This was opportunistic on another pal's car while the engine was out to replace a faulty overdrive unit. First thing noticed was that the interior of the bell-housing was almost identical to that in 2008, i.e. gungy and shiny with sticky oil, but no dripping. The release bearing was slightly worn compared to the new one, plenty of life left in it, but not worth considering reuse unless one was really desperate. The release arm needs a bit of work as the clevis pin is seized in the arm. No big deal as the slave push-rod is free on the clevis pin, but easier to deal with off-car than on. Michael has a spare complete with rubber boot and push-rod off another gearbox which we thought of using complete, but the boot is a different shape so we have to use the original which fortunately is in good condition, and decide to use the original push-rod as well in case of dimensional differences. That arm is sloppier in the bell-housing than the original, so reject that as well in favour of the original, pressing out the seized clevis pin in a vice using a socket that just fits over the head, then drifting it out, and using just the clevis pin off the spare release arm.

However on slackening the cover plate bolts the cover plate was pushed off a significant amount by the diaphragm spring compared to the RB in 2008, i.e. indicating plenty of life in the friction plate.

When removed the wear was negligible, so that and the cover plate will be kept for another day.

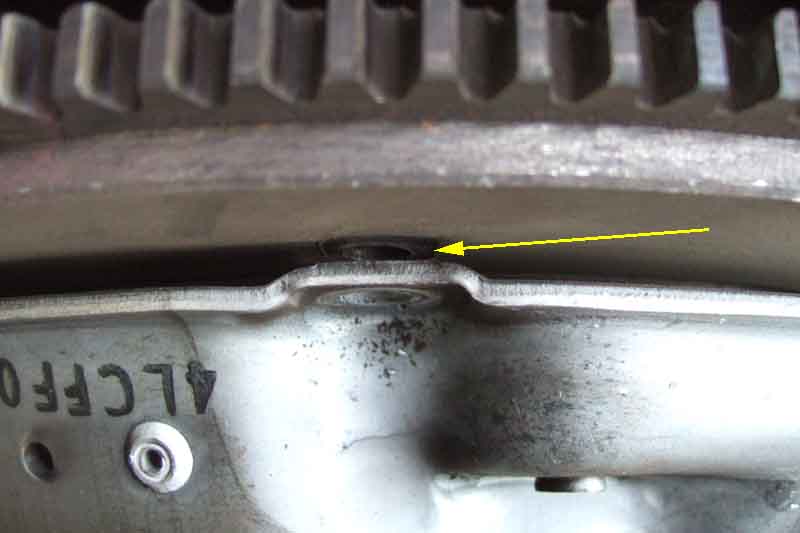

Witness marks as the rivets pass by, but no grooves on the flywheel, which could have happened with any previously worn-out clutch

New cover plate

No marking on the friction plate as to which way it goes round, but offering it up to the flywheel both ways clearly shows which is the right way, as the wrong way the metal parts in the middle hold the friction area well clear of the flywheel.

Fitted correctly, no gap

Forgot to trial fit the friction plate to the gearbox shaft before fitting the cover plate, so decided to remove it again to make sure.

A bit of a struggle refitting the gearbox to the engine, trying to keep it square in four orientations while turning the OD output shaft (gearbox in gear) to align the splines. Confirmation that it is much easier splitting and joining the two while the gearbox is still in the car, so much so that I would probably do it that way even I wanted to ultimately remove the gearbox. Refitted the gearbox harness to the switches, solenoid and mounting points while it was still on the floor - much easier than trying to do it once installed! Note that the harness should go under the remote extension between the two switches, not over as here.