Parking Lights

Headlights

Switch Connections

'Lights on' Warning Buzzer

Number Plate Lights

Brake Lights

Indicators/Turn Signals

Instrument Lighting

Ignition Warning Light

Map/Interior Lights

Roadster boot/GT loadspace lights

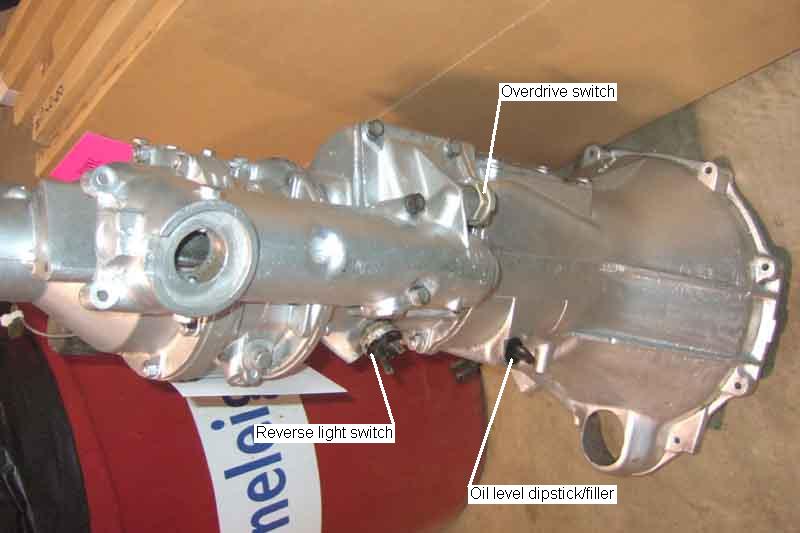

Reversing Lights

Hazard Flashers

Side-marker Lights (North America)

Fog & Spot lights

Switch Illumination

Brake and Seat-belt Warning Lights

Fusing

Bulbs

Daytime Running Lights (DRLs)

1st March 2023: MOT rules changed yet again to clarify conversions to LED and HID conversions on cars first registered before 1st April 1986. The previous legislation dated 22nd March 2021 was confusing not to say incorrect as it seemed to differentiate between halogen and sealed-beam.

1st January 2021: MOT rules have been changed to fail cars with LED headlamp conversions:

4.1. Headlamps

4.1.4. Compliance with requirements

"Existing halogen headlamp units should not be converted to be used with high intensity discharge (HID) or light emitting diode (LED) bulbs. If such a conversion has been done, you must fail the headlamp."

October 2020: The legality or otherwise of LED external lighting, from Classic Car LEDs and the Federation of British Vehicle Clubs.

Chrome bumper front and all and rear park/brake/indicator light clusters rely on the physical fixings to the wings to pick up an earth, as do number-plate lights that are mounted on the bumpers and overriders. Corrosion, particularly at the front where both front and rear of the panel are exposed to water and salt, can cause problems with these lights, rear clusters being inside the boot/load space are protected to a large extent. When there is a bad earth feeding a light unit with more than one bulb or filament such as chrome bumper front park/indicator light units and all rear light units you will get interactions between them when more than one is powered, i.e. some being dimmer than they should be and others glowing dimly when they shouldn't, known as 'discoing'. Rubber bumper front indicators have a wired earth, shared with the headlights, as do the front 'parking' lights which are part of the headlamp assembly, and these can also experience unwanted interactions if the fault is in the earth wiring or its connection to the body. Reversing lights and number-plate lights that are attached to the number-plate backing-plate also have a wired earth.

With any bulb you can get a bad connection between the bulb base and the bulb holder causing dimness, with dual-filament bulbs it can cause unwanted interactions between brake lights and parking lights as well, but the single filament bulb for indicators (usually) will be unaffected. If multiple circuits on both sides are affected particularly when the indicators are being used i.e. 'discoing' then the problem is more likely to be where the light unit is attached to the wing.

