331, at least. Note the varistor is connected across the points, the same as the capacitor quench. Image from Peter Ugle

A later type of transient voltage suppressor as supplied by SU Burlen, also bi-directional

The mounting points of the various devices are shown here, and also given in this Burlen document. However note that the drawing shows the diode-resistor connected as for a positive earth pump i.e. the black wire would be on the 12v terminal and the red wire under the fixed point mounting screw.

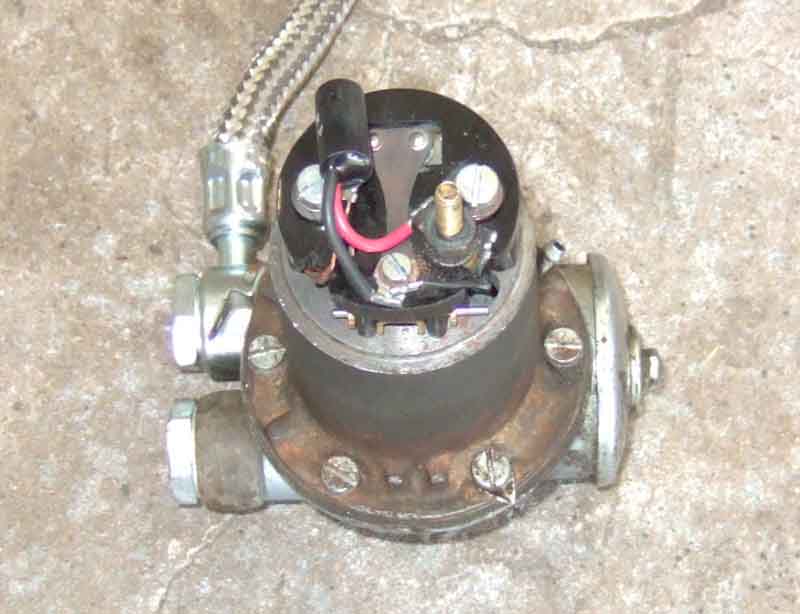

Plastic-bodied Moprod pump, same pipe fittings mounting arrangements as the SU so an easy swap. Even though these contain electronics there is only one version for both polarities of car as both +ve and -ve electrical connections are in the end cap. Clearly marked, and you need to get them the right way round for the pump to operate, but there is a series diode to protect the electronics against reverse connection, in this case the pump simply won't operate until it is connected correctly. No vent ports, so existing vent tubes should be tied up out of the way ready for refitting a 'proper' pump!

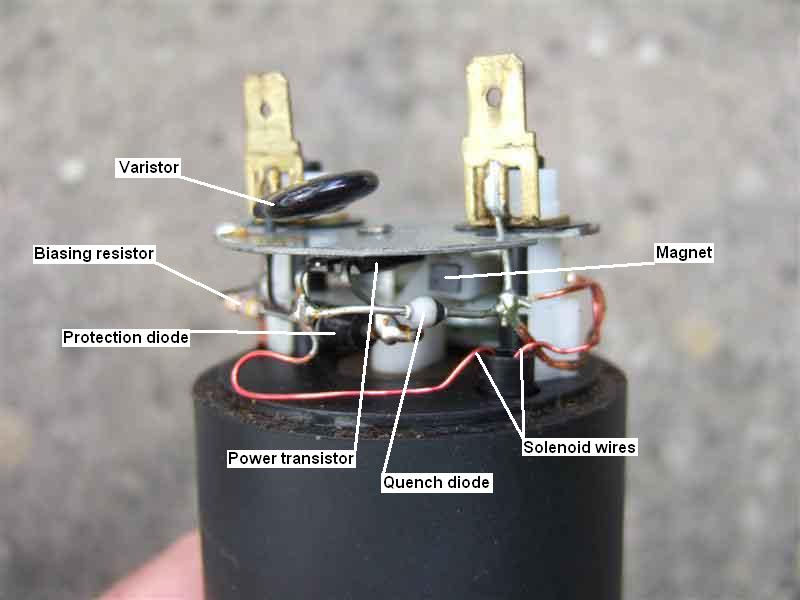

Internals showing the electronic components and the magnet on the end of the diaphragm shaft (this is the 'unused' end, it is the other end that passes across the magnetic reed switch as the diaphragm moves to open and close the switch). The quench diode performs the same function as the quench capacitor and diode in points pumps but to protect the transistor from the back EMF of solenoid winding. The resistor biases the transistor to switch off in the absence of a signal from the closed reed switch. The protection diode isolates the electronic components in the even of the power supply being connected the wrong way round. The varistor connection is curious. A varistor is normally high resistance in both directions, but when the voltage across it in either direction exceeds a certain value (18v in this case) it 'breaks down' to a relatively low resistance. As such it can be used to protect points-type pumps, which means that they will no longer be polarity sensitive as diode-protected pumps are. So far so good, maybe it is just another quench or protection against spikes from the supply, but it is connected between the -ve terminal and the heat-sink for the transistor/mounting plate for the reed switch, with no apparent electrical connection to those or anything else.

Showing the reed switch pegged, glued and screwed at a specific angle. What isn't apparent on this pump is the 'hysteresis' that exists in the design of the points in that type of pump. This hysteresis ensures that when the solenoid is energised and moves the points, they don't open until the diaphragm has reached nearly full travel. When they do open the solenoid is de-energised, so the return spring on the diaphragm starts to move it back again (and pump fuel), which moves the points back again, but they don't close again until the diaphragm is nearly fully returned. This prevents the diaphragm 'fluttering' with a very small amount of travel back and fore which is what would happen if the points opened and closed at the same physical position of the diaphragm. As I say I can't see this in the physical design of the Moprod pump, other than the fact that a reed switch requires less magnetism to keep the contacts closed than it did to close them in the first place. The problem I had with mine was that the diaphragm did start to flutter, i.e. very short travel back and fore, which caused severe fuel starvation, would start and stop doing that for no reason that I could see, and once started nothing I did would make it start working properly again until it decided to do so for itself. Which is why it now languishes in a cupboard and is only used as a very short-term spare.

Hardi electronic pump, both terminals also on the end cap: