Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

| Electrical System |

|

Automotive Electrics Basics - Part 1 - Terminology and Part 2 - Typical faults, symptoms, and diagnostic techniques

Ammeters_and_Voltmeters

Alternator/Dynamo

Anti_Run-on_Valve

Batteries_and_Chargers

Battery_Cut-off_Switch

Brake_Balance_and_Handbrake_Warning

Bulbs

Cable_and_Pipe_Routing

Clocks

Connectors_and_Terminals

Cooling_Fans

Cruise_Control

Fan_Belt

Fuel_Pumps

Fuses_and_Fusebox

Gauges

Hazard_Flashers

Heated_Rear_Window

Heater_Fan

Horns

Ignition_Switch

Ignition_System

Ignition_Warning_Light

Indicators/Turn_Signals

Instruments

Lighter_Socket

Lighting

North_American_'Key_in'_Warning

Overdrive

Polarity

Radio

Relays

Schematics![]() Screen_Washers

Seat_Belt_Warning

Sealed_Wiring_Junctions

Starter

Steering_Lock

Switches_in_General

Tachometer

Wipers

Wires_&_Terminal_Numbering

Wiring_Harness_Replacement

Won't_Start

Won't_Switch_Off!

Torque_Values

Links

Screen_Washers

Seat_Belt_Warning

Sealed_Wiring_Junctions

Starter

Steering_Lock

Switches_in_General

Tachometer

Wipers

Wires_&_Terminal_Numbering

Wiring_Harness_Replacement

Won't_Start

Won't_Switch_Off!

Torque_Values

Links

| (Image posted by Geoff Hutton on the MGOC forum) |

Lighter Socket November 2018

USB Sockets

Going by the Leyland Workshop Manual schematics it was optional in all markets until the 1973 model year when it became standard, although Clausager says it was standard on North American Mk2. It was always illuminated with the parking lights, under the control of the panel light dimmer rheostat/switch.

When dealer-fitted it was powered from the white circuit on the ignition switch on Mk1 cars, i.e. unfused and only available with the ignition on. On the first year of RHD and non-North American LHD Mk2 models it was powered from the brown circuit at the ignition switch i.e. now available at any time but still unfused. 1969 and 70 RHD and non-North American LHD models were powered from the accessories position of the ignition switch but still unfused. 1971 RHD and non-North American LHD models were powered from the accessories position of the ignition switch, but were now fused from the 'accessories' fuse that powered the wipers and heater fan. All Mk2 North American spec cars, and from 1972 onwards all other models, were powered from the purple circuit i.e. fused and always available. When dealer-fitted it may or may not have needed a dedicated earth wire, but when mounted in the various plastic centre consoles it will.

There are many different types - some where the whole of the removable part is pushed into the socket against spring pressure and locks in position to heat it up, then pops out when hot. Others with a smaller 'push-button' inside the removable part that is pushed in and pops out. When pushing in to start heating the centre connection which is a circular disc gets pushed into a spring clip that retains it. This clip is bi-metallic so as the element heats up so does the clip, which starts opening up, and eventually releases the disc to pop out. Typically they are retained in the bracket or console by a large sleeve that screws onto the lighter from the back. This may have a large slot on one side for the bulb holder to clip in to, by pinching the sides of the holder.

USB Sockets: July 2023

In this day and age of phone sat-nav it's probably better to have the phone powered and recharging rather than run the battery down on a long journey and get stranded later. For a while I've been using a charger that plugs into the cigar lighters but as well as having a couple fail I've had to replace it for different phones whereas probably all phones these days come with a charging cable with a standard USB plug on the end so a USB socket in the car makes more sense. I didn't want to replace the lighter with a USB socket, I'd used a USB adapter that plugged into the socket but that also failed, so something needed to be added. I don't like drilling holes and wanted it to be unobtrusive but there should be plenty of places to position one under the dash and on the side of the centre-console without catching it with one's legs and the Navigator's bags. Looking around some rectangular very low profile sockets would seem to fit the bill, so one was purchased. The obvious place to me was flat on the sides of the centre-console - in my footwell as I don't want to get my face slapped by said Navigator. One of the securing screws for the centre console seems to be the most obvious, and although the (dual) socket comes with fixing screws and only one would be needed it would have to go through the centre-console and existing spire clip so needed to be longer - no problem given my stock of nuts, screws washers and bolts. Bee would be my first candidate as she is used more for touring than Vee and as a CB I have to bear in mind access to the rubber plug in the tunnel for the gearbox dipstick, and it can mount vertically only intruding into the space slightly. Vee has the alarm controller in that position so it has to be mounted horizontally projecting across the space behind the console, but being an RB with the side-fill and level plug on the gearbox the tunnel plug is never accessed. The mounting screw where it goes through the spire-clip behind the console also offers a convenient point to pick up an earth for the sockets. 12v ideally picked up from the fused accessories circuit i.e. the green/pink behind the centre-console feeding the radio (and heater fan and wipers) from 72 to the end of CB production and all V8s which means it can remain powered when the ignition is off but the key still in. Otherwise from the fused purple circuit to be powered all the time, or the fused green circuit just for when the ignition is on. Of course you can add your own in-line fuse and power it from wherever you want - certainly safer to have it fused.

In this day and age of phone sat-nav it's probably better to have the phone powered and recharging rather than run the battery down on a long journey and get stranded later. For a while I've been using a charger that plugs into the cigar lighters but as well as having a couple fail I've had to replace it for different phones whereas probably all phones these days come with a charging cable with a standard USB plug on the end so a USB socket in the car makes more sense. I didn't want to replace the lighter with a USB socket, I'd used a USB adapter that plugged into the socket but that also failed, so something needed to be added. I don't like drilling holes and wanted it to be unobtrusive but there should be plenty of places to position one under the dash and on the side of the centre-console without catching it with one's legs and the Navigator's bags. Looking around some rectangular very low profile sockets would seem to fit the bill, so one was purchased. The obvious place to me was flat on the sides of the centre-console - in my footwell as I don't want to get my face slapped by said Navigator. One of the securing screws for the centre console seems to be the most obvious, and although the (dual) socket comes with fixing screws and only one would be needed it would have to go through the centre-console and existing spire clip so needed to be longer - no problem given my stock of nuts, screws washers and bolts. Bee would be my first candidate as she is used more for touring than Vee and as a CB I have to bear in mind access to the rubber plug in the tunnel for the gearbox dipstick, and it can mount vertically only intruding into the space slightly. Vee has the alarm controller in that position so it has to be mounted horizontally projecting across the space behind the console, but being an RB with the side-fill and level plug on the gearbox the tunnel plug is never accessed. The mounting screw where it goes through the spire-clip behind the console also offers a convenient point to pick up an earth for the sockets. 12v ideally picked up from the fused accessories circuit i.e. the green/pink behind the centre-console feeding the radio (and heater fan and wipers) from 72 to the end of CB production and all V8s which means it can remain powered when the ignition is off but the key still in. Otherwise from the fused purple circuit to be powered all the time, or the fused green circuit just for when the ignition is on. Of course you can add your own in-line fuse and power it from wherever you want - certainly safer to have it fused.

North American 'Key In' Warning June 2013

For the 1970 model year North American gained a warning buzzer that sounded whenever the drivers door opened if the key was still in the ignition. This used an additional contact on the ignition switch to send an earth to the buzzer when the key was in, and an additional drivers door switch. This door switch (BHA4984) differs from the courtesy light switches in that it is insulated from the body and has two wires - a purple (always on, fused) supplying 12v to the switch and a purple/green going to the buzzer. Both switches have to be 'closed' to sound the buzzer, i.e. either the door being closed, or the key being out, will stop it. It stayed the same for the 1971 model year and the first four months of the 1972 model year, but when these cars got the seat-belt warning system in December 1971 it was combined with that.

For the 1970 model year North American gained a warning buzzer that sounded whenever the drivers door opened if the key was still in the ignition. This used an additional contact on the ignition switch to send an earth to the buzzer when the key was in, and an additional drivers door switch. This door switch (BHA4984) differs from the courtesy light switches in that it is insulated from the body and has two wires - a purple (always on, fused) supplying 12v to the switch and a purple/green going to the buzzer. Both switches have to be 'closed' to sound the buzzer, i.e. either the door being closed, or the key being out, will stop it. It stayed the same for the 1971 model year and the first four months of the 1972 model year, but when these cars got the seat-belt warning system in December 1971 it was combined with that.

The ignition switch contact. Examination indicates that this contact is only closed with the key inserted and the switch in the 'OFF' position. However one would have expected it to also be closed in the 'ACCESSORIES' position, if not in the 'RUN' position as well in case the engine has stalled with the ignition still on. The Leyland Workshop Manual has a test procedure for the sequential seatbelt system including this warning feature, however it does not give different conditions for any of the possible ignition switch positions. Furthermore it says "Test 10 Warning buzzer: Requirements: (l) Warning buzzer operates - ignition key removed: Remarks: If the warning buzzer does not operate in (l), either the warning buzzer or the circuit wiring is faulty". This seems to be incorrect, as the warning buzzer should NOT operate when the key is removed, only when it is inserted, and the driver's door should be open as well. The Austin MG Technical Service Bulletin gives even less information, just saying "Connect wire (between) pins 5 and 7, Warning buzzer on" without saying anything about the ignition key or switch or drivers door.

The ignition switch contact. Examination indicates that this contact is only closed with the key inserted and the switch in the 'OFF' position. However one would have expected it to also be closed in the 'ACCESSORIES' position, if not in the 'RUN' position as well in case the engine has stalled with the ignition still on. The Leyland Workshop Manual has a test procedure for the sequential seatbelt system including this warning feature, however it does not give different conditions for any of the possible ignition switch positions. Furthermore it says "Test 10 Warning buzzer: Requirements: (l) Warning buzzer operates - ignition key removed: Remarks: If the warning buzzer does not operate in (l), either the warning buzzer or the circuit wiring is faulty". This seems to be incorrect, as the warning buzzer should NOT operate when the key is removed, only when it is inserted, and the driver's door should be open as well. The Austin MG Technical Service Bulletin gives even less information, just saying "Connect wire (between) pins 5 and 7, Warning buzzer on" without saying anything about the ignition key or switch or drivers door.

June 2020:

Arthur Taylor writes that he has been working on two 1973 models where the warning buzzer sounds when the key has been removed but the steering is not yet locked. Looking at the Parts Catalogue and Clausager there were three different ignition switches for the USA, Canada, Sweden and Germany 1973 model year - at the start in September 72 and chassis number 296000, chassis numbers 324942 and 325855, and it changed again at the start of the 74 model year at chassis number 328800.

Arthur Taylor writes that he has been working on two 1973 models where the warning buzzer sounds when the key has been removed but the steering is not yet locked. Looking at the Parts Catalogue and Clausager there were three different ignition switches for the USA, Canada, Sweden and Germany 1973 model year - at the start in September 72 and chassis number 296000, chassis numbers 324942 and 325855, and it changed again at the start of the 74 model year at chassis number 328800.

Which battery terminal is which?

Polarity Conversion

Dynamo polarity

Coil polarity

Tachometer polarity

Fuel pump polarity

Heater fan motor polarity

Instrument stabiliser polarity

First, a history lesson: Why was the MGB positive earth to begin with, and why are some even older cars negative earth? Originally negative earth was the norm as on the low-output HT systems of the day a positive HT pulse gave a better spark at the plug than a negative one. Wired negative return was also originally used, but it was soon realised that chassis return was cheaper and easier. Before plastic-insulated wire all sorts of other materials were used, but all had a certain amount of leakage where they touched metal parts, which were now at earth potential. It was then discovered that the leakage from wires at positive potential to the chassis at negative potential was causing the wires to corrode and fail, hence the change to positive earth. Battery terminals also suffer from corrosion, particularly with the proximity of acid, and it was found that positive earth reduced this as well. This now meant that any leakage caused corrosion at that point on the chassis, which wasn't ideal, but the chassis is a lot more substantial than the wiring. By this time modern coil design meant a positive HT pulse could be produced from a negative supply, so the spark wasn't adversely affected by the change in polarity. Post WW2 most wiring was plastic insulated, which has negligible to zero leakage, so the polarity issue went away. No point in changing back to negative earth just for that, but with the advent of television post-war, interference from the ignition systems of passing cars became an issue, and negative-earth system are easier to suppress. Nevertheless, the MGB and presumably other marques and models in the BMC stable, didn't switch back until the fitting of alternators in 1968, but certainly had adequate suppression systems before that. Electronic components in cars - transistor radios being the first - can be instantly destroyed by the wrong polarity, unlike simple electric components like bulbs and coils. Early radios usually had a polarity switch on the back, but with the growing use of electronics it was decided that polarity switches on everything would be costly, so a standard polarity need to be adopted by all manufacturers, and negative earth - for its suppression benefits - it was.

Whilst there is no safety benefit with one polarity over another, whichever polarity you have it is very important to observe the same rule when disconnecting or reconnecting the battery, and that is to remove the earth connection from the battery first, and reconnect it last. This is regardless of whether the car is negative earth/ground or positive earth/ground, and the reason for this is that if your spanner should happen to touch the body whilst it is also touching the earth/ground post of the battery nothing will happen. Once the earth/ground connection is removed it is now safe to undo the 12v (aka 'hot' or 'live') connection, because if your spanner should happen to touch the body while it is on the hot post still nothing will happen because the earth/ground connection has already been removed. If you work on the 12v post with the earth still connected, and your spanner should happen to touch the body which on the MGB with its batteries in a hole in the rear shelf is very easy to do. This has the effect of shorting out the battery, generating a large arc which could cause any battery gases in the locality to explode, which can itself cause the battery to explode, and your face is quite likely to be right above it. Modern automotive advice sources often say to remove the negative cable first, but they are talking about modern cars which are all negative earth, and are not taking into account the many classic and older cars that are still positive earth. It's earth cable off first and on last, regardless of polarity.

What Polarity is my Car!? July 2014

The first thing to say is that if it has an alternator it has almost certainly been converted to negative earth, and very probably so if it contains any after-market electronic equipment like electronic ignition or a modern radio. Period radios often had a polarity changing connector, so this can be a clue. If it has a dynamo then it could be either polarity, according to which way it has been polarised.

Another possible way to determine polarity is to examine the battery connectors. Are these marked + and -? If not, then on UK batteries at least, the +ve and -ve posts on the batteries are different sizes, and the connectors are similarly different sizes. The posts typically measure 0.756" for the positive and 0.690 for the negative, i.e. the positive is bigger. Try connecting them one at a time and see if that indicates anything by one way fitting better than the other. The original cup-type connectors will be obvious, but bear in mind that the bolt-up type can be bodged to fit either post.

If it's a 62 to 64 i.e. with a mechanical rev counter instead of a tachometer, and if there is no aftermarket electronic equipment, then with one exception connecting the battery either way round won't hurt anything. The exception is fuel pumps. The original pump was capacitor quenched and can be used on either polarity. Later pumps were diode-resistor and are polarity sensitive. Connecting these the wrong way round still won't do any harm, but will cause the pump to take about 1 amp more current than normal. Later versions still have transient voltage suppression devices which again are polarity independent. You may have to take the end-cap off the pump to see if it has the diode-resistor, and if so which way round it is connected. However bear in mind that someone could have fitted a positive earth pump, then someone else reversed the polarity. Or indeed someone simply fitted the wrong type!

As a 65 to 67 Mk1 (Mk2 cars were negative earth from the factory) it should have the electronic tach, which is polarity sensitive. I'm not aware of reverse connection blowing these up, but can't promise. Tachometers were marked with the original polarity - positive and negative - from inception, at least until they changed from chrome bezels to plastic for the 1977 model year. But bear in mind that a PO may have changed the internal wiring of a positive earth tach and not changed the legend on the dial. Short of removing that and opening it up and working out whether it has been modified or not, really you need to remove the white 12v supply wire from the spade connection on the back to protect the electronics while you work out what the polarity actually is. But it's complicated by having three white wires, the other two being the ignition feed, usually as a single loop of white going through the external pickup. And even if you do open up the tach, there is nothing to say that it is the original tach and was working before the car came to you.

As a 65 to 67 Mk1 (Mk2 cars were negative earth from the factory) it should have the electronic tach, which is polarity sensitive. I'm not aware of reverse connection blowing these up, but can't promise. Tachometers were marked with the original polarity - positive and negative - from inception, at least until they changed from chrome bezels to plastic for the 1977 model year. But bear in mind that a PO may have changed the internal wiring of a positive earth tach and not changed the legend on the dial. Short of removing that and opening it up and working out whether it has been modified or not, really you need to remove the white 12v supply wire from the spade connection on the back to protect the electronics while you work out what the polarity actually is. But it's complicated by having three white wires, the other two being the ignition feed, usually as a single loop of white going through the external pickup. And even if you do open up the tach, there is nothing to say that it is the original tach and was working before the car came to you.

I would not recommend simply firing it up and seeing what happens to the battery voltage i.e. to see if the dynamo is charging or not. The dynamo will generate it's output voltage according to its polarisation, independently of the battery voltage. If the polarity of one is opposite to the other and the control box cut-out relay operates the voltages will be added together and a very high current will flow. This could well burn wiring and damage the dynamo and control box. Disconnect the wiring from the F and D terminals of the dynamo. Connect the battery using your best guess as to polarity, switch on, and start up. Then with the engine running at less than 1000rpm, link the F and D terminals of the dynamo together, and connect a voltmeter between that link and a good earth on the engine. Assuming you get a voltage reading, the polarity of that will tell you which way the dynamo is polarised, i.e. if you see the F and D are negative with respect to earth, then it hasn't been converted. But if the voltage is positive with respect to the earth, then it has been converted. Remember that the battery polarity will be opposite to this, i.e. if you see a negative voltage on the F and D terminals the battery needs to be connected for positive earth, and vice-versa. However with a car new to you and a non-runner there is nothing to say that the previous owner fitted a dynamo of the opposite polarity in an effort to correct a charging problem, and when it didn't gave up and sold the car. You can connect the battery according to the dynamo polarity, but that still might be wrong for the tach electronics.

If you do see a voltage, and slowly raising the revs towards 1000rpm increases the voltage towards 20v (do not exceed 20v), then you know the dynamo at least is working. However if you get no voltage, you are no further forwards without diagnosing what is wrong with the dynamo.

Which Terminal is Which? July 2009:

Modern 12v batteries usually have the polarity symbols + and - moulded into the battery top by the respective posts, as well as being supplied with colour-coded caps (red for +ve and blue or black for -ve) over the post (discarded on fitting), and possibly coloured rings around the base of the posts (permanent). But some 6v batteries don't seem to have markings, even current supply. These seem to be the ones with the individual screw caps for the cells of which there are least two designs - the original tar-tops with black caps as well as a more modern smooth-topped battery with coloured caps. My present 6v batteries have a single rectangular cover (red) over all three cells and do have + and - markings. There is a possibility that some makes may have a distinct vertical groove in the negative post (no + or - markings), but this remains to be confirmed. Easy to use a meter to determine polarity - as long as you are sighted and the battery has some charge in it! Other than that all the batteries and cars in my experience have had the posts and connectors of different sizes - positive larger than negative. It's not much by sight or touch, only about 1/20" in diameter, but it makes a big difference if you try to put the negative connector on the positive post (it won't fit) or the positive connector on the negative post (it drops on and is loose). If you do need to test-fit the connectors, make sure you only do one at a time, and only one battery at a time, to avoid reverse connection and the risk of shorts from the loose end of the link cable. When changing polarity always change the connectors as well, junking the cup-shaped type (if you still have them) for bolt-up type, as whilst the bolt-up type can be made to fit the wrong posts it would be rather short-sighted. I've seen a couple of comments from people who have flattened the battery, then charged it up in reverse, which seems a really iffy process to me, if not downright dangerous if someone else should go by any + and - markings for reconnection, boosting or even charging. Also some sources stating that +ve and -ve plates are made of slightly different materials which aid battery performance, which would work against you if the polarity is reversed.

Modern 12v batteries usually have the polarity symbols + and - moulded into the battery top by the respective posts, as well as being supplied with colour-coded caps (red for +ve and blue or black for -ve) over the post (discarded on fitting), and possibly coloured rings around the base of the posts (permanent). But some 6v batteries don't seem to have markings, even current supply. These seem to be the ones with the individual screw caps for the cells of which there are least two designs - the original tar-tops with black caps as well as a more modern smooth-topped battery with coloured caps. My present 6v batteries have a single rectangular cover (red) over all three cells and do have + and - markings. There is a possibility that some makes may have a distinct vertical groove in the negative post (no + or - markings), but this remains to be confirmed. Easy to use a meter to determine polarity - as long as you are sighted and the battery has some charge in it! Other than that all the batteries and cars in my experience have had the posts and connectors of different sizes - positive larger than negative. It's not much by sight or touch, only about 1/20" in diameter, but it makes a big difference if you try to put the negative connector on the positive post (it won't fit) or the positive connector on the negative post (it drops on and is loose). If you do need to test-fit the connectors, make sure you only do one at a time, and only one battery at a time, to avoid reverse connection and the risk of shorts from the loose end of the link cable. When changing polarity always change the connectors as well, junking the cup-shaped type (if you still have them) for bolt-up type, as whilst the bolt-up type can be made to fit the wrong posts it would be rather short-sighted. I've seen a couple of comments from people who have flattened the battery, then charged it up in reverse, which seems a really iffy process to me, if not downright dangerous if someone else should go by any + and - markings for reconnection, boosting or even charging. Also some sources stating that +ve and -ve plates are made of slightly different materials which aid battery performance, which would work against you if the polarity is reversed.

The first consideration is the batteries. Before doing anything else make sure the battery earth connection is the first thing you remove, and the last thing to reconnect at the end. All the batteries I have seen have different-sized posts for +ve and -ve so in theory you cannot connect them the wrong way round, therefore the connectors will have to be swapped over or replaced. The original 'helmet' type that completely cover the post and are secured with a small screw that goes into the post expand and get loose with age and repeated removal and replacement, giving poor connections, and some resort to using silver paper to get a tight fit. Seeing as you are changing the polarity originality is not an issue, so if you haven't already then replace these with the bolt-up type which give a much better connection. The other thing with the helmet type is that they are usually moulded on, these have to be cut off and replaced with the clamp on type, which usually have two large screws to secure the cable. This results in shortening each cable by about an inch but that shouldn't be a problem. If it is, then you will have to replace the cable(s) and get ones with moulded-on clamps. If you already have clamp-up type connectors remove these from the 12v and earth cables and swap them over. Unless you have already replaced the twin-6v with a single-12v you will also have to deal with the interconnecting cable in the same way, and unless it can be physically removed from the car and reversed you will have to cut off and replace moulded-on helmet-type connectors, or remove and swap over the clamp-up type.

If you are retaining the dynamo this has to be repolarised so that it generates the correct polarity voltage. Disconnect the wires from the F and D terminals of the dynamo and with the batteries connected take a jumper lead and connect it briefly between the brown at the fusebox and the F terminal of the dynamo so as you see a small spark. Just one flash is enough, then reconnect the dynamo.

Cars after 64 had the electronic tach and this has to be converted too. You have to get into the case, find the supply and earth wires from the case to the circuit board, and reverse the connections. But note that some cars (e.g. a 67 B belonging to John Schroeder) have the circuit board screwed to the case and pick up the earth connection this way. In this case you have to isolate the circuit board from the case, move the original 12v supply wire from the terminal on the case to the body of the case, and provide a new wire from the earth connection on the circuit board to the 12v supply terminal on the case. John intends to publish notes and pictures of this on the Chicagoland MG Club website. In all cases you have to reverse the direction of the current pulse through the pickup and this also varies. Originally positive-earth cars had a tach with an external pickup and a continuous white wire comes out of the harness, through the pickup twice (i.e. one turn) then back into the harness. With these carefully note the route the wire takes now, remove it, and reverse the direction of the wire through the pickup, but keeping everything else the same e.g. the position of the loop. However there seems to be another variant with a short flying lead through the external pickup, terminated with two male bullets. In this case the harness should have two female bullet connectors, making it very easy to do this part of the switch. Tachs for negative-earth cars up to 1972 all have the pickup inside the case, with male and female bullets on the back of the case, and female (from the ignition switch) and male (to the coil) bullets on the ends of the harness wires.

Added December 2009: It's frequently stated that when changing the car's polarity you should also reverse the coil connections to keep the polarity of that and the HT spark the same. I usually mention it when the subject comes up, but you do end up with slightly less HT voltage than before either way, replacing the coil with one intended for negative earth cars would be preferable, see Ignition Coil polarity.

If you have the heater fan motor with black and green/brown wires these may have to be reversed at the connectors by the motor. If in doubt try them both ways (you can't do any harm) and if one way blows more air than the other that is how to connect it. More detail here.

Fuel pumps: Original pumps used capacitor quenching to reduce points burning and these pumps work on either polarity. Towards the end of production diode quenching was used which gives improved quenching, and these pumps are polarity sensitive. They will work on the 'other' polarity, but quenching will be reduced and hence points burning will increase. These can be converted quite easily. More recently the quenching component used is bi-directional, and these pumps will work correctly on either polarity. 'Pointless' electronic pumps may not work at all on the 'other' polarity, or may be destroyed. More detail here.

Finally, whereas the original instrument voltage regulators works on either polarity many replacements contain electronics, and most of these will only work on the correct polarity. They may be destroyed, or not work, on the 'other' polarity. More detail here.

That's it, unless you have any other electronic devices, which will be aftermarket and so up to you. The only possible other thing might be that the wipers now park in a slightly different place. If it bugs you then move the arms on the spindles. Start the car, check the tach is working, and measure the voltage on the brown at 3000rpm with minimal load. With a dynamo you should see in the order of 14.3v to 15.5v depending on ambient temperature (lower volts at higher temps), with an alternator you should see 14.3v to 14.7v.

Radio August 2009

Speakers

Interference suppression

This is not intended to be a dissertation on all the different types of radio or 'in car entertainment' and how to install them, but touches on one aspect of improving security that might not be immediately obvious.

As the V8 was my daily driver I installed an 'el-cheapo' radio-cassette from Halfords that had a removable face-plate, and was always diligent about removing this from the car when parked up. At that time the car was parked under a car port in front of my house, and despite there being a security light under the porch and a street lamp right outside I came down one morning to find the screen rubber partially cut away and the glass cracked from top to bottom in two places where 'they' had tried to lever it out. Obviously an attempt to break in, and thinking it was an attempt at theft I bought a wheel clamp. A couple of weeks later I came down to find the 1/4-light levered open, window wound down, glovebox and arm-rest cubby open, and the radio missing. So that was what they were after! The trouble is that so many people are lazy that although they remove the face-plate from the radio they leave it somewhere in the car, so it worth these peoples time to break in as more often than not they will find it (but not mine which was in the house), totally destroying the objective of a removable face-plate! I was very lucky, after the first attack the screen was replaced without loss of NCD, and the second time the only damage was a small tear in the shoulder rail under the 1/4-light where they had levered it open, and a broken 1/4-light hinge. They hadn't even scratched the paint levering the glovebox open. MGBs being what they are I was able to purchase just the broken half of the hinge and replaced that, and glued the tear down. I didn't bother claiming for the radio as it would have affected the NCD.

I still wanted a radio-cassette, so got another el-cheapo from Halfords, but this time a fully removable one where only the chassis is left in the car. This leaves a gaping hole in the console, and so might still attract attention from people expecting it to be left in the car somewhere, but I had another idea up my sleeve! I still had the blanking plate from before I fitted the original radio, which fixes in the console with two flattish clips attached to the back of the blanking plate, that can swivel round to lock behind the back of the console. I bent these into a sort of U-shape so instead of locating behind the console they now fit into the chassis, gripping it top and bottom to hold the blanking plate in place. Even though it is only a friction fit it has never come loose. So now, if anyone does peek in to check out the radio, to all intents there isn't one installed (despite the aerial) so it isn't worth breaking in to look for it. You may well be able to fit one over the top of a radio where only the face-plate is removed, but I'll leave that up to you. I also had an all-singing, all-dancing alarm installed with the usual ultrasonic and perimetric (door, bonnet and boot to you and me) sensing plus a dual-zone microwave unit which will set off the main alarm if anyone gets in the car, and also sounds a warning beeper if anyone gets too close to the outside. But that is another story.

I still wanted a radio-cassette, so got another el-cheapo from Halfords, but this time a fully removable one where only the chassis is left in the car. This leaves a gaping hole in the console, and so might still attract attention from people expecting it to be left in the car somewhere, but I had another idea up my sleeve! I still had the blanking plate from before I fitted the original radio, which fixes in the console with two flattish clips attached to the back of the blanking plate, that can swivel round to lock behind the back of the console. I bent these into a sort of U-shape so instead of locating behind the console they now fit into the chassis, gripping it top and bottom to hold the blanking plate in place. Even though it is only a friction fit it has never come loose. So now, if anyone does peek in to check out the radio, to all intents there isn't one installed (despite the aerial) so it isn't worth breaking in to look for it. You may well be able to fit one over the top of a radio where only the face-plate is removed, but I'll leave that up to you. I also had an all-singing, all-dancing alarm installed with the usual ultrasonic and perimetric (door, bonnet and boot to you and me) sensing plus a dual-zone microwave unit which will set off the main alarm if anyone gets in the car, and also sounds a warning beeper if anyone gets too close to the outside. But that is another story.

Quite apart from the security issue technology moves on, and although the quality of tapes was perfectly adequate for the noisy driving environment of the MGB it was a fiddle copying CDs to tapes so I bought a portable CD player with cassette attachment slot that allowed me to play direct from CD via the radio. fast-forward another few years, and it's all about MP3 now, and the ability to get hundreds of tracks onto a single device and so not even have to change CDs. I was given a hard-disk MP3 player that is usually used as a personal player i.e. with headphones, but I found the cassette adapter from the CD player fitted the MP3 player as well so that could be played through the radio. That left the original problem with the cassette attachment that although the transfer of the signal is from an electro-magnetic device sitting in front of the playback head rather than tape, there was still an endless loop of tape driven by the capstan wheel to keep the spool wheels turning. This is nothing to do with playback per se, but some cassette players will stop or go into reverse if one or other of the spool wheels stops during playback. No problem with that, but it was very noisy. I tried opening it up and lubricating the moving parts with powdered graphite but it made little difference. Not knowing whether mine was one of these auto-reverse or stop players I decided to remove the tape altogether, and bingo, it just plays as it should with no added noise.

Quite apart from the security issue technology moves on, and although the quality of tapes was perfectly adequate for the noisy driving environment of the MGB it was a fiddle copying CDs to tapes so I bought a portable CD player with cassette attachment slot that allowed me to play direct from CD via the radio. fast-forward another few years, and it's all about MP3 now, and the ability to get hundreds of tracks onto a single device and so not even have to change CDs. I was given a hard-disk MP3 player that is usually used as a personal player i.e. with headphones, but I found the cassette adapter from the CD player fitted the MP3 player as well so that could be played through the radio. That left the original problem with the cassette attachment that although the transfer of the signal is from an electro-magnetic device sitting in front of the playback head rather than tape, there was still an endless loop of tape driven by the capstan wheel to keep the spool wheels turning. This is nothing to do with playback per se, but some cassette players will stop or go into reverse if one or other of the spool wheels stops during playback. No problem with that, but it was very noisy. I tried opening it up and lubricating the moving parts with powdered graphite but it made little difference. Not knowing whether mine was one of these auto-reverse or stop players I decided to remove the tape altogether, and bingo, it just plays as it should with no added noise.

Relays Expanded March 2009

Relays were used at various times in various places on the MGB:

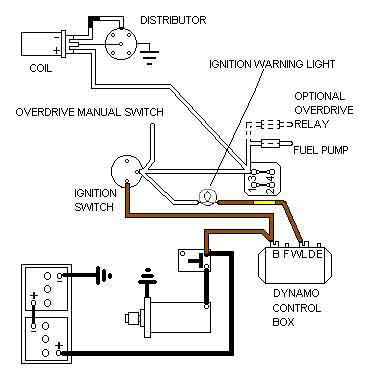

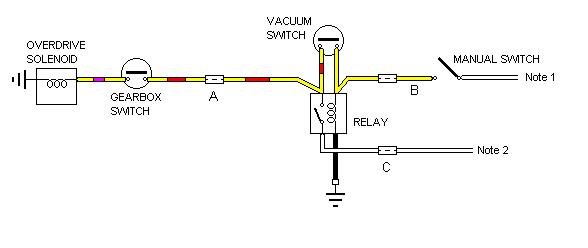

- The first usage was as part of the D-type overdrive circuit, until 67 and the MkII and 4-synch gearbox.

- From 1970 until the end of production a starter relay was used between the ignition switch and the starter solenoid on all models.

- On all V8s (73 to 76) a relay was used in the cooling fan circuit.

- On rubber bumper GTs up to 76 a relay was used in the heated rear window circuit.

- From 77 (but see below) to the end of production an ignition relay was provided. Originally this powered all the ignition circuits on UK cars, and everything bar the fuel pump, overdrive and ignition warning light on North American spec cars. In 1978 a number of circuits on RHD cars such as the ignition and heated rear window were moved back to the ignition switch, possibly after problems with the relays sticking closed and draining the battery. Although why this included the heater fan and indicators when it should have been obvious if they were still running after the ignition had been turned off, while leaving the cooling fan (which may only come on a short time after parking the car) and the fuel pump on the relay, is a bit of a mystery. Click the link for ignition schematics

.

.

- One as-yet unresolved oddity concerns MGBs for North America. The Parts Catalogue and other sources show a 'battery cut-off' relay for the 1976 year on, Part No. 13H9475 and also an 'ignition switch' relay Part No. AAU 3334 for the 1977 year on (when all models got one). However no schematics I have seen show both these relays, and none are shown for the 76 model year in North America as they no longer had the GT so no HRW relay. For 1977 and later the catalogue lists no less than four relays, including an HRW relay and an ignition relay apparently for all versions but when the ignition relay was provided the HRW was deleted. This catalogue again shows the 13H9747 'battery cut-off relay' for North America, which suppliers show as a cooling fan relay, but 4-cylinder cars never had a relay controlling the fans.

Originally the Lucas 6RA rectangular metal can type, but you need to be careful with these if replacing them as there are many different types, and in some cases you need to make sure you get the correct replacement. Basically the starter relay is designed for intermittent usage with a low contact resistance to supply the high current required by the pre-engaged starter solenoid, and has a winding resistance of about 40 ohms. The others are designed for continuous operation with a winding of 75 ohms resistance. If you use an intermittent-type relay in a continuous application it will overheat. Using a continuous relay for the starter is less of an issue but may eventually burn its contacts, which will eventually go high-resistance and cause starting problems. Note that when relays get old their contact resistance increases, and on high-current applications like the twin V8 cooling fans this will also cause the relay to get hot. An important thing to note is that if you replace your inertia starter with a pre-engaged you should also consider installing a relay at the same time to protect the ignition switch against the higher solenoid current. One way of doing this is to leave the original solenoid in place and use that as the relay, as per the relevant schematic

Originally the Lucas 6RA rectangular metal can type, but you need to be careful with these if replacing them as there are many different types, and in some cases you need to make sure you get the correct replacement. Basically the starter relay is designed for intermittent usage with a low contact resistance to supply the high current required by the pre-engaged starter solenoid, and has a winding resistance of about 40 ohms. The others are designed for continuous operation with a winding of 75 ohms resistance. If you use an intermittent-type relay in a continuous application it will overheat. Using a continuous relay for the starter is less of an issue but may eventually burn its contacts, which will eventually go high-resistance and cause starting problems. Note that when relays get old their contact resistance increases, and on high-current applications like the twin V8 cooling fans this will also cause the relay to get hot. An important thing to note is that if you replace your inertia starter with a pre-engaged you should also consider installing a relay at the same time to protect the ignition switch against the higher solenoid current. One way of doing this is to leave the original solenoid in place and use that as the relay, as per the relevant schematic ![]() here.

here.

As I say there are very many Lucas 6RA relays - 6v, 12v and 24v as well as many different 12v types in addition to the ones mentioned above, you need to compare reference numbers and voltage when replacing, don't just go by the '6RA' and the terminals. Having said that many types are suitable for a number of applications, but you need to check the terminal labelling carefully and change wires over by terminal designation and not physical position. These are the MGB variants:

rating rating 563417 | 33243J | SRB113 | 4 terminal/spade | 40 ohm | 20 amps | intermittent | Starter relay see note

| BMK685 | 33302B | SRB111 | 4 terminal, 5 spade | 76 ohm | 20 amps | continuous | D-type Overdrive, HRW

| UKC5146 | 33188H | SRB102 | 3 terminal, 4 spade | ? | ? | continuous | V8 cooling fan

| | |||||||

Note: Some starter relays are shown as being Lucas number 33231 which are type SRB111 and may have the higher resistance winding and be less suitable for starter solenoid current.

At the time of writing (September 2021) suppliers are showing starter relay 142169A and some images show this as having a double-spade on C1 i.e. for the brown wire. This makes it an SRB111 for continuous operation rather than SRB113 for intermittent operation. The difference is that SRB111 has a higher resistance winding so won't close the contacts as quickly and as hard as the SRB113, which with the high current of the starter solenoid (an initial 30 amps) may cause some contact burning over time.

4 terminal 5 spade types have a double spade on C1 which is useful for daisy-chaining a circuit to another component without cutting into the wiring.

The V8 cooling fan relay is an oddity with only three terminals, one being common to both the winding and the contacts, with the missing W2 terminal being connected internally to C2. The idea is that the temp sensor is used to send an earth to W1, with 12v on C2, and the output to the fan motors on C1. Browsing it seems this relay was commonly used as a horn relay on motorbikes, but also on classic Ferrari, Daimler/Jaguar and Rover. There are a few NOS versions around (£130 from a Ferrari supplier, anyone?) indicating it was designated SRB102, but it doesn't seem to be in current production, all the new relays I have seen advertised with the 33188 number are actually four and five terminal relays. These can be used with the existing three-wire harness connections by jumpering W2 to C2, then connecting the harness wires as before. However that would need a piggy-back connector on C2, so better to get a five-terminal relay with two spades on C1 with one jumpered to W2, and reverse the original C1 and C2 connections i.e. the wire that went to C2 now goes to the second spade on C1, and what was on C1 goes to C2.

However I suspect the V8 relay was replaced by a more conventional 4-terminal relay during production. The reason being the 12v to C2 came from the green circuit fuse, which meant that circuit was powering all the fused ignition circuits including the HRW and the fan relays. This puts a huge current on that fuse and I suspect it suffered from overheating, so they substituted a 4-terminal type with 12v from the brown at the fusebox connected to C2. The drawback with that is that it makes the fan circuit unfused, so I have added an inline in that brown wire. North American cars didn't have a relay despite having the same twin cooling fans, but in that case the fuse was replaced by a self-resetting thermal cut-out, so I suspect they had the same overheating problems there as well.

More info on Lucas relays here.

The starter and OD/HRW types have the same configuration of two winding terminals (W1 and W2) and two contact terminals (C1 and C2). The V8 cooling fan relay is a one-off in that it only has three terminals, W2 being connected internally to the C2 terminal hence no W2 terminal. Unlike the other types, in which the winding wires can be reversed, or the contact wires reversed (but winding wires can't be swapped around with contact wires!) on the V8 cooling fan relay the green wire must be connected to C2 and the black/green wire to C1 or the relay won't operate. See also the schematics in electric cooling fans ![]() for how to use a conventional 4-terminal relay in place of the original V8 3-terminal cooling fan relay.

for how to use a conventional 4-terminal relay in place of the original V8 3-terminal cooling fan relay.

From January 1976 Part No. CHM68, Lucas 26RA 12v 20A cylindrical relay SRB402 with bracket, was used for the starter relay, and AAU3334 for the ignition relay on UK cars from the start of the 77 model year. These use the modern terminal numbering, see below. There only seem to be four variants of this relay, the others being 12v 20A double-normally open, a 12v 20A changeover, and a 24v 10A changeover. The 77 and later Parts Catalogue shows 'Relay - battery cut-off' 13H9475 for the USA and Canada, how this differed from the ignition relay for other markets I don't know, currently suppliers show it as the Bosch cube-type, i.e. it could be the Lucas SRB520 28RA type.

From January 1976 Part No. CHM68, Lucas 26RA 12v 20A cylindrical relay SRB402 with bracket, was used for the starter relay, and AAU3334 for the ignition relay on UK cars from the start of the 77 model year. These use the modern terminal numbering, see below. There only seem to be four variants of this relay, the others being 12v 20A double-normally open, a 12v 20A changeover, and a 24v 10A changeover. The 77 and later Parts Catalogue shows 'Relay - battery cut-off' 13H9475 for the USA and Canada, how this differed from the ignition relay for other markets I don't know, currently suppliers show it as the Bosch cube-type, i.e. it could be the Lucas SRB520 28RA type.

Lucas 28RA 12v 30A SRB520 cube-type were also factory fitment on late cars, and this style are what is commonly available from after-market sources for accessory switching. No less than 26 different types, just one applicable to the MGB, suitable for both starter and ignition. However as the starter solenoid initially takes a calculated 30 amps it might be better to go for the 40 amp SRB537 for the starter relay.

Lucas 28RA 12v 30A SRB520 cube-type were also factory fitment on late cars, and this style are what is commonly available from after-market sources for accessory switching. No less than 26 different types, just one applicable to the MGB, suitable for both starter and ignition. However as the starter solenoid initially takes a calculated 30 amps it might be better to go for the 40 amp SRB537 for the starter relay.

July 2015:

Note: Be aware that there are two pin layouts for these relays, pins 30 and 86 can swap positions. This is significant as 86 is one side of the operate winding and 30 is usually the 12v source to the load. Reversing these can cause weird results. Initially I only found one reference to this - by Vehicle Wiring Products, although it is only detailed in its printed catalogue. However although their web site allows you to order Type A or Type B only Type B shows the terminal layout. The choice is only available with their basic four-terminal 12v relay, their other types (e.g. fused, dioded) are to the Type B layout which is said to be a more logical arrangement. Maybe only the basic 4-terminal type were available before it had been decided that Type B was preferable, so these later types were never made in Type A and are all Type B. I got caught out by this when buying a replacement relay for a commercial headlamp relay system where one dip didn't work, swapped the relays over (which plugged into wired sockets) and the fault moved with the relay so decided the relay was faulty, but the new relay didn't work either! Testing with first principles with a voltmeter, and connecting the 12v source direct to the output wire all indicated the wiring was correct. In desperation I looked at the relay numbering on the base, and spotted the difference. Mentioned it to a pal who had the Vehicle Wiring Products catalogue, he looked it up and found the reference to the two types. I altered the wiring on the one relay socket, but it offends me as the two sides or beams are now different. Checked some eight relays I have dotted around various places and find I have a mix of types. However none are in sockets, so I've always connected the wiring to them directly i.e. looking at the terminals numbers. It's something you would have to be very careful about when replacing plug-in relays anywhere, on modern cars for example.

Note: Be aware that there are two pin layouts for these relays, pins 30 and 86 can swap positions. This is significant as 86 is one side of the operate winding and 30 is usually the 12v source to the load. Reversing these can cause weird results. Initially I only found one reference to this - by Vehicle Wiring Products, although it is only detailed in its printed catalogue. However although their web site allows you to order Type A or Type B only Type B shows the terminal layout. The choice is only available with their basic four-terminal 12v relay, their other types (e.g. fused, dioded) are to the Type B layout which is said to be a more logical arrangement. Maybe only the basic 4-terminal type were available before it had been decided that Type B was preferable, so these later types were never made in Type A and are all Type B. I got caught out by this when buying a replacement relay for a commercial headlamp relay system where one dip didn't work, swapped the relays over (which plugged into wired sockets) and the fault moved with the relay so decided the relay was faulty, but the new relay didn't work either! Testing with first principles with a voltmeter, and connecting the 12v source direct to the output wire all indicated the wiring was correct. In desperation I looked at the relay numbering on the base, and spotted the difference. Mentioned it to a pal who had the Vehicle Wiring Products catalogue, he looked it up and found the reference to the two types. I altered the wiring on the one relay socket, but it offends me as the two sides or beams are now different. Checked some eight relays I have dotted around various places and find I have a mix of types. However none are in sockets, so I've always connected the wiring to them directly i.e. looking at the terminals numbers. It's something you would have to be very careful about when replacing plug-in relays anywhere, on modern cars for example.

Subsequently I came across this from 12 Volt Planet which covers it along with much other information about these Bosch-type relays, saying that the change was made to put the operate terminals on one pair of opposite sides, and the contact terminals on the other two opposite sides, to make visualisation of the connections easier.

If you don't want to keep with the 6RA and 26RA types for originality the modern black cube relays will be at least as good if not better, 12v items are rated from 20A to 70A. Cube relays come in a variety of contact configurations as well as the basic single-pole normally-open type which is used in all MGB applications except the V8 cooling fan relay. If using an alternative 6RA or modern relay in place of the V8 cooling fan relay at the very minimum you will need to connect the green wire to one of the winding terminals as well as one of the contact terminals. Some types of these modern relays also have integral fuses, which can be no bad thing for accessories on the lightly-fused MGB. However it is no advantage on the HRW or V8 cooling fan relays as the supply to these is fused already (the green circuit). Another variation includes a diode across the winding (see 50 amp Sealed Automotive Relay With Diode) which will protect the circuit operating it. Present stock brake light switches are said to be so poor that as well as not being man enough to operate the lights they need this diode or they still fail from the back emf generated by the relay. With this type you need to connect the power to the winding the correct way round or it will present a short to the operating circuit, although there is a variant of this with a second diode in series with the winding protecting the parallel diode from reverse connection! Yet another variant has a resistor across the winding, these aren't polarity sensitive but don't give as much quenching of back emf as the diode type. Some have a plastic mounting bracket moulded into the casing, some have a slot for an optional metal mounting bracket, and some have no provision for mounting and these are usually plugged into sockets on modern cars. The mounting bracket bolt can be used to provide an earth for the relay where this is required.

The contact numbering of modern relays is different from the originals. On the originals W1 and W2 are the Lucas winding connections, C1 and C2 the contact connections, on all bar the V8 cooling fan relay as described above. The equivalents on late MGB cylindrical relays and modern cube relays are 85 and 86 for the winding, and 30 and 87 for the contacts. On the basic single-pole, on-off relays as used on the ignition and starter circuits it doesn't matter which way round the two winding connections go, or which way round the two contact connections go, but you mustn't mix up the winding and contact connections. Having said that the convention is that terminal 30 is where the 12v (brown) supply is usually connected to, and 87 feeds whatever the relay controls. Some cube relays have five terminals, the additional terminal in the centre being a normally closed contact 87a, or an additional normally open contact also 87, in which case it will be important to get the three contact wires on the correct terminals. Les common are relays that have diode protection on the winding, to prevent damaging voltage spikes being reflected back into whatever has operated the relay. With these it is important to get the winding terminals the correct way round as well as the relay is polarity dependant. Failure to do this could well damage the relay, and/or whatever is operating the relay, and/or blow a fuse, or the relay may not operate at all.

You may well wonder at the weird numbering instead of the more logical W1 and W2 for the winding and C1 and C2 for the contacts, but it is part of international standard DIN72552 for automotive components ('DIN' stands for 'Deutsches Institut für Normungstandard' or German Institute for Standardisation), but only relays are likely to be applicable to MGBs. Even then, you will see the format has been changed for relays, with 87 replacing 30 or 51 as the common contact and 87b replacing 87 as the normally open contact. 87a remains as the normally closed contact, where provided. However all the relays I have bought in recent years still use the 30 and 87 convention for 'common' and 'normally open'.

References:

http://www.lucaselectrical.co.uk/downloads/lucas-switchgear.pdf Another Lucas relay and switchgear catalogue but including fuseboxes, some duplication with the above, but only 43 pages, 2.8MB.

This block diagram originally drawn by Graham Moore gives a simple but clear overview of the main parts of the MGB electrical system. There were some 18 variations over the years this being probably the most common arrangement with relatively minor variations for year and market, however North America diverged significantly from 'other' markets starting with the Mk2. For details of a particular circuit refer to the sections below.

This block diagram originally drawn by Graham Moore gives a simple but clear overview of the main parts of the MGB electrical system. There were some 18 variations over the years this being probably the most common arrangement with relatively minor variations for year and market, however North America diverged significantly from 'other' markets starting with the Mk2. For details of a particular circuit refer to the sections below.

Many components share wired earths going back to a handful of common body earthing points as well as many branching points including bullet connections. Earth faults can cause some very strange interactions and knowing which components share earths can help track down the source of a problem. Earth paths are not depicted on the simplified Autowire drawings so I have started extracting them from the Leyland drawings and including them at the end of each page that lists the wire colours and functions for each year.

Many components share wired earths going back to a handful of common body earthing points as well as many branching points including bullet connections. Earth faults can cause some very strange interactions and knowing which components share earths can help track down the source of a problem. Earth paths are not depicted on the simplified Autowire drawings so I have started extracting them from the Leyland drawings and including them at the end of each page that lists the wire colours and functions for each year.

See also these redrawn schematics from Dan Masters. Capable of being enlarged by several times, they are also laid out so that generally the circuit elements are physically closer together and not placed more or less where they would be on the car. This results in much less wiring snaking all over the place and so are easier to 'read'. They are based on the Workshop Manual, Bentley and Haynes diagrams and so have the same limitations of particularly the later diagrams in Haynes where several slightly different eras of circuitry diagrams are combined into a single diagram, and some of the minor and late changes seem to have been missed altogether. However because the Workshop Manual and Haynes also act as 'layout' drawings they have all the branching and common connection points which are great help in locating wiring faults, including showing earth connections that come from the physical mounting of a component and wired earths, something the Masters simplifications don't have. OTOH the factory drawings are not without errors such as showing early rubber bumper cars having the front parking lights and the indicators in the same housing whereas by that time the parking lights had moved into the headlights, and even when showing that correctly for 1977 cars it doesn't show that the front indicators had wired earths, which all rubber bumper types did.

The Masters drawings are also confusing because the first batch are numbered as in the Workshop Manual but don't have the index so it's not obvious which market (North America or UK) each is applicable to, you have to look for subtleties like whether it has a brake balance test and warning circuit or not. It's only towards the end that the title box tells you the market, but there is another batch in the middle that doesn't have either! However every one has a sheet number, so the following table lists all three types of designation and confirms which market it is for. Clicking the link for the model will show the diagram full-screen. You should notice the cursor displays a magnifying glass with a plus symbol - position this over a part of the circuit you want to examine more closely, left-click, and it will zoom in to more than double size for even greater clarity. Use the scroll bars to move around.

| Model | Drawing | Sheet | Market | Note | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62-64 MGB | 1 | 1 | All | Not 62/64 as shown

| 64-67 MGB | 2 | 2 | All | Not 64/67 as shown

| 67/68 MGB | 3 | 3 | UK | I.e. includes 68 models built in 67, ditto other drawings

| 68/69 MGB | 4 | 4 | UK |

| 69/70 MGB | 5 | 5 | UK | Not 68/70 as shown

| 70/71 MGB | 6 | 6 | UK |

| 71/72 MGB | 11 | 11 | UK |

| 72/73 MGB | 14 | 14 | UK |

| 73/74 MGB | 16 | 16 | UK |

| 73/74 UK MARKET MGB | 29 | UK | Electrically identical to Sheet 16

| 74 1/2 - 76 MGB | 18 | 18 | UK | Not 75/76 as shown

| 75/76 UK MARKET MGB | 31 | UK | Functionally identical to Sheet 18

| LATE UK MARKET MGB | 33 | UK | This is a Haynes amalgam of 77, 78, 79 and 1980 models and not all changes in those years are shown.

| MGC - UK MARKET | 26 | UK |

| MGBGTV8 | 28 | UK |

| 67/68 MGB | 7 | 7 | North America |

| 68/69 MGB | 8 | 8 | North America |

| 69/70 MGB | 9 | 9 | North America | Not 69/71 as shown

| 71/72 MGB | 12 | 12 | North America | Without seat belt warning

| 71/72 MGB | 13 | 13 | North America | With seat belt warning

| 72/73 MGB | 15 | 15 | North America |

| 73/74 MGB | 17 | 17 | North America |

| 73/74 US MARKET MGB | 30 | North America | Functionally identical to Sheet 17

| 1975 MGB W/PERIOD WARNING | 19 | North America |

| 1975 MGB W/SEQUENTIAL SEAT BELT WARNING | 20 | North America |

| 1976 MGB W/CAT CONV | 21 | North America |

| 1976 MGB W/O CAT CONV | 22 | North America |

| 1977 MGB W/CAT CONV | 23 | North America | Omits the ignition relay

| 1977 MGB W/O CAT CONV | 24 | North America | Omits the ignition relay

| 1978 & LATER MGB | 25 | North America | Shows the coil powered from the fusebox when it should be with the white on the ignition relay

| LATE US MARKET MGB | 32 | North America | This is a Haynes amalgam of 77, 78, 79 and 1980 models and not all changes in those years are shown.

| MGC - US MARKET | 27 | North America |

| |

North American 1972-73: If the ignition was on, the car in any gear, and the drivers seat belt was not fastened, there was a continual audible and visual warning. Additionally if the passenger seat was occupied and their seat-belt not fastened the same warnings applied. Independently of this if the drivers door was opened with the keys in the ignition, in any position including completely off, there was the same audible warning but no visual.