One oddity on early cars (for those used to later ones) is that the main harness only has one group of bullets at the front, not one by each headlight as on later cars. This reaches to the middle of the car i.e. behind the latch, and the tails from both headlights and parking/indicator lights also reach the middle of the car. At least, they did originally, but it seems some current stock has tails that only reach the later main harness bullets by the headlights. These tails are not itemised in the Parts Catalogue, suppliers have them as BAU2110 (for CB cars, BAU2111 for RB)

One oddity on early cars (for those used to later ones) is that the main harness only has one group of bullets at the front, not one by each headlight as on later cars. This reaches to the middle of the car i.e. behind the latch, and the tails from both headlights and parking/indicator lights also reach the middle of the car. At least, they did originally, but it seems some current stock has tails that only reach the later main harness bullets by the headlights. These tails are not itemised in the Parts Catalogue, suppliers have them as BAU2110 (for CB cars, BAU2111 for RB)

Later harnesses have a group of bullets by each headlight, which should be relatively easy to access on cars other than V8s and 4-cylinder 1977 model year and later from between the radiator and the slam panel. On the others you have to remove the mesh grille, and access is still pretty restricted.

Later harnesses have a group of bullets by each headlight, which should be relatively easy to access on cars other than V8s and 4-cylinder 1977 model year and later from between the radiator and the slam panel. On the others you have to remove the mesh grille, and access is still pretty restricted.

For 1977 until the end of production on all models the main lighting switch moved to the side of the steering column cowl - right-hand side on RHD cars and left-hand side on LHD. Care is needed on refitting the cowl as it is possible to trap the lighting wires, which being unfused will burn the harness.

Parking lights (aka sidelights or position lamps, not to be confused with North American 'side-marker' lights!)

1970 on

CB front units

RB front units

Rear units

The parking lights were not fused originally. Mark II cars introduced fuses, although for 1968 and 1969 the fronts were on one fuse and the rears on another, so if you had a fuse fail you lost both at one end, a particular problem at the rear as you lose all lighting until you brake or indicate. The fuses were of the in-line type, installed where the rear harness joined the main harness near the fusebox. Fuses can be added to Mk1 cars quite easily to make them the same as 68/69 cars.

The parking lights were not fused originally. Mark II cars introduced fuses, although for 1968 and 1969 the fronts were on one fuse and the rears on another, so if you had a fuse fail you lost both at one end, a particular problem at the rear as you lose all lighting until you brake or indicate. The fuses were of the in-line type, installed where the rear harness joined the main harness near the fusebox. Fuses can be added to Mk1 cars quite easily to make them the same as 68/69 cars.

For the 1970 model year a four-fuse fusebox was provided, the additional two fuses (at the top) separately fusing each side, with additional wires run to the front and the rear of the car. This was a much better arrangement which in the event of a short and a fuse blowing you still had one front, one rear, and the number plate light on one side still working. There is only one wire (red/green) feeding the front of the parking light fuses - they are linked there, which means if refitting these fuseboxes you must be careful to fit it the right way up, or you can get the brown and purple circuits linked to the green and white circuits, i.e. effectively powering the ignition all the time. If one side has failed check the cleanliness of the fuses, fuse holders and connections. Be aware that the fuse holder is riveted to the connection spades on the back of the fuse block and corrosion can also occur here.

For the 1970 model year a four-fuse fusebox was provided, the additional two fuses (at the top) separately fusing each side, with additional wires run to the front and the rear of the car. This was a much better arrangement which in the event of a short and a fuse blowing you still had one front, one rear, and the number plate light on one side still working. There is only one wire (red/green) feeding the front of the parking light fuses - they are linked there, which means if refitting these fuseboxes you must be careful to fit it the right way up, or you can get the brown and purple circuits linked to the green and white circuits, i.e. effectively powering the ignition all the time. If one side has failed check the cleanliness of the fuses, fuse holders and connections. Be aware that the fuse holder is riveted to the connection spades on the back of the fuse block and corrosion can also occur here.

From 1970 North America used a dual filament 21w/6w bulb for the front indicators and parking lights for both CB and RB models, with an all-amber lens. Prior to that it seems that the lens used with the two separate bulbs could be either mixed amber and white as per non-North American models, or all white.

At the same time the location of the studs on the front indicator/side-light unit seem to have moved from being in-line in the centre of the light unit to being in opposite corners. Clausager says some export markets may have required the indicator part to be outboard of the parking lights instead of the other way round as in the UK which studs in line would allow, and may have been done inadvertently on other cars. But if you think about it with the studs in opposite corners the light unit can still be reversed! They would both need to above or below the centre-line to prevent that but still sit correctly on the plinth, so the reason for the change remains a mystery. The Leyland Parts Catalogue and suppliers such as Moss Europe and Brown & Gammons only list one light unit (BHA4966), and with suppliers showing both types of wing (with Moss showing the two different stud arrangements) it begs the question of how can the one light unit fit both wings? This question arose when Dave O'Neil wondered why, when he needed to replace one on his Mk1, neither of the NOS units he had in stock had studs in the right place for his wing, in fact one didn't have any studs at all! In the end he decided not to drill the wing (as someone suggested), but to drill holes in the correct places on the unit he had with no studs. He went to the extent of squaring them off, and used the studs from his old light unit, they pressed out and back in quite easily (as I found with a number-plate light unit). The wing aperture is also different but that doesn't seem to hinder fitting modified later units to the earlier wing.

At the same time the location of the studs on the front indicator/side-light unit seem to have moved from being in-line in the centre of the light unit to being in opposite corners. Clausager says some export markets may have required the indicator part to be outboard of the parking lights instead of the other way round as in the UK which studs in line would allow, and may have been done inadvertently on other cars. But if you think about it with the studs in opposite corners the light unit can still be reversed! They would both need to above or below the centre-line to prevent that but still sit correctly on the plinth, so the reason for the change remains a mystery. The Leyland Parts Catalogue and suppliers such as Moss Europe and Brown & Gammons only list one light unit (BHA4966), and with suppliers showing both types of wing (with Moss showing the two different stud arrangements) it begs the question of how can the one light unit fit both wings? This question arose when Dave O'Neil wondered why, when he needed to replace one on his Mk1, neither of the NOS units he had in stock had studs in the right place for his wing, in fact one didn't have any studs at all! In the end he decided not to drill the wing (as someone suggested), but to drill holes in the correct places on the unit he had with no studs. He went to the extent of squaring them off, and used the studs from his old light unit, they pressed out and back in quite easily (as I found with a number-plate light unit). The wing aperture is also different but that doesn't seem to hinder fitting modified later units to the earlier wing.

This reminds me of an issue I had fitting new ones to the roadster - the chrome surround was pressed up against the paint when everything was screwed together, and I'd seen that had cut into the paint on a concourse example at the Classic Car Show. I ran a nut onto each stud first and that spaced it away, but left visible gap through as the sponge pads are not thick or dense enough. But a couple (from memory) of extra pads each side solved that.

North American spec cars got the same one-piece amber lens in the front bumper as RHD and other LHD cars, but the light-unit is different as it contains a dual filament 21W/6W bulb with offset location pins, the same as the stop/tail lights. This means that when the lights are on the indicators flash bright-dim-bright-dim instead of on-off-on-off. The Leyland diagrams are confusing as they still show the same two-bulb light unit as for chrome bumper cars, instead of a single bulb with two filaments as are shown for the stop/tail lamps. As the Advance Autowire diagrams show all lighting filaments separately there is no indication as to which is shared with which, for light units or bulbs.

Having upgraded the headlights to HID it left the halogen pilot lights looking distinctly yellow, and the same would be true for LED. I could use LED pilots - mine are wedge 501 T10 - but I have also pondered using them as DRLs if I can get some bright enough. Halogen are 1.7W but LED are classified in lumens (as well as colour) and can range from 300lM single element to 900lM multi element. Check the physical sizes as while many are the same as halogen at 25mm the brightest can be 34mm or more. I settled for 500lM which were the brightest I could find in the standard size, being in the headlight length probably wouldn't be an issue but I didn't want to risk it. I did find some 900lM at 34mm but the postage on those was more than the bulbs. The 500lM have an element on the front as well as a series of them round the side which I hoped would shine in the reflector, but unfortunately they don't.

The only significant change in the rear light clusters was for the 1970 model year when the lenses changed from rounded to angular.

The only significant change in the rear light clusters was for the 1970 model year when the lenses changed from rounded to angular.

Special 'nuts' (BHA 4242 'Dotloc', NLA, use 10/32" UNF with star-washer) were used to attach the rear light clusters to the wings. These have a spike that scratches through the paint to get a connection - pretty crude but there we are, and being in the boot/load space it's better protected from wet and salt weather than other light units. I've also heard of a problem causing interactions between dual filament stop and parking light circuits where the connection between the bulb-holder and bulb was good, but the bulb holder was making a poor connection to the base of the light-unit. You can test for this from the back i.e. inside the boot or luggage space. March 2020: This has just cropped up again on the MGOC forum where the owner noticed the parking lights had started coming on every time he applied the brakes, but there were no interactions involving the indicators. Cleaning everything in sight seems to have fixed it, but no root cause tested for or identified. Incidentally he first noticed this when all-LED lighting was installed, still there when standard bulbs were installed. Now the standard bulbs work as they should, but LED stop/tails cause the original problem again.

Special 'nuts' (BHA 4242 'Dotloc', NLA, use 10/32" UNF with star-washer) were used to attach the rear light clusters to the wings. These have a spike that scratches through the paint to get a connection - pretty crude but there we are, and being in the boot/load space it's better protected from wet and salt weather than other light units. I've also heard of a problem causing interactions between dual filament stop and parking light circuits where the connection between the bulb-holder and bulb was good, but the bulb holder was making a poor connection to the base of the light-unit. You can test for this from the back i.e. inside the boot or luggage space. March 2020: This has just cropped up again on the MGOC forum where the owner noticed the parking lights had started coming on every time he applied the brakes, but there were no interactions involving the indicators. Cleaning everything in sight seems to have fixed it, but no root cause tested for or identified. Incidentally he first noticed this when all-LED lighting was installed, still there when standard bulbs were installed. Now the standard bulbs work as they should, but LED stop/tails cause the original problem again.

|

LED park/stop/tail lights |

|

Trim Ring Headlamp Adjustment Headlamp Mounting Uprating

As far as I can tell up to the 77 model year MGB headlamps were sealed beam. In the UK prior to 1970 GLU101 60/45W, then it gets a bit confused. The Parts Catalogue says for GLU101 'use before BHA4999' but that number isn't listed in the catalogue index nor does Google show anything for it. The next entry for 1970 to the end of chrome bumpers for 4-cylinder and V8 says GLU106, which the V8 Driver's Handbook (only CB cars) says is 75/55W, but the late CB 4-cylinder Driver's Handbook says 'GLU101 75/55W'. For rubber bumpers GLU123 is listed, and again I can only find two references both saying it is a sealed beam 75/50W with pilot light. For 1977 on H4 GLB472 halogen bulbs were used which any number of sites say is 60/55W. There were many variations for other markets and years.

The headlamp always used a 3-pin connector. On sealed beam rubber bumper cars it was combined with a holder and shroud for the pilot light to hold the pilot light against a 'window' on the sealed beam unit. From 77 on the halogen connector supports a gaiter that carries a separate bulb holder and positions the pilot bulb in a hole in the reflector assembly.

The headlamp always used a 3-pin connector. On sealed beam rubber bumper cars it was combined with a holder and shroud for the pilot light to hold the pilot light against a 'window' on the sealed beam unit. From 77 on the halogen connector supports a gaiter that carries a separate bulb holder and positions the pilot bulb in a hole in the reflector assembly.

Headlights were never fused from the factory and if uprating them with higher power halogen and particularly with relays consideration should be given to fusing them.

Headlights have a wired earth, to a bolt near the right-hand headlight on early cars, moved to near the fusebox on later cars, probably with the alternator in 1968, but definitely with the starter relay in 1970.

On these later cars the main harness has several bullets and a tail by the right hand headlight for lighting and horn that side. The three headlamp wires are duplicated as one set brings power in to that point, and the second set feeds power back in to the main harness which then goes across to the left-hand side. Additionally there are single wires each side for the parking and indicator lights, and a 2-wire (until 1977, then a single wire) tail each side for the horns. One disadvantage of this arrangement is that the main and dipped beams for the left-hand side have to go via double bullets by the right-hand headlight as well as single bullets by the left-hand headlight, giving more opportunities for poor connections than the earlier arrangement, and these bullets suffer most from corrosion due to their exposure to the elements.

You have to be careful with replacement headlamp units as some are too deep to fit in the bowls.

You have to be careful with replacement headlamp units as some are too deep to fit in the bowls.

Brighter halogen bulbs are a direct replacement in these 77 and later cars, but to fit them to earlier cars you also need an H4 conversion. Many variations of these, some are described as having 'flat' glass, Vee has H4 with a domed glass (presumably a PO mod), although the dome is only half the height of that on Bee's sealed beams. They both have various ribs and patterns moulded into the glass so you have to see them side by side or measure the protrusion of the lens to see the difference, and some of them are too deep to fit in the bowls. The truly flat moulded glass variants are a little more obvious. But there are also variants with plain flat glass where all the focusing and beam shaping is done in the reflector rather than having a plain reflector with the moulded glass as originally, and these look very different. There are also LED conversions originally produced for Land Rovers which make the headlight black to a greater or lesser degree and these look truly horrible on an MGB.

Brighter halogen bulbs are a direct replacement in these 77 and later cars, but to fit them to earlier cars you also need an H4 conversion. Many variations of these, some are described as having 'flat' glass, Vee has H4 with a domed glass (presumably a PO mod), although the dome is only half the height of that on Bee's sealed beams. They both have various ribs and patterns moulded into the glass so you have to see them side by side or measure the protrusion of the lens to see the difference, and some of them are too deep to fit in the bowls. The truly flat moulded glass variants are a little more obvious. But there are also variants with plain flat glass where all the focusing and beam shaping is done in the reflector rather than having a plain reflector with the moulded glass as originally, and these look very different. There are also LED conversions originally produced for Land Rovers which make the headlight black to a greater or lesser degree and these look truly horrible on an MGB.

There have been comments about how poor sealed-beam headlights are and at one point they were uprated slightly for the UK market. When converted to H4 halogen the wattage reverted to the earlier value, however it's quite likely that the perceived brightness did increase which can be done through manufacturing techniques while keeping the nominal wattage i.e. current drawn the same (see Uprated Halogen). However the difference between sealed beam and H4 on the MGB is negligible compared to the difference between H4 and HID on modern cars.

Needing to replace one of Vee's headlamps (with the same type - Moss quad-optic) I was surprised how 'misty' the reflectors/back of the lens had become with the new one fitted, so had to replace the other one.

Needing to replace one of Vee's headlamps (with the same type - Moss quad-optic) I was surprised how 'misty' the reflectors/back of the lens had become with the new one fitted, so had to replace the other one.

There was a floor-mounted dip-switch until the 1970 model year, column-mounted after that. The schematics show a headlamp flasher as part of the indicator switch was available from the outset powered from the brown (unfused always live) circuit - optional on Mk1 cars.

There was a floor-mounted dip-switch until the 1970 model year, column-mounted after that. The schematics show a headlamp flasher as part of the indicator switch was available from the outset powered from the brown (unfused always live) circuit - optional on Mk1 cars.

The column mounted dip-switch can be a bit difficult to puzzle out as it incorporates a headlamp flasher (now powered from the purple i.e. fused always live) circuit, indicator/turn signal, and on some years the horn wiring as well. The accompanying pictures show which contacts are which as far as the dip/main/flash circuits go. Several problems can develop with this unit, like failure to flash or light the appropriate lights, failure to cancel, loss of spring tension, etc. There is some scope for repair, although like many components of that and later eras they were only intended for one-off assembly and use, replacement thereafter, which isn't cheap.

The column mounted dip-switch can be a bit difficult to puzzle out as it incorporates a headlamp flasher (now powered from the purple i.e. fused always live) circuit, indicator/turn signal, and on some years the horn wiring as well. The accompanying pictures show which contacts are which as far as the dip/main/flash circuits go. Several problems can develop with this unit, like failure to flash or light the appropriate lights, failure to cancel, loss of spring tension, etc. There is some scope for repair, although like many components of that and later eras they were only intended for one-off assembly and use, replacement thereafter, which isn't cheap.

77 and later with even less possibility of repair of some functions.

77 and later with even less possibility of repair of some functions.

As far as the wires go:

The dip-switch should have three fore and aft (towards you and away) positions: Clicked towards you lights the dipped beams. Clicked away from you lights the main beams. Both of these are only when the main lighting switch is in its 'headlights on' position. In the dipped beam position the lever can also be pulled towards you against spring pressure to light the main beams in 'flash' mode, and this is independently of whether the main lighting switch is on or off. When released the lever should return to the central/dipped beam position to extinguish the main beams. If the lever is pulled towards you when the headlights are on, the main beams will be illuminated from the headlamp flasher circuit as well as the dipped beams from the main lighting circuit.

Some of the contacts are fixed and others are 'springy'. The springiness applies pressure to the contacts to give a good electrical contact, but all the contacts can burn and blacken over time which can reduce headlight brightness and cause the switch to get warm in use. Cleaning of all the contacts and careful bending of the spring contacts can restore functionality, but it is easy to overdo it and mess things up even further. The contact springs are nothing to do with limiting the fore and aft movement of the stalk or the spring return from the flash position, they are derived from plastic 'springs' on the switch body and arm, as indicated in the accompanying pictures.

Fitted in the speedometer on Chrome bumper cars except V8, in the panel by the speedometer on V8s and RB cars. In the former case it uses a 'claw' type single-wire instrument bulb holder 13H1924 picking up an earth from the metal case of whatever it is pushed into. In the latter case it uses a 2-wire bulb holder and a wired earth (BCA4780) as it is fitted to a plastic panel. I suggest the original reason for fitting them was with the push-push dip switch as that gives no feedback as to which way it is switched. Our column stalks will tell you at a touch, but modern pull-pull stalks take us back to 'no feedback' and are an abomination, I have to look at the tell-tale on my ZS 180 to see if they are on or not when first turning on headlights. It would be better if they didn't 'latch' to main-beam while not turned on. Should I use an LED in this position? It's up to you, but I wouldn't want the additional brightness of an LED when I'm driving on unlit roads at night. Also with column stalks as said above you can tell at a touch if you are on main beam, and I suggest you would need to be driving a very long time after switching them to main beam to forget to dip when you see approaching traffic.

Fitted in the speedometer on Chrome bumper cars except V8, in the panel by the speedometer on V8s and RB cars. In the former case it uses a 'claw' type single-wire instrument bulb holder 13H1924 picking up an earth from the metal case of whatever it is pushed into. In the latter case it uses a 2-wire bulb holder and a wired earth (BCA4780) as it is fitted to a plastic panel. I suggest the original reason for fitting them was with the push-push dip switch as that gives no feedback as to which way it is switched. Our column stalks will tell you at a touch, but modern pull-pull stalks take us back to 'no feedback' and are an abomination, I have to look at the tell-tale on my ZS 180 to see if they are on or not when first turning on headlights. It would be better if they didn't 'latch' to main-beam while not turned on. Should I use an LED in this position? It's up to you, but I wouldn't want the additional brightness of an LED when I'm driving on unlit roads at night. Also with column stalks as said above you can tell at a touch if you are on main beam, and I suggest you would need to be driving a very long time after switching them to main beam to forget to dip when you see approaching traffic.

For 1970-on the headlamp flasher switch was part of the dip switch, see here for wiring and operation.

If your lights fail while you are driving at night,

and if you have the presence of mind when suddenly plunged into blackness at 60mph on a mountain road,

try the other beam (dip to main or vice-versa) or pull on the headlamp flasher. Because the headlamp flasher gets its supply from a different source it bypasses any problems in the main lighting switch or dip switch. It may just be enough to enable you to bring the car to a safe halt.

If you have done any work involving removal and refitting of the front wing or any headlamp components, I would strongly recommend you leave the rings off until successfully passing the headlamp alignment test in the MOT or remove them yourself beforehand, likewise if taking it somewhere for headlamp alignment for other reasons. You don't want some scruffy oik in a garage levering them off.

The theory is that the top is retained by two lips on the headlamp bowl, and the bottom by a spring-clip attached to the bottom of the bowl that rests in the curve of the trim ring when fitted. The clip is supposed to slide out of the curve as the bottom of the ring is eased forwards, however open to all the weather the clips and the trim ring can rust and make this extremely difficult. Going by the Parts Catalogues all MGBs had the same trim ring regardless of year - 57H 5296, although late models seem to have had rings with notches in to allow for adjustment without removal.

When Bee and Vee came to me more than 30 years ago they both had non-magnetic trim-rings so probably chrome-plated brass. I replaced Bee's at that time and those are magnetic, so probably steel-based, nevertheless still perfect. Vee's are lightly 'patinated' but I didn't bother replacing any of the bright-work (bar the heater intake) with the repaint as it all seems too 'blingy' and the quality of replacement parts these days is not good. The heater intake was looking a bit rough so I did get a new one - and true to form it has the wrong curvature!

Some years ago I replaced one of the bowls on Vee as it had rotted, and the replacement from the MGOC came with a screw fitting instead of the spring-clip. This is standard for cars using the same headlight like the Mini, which has a screw-hole in the bottom of the ring (one of the Parts Catalogue drawings does show such a screw, but this must be an error as the part number is the same as the others), however there is no access to such a screw on the MGB. Fortunately the spring-clip on the old bowl was reusable and I could change them over. Subsequently I worked on a car with aftermarket Wipac plastic headlamp bowls that also had the screw, but no option to replace that with a clip as it was a one-piece moulding. But the screw had been fitted to the bowl before the ring, and adjusted such that the head just fitted into the curve of the ring. Careful adjustment is needed to get the screw just right so the ring doesn't fall off (screw in too far) or jam (screw not in far enough), but get it right and it is easier to get the ring off and on than the original spring-clip.

But back to the original arrangement. There seems little option but to lever the bottom of the ring forwards somehow until hopefully it pops off the spring-clip at the bottom ... but that has never happened for me. Brute force has been needed to pull the bottom of the ring off the clip which bends the clip forwards and it has to be pushed back again to refit the ring, with the risk of eventual fracture. Pressing down hard on the top of the ring with the other hand can help, until you can see what is going on inside. Tackling Vee's which hadn't been moved for about 10 years or so I could see that instead of a recess in the spring sitting on the rear edge of the trim ring, the end of the spring had lodged behind a lip on the rear edge of the ring. This means that instead of the ring sliding off the clip as the ring is eased forwards, the clip has to be bent right forwards, severely distorting it. With the bottom pulled forwards this far I did then try levering the ring upwards to get the top of the ring unhooked from the two lips at the top. I could get the one side off but not the other, so had to resort to putting a small screwdriver through the gap at the bottom and levering the clip up off the ring, but as often as not the screwdriver slips off. I put fresh Waxoyl on the back of the ring and on the clip and tried refitting it with the recess of the clip sitting on the rear edge of the ring, but as soon as I pushed it home the end of the clip dropped down in front of the rear edge of the ring just as before, and trying to remove it again even with fresh Waxoyl I was back to square one. I then tried pushing the spring as far back and upward as it would go, and this time the recess in the clip did stay on the rim of the ring. This did make it easier to remove, although still required some force, and pulled the spring downwards and forwards again, so had to be pushed back and up again before refitting. If there were a small cut-out in the rear edge of the ring such that you could rotate the ring to line that up with the clip it would make life easier, and indeed some of the rings in the Parts Catalogues do show a cut-out in that location, but again the part numbers are the same as before. It's possible that the design was changed at some time, but kept the part number as the change was so small and it was fully backwards compatible. But replacement rings bought in 1990 for Bee do not have the cut-out. However you get the ring off, daub the back of the ring with Waxoyl to protect that from rusting through from the back as well as to aid fitting and removal, and daub the spring-clip as well.

Combined trim-ring puller and beer-bottle opener! December 2020

Many years ago and occasionally since I have heard Americans talking about using a 'paint can lid remover' to get these rings off. But since I've been using screwdrivers to open paint cans for the past 55 years I couldn't imagine what they were like and how they were any better, and there were no images and precious little internet in those days. More recently a pal in Philadelphia happened to mention it, and asking him about it he made a video to show what it was like and how he used it, and because I was interested he very kindly sent me four. Initially I had Googled 'paint can lid remover' and although there were a few of a similar design in the UK for a couple of pounds the end of those was basically flat and not much different to a screwdriver, whereas the American ones are almost a right-angle at the end. Then I found them on Amazon UK, but they are supplied from the US at £10 including P&P which is quite pricey. The bonus feature of this ring-handled type is that they can also be used to open beer bottles!

Many years ago and occasionally since I have heard Americans talking about using a 'paint can lid remover' to get these rings off. But since I've been using screwdrivers to open paint cans for the past 55 years I couldn't imagine what they were like and how they were any better, and there were no images and precious little internet in those days. More recently a pal in Philadelphia happened to mention it, and asking him about it he made a video to show what it was like and how he used it, and because I was interested he very kindly sent me four. Initially I had Googled 'paint can lid remover' and although there were a few of a similar design in the UK for a couple of pounds the end of those was basically flat and not much different to a screwdriver, whereas the American ones are almost a right-angle at the end. Then I found them on Amazon UK, but they are supplied from the US at £10 including P&P which is quite pricey. The bonus feature of this ring-handled type is that they can also be used to open beer bottles!

