One speed or two?

Switches

Flick-wipe

Parking Systems

Motors, gears, arms and blades

Wheelboxes

Arm fitting

Problems

Intermittent Enhancement

Screen Washers

Lucas Wiper Catalogue

|

Note 1: From 1971 for the remainder of chrome bumper production and all V8s the wipers (and heater fan and electric washers where fitted) were powered from the accessories position of the ignition switch via a white/green to an in-line fuse under the fusebox, and then via a green/pink.

Note 2: In 1970 (North America), 1974 (V8), and from the start of rubber-bumper production for remaining cars the wiper switch moved from the dash-board to a column stalk. Some time later possibly for the 1977 model year on the wiper stalk incorporated a flick-wipe feature. The wire colours remained the same through all these changes, Note 1 excepted.

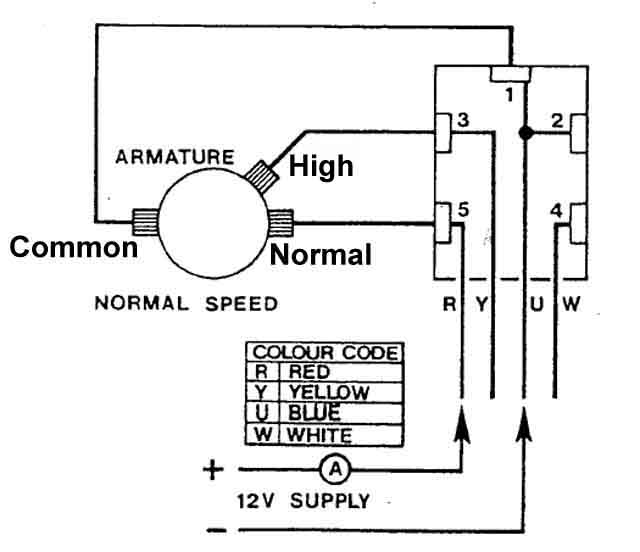

The 1977 LHD Workshop Manual AKM3524 gives the 'normal' speed current as 1.5 amps, the high speed current as 2 amps, the normal speed wiping as '4.6 to 52 rev/min' (presumably 46 to 52 sweeps per minute), and the high speed as 60 to 70 rev/min, both after 60 seconds, and presumably a wet screen.

One speed or two? Rewritten February 2012

The MkI roadster used a square, single-speed motor 17H2013/57H5599/GEU714 with a basic internal parking circuit, three wires, and a simple on/off switch with just two wires.

The MkI GT had a round single-speed motor 27H6409 with a more complex parking circuit that involved the manual switch, with four wires at the motor and three at the switch. There was an adapter harness that allowed its different motor to use the roadster harness for three of the wires, the fourth wire running direct from the motor to a different manual switch (13H 1909) with an extra terminal. The Leyland Parts Catalogue for the Mk1 GT says to use GEU708 as an alternative to 27H6409 - GEU708 is the Mk2 two-speed motor but it is 'plug compatible' with the Mk1 GT albeit only giving the 'standard' speed unless a wiring and switch modification is made.

In May 67 the MkI GT switch was also fitted to the MkI roadster for standardisation, with the extra 'park' terminal left unused.

In Nov 67 all MkII cars got a new round two-speed motor 37H2732/GEU708 with a similar parking system to the MkI GT, with five wires at the motor. The switch was changed again to give two 'on' positions and a park contact, making four wires at the switch.

Upgrading Mk1 roadster to two-speed

Two aspects - motor mounting and electrical. As the 2-speed 14W motor and its mounting arrangements differ to those of the original have a look at this document from Colyn Firth regarding this job on his MGA. For the electrical side Colyn chose to provide relays so he could continue to use an original MGA pull-switch (albeit the three-position lighting switch) instead of mounting an MGB toggle switch elsewhere. For the MGB you will need the Mk2 toggle wiper switch (BHA4786, Lucas 35927 57SA) with six spades giving two 'on' positions as well as the 'park' function. Ideally you would have the wiring connector to fit the connector block on the motor, but could get away with insulated spade connectors on each wire. You need to add two more wires from the motor to the switch - for the second speed and the park function. Strictly speaking you should correct the polarity by providing a 12v supply to the switch in place of the earth, and use the motor connections to 12v and earth as for the later cars. It will work without but in that case you must reverse the 12v and earth connections at the motor from those shown in the schematics for MkII cars or it will blow the fuse. Also with an earth from the switch and 12v at the motor the two-speed motor will run backwards, being permanent magnet stator rather than wound. But that will happen on the many MkI cars that have had their battery polarity reversed, and I've never heard of any problems with the wipers subsequently.

Upgrading Mk1 GT to two-speed

Much easier as the motor mounting is the same and the motor is 'plug compatible' with the existing wiring, you only need to provide one additional wire for the second speed, plus the switch as above. But Keith Evans contacted me with the following:

Mk1 GTs had a later system with a more consistent parking method that used a more complex switch and an extra wire - the 'park' wire. It's possible this was found necessary on the GT with its longer wiper blades and arms as at speed they could interfere with the driver's view.

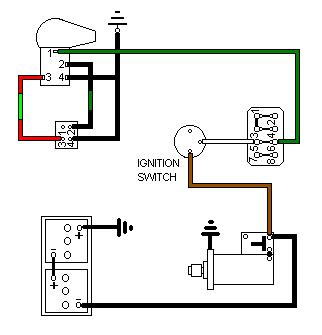

Two-speed systems use a similar parking system to the GT but with a three-position manual switch with a power wire, 'standard' and 'fast' wires, and a 'park' wire. that connects 12v to the standard and fast speed windings as required, but when switched off an additional wire on the switch - the park wire - is connected to the standard-speed wire. With the wipers not parked the motor park switch connects 12v to this park wire, which with the manual switch in the 'off' position is connected to the standard speed wire and causes the motor to continue to run. When the wipers reach the park position the motor park switch disconnects 12v from the park wire (and hence from the standard speed winding) and connects an earth to it instead. This parking system ensures that the motor stops dead which stops the blades in a more consistent position, the earlier system was affected by whether the screen was wet or dry. Originally a toggle switch, from 1972 it was a rocker switch, then rubber bumper 4-cylinder cars and all V8s had a column switch.

1977 and later models use basically the same system but with an additional 'flick-wipe' feature.

Stalk Switch:

V8s and rubber bumper had a column stalk switch for the two-speed wipers, overdrive and screen washer of two different types, for 77 and later it incorporated a flick-wipe function.

V8s and rubber bumper had a column stalk switch for the two-speed wipers, overdrive and screen washer of two different types, for 77 and later it incorporated a flick-wipe function.

1977 and later models came with a flick-wipe feature by moving the stalk down (on RHD cars, LHD used the same switch mechanism but on the other side of the car so flick is up and the continuous speeds down). The manual switch was basically the same but with an additional non-latching contact to connect 12v to the standard-speed winding while the stalk is held down, then parks as normal when released, click the thumbnail for details.

1977 and later models came with a flick-wipe feature by moving the stalk down (on RHD cars, LHD used the same switch mechanism but on the other side of the car so flick is up and the continuous speeds down). The manual switch was basically the same but with an additional non-latching contact to connect 12v to the standard-speed winding while the stalk is held down, then parks as normal when released, click the thumbnail for details.

Be aware that replacement switches from some suppliers have been incorrectly assembled so the flick-wipe function does not work, click the thumbnail for details. Simon Holland received two incorrect switches from one supplier before receiving the correct item from Moss UK. Most of the Google images I have been able to find show the incorrect assembly, Moss, Brown & Gammons and Midland Sports and Classics are correct (at the time of writing, in September 2019 of those three only MSC shows the correct orientation), but it is relatively easy to tell the difference from suppliers photos.

Be aware that replacement switches from some suppliers have been incorrectly assembled so the flick-wipe function does not work, click the thumbnail for details. Simon Holland received two incorrect switches from one supplier before receiving the correct item from Moss UK. Most of the Google images I have been able to find show the incorrect assembly, Moss, Brown & Gammons and Midland Sports and Classics are correct (at the time of writing, in September 2019 of those three only MSC shows the correct orientation), but it is relatively easy to tell the difference from suppliers photos.

To add flick-wipe to MkI roadsters you simply need a non-latching normally-open contact (SPST) to connect a momentary earth to the black/green wire for the wipers to complete a single sweep and then park.

The MkI GT and all MkII two-speed wipers need a more complicated circuit because of the different parking system, suggested wiring is shown here.

The MkI GT and all MkII two-speed wipers need a more complicated circuit because of the different parking system, suggested wiring is shown here.

The square MkI roadster motors have a earth supplied from the manual switch and 12v at the motor. The parking circuit consists of a moving contact on the large gear wheel running on an arc which has a break where the wipers are required to stop. The contact is connected to earth and the arc is connected to the motor, bypassing the manual switch. Thus when the wipers are away from their park position the motor has an alternative earth supply to keep it running until the park position is reached. This parking mechanism is fairly crude in that the inertia of the motor and wipers allows them to 'over-shoot' a little meaning the actual stopping position varies with conditions, i.e. a dry screen will stop them sooner compared to when the screen is fully wet. The wire colours and functions are as follows:

The square MkI roadster motors have a earth supplied from the manual switch and 12v at the motor. The parking circuit consists of a moving contact on the large gear wheel running on an arc which has a break where the wipers are required to stop. The contact is connected to earth and the arc is connected to the motor, bypassing the manual switch. Thus when the wipers are away from their park position the motor has an alternative earth supply to keep it running until the park position is reached. This parking mechanism is fairly crude in that the inertia of the motor and wipers allows them to 'over-shoot' a little meaning the actual stopping position varies with conditions, i.e. a dry screen will stop them sooner compared to when the screen is fully wet. The wire colours and functions are as follows:

The round MkI GT motor parking system differs in that it stops in a much more predictable and controlled fashion. The parking circuit consists of a normally-closed contact at the manual switch and a change-over switch at the motor which consists of a segmented disc with three sections that rotates with the large gear wheel, and three fixed brushes that are part of the connector plug. With the manual switch on an earth is connected to the red/light-green 'run' wire that goes to the motor to operate the motor. When the manual switch is turned off the red/light-green is disconnected from earth and connected instead to the black/green 'park' wire that goes to one contact on the parking disc. With the wipers not parked this part of the disc is connected to an earth on another part of the disc to keep the motor running. Just before the park position is reached the earth is disconnected from the segmented disc to remove power from the motor, but inertia allows the motor to continue to turn as it slows down, then shortly afterwards 12v is connected to the third section of the segmented cam, which is picked up by the black/green wire, which goes back to the manual switch (off) then comes back to the motor on the red/light-green wire, which effectively short-circuits the winding. The motor now has 12v both sides which effectively stops it instantly. The theory behind this is that when power is disconnected from a motor it has inertia and continues to spin as it is slowing down and in the case of the wiper motor this means that the blades can stop in different positions according to how wet the screen is and vehicle speed. While it is spinning down it becomes a dynamo generating a voltage at its windings, and by shorting out the winding the dynamo is effectively being asked to supply a very high current which puts a heavy load on it, which is why it stops very quickly, and this gives it a consistent park position. The wire colours and functions from the Workshop Manuals are as follows:

The round MkI GT motor parking system differs in that it stops in a much more predictable and controlled fashion. The parking circuit consists of a normally-closed contact at the manual switch and a change-over switch at the motor which consists of a segmented disc with three sections that rotates with the large gear wheel, and three fixed brushes that are part of the connector plug. With the manual switch on an earth is connected to the red/light-green 'run' wire that goes to the motor to operate the motor. When the manual switch is turned off the red/light-green is disconnected from earth and connected instead to the black/green 'park' wire that goes to one contact on the parking disc. With the wipers not parked this part of the disc is connected to an earth on another part of the disc to keep the motor running. Just before the park position is reached the earth is disconnected from the segmented disc to remove power from the motor, but inertia allows the motor to continue to turn as it slows down, then shortly afterwards 12v is connected to the third section of the segmented cam, which is picked up by the black/green wire, which goes back to the manual switch (off) then comes back to the motor on the red/light-green wire, which effectively short-circuits the winding. The motor now has 12v both sides which effectively stops it instantly. The theory behind this is that when power is disconnected from a motor it has inertia and continues to spin as it is slowing down and in the case of the wiper motor this means that the blades can stop in different positions according to how wet the screen is and vehicle speed. While it is spinning down it becomes a dynamo generating a voltage at its windings, and by shorting out the winding the dynamo is effectively being asked to supply a very high current which puts a heavy load on it, which is why it stops very quickly, and this gives it a consistent park position. The wire colours and functions from the Workshop Manuals are as follows:

- Green - 12v supply to motor

- Black - earth to motor for parking circuit and manual switch for running

- Red/Light-green - running connection to motor earthed by manual switch in the 'on' position, connected to the park circuit in the 'off' position

- Black/Green - motor to manual switch for park circuit Note the adapter harness has the first three as short wires between the main harness and the motor, and the last is a long wire from the motor to the manual switch.

February 2014:

Click the thumbnail for how to test this motor with the five-pin (but only four wires) connector .

Click the thumbnail for how to test this motor with the five-pin (but only four wires) connector .

MkII and later: The round two-speed motor on these cars has a similar park principle to the MkI GT, but now the motor is backed by earth and the manual switch puts out 12v instead of earth to run the motor. The manual switch again has the normally-closed contact which connects the standard-speed wire to the park wire when the manual switch is in the off position. But now there is second changeover switch on the motor, that supplies 12v to run the motor when the manual switch is off and while the wipers are not parked, and an earth in the park position to short-out the motor and stop it rapidly as before. The wire colours and functions are shown here.

However this motor is not without its own confusions as although there was only one part number for the complete motor assembly there were at least two different types of park switch. The motors could be suffixed A, B etc. up to F or maybe higher. A and B have a screw-on park switch (originally 37H 2734, later 517645A but probably NLA), examples of D and F have the more common clip-on park switch (originally 37H 6784 now 520160A and available from the usual suspects). The brush plates also differ.

However this motor is not without its own confusions as although there was only one part number for the complete motor assembly there were at least two different types of park switch. The motors could be suffixed A, B etc. up to F or maybe higher. A and B have a screw-on park switch (originally 37H 2734, later 517645A but probably NLA), examples of D and F have the more common clip-on park switch (originally 37H 6784 now 520160A and available from the usual suspects). The brush plates also differ.

Which side do you dress I mean park? Added October 2008

This question seems to crop up from time to time, particularly in North America. Parking in front of the driver seems the most logical, as they will clear the driver's view first which is safer when first turning them on in the event of sudden spray being thrown across the screen. However that needs the arms to be angled such that the blades lie flat across the bottom of the screen, straight arms would be across part of the drivers view, and indeed some photos of early cars do show the blades like this, particularly the 64 car on the front of Clausager which looks like it could have straight arms. FWIW modern cars seem to park on the passenger side, but with their much deeper screens they can have much longer arms and blades which move about 90 degrees i.e. from the horizontal parked position against the bottom edge to the vertical position against the right-hand edge as compared to the 106 degrees of roadsters and 115 degrees of GTs. This gives a far greater proportion of swept area, leaving little more than a small arc at the top corner on the passenger side.

It seems quite clear that RHD cars always parked in front of the driver i.e. on the right-hand side. Many North Americans say theirs also park on the right, some say they park on the left, and some say that when ordering new arms they get the 'wrong' ones i.e. angled for parking on one side when they need the other. All the photos of LHD cars in Clausager show them parking on the right, but interestingly the Coune Berlinette on page 107 is parked on the left even though it is an RHD! It's not difficult to get them parked on the 'other' side - on the earlier round motors with the park switch on the domed cover over the main gear you can slacken the cover screws and rotate the domed part by 180 degrees.

On the later round 14W motors with the plastic park switch and connector block combined you can dig the plastic cam out of the back of the main gear and reposition it. The intermediate GT system is significantly different to either the earlier single-speed or the later two-speed. May 2009: Bob Muenchausen has contacted me to say that 20 years ago all he did to change sides was to simply rotate the wheel boxes 180 degrees so that the rack drives them from the top instead of the bottom, and reset the arms - brilliantly simple! You have to remove the rack and tubes from the wheelboxes to do this, so obviously easier with the dashboard out for example during a rebuild as Bob did. It is possible to get motor, tubes and wheelboxes out and back in as an assembly (a pal has done that for other reasons) in order to do that.

On the later round 14W motors with the plastic park switch and connector block combined you can dig the plastic cam out of the back of the main gear and reposition it. The intermediate GT system is significantly different to either the earlier single-speed or the later two-speed. May 2009: Bob Muenchausen has contacted me to say that 20 years ago all he did to change sides was to simply rotate the wheel boxes 180 degrees so that the rack drives them from the top instead of the bottom, and reset the arms - brilliantly simple! You have to remove the rack and tubes from the wheelboxes to do this, so obviously easier with the dashboard out for example during a rebuild as Bob did. It is possible to get motor, tubes and wheelboxes out and back in as an assembly (a pal has done that for other reasons) in order to do that.

November 2021: A really strange thing happened to the MGC of Geoff Thirlby in that the blades suddenly started parking on the other side! I listed a number of things to check, even though Geoff said there had been no changes made to the car, and I couldn't see how any of them could happen by themselves. Then Geoff removed the large gear from the motor to look at the parking cam.

His is quite different to the other one I had seen, and with Geoff's I can imagine that if the plastic gear started sliding down the shaft of the cam plate the location pegs could become disengaged, which would stop the blades while the gear carried on turning. Then the pegs could re-engage 180 degrees out and the blades carry on but would park at the other end of the sweep. It seems unlikely, but what else could it have been apart from the garage pixies, as Geoff said? He was able to slide it down and turn it through 180 degrees to correct the problem. On the other type of gear its probably impossible for the cam to move round the gear and re-engage, but depending on how the gear is attached to the cam plate that could still move as Geoff's seems to have done.

His is quite different to the other one I had seen, and with Geoff's I can imagine that if the plastic gear started sliding down the shaft of the cam plate the location pegs could become disengaged, which would stop the blades while the gear carried on turning. Then the pegs could re-engage 180 degrees out and the blades carry on but would park at the other end of the sweep. It seems unlikely, but what else could it have been apart from the garage pixies, as Geoff said? He was able to slide it down and turn it through 180 degrees to correct the problem. On the other type of gear its probably impossible for the cam to move round the gear and re-engage, but depending on how the gear is attached to the cam plate that could still move as Geoff's seems to have done.

However that's not the whole story, you have to consider any angle in the arms which tilts the blades one way or the other. Whether the blades park in front of the driver or the passenger, you would always want them to sweep right down parallel to the bottom edge of the screen in front of the driver or he will have quite a large unswept arc in front. This means that when they park in front of the passenger, they will be angled up across their view, and partially across the drivers when they look across - see the photos of my V8 and roadster temporarily stopped in this position. Bob tells me that when he changed his parking position he replaced the arms which is fair enough, but he used generic arms which could be angled either way, something I haven't come across before.

However that's not the whole story, you have to consider any angle in the arms which tilts the blades one way or the other. Whether the blades park in front of the driver or the passenger, you would always want them to sweep right down parallel to the bottom edge of the screen in front of the driver or he will have quite a large unswept arc in front. This means that when they park in front of the passenger, they will be angled up across their view, and partially across the drivers when they look across - see the photos of my V8 and roadster temporarily stopped in this position. Bob tells me that when he changed his parking position he replaced the arms which is fair enough, but he used generic arms which could be angled either way, something I haven't come across before.

Going back to Clausager's photos, these all appear to be triple wipers, and that raises an interesting point. North America changed to triple wipers in November 68 as the authorities required a greater proportion of the glass to be swept (the relatively short screens necessitating short blades to avoid going off the top of the screen, which left large areas either side and between the swept arcs). As this moved the left-hand arm closer to the left-hand side of the car, more of the glass would have been swept that side, so the blades could park in front of the passenger but still sweep an 'acceptable' area in front of the driver. This changes the unswept area from being an arc at the top corner of the screen to a triangle at the bottom corner. The latter may be smaller, but to me having a clear screen to see people and objects at street level is preferable to being able to see things up in the sky (traffic lights excepted)! Whereas previously - for some of the time at any rate - LHD cars seem to have parked in front of the driver, it looks like cars with triple wipers changed to park on the right-hand side i.e. same as RHD cars. This must have been the case from April 71 as RHD cars got the same arms as LHD cars, and as the arms have a bend at the top to allow the blades to park against the bottom edge of the screen, they must have both parked on the same side, i.e. the right. From the Parts catalogues it would also seem likely that LHD GTs always parked in front of the driver, as the gears and arms were always different between LHD and RHD, LHD were common to all markets, and they never had triple wipers.

Before triple wipers the situation is less clear. Up to February 63 the complete wiper system was the same for both left and right-hand drive. If the change of parking side on the early motor was very easy i.e. just turning the park switch dome over the main gear through 180 degrees, then possibly the factory made the change themselves. And if the arms were straight it wouldn't have made much difference either way. In February 63 the arms changed to have stronger springs, and also changed to be different between RHD and LHD. In November 67 motors, gears (which now controlled the park position) and arms were all different, and if the parking side wasn't different before it almost certainly was now. That takes us up to November 68 when North American cars triple wipers, and got different arms to other LHD cars. The difference in arms continued up to April 71 when the North American arms were fitted to RHD cars. It wasn't until September 74 when all LHD cars were produced to North American spec that other LHD cars got the North American arms.

The MG Enthusiasts bulletin board has a pretty comprehensive series of photos of cars from 1962 to 1981 and these roadsters make interesting viewing:

| Year | USA | Park side | Europe | Park side |

| 1962 | not available | Denmark | Driver | |

| 1963 | Originally Californian, exported to Norway | Passenger | Germany | Driver |

| 1964 | USA | Driver | Sweden | Driver |

| 1965 | USA | Driver | Sweden | Driver |

| 1966 | not available | Holland | Driver | |

| 1967 | USA | Driver | not available | |

| 1968 | USA | Driver | not available | |

| 1969 | USA | Passenger (triple) | Sweden | Passenger (triple) |

| 1972 | LHD V8 (Switzerland, Holland, Germany) | Driver | UK | Driver |

The confusing thing is that even when North American cars got triple wipers, and changed over to park on the right when they weren't before, they kept the same motor and gear as before - according to the Parts Catalogue, that is. Other LHD cars had the same motor and gear as North American spec cars. Where the Parts Catalogue gives the North American items a different part number to other LHD items and with a 'Safety' marking this is more likely to indicates a difference in material or construction methods and not function. The other thing to be aware of when comparing part numbers is that roadster wiper motors from November 67 to June 76 had suffix letters A, B and D. The motors were less the gear, the gears did not have suffix letters i.e. were just RHD or LHD, but the park switch (and brushes) had one part number with an A and B suffix and another with the D suffix or no suffix. The Catalogue has a note saying reference must always be made to the suffix letter to ensure the correct part is received, so it is probably the suffix letter that determines which side parking takes place. Unfortunately it doesn't say which suffix letter applies to which situation, i.e. RHD, LHD North America or LHD elsewhere. RHD cars had the same motor as LHD, but their own gear, from November 67 until the end of production. Other part number changes will be due to the change from bright arms and blades to matt-black, and there also seems to have been a change in position of roadster wiper spindles which required a change in arm and/or blade length.

Looking at GT pictures on the MG Enthusiasts bulletin board only one LHD (undated but between a 75 and a 77, the cars all being in date order) has the wipers on the right i.e. in front of the passenger, at least one LHD from each year having them in front of the driver.

The full (as near as I can judge) list of part number changes:

| Roadster | |||||||||

| Change-point | Motor | Comments | Gear | Arms | Comments | Blades | |||

| HN3-101 | May-62 | HN3-6916 | RHD/LHD | 17H 2013 | Use GEU 714 | 57H 5589 | BHA 4321 | 10.25" arms, 10" blades | GWB 202 |

| HN3-6917 | Feb-63 | HN3-138400 | RHD | 57H 5599 | Use GEU 714 | 47H 5307 | 37H 4952 | Heavier (13 oz) wiper arms | GWB 202 |

| HN3-6917 | Feb-63 | HN3-138400 | LHD | 57H 5599 | Use GEU 714 | 47H 5307 | BHA 4396 | Heavier (13 oz) wiper arms | GWB 202 |

| HN4-138401 | Nov-67 | HN4-158230 | LHD NA | 37H 2732 | Use GEU 708 | 37H 3046 | BHA 4816 | GWB 202 | |

| HN4-138401 | Nov-67 | HN4-167576 | RHD | 37H 2732 | Use GEU 708 | 37H 3045 | BHA 4814 | GWB 202 | |

| HN4-138401 | Nov-67 | HN4-167576 | LHD not NA | 37H 2732 | Use GEU 708 | 37H 3046 | BHA 4816 | GWB 202 | |

| HN4-158231 | Nov-68 | HN4-164063 | LHD NA | 37H 2732 | Use GEU 708 | 37H 3046 | 13H 5460 | Triple wipers | GWB 202 |

| HN4-164064 | Dec-68 | HN5-294250 | LHD NA | 37H 2732 | Use GEU 708 | 37H 3046 | BHA 4913 | Magnatex arms instead of Lucas | GWB 141 |

| HN4-167577 | Feb-69 | HN5-246076 | RHD | 37H 2732 | Use GEU 708 | 37H 3045 | BHA 4914 | Magnatex arms instead of Lucas | GWB 141 |

| HN4-167577 | Feb-69 | HN5-294250 | LHD not NA | 37H 2732 | Use GEU 708 | 37H 3046 | BHA 4915 | Magnatex arms instead of Lucas | GWB 141 |

| HN5-246077 | Apr-71 | HN5-294250 | RHD | 37H 2732 | Use GEU 708 | 37H 3045 | BHA 4913 | LHD NA arms fitted | GWB 141 |

| HN5-294251 | Aug-72 | HN5-410000 | RHD | 37H 2732 | Use GEU 708 | 37H 3045 | BHA 5201 | Matt black arms and blades | GWB 216 |

| HN5-294251 | Aug-72 | HN5-360300 | LHD not NA | 37H 2732 | Use GEU 708 | 37H 3046 | BHA 5203 | Matt black arms and blades | GWB 216 |

| HN5-294251 | Aug-72 | HN5-410000 | LHD NA | 37H 2732 | Use GEU 708 | 37H 3046 | BHA 5201 | Matt black arms and blades (3) | GWB 216 |

| HN5-360301 | Sep-74 | HN5-410000 | LHD not NA | 37H 2732 | Use GEU 708 | 37H 3046 | BHA 5201 | NA arms fitted | GWB 216 |

| HN5-410001 | Jun-76 | on | RHD | 37H 8221 | 37H 3045 | BHA 5201 | GWB 184 | ||

| HN5-410001 | Jun-76 | on | LHD | 37H 8221 | 37H 3046 | BHA 5201 | GWB 184 | ||

| GT | |||||||||

| Change-point | Motor | Comments | Gear | Arms | Comments | Blades | |||

| HD3 | RHD | 27H 6409 | Use GEU 708 (see note) | 27H 6420 | BHA 4546 | 12" arms, 11" blades | GWB 142 | ||

| HD3 | LHD | 27H 6429 | 27H 6424 | BHA 4548 | 12" arms, 11" blades | GWB 142 | |||

| HD4-138401 | Nov-67 | HD4-158230 | RHD | 37H 2732 | Use GEU 708 | 37H 3047 115° | BHA 4817 | 13" blades | GWB 143 |

| HD4-138401 | Nov-67 | HD4-158230 | LHD | 37H 2732 | Use GEU 708 | 37H 3048 115° | BHA 4819 | 13" blades | GWB 143 |

| HD4-158231 | Nov-68 | HD5-296000 | RHD | 37H 2732 | Use GEU 708 | 37H 4308 125° | BHA 4881 | 13" blades | GWB 144 |

| HD4-158231 | Nov-68 | HD5-296000 | LHD | 37H 2732 | Use GEU 708 | 37H 4309 | BHA 4880 | 13" blades | GWB 144 |

| HD5-296001 | Aug-72 | on | RHD | 37H 2732 | Use GEU 708 | 37H 4308 125° | BHA 5205 | Matt-black 12" arms and 13" blades | GWB 217 |

| HD5-296001 | Aug-72 | on | LHD | 37H 2732 | Use GEU 708 | 37H 4309 125° | BHA 5204 | Matt-black 12" arms and 13" blades | GWB 217 |

| V8 | |||||||||

| All | RHD | 37H 2732 | Use GEU 708 | 37H 4308 125° | BHA 5205 | Matt-black 12" arms and 13" blades | GWB 217 | ||

Notes:

- GEU 708 is a two-speed motor but is 'plug compatible' with the Mk1 GT wiring albeit giving only the 'standard' speed without modifying the wiring and switch.

- Info on gear part numbers May 2024 varies somewhat:

Chassis No. Leyland PC Moss Europe B&G MGOC Rimmer Mk1 Roadster 101 – 6916 57h5559 511007 511007 6917 – 138400 47h4307 520939 nca 520939 nca Mk1 GT rhd 27h6420 27H6420 nca 27H6420 nca lhd 27h6424 Mk2 roadster rhd 37h3045 37H3045 37h3045 105° 37h3045 105° 37h3045 105 lhd 37h3046 Mk2 GT 138400 – 158230 rhd 37h3047 37h3048 115° 37h3048 115° 517622 138400 – 158230 lhd 37h3048 158231 – on rhd 37h4308 37H3048 37h4309 125° oos V8 37h4308 158231 – on lhd 37h4309

Wheelboxes have their own variations, these are the original numbers, several NLA. Early versions are shown as 'assemblies' so may have come with bush kits:

The original bush kits have an angled spacer under the panel (roadster are longer than GT) as well as the angled chrome bezel with gasket (roadster ADC560 GT 27H6428) above the panel, to clamp the wheelbox to the panel and seal against water ingress. Suppliers only seem to have the upper kit (gasket, bezel and nut) and not the lower spacer, without that the wheelbox will be loose on the panel and leak. Moss Europe does picture the lower spacer for Mk1 cars but without a part number so not available. B&G does have what looks like the roadster item although it is not pictured at the top of their main 'wipers' pages, at £8.34 plus P&P. However Andy Jennings has new 3D printed at £7 a pair with free postage!

GT wipers have a wider sweep angle than roadsters and this is set by the position of the crank pin on the main gear - that for the GT will be further out from the spindle than the roadster. Roadsters were 106 degrees, GTs were 115 degrees originally then 125 degrees for 1969 models on according to the Parts Catalogue, but suppliers indicate this change was much earlier. It looks like the main gear is stamped with the applicable sweep angle.

Arm fitting:

From what I can tell wiper arms always attached to the spindles with a spring-clip, never a screw. A very simple arrangement but seemingly effective, so far in over 30 yrs and 200k with two cars none of mine have gone flying off into a hedge or the middle of the road. As the spring pushes the blade against the glass the 'cup' tilts on the spindle and the clip lodges behind it. To release them pull the blade back, angle the hinge side of the cup towards the glass instead of away, and wiggle and pull. To replace just push back onto the splines with the blade in your preferred position relative to the screen glazing seal.

From what I can tell wiper arms always attached to the spindles with a spring-clip, never a screw. A very simple arrangement but seemingly effective, so far in over 30 yrs and 200k with two cars none of mine have gone flying off into a hedge or the middle of the road. As the spring pushes the blade against the glass the 'cup' tilts on the spindle and the clip lodges behind it. To release them pull the blade back, angle the hinge side of the cup towards the glass instead of away, and wiggle and pull. To replace just push back onto the splines with the blade in your preferred position relative to the screen glazing seal.

T Aczel in Australia has had problems with TEX arms flying off, losing about four of them. He posted pictures of two different types of TEX fitting which as well as being different to the originals are different to each other.

T Aczel in Australia has had problems with TEX arms flying off, losing about four of them. He posted pictures of two different types of TEX fitting which as well as being different to the originals are different to each other.

December 2011:

That leaves the angle the parked blades make to the screen. Clausager shows a 1964 Tartan Red on page 17 with the right-hand wiper at an angle to the screen, but the inner end on the screen surround so it can't go down any more. However the left-hand wiper is cocked way up, and is clear of the surround, so I'd be looking if that arm could be moved on the spindle by one spline. The 68 MGC on the facing page has them lower, with the right-hand pretty-well flat, and the left-hand angled but much lower. Most other images in the book have them flat to the surround, and both my cars are like that. I'm pretty sure I have never altered the V8, but following a comment on a BBS I do recall increasing the angle at the blade-end of the roadster arms to make the blades lie flat before repainting them. There have also been reference to 10 or 12 degree arms, and 20 degree arms, the difference being the larger angle makes them lie flat where the smaller angle doesn't. GT arms and blades are longer and the spindles are positioned differently to the roadster partly because of the deeper glass, the overall effect being that the arms need less of an angle for the blades to lie flat to the lower edge of the glass. Where they park in front of the driver, parking flat is desirable, and I adjusted my roadster arms as follows: With the edges of the blade-end of the arm clamped lightly between the jaws of a vice, I gripped the flat sides just above the jaws with a pair of large pliers so stop the arm turning over and buckling, then pulled the splined-socket end of the arm towards me. I didn't bother about the angle, just did each until the blade lay flat, only took a couple of goes. This may chip the paint on painted, but that can be touched-up if you aren't repainting them anyway. For bright arms probably best to use plastic vice jaw inserts and similar in the plier jaws, but then again they can be polished.

That leaves the angle the parked blades make to the screen. Clausager shows a 1964 Tartan Red on page 17 with the right-hand wiper at an angle to the screen, but the inner end on the screen surround so it can't go down any more. However the left-hand wiper is cocked way up, and is clear of the surround, so I'd be looking if that arm could be moved on the spindle by one spline. The 68 MGC on the facing page has them lower, with the right-hand pretty-well flat, and the left-hand angled but much lower. Most other images in the book have them flat to the surround, and both my cars are like that. I'm pretty sure I have never altered the V8, but following a comment on a BBS I do recall increasing the angle at the blade-end of the roadster arms to make the blades lie flat before repainting them. There have also been reference to 10 or 12 degree arms, and 20 degree arms, the difference being the larger angle makes them lie flat where the smaller angle doesn't. GT arms and blades are longer and the spindles are positioned differently to the roadster partly because of the deeper glass, the overall effect being that the arms need less of an angle for the blades to lie flat to the lower edge of the glass. Where they park in front of the driver, parking flat is desirable, and I adjusted my roadster arms as follows: With the edges of the blade-end of the arm clamped lightly between the jaws of a vice, I gripped the flat sides just above the jaws with a pair of large pliers so stop the arm turning over and buckling, then pulled the splined-socket end of the arm towards me. I didn't bother about the angle, just did each until the blade lay flat, only took a couple of goes. This may chip the paint on painted, but that can be touched-up if you aren't repainting them anyway. For bright arms probably best to use plastic vice jaw inserts and similar in the plier jaws, but then again they can be polished.

Poor clearing

Flying off

Parking on the wrong side

One thing that plagues BMC rack-and-pinion wipers is excessive slop after many years use. I used to think that this was all due to wear in the wheel-boxes and rack, and no doubt some is. If you think about it, the wheel-boxes consist of a gear wheel in which slightly less than half is ever used, and only one side of the rack is ever used. So if you remove the wiper arms, disconnect the rack at the motor and withdraw it until the wiper spindles are free, rotate the wiper spindles through 180 degrees, turn over the rack and put everything back, you should be running on unused portions of the wiper boxes and rack. I tried that on my V8 but if anything it has made things worse - maybe a PO had already done it - so I had a careful look at the rack. It consists of a flexible-ish straight wire with a stiff wire wrapped round it in a spiral to form the 'teeth' of the rack. It looked to me as if the pitch between the turns of the spiral that ran in the wheel-boxes was greater than elsewhere, not due to wear but distortion, and that would account for some slop. My next task is to see if I can get a new rack and try that. In fact shortly after writing this the rack broke anyway! I got a replacement from the MGOC, it had to be cut to the correct length, and it did indeed cure the slop!

Slow or non-running: Updated September 2008: Another problem is slow running, and that is about the most difficult thing to investigate on the MGB, worse even than slow indicators. This can be caused by dry spindles in the wheel-boxes, some say old stiff grease in the gearbox causes it but I have not experienced this. Worn brushes can also cause it, and also cause intermittent running. A common cause is low voltage at the motor caused by bad connections. As the power has to come from the solenoid on the brown circuit, through the ignition switch (or ignition relay) onto the white or white/brown, through the fuse onto the green (or green/pink) circuit, through the wiper switch to the motor, and from the motor to an earth connection, plus the many spade and bullet connections in that circuit. The problem is that low voltage causes slow running, which causes high current. But mechanical drag also causes slow running, which causes high current, and both cause additional voltage drop. So it is extremely difficult to know whether the cause is electrical or mechanical, especially as the harness plug for the motor is hidden between the motor and the bulkhead and very difficult if not impossible to get meter probes onto. Removing the motor and connecting a good 12v and earth supply to the connector pins will show if the motor itself is the cause, but if not that still leaves mechanical drag from the rack, wiper boxes and blades, or electrical connections and doesn't put you much further forward.

February 2013: Manek Dubash of Lewes reported on MG Enthusiasts that his wipers weren't working or very slow, the motor got very hot and was blowing fuses. He measured the running current on the bench (i.e. not wiping the screen) at 5.2 to 5.5 amps, whereas the book says it should be 2.7 to 3.4 amps when it is wiping the (wet) screen (on the standard speed if a 2-speed motor). The wheelboxes and rack being attached or not made little difference, neither did resisting movement by hand. He decided to get a new armature as they are only £9.50 compared to £50 for a complete motor (well spotted), and with that fitted on the bench (i.e. no wiper blade load) it was drawing only 1.6 amps on the standard speed and 2.2 on the fast, so the fault was probably a partially burnt-out armature winding. Note that on a stationary motor a typical standard winding measures 1.5 ohms and fast 1 ohm, so it's possible to get a current of up to 14 amps with a stalled motor.

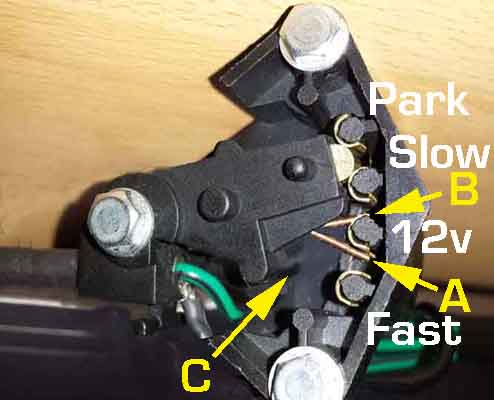

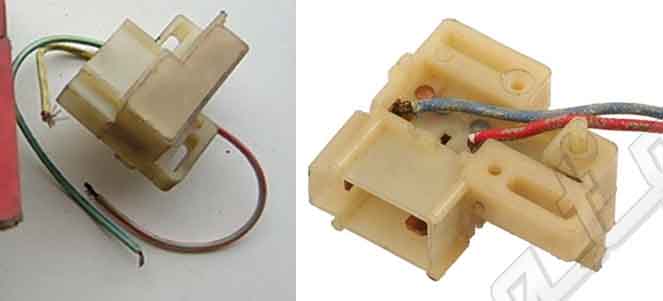

Failure to park (just stops when the manual switch is turned off) can be caused by a worn park switch in all types of motor as well as disconnected wiring or a faulty manual switch in the case of the later parking system. The park-switch (see left) is in a single unit with the multi-connector plug on the motor and has a nylon peg that pokes through the gearbox casing which is lifted up by a cam on the large gear, the nylon peg can wear down as well as the switch contacts fail. The park-switch/connector (which also kept playing up on the V8 until replaced) is also available from the parts houses.

Failure to park (just stops when the manual switch is turned off) can be caused by a worn park switch in all types of motor as well as disconnected wiring or a faulty manual switch in the case of the later parking system. The park-switch (see left) is in a single unit with the multi-connector plug on the motor and has a nylon peg that pokes through the gearbox casing which is lifted up by a cam on the large gear, the nylon peg can wear down as well as the switch contacts fail. The park-switch/connector (which also kept playing up on the V8 until replaced) is also available from the parts houses.

September 2008:

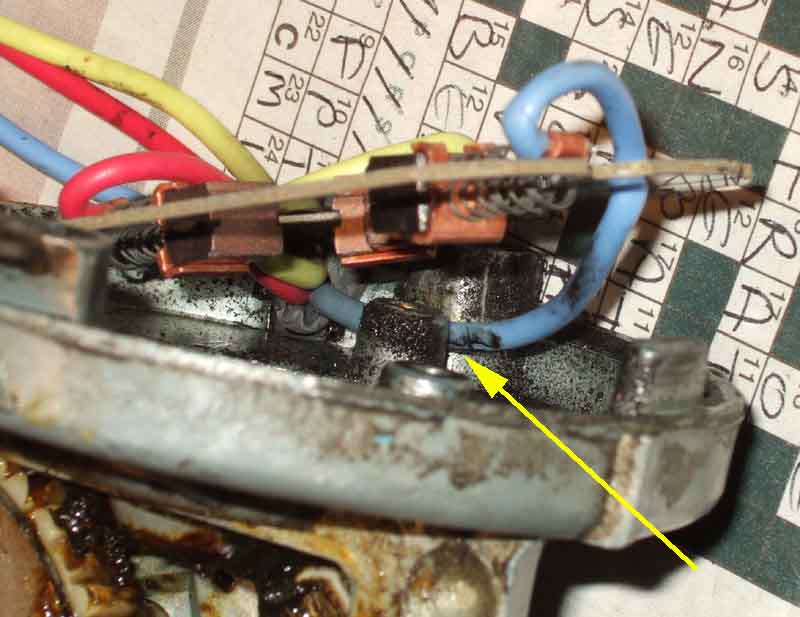

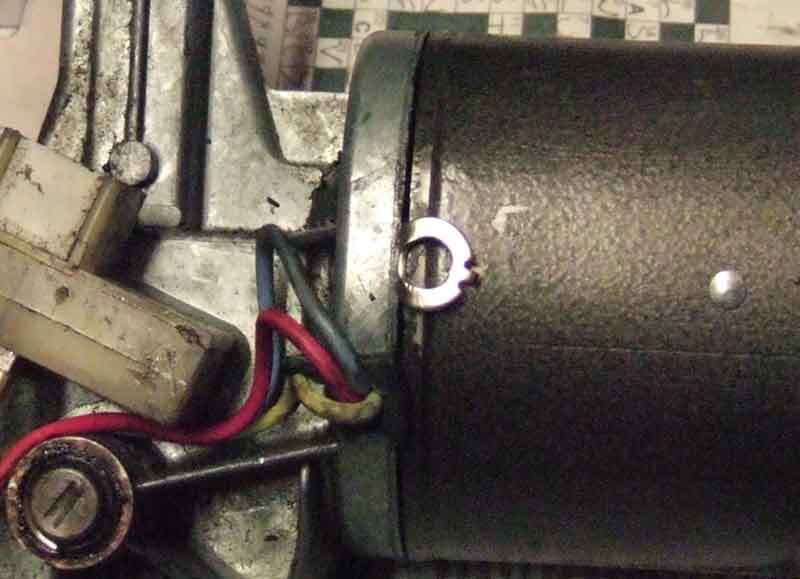

Vee's wipers suddenly stopped working, moving about 1/4 the way across then stopping, and not parking or running at either speed. Fortunately I didn't need them as I had operated the wiper stalk instead of the indicator, otherwise it would probably have happened when I did need them! The fuse hadn't blown as the heater fan was still working. The electrical conditions at the (unplugged) harness connector seemed to be correct, so there was nothing for it but to remove the motor. Applying 12v and earth directly to the appropriate spades on the connector block got nothing out of the standard speed and just a brief movement out of the fast, then nothing, not even any sparking. So I opened it up, full story by clicking the thumbnail to the left.

Vee's wipers suddenly stopped working, moving about 1/4 the way across then stopping, and not parking or running at either speed. Fortunately I didn't need them as I had operated the wiper stalk instead of the indicator, otherwise it would probably have happened when I did need them! The fuse hadn't blown as the heater fan was still working. The electrical conditions at the (unplugged) harness connector seemed to be correct, so there was nothing for it but to remove the motor. Applying 12v and earth directly to the appropriate spades on the connector block got nothing out of the standard speed and just a brief movement out of the fast, then nothing, not even any sparking. So I opened it up, full story by clicking the thumbnail to the left.

Brush Replacement May 2016: For a long time Bee's wipers have been reluctant to start moving, especially if not used for a long time like over winter. Sometimes I've had to switch to fast speed before they would get going properly, and after that they have continued to work back on normal speed. On our first run of the season I had to use them and they were even reluctant to start and keep going on the fast speed, so definitely time to investigate. We have a run in a few days where rain is expected again, so I decide to do something about it.

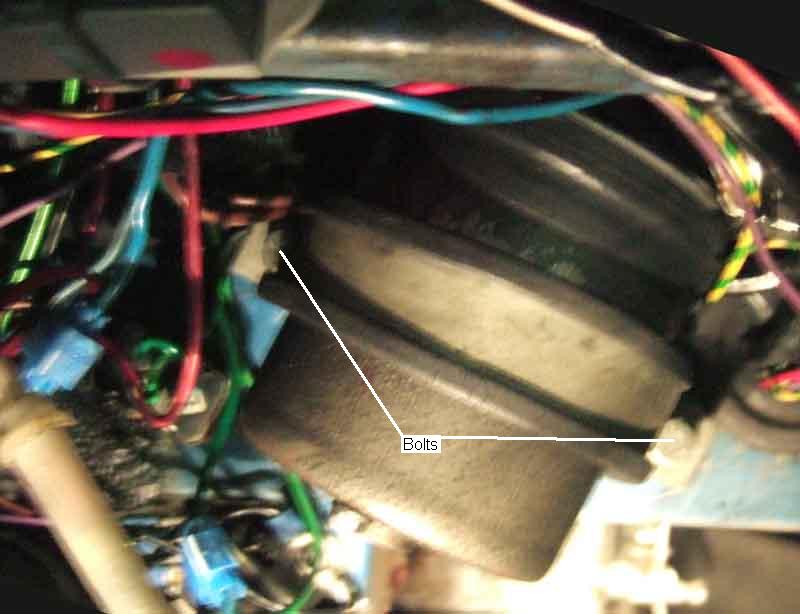

The first thing I did was check the voltage reaching the motor, which to do properly one must do right on the connectors for the brush wires, which means taking the motor off to get at them. Remove the U-clamp securing the motor to the bulkhead, which makes access to the gearbox cover screws slightly easier.

The first thing I did was check the voltage reaching the motor, which to do properly one must do right on the connectors for the brush wires, which means taking the motor off to get at them. Remove the U-clamp securing the motor to the bulkhead, which makes access to the gearbox cover screws slightly easier.

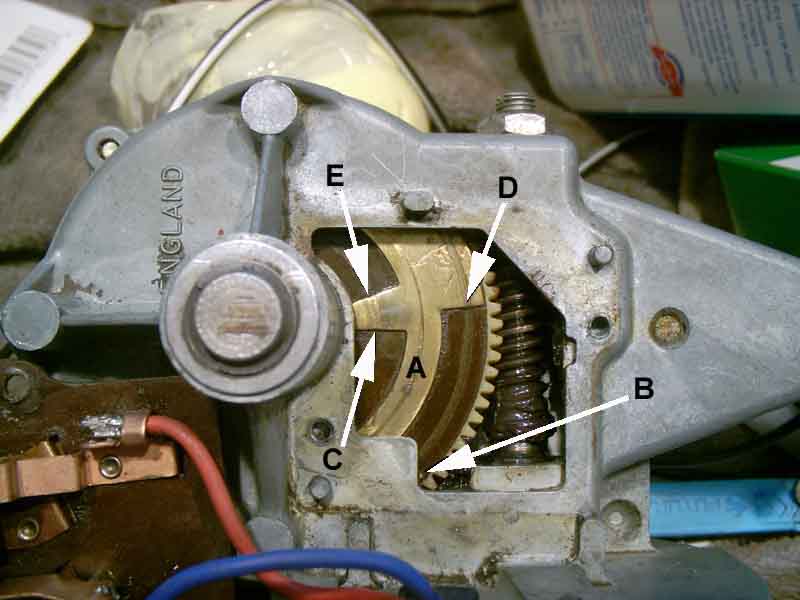

Take the cover off, slide the circlip off the large wheel crank pin, remove the shim under it, and remove the connecting rod that pushes and pulls the rack inner. Note another larger shim under the connecting rod. If you lift the blades off the glass, turn the wiper switch on, then turn the ignition on and off while watching the crank pin, you can position it to be lower down and so easier to access. Then the rack can be lifted out of the end of the gearbox, the motor unit lowered and turned over to unplug the harness connector. In theory you can undo the big nut where the rack joins the gearbox, and withdraw the motor complete with rack inner and so not have to fiddle with the connecting rod - if you can wield a large spanner that high up behind the dashboard. Many years ago that nut did work loose in torrential rain on a run, and I managed to reach up and hand-tighten it while still driving along, tightening it properly on our return home, but with all the extra wiring I have up there now I decided it would be easier to remove the con-rod as I did before.

Take the cover off, slide the circlip off the large wheel crank pin, remove the shim under it, and remove the connecting rod that pushes and pulls the rack inner. Note another larger shim under the connecting rod. If you lift the blades off the glass, turn the wiper switch on, then turn the ignition on and off while watching the crank pin, you can position it to be lower down and so easier to access. Then the rack can be lifted out of the end of the gearbox, the motor unit lowered and turned over to unplug the harness connector. In theory you can undo the big nut where the rack joins the gearbox, and withdraw the motor complete with rack inner and so not have to fiddle with the connecting rod - if you can wield a large spanner that high up behind the dashboard. Many years ago that nut did work loose in torrential rain on a run, and I managed to reach up and hand-tighten it while still driving along, tightening it properly on our return home, but with all the extra wiring I have up there now I decided it would be easier to remove the con-rod as I did before.

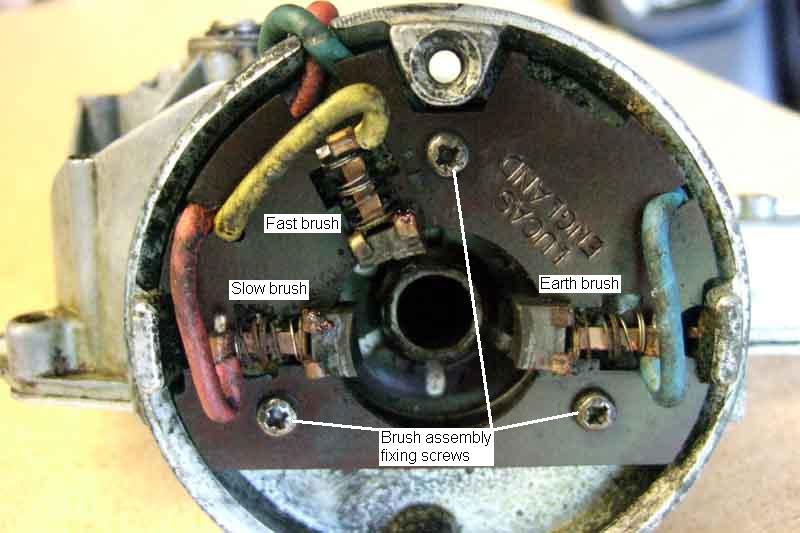

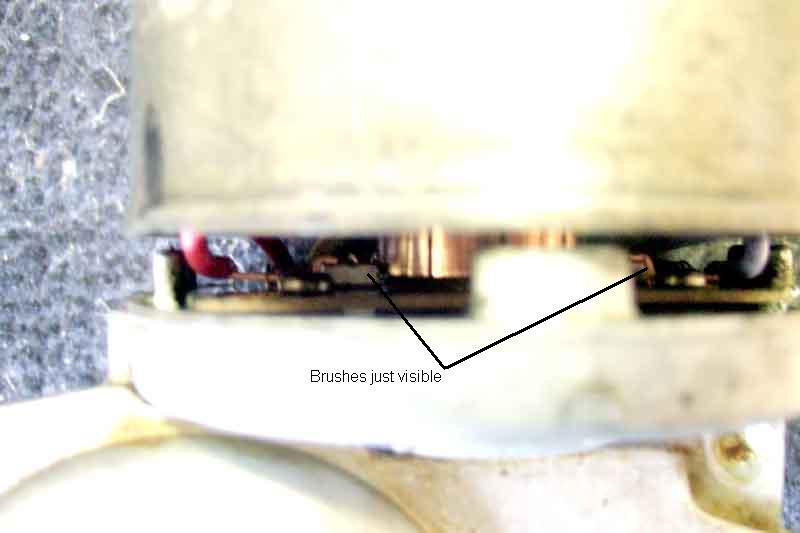

I poked some thin single-strand wire up the normal and fast connectors where the brush wires go onto the connector block, plugged the harness back, connected a meter to the wires, and switched on. Now this doesn't have the load of the wipers of course, but even so I'm only losing about half a volt, so the connections are OK. Next was to examine the brushes. Remove the two long screws that go through the motor case into the gearbox, and pull the motor unit off.

It was immediately apparent that the brushes were very worn, even more so than when I had changed Vee's brushes when that stopped altogether. However it was only when reviewing this picture that I realised something else. Whilst the brush material itself is considerably longer on the unworn new item, the springs aren't pushing the back of the brushes anywhere near as far out as the old springs are. So unless they work out as they are used, only a small amount of wear will need to take place before these stop working properly as well.

It was immediately apparent that the brushes were very worn, even more so than when I had changed Vee's brushes when that stopped altogether. However it was only when reviewing this picture that I realised something else. Whilst the brush material itself is considerably longer on the unworn new item, the springs aren't pushing the back of the brushes anywhere near as far out as the old springs are. So unless they work out as they are used, only a small amount of wear will need to take place before these stop working properly as well.

When fitting the new brush set make sure the blue wire is positioned between the screw boss and the side of the gearbox casing, and doesn't get trapped. It's the earth wire so shouldn't cause an electrical problem, but it will affect the alignment of the brushes.

When fitting the new brush set make sure the blue wire is positioned between the screw boss and the side of the gearbox casing, and doesn't get trapped. It's the earth wire so shouldn't cause an electrical problem, but it will affect the alignment of the brushes.

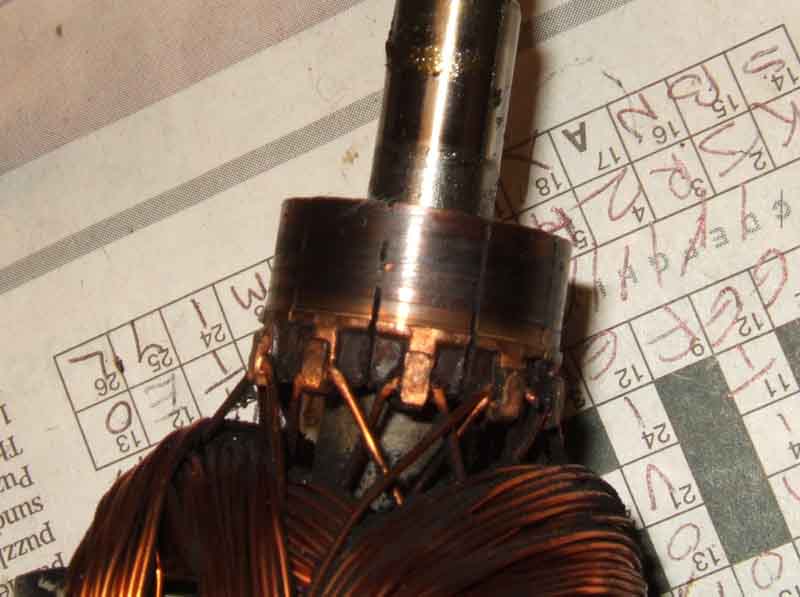

I took the opportunity to clean the commutator with white spirit, and draw a knife blade between the segments to clean them out.

I took the opportunity to clean the commutator with white spirit, and draw a knife blade between the segments to clean them out.

When refitting the motor, carefully hook the brushes back one by one so they fit over the end of the commutator ...

When refitting the motor, carefully hook the brushes back one by one so they fit over the end of the commutator ...

... and position the alignment marks correctly.

... and position the alignment marks correctly.

With the motor casing screwed to the gearbox casing I plugged the harness in for an electrical test - and immediately found the same problem I had had with Vee's new brush set and that was the motor binding and running very slowly. Slackening the motor screws and tilting its case slightly freed the motor up, again exactly as before. This time determined to try and find the cause, I removed the motor case, refitted the old brush set, and refitted the motor, and it ran perfectly. Several times I had the motor off and on with both new and old brush sets and it always ran correctly with the old set, and always ran slowly with the new. The only point of contact between the brush set and the armature is between the brushes and the commutator, so there is no way they can be causing it when tilting the motor 'cures' it. It can't be the upper bearing in the gearbox casting as that is spherical externally in a spring mount so orientates itself to match the spindle. And it isn't the large screw in the gearbox casing that bears on the end of the armature spindle as I slackened that to give a clearance and it made no difference, and there is a nylon bush between the two anyway. It's a mystery, so again I resort to a washer inserted to create a gap on one side, i.e. tilting the motor relative to the gearbox. I reinstall everything, but may well investigate further when time and no imminent runs allow.

With the motor casing screwed to the gearbox casing I plugged the harness in for an electrical test - and immediately found the same problem I had had with Vee's new brush set and that was the motor binding and running very slowly. Slackening the motor screws and tilting its case slightly freed the motor up, again exactly as before. This time determined to try and find the cause, I removed the motor case, refitted the old brush set, and refitted the motor, and it ran perfectly. Several times I had the motor off and on with both new and old brush sets and it always ran correctly with the old set, and always ran slowly with the new. The only point of contact between the brush set and the armature is between the brushes and the commutator, so there is no way they can be causing it when tilting the motor 'cures' it. It can't be the upper bearing in the gearbox casting as that is spherical externally in a spring mount so orientates itself to match the spindle. And it isn't the large screw in the gearbox casing that bears on the end of the armature spindle as I slackened that to give a clearance and it made no difference, and there is a nylon bush between the two anyway. It's a mystery, so again I resort to a washer inserted to create a gap on one side, i.e. tilting the motor relative to the gearbox. I reinstall everything, but may well investigate further when time and no imminent runs allow.

Poor clearing: From time to time there are complaints on the various fora about poor clearing of the screen by the wipers - smearing and missed areas being the main ones. It's possible that people are comparing them with their modern cars, which is always a big mistake. It's also possible that people rarely use their MGBs in wet weather, so if they do get caught in a shower it's quite likely they are going to have dust, traffic film and flies, unless they are forever cleaning the screen before going out - and dust in particular is something I notice when taking one of them out after a break of a couple of weeks or so. After that it's down to arm and blade performance.

I've done nothing special to either of mine but find particularly on the V8 that after the first few strokes after not being used for a long time the clearing is perfectly acceptable, and very similar to the ZS under similar circumstances. The roadster needs a bit longer perhaps, but again is perfectly acceptable. I have Smartscreen on both and use that far more than needing the wipers to be on constant, even in quite heavy rain, it just seems to bead and roll off, as if I was using Rain-X.

Juddering is usually down to traffic film on either the screen or the blades, but can also be due to the 'angle of attack' of the blade to the glass. The blades work best if they can spread a microscopic layer of water across the glass as a lubricant, sweeping the rest away, a bit like when using a palette knife to ice a cake (you haven't lived ...). Lifted just off the glass the blade should be pointing straight at the glass, and movement in how the rubber is attached to the metal parts of the blade, and the shape and flexibility of the rubber tip, should allow the tip to lean first one way then the other as it sweeps across the glass. If the tip of the blade can't lean to perform a sweeping action and instead performs a chiselling action then it may well judder.

Juddering is usually down to traffic film on either the screen or the blades, but can also be due to the 'angle of attack' of the blade to the glass. The blades work best if they can spread a microscopic layer of water across the glass as a lubricant, sweeping the rest away, a bit like when using a palette knife to ice a cake (you haven't lived ...). Lifted just off the glass the blade should be pointing straight at the glass, and movement in how the rubber is attached to the metal parts of the blade, and the shape and flexibility of the rubber tip, should allow the tip to lean first one way then the other as it sweeps across the glass. If the tip of the blade can't lean to perform a sweeping action and instead performs a chiselling action then it may well judder.

The 'refill' i.e. the rubber and its steel backing should be free to move up and down through the pivoting parts of the arm. This enables it to follow the curve of the screen, and to move from a curved part to a flat part staying in contact with the glass. When mine are parked - right down on the rubber surround - only the very tip of the blade is not touching the glass, and only by a tiny amount. As soon as the blade starts it sweep it is fully in contact with the glass.

The 'refill' i.e. the rubber and its steel backing should be free to move up and down through the pivoting parts of the arm. This enables it to follow the curve of the screen, and to move from a curved part to a flat part staying in contact with the glass. When mine are parked - right down on the rubber surround - only the very tip of the blade is not touching the glass, and only by a tiny amount. As soon as the blade starts it sweep it is fully in contact with the glass.

The spring in the arm may be weak. After the first six months of production heavier 13oz arms were fitted.

It's possible all the above may be correct, but the quality of the rubber (!) is just not good enough. From notes (which may be incomplete) Vee's came from Halfords in 2015, possibly Bosch, and Bee's have possibly been on since 1991! There are comments that 'Tex' blades are poor, but seem to be the ones most commonly stocked, NOS Trico being better. Googling shows Trico as currently available, quality unknown.

Parking on the wrong side: November 2021

- If you have just reinstalled the wiper rack/wheelboxes then check that the rack goes under the wheelboxes, not above, as here.

- If you have just fitted a different motor then remove the cover when the wipers are parked and see where the crank-pin on the large gear is. It should have pushed the rack out of the gearbox housing, as here.

- If it has pulled the rack into the gearbox housing on the 14W 2-speed motor then the parking cam is probably in the wrong position, see here.

- But if your wipers suddenly start parking on the wrong side when no work has been done, look here!

Flying off: March 2020

The arms should have some method of retaining them on the spindles. Mine have a spring-clip that hooks under the base of the splined section, and the blade has to be lifted off the glass to remove the tension between arm and spindle before I can remove them. If the splines are worn it may allow the arm to fly off when in use.

The arms should have some method of retaining them on the spindles. Mine have a spring-clip that hooks under the base of the splined section, and the blade has to be lifted off the glass to remove the tension between arm and spindle before I can remove them. If the splines are worn it may allow the arm to fly off when in use.

Smartscreen Intermittent Control

Smartscreen:

The MG Owners Club and others sell a device called 'Smartscreen' which is eminently suitable for MGBs and Midgets at least and because the time delay is set using the standard wiper switch the device can be tucked away out of sight as it has no controls of its own. You use the existing switch on and off to start a 'learning' phase, then use the existing switch a second time on and off to terminate the learning phase, thereafter it repeats the delay until you turn the manual switch on for longer than one wipe or turn off the ignition. There is an enhanced version which operates the wipers briefly whenever the electric washers are used. I have the non-washer version and they are extremely useful, I find myself using intermittent far more than full-time, which saves wiper motor, blades and screen, as well as the switch when light rain/spray means you would otherwise need to keep turning them on and off (or flick-wipe) manually.

The MG Owners Club and others sell a device called 'Smartscreen' which is eminently suitable for MGBs and Midgets at least and because the time delay is set using the standard wiper switch the device can be tucked away out of sight as it has no controls of its own. You use the existing switch on and off to start a 'learning' phase, then use the existing switch a second time on and off to terminate the learning phase, thereafter it repeats the delay until you turn the manual switch on for longer than one wipe or turn off the ignition. There is an enhanced version which operates the wipers briefly whenever the electric washers are used. I have the non-washer version and they are extremely useful, I find myself using intermittent far more than full-time, which saves wiper motor, blades and screen, as well as the switch when light rain/spray means you would otherwise need to keep turning them on and off (or flick-wipe) manually.

September 2024: On a very wet journey to Doncaster and back for a photoshoot with the Vulcan I was using Smartscreen a lot when I started noticing my (instantaneous) voltmeter momentarily dropping a volt or two and wondered if the alt was on the way out, perhaps the rain. But then I realised it coincided with Smartscreen triggering the wipers so was less bothered. Next day I started looking at voltages and currents when I remembered that although the wipers are powered from the accessories position of the ignition switch Smartscreen is powered from the fused ignition, via quite a long daisy-chain of things I have added, together with the voltmeter. With Smartscreen disabled operating the wipers manually shows only a marginal dip on the voltmeter, so possibly one of those connections isn't 100%. But while I'm messing about I decide to power Smartscreen from the accessories position as well so both are the same, just leaving the voltmeter on the previous connection, and now both manual and Smartscreen operation result in the merest dip of the voltmeter.

February 2013: I fitted the Smartscreen to Vee in 2001 and it has just packed up (lasted longer than many replacements for factory stuff) - the wipers start to run as soon as the ignition was turned on. I knew it was the Smartscreen and not the wiper switches as on this era the wipers are available with the key in the Accessories position, and they worked as they should, it was only when turned to Run before cranking that they started up, and I had powered Smartscreen from the ignition and not the accessories. After a bit of confusion - I got no confirmation web page or email or entry on my credit card, so thought the order had failed somehow and ordered again a week later. This time I got a confirmation email, but still no credit card entry or Smartscreen after a few days. Contacted the vendor who said he had received both orders so at least I was able to cancel the spurious one, and eventually it came another week later. Easy enough to swap the wires one by one and we are back working again. Always intrigued as to what's inside sealed boxes I opened it up to take a peek.

Update January 2006: Apparently out of stock with the MGOC for a long time there have been rumours that they are available again. The suppliers web site is still online but there is no date information to indicate that it is still current, the contact page gives a phone number for enquiries. However Moss Europe show them with a price so maybe they are available again. Update August 2008: Allen Bachelder has commented on the MG Enthusiast BB that he ordered one from Moss (presumably UK as USA don't reference them) a couple of years ago but a different product arrived which uses its own control and so is not as neat as the Smartscreen system. Moss currently show the Smartscreen in the link above, so maybe you should check before you buy to see which you are getting.

RWTM Windscreen Wiper Timer Module August 2021

There has been a question about connecting these on the MGOC forum. A less convenient device as it has its own rotary switch that has to be mounted somewhere, and only has five fixed intervals. Of the online instructions only one is directly applicable - earth-side switching for Mk1 roadsters - the rest vary to some degree. Mk1 GTs have a system that is only similar to Mk2 cars, Mk1 roadsters are completely different. Because the instructions are generic i.e. apply to lots of different marques and models they do not give any colours for the cars wiring, so you have to work that out for yourself. There is sufficient information on this site to work that out for the three (or four) options but I have added the colours to the Retronics drawings to make it easier.

There has been a question about connecting these on the MGOC forum. A less convenient device as it has its own rotary switch that has to be mounted somewhere, and only has five fixed intervals. Of the online instructions only one is directly applicable - earth-side switching for Mk1 roadsters - the rest vary to some degree. Mk1 GTs have a system that is only similar to Mk2 cars, Mk1 roadsters are completely different. Because the instructions are generic i.e. apply to lots of different marques and models they do not give any colours for the cars wiring, so you have to work that out for yourself. There is sufficient information on this site to work that out for the three (or four) options but I have added the colours to the Retronics drawings to make it easier.