North American 1972-73: If the ignition was on, the car in any gear, and the drivers seat belt was not fastened, there was a continual audible and visual warning. Additionally if the passenger seat was occupied and their seat-belt not fastened the same warnings applied. Independently of this if the drivers door was opened with the keys in the ignition, in any position including completely off, there was the same audible warning but no visual.

North American 1974: A rather complex interlock system requiring a box of electronics with no less than 12 connections plus 10 other components was installed at the behest of the American authorities. One of these components was a 500mA fuse feeding the electronics. This lasted just one year as reputedly American manufacturers complained that the requirements were too complex to implement! With this system there was a drivers seat switch as well as the passengers. Much as before under the appropriate conditions the audible and visual warnings would sound, but additionally the starter circuit was interrupted to prevent starting of the car. There was the same gearbox switch as before, which probably means you can only start the car in neutral, so preventing it leaping forward if inadvertently left in gear. Additionally one has to sit in the seat, then fasten the appropriate belt, then turn the key to crank before the starter will operate, to prevent people leaving the belt fastened behind the seat. If you stall the engine it can be restarted immediately, unless you have switched the ignition off, in which case you must get out of the car and repeat the sit, buckle, start sequence! However there is also a timing delay function, which apparently allows the starter to be operated under any seat-belt conditions i.e. fastened or unfastened, after the drivers seat has been vacated, for a period of three minutes. Which conflicts a bit with the previous sentence. Also if neither seat is occupied one can start the engine by leaning in and turning the key, which would help with manoeuvring the car in and out of the garage. However in this case it seems that the gearbox switch is ignored as the instructions warn that gearbox must be in neutral and the handbrake applied. More information on this system can be found here. Although it shares the buzzer with the seat-belt system the 'key in, door open' warning operates independently.

North American 1974: A rather complex interlock system requiring a box of electronics with no less than 12 connections plus 10 other components was installed at the behest of the American authorities. One of these components was a 500mA fuse feeding the electronics. This lasted just one year as reputedly American manufacturers complained that the requirements were too complex to implement! With this system there was a drivers seat switch as well as the passengers. Much as before under the appropriate conditions the audible and visual warnings would sound, but additionally the starter circuit was interrupted to prevent starting of the car. There was the same gearbox switch as before, which probably means you can only start the car in neutral, so preventing it leaping forward if inadvertently left in gear. Additionally one has to sit in the seat, then fasten the appropriate belt, then turn the key to crank before the starter will operate, to prevent people leaving the belt fastened behind the seat. If you stall the engine it can be restarted immediately, unless you have switched the ignition off, in which case you must get out of the car and repeat the sit, buckle, start sequence! However there is also a timing delay function, which apparently allows the starter to be operated under any seat-belt conditions i.e. fastened or unfastened, after the drivers seat has been vacated, for a period of three minutes. Which conflicts a bit with the previous sentence. Also if neither seat is occupied one can start the engine by leaning in and turning the key, which would help with manoeuvring the car in and out of the garage. However in this case it seems that the gearbox switch is ignored as the instructions warn that gearbox must be in neutral and the handbrake applied. More information on this system can be found here. Although it shares the buzzer with the seat-belt system the 'key in, door open' warning operates independently.

North American February 1975-on: A very much simplified system, even more so than the original 72-73 system as the only sensor was on the drivers seat belt (presumably passengers are now expendable). This also had a box of electronics but the main purpose of this was to give a limited period audible warning. The electronics didn't have their own fuse any more, but picked up a 12v supply from the purple circuit instead. This time the 'key in, door open' circuit is connected in to the electronics, which contained the buzzer, but whether this circuit operates the buzzer continually as before or again on a timer as with the seat-belt I don't know. There was no starter inhibition, but there was still a connection from the start circuit to the electronics. This is to trigger the warning if the car is started without the drivers belt being fastened, rather than as soon as the ignition was turned on as previously, as there is no direct connection to an ignition circuit. There was no gearbox switch. The same starter connection was used to test the warning light for the EGR valve service indicator, fitted in 1975 only (Canada) and 1975 and 76 (rest of North America) but may not have been fitted to all cars.

North American February 1975-on: A very much simplified system, even more so than the original 72-73 system as the only sensor was on the drivers seat belt (presumably passengers are now expendable). This also had a box of electronics but the main purpose of this was to give a limited period audible warning. The electronics didn't have their own fuse any more, but picked up a 12v supply from the purple circuit instead. This time the 'key in, door open' circuit is connected in to the electronics, which contained the buzzer, but whether this circuit operates the buzzer continually as before or again on a timer as with the seat-belt I don't know. There was no starter inhibition, but there was still a connection from the start circuit to the electronics. This is to trigger the warning if the car is started without the drivers belt being fastened, rather than as soon as the ignition was turned on as previously, as there is no direct connection to an ignition circuit. There was no gearbox switch. The same starter connection was used to test the warning light for the EGR valve service indicator, fitted in 1975 only (Canada) and 1975 and 76 (rest of North America) but may not have been fitted to all cars.

UK 1977-on: Much like the later American system but even simpler - no 'key in, door open' function, just a seat-belt warning. It includes a 'timer module' but it's not clear what this is supposed to do.

UK 1977-on: Much like the later American system but even simpler - no 'key in, door open' function, just a seat-belt warning. It includes a 'timer module' but it's not clear what this is supposed to do.

Switches in General Added May 2009

Another common problem is with the hazard switch. Not so much with replacement quality this time, as hardening of the internal lubricating grease after many years and little use so that it tends to insulate the contacts. Sometimes flipping the switch back and fore will sort it out, but sometimes only temporarily. I had to dismantle Vee's (in a poly bag to catch all the bits), dig out the old grease and put in some fresh some years ago and it has worked fine ever since. That is with the original style of rocker switch, a friends 78 with the later smaller switches had intermittent heater and hazard switches. I tried dismantling these and cleaning them but the bits inside are so small, fiddly and delicate it wasn't successful and we had to resort to buying new.

Another quite common problem concerns the overdrive lockout switch on the gearbox. In this case it isn't the contacts that go faulty but mechanical wear in the linkages between gear-lever and the button on the switch causing the switch to be pushed not quite far enough to close and engage OD. With this often by pulling the gear lever around in 4th gear you can make OD engage and disengage at will. This can usually be corrected by an 'adjustment' at the switch. The switch was originally fitted with two fibre spacer washers, and removing one of these usually cures the problem. Unfortunately the switch is awkward to reach, particularly on 4-synch cars which only have a small removable panel on top of the transmission tunnel. Remove the centre arm-rest, remove the screws from the centre console, pull back the tunnel carpet, and remove the small access panel. But even then it isn't easy to get at the switch. You can get a bit more space by undoing the rear crossmember bolts and allowing the tail of the OD to rest on the fixed crossmember, being careful not to damage the speedo cable.

One thing to be aware of is that testing switches with an ohmmeter is not good enough. Ohmmeters only pass a minute current through a circuit - especially digital meters, MGB switches don't have gold contact surfaces, and so they will oxidise especially if not used for a while, which presents a resistance to an ohmmeter. However when carrying their normal current this will burn through any slight surface film, and the circuit will usually work as they should. Because of this the only valid test for detecting bad connections is looking for volt-drops where there shouldn't be any when the circuit is carrying it's design current. April 2017: Even overnight can be enough for the switch resistance to start getting erratic. When Bee's OD started dropping out after a few miles the first thing I did when back home was to check the current by inserting an ammeter at the manual switch, which was correct at about 800mA, and double-checked by measuring the solenoid resistance at about 15 ohms which is also correct. After leaving it overnight I went straight for the resistance check and was surprised to see it varying all over the place as I moved the gear lever round, anywhere between 15 ohms and over 200 ohms. But powering the solenoid with an ammeter in series I got the correct 800mA, and when testing the resistance again I got a consistent 15 ohms. Passing normal current through the switch had 'cleaned' its contacts.

Washers schematic ![]()

Nozzles and valves

Convert manual to electric

Washer bottle decals