I start off at the side but because the end is bent at a right-angle the ring can be pulled forwards rather than levering against the wing. As the lower half of the ring comes forwards, the tool is moved down and round to pull the ring further forwards at the bottom.

I start off at the side but because the end is bent at a right-angle the ring can be pulled forwards rather than levering against the wing. As the lower half of the ring comes forwards, the tool is moved down and round to pull the ring further forwards at the bottom.

With the ring pulled forwards 1/2" or so the clip is visible, but trying to lever it up off the ring with a screwdriver doesn't work as it just slips off nine times out of ten. Brute-force has to be used which bends the clip right forwards, and it has to be pushed back again to refit the ring. How long it would stand up to that treatment without fracturing I don't know.

With the ring pulled forwards 1/2" or so the clip is visible, but trying to lever it up off the ring with a screwdriver doesn't work as it just slips off nine times out of ten. Brute-force has to be used which bends the clip right forwards, and it has to be pushed back again to refit the ring. How long it would stand up to that treatment without fracturing I don't know.

The difference with this tool is that with the end angled upwards under the clip it can be levered up from the ring very easily, the clip is not bent, and the ring just snaps back into place when refitting. To check it wasn't a fluke I tried it on the other side of Vee a couple of times with the same result. I haven't tried Bee yet as I'm not expecting to have to remove the rings any time soon, but on Vee with the new uprated headlights they may need adjustment at the next MOT. Nevertheless I shall keep one in each car - just in case.

The difference with this tool is that with the end angled upwards under the clip it can be levered up from the ring very easily, the clip is not bent, and the ring just snaps back into place when refitting. To check it wasn't a fluke I tried it on the other side of Vee a couple of times with the same result. I haven't tried Bee yet as I'm not expecting to have to remove the rings any time soon, but on Vee with the new uprated headlights they may need adjustment at the next MOT. Nevertheless I shall keep one in each car - just in case.

Without a tool such as the above there seems little option but to lever near the bottom of the ring with a screwdriver using the curve of the wing as a fulcrum, and a thick pad to protect the paint. Note that sound wings are required to perform this manoeuvre! Then use brute-force to pull it off the clip. It's the only method that worked for me for 30 years, fortunately not a frequent operation.

Without a tool such as the above there seems little option but to lever near the bottom of the ring with a screwdriver using the curve of the wing as a fulcrum, and a thick pad to protect the paint. Note that sound wings are required to perform this manoeuvre! Then use brute-force to pull it off the clip. It's the only method that worked for me for 30 years, fortunately not a frequent operation.

Even though I used the tool previous 'brute force' had obviously taken it's toll as removing one of Vee's the end of the clip snapped off, but replacements clips BAU1460 are available on only take moments to replace ... once you have removed the lens and reflector, inner bowl from the outer bowl, and the outer bowl from the wing ... Note that once the spring has been detached the inner bowl should rotate off the adjuster screws without needing to remove or alter the position of those screws, which avoids upsetting the beam alignment.

Even though I used the tool previous 'brute force' had obviously taken it's toll as removing one of Vee's the end of the clip snapped off, but replacements clips BAU1460 are available on only take moments to replace ... once you have removed the lens and reflector, inner bowl from the outer bowl, and the outer bowl from the wing ... Note that once the spring has been detached the inner bowl should rotate off the adjuster screws without needing to remove or alter the position of those screws, which avoids upsetting the beam alignment.

February 2023:

Had occasion to remove the other trim-ring from Vee and that clip snapped off as well. I'd already used both I had bought previously so bought two more, and this time replaced it with minimal dismantling. Once done I found that on refitting the trim-ring it dropped into the notch in the clip as it should, rather than lodging behind it, and came off again with the puller much easier than any of them had before, but still held firmly.

Had occasion to remove the other trim-ring from Vee and that clip snapped off as well. I'd already used both I had bought previously so bought two more, and this time replaced it with minimal dismantling. Once done I found that on refitting the trim-ring it dropped into the notch in the clip as it should, rather than lodging behind it, and came off again with the puller much easier than any of them had before, but still held firmly.

Clearance to wing: October 2021:

Graham Moore on the MGOC forum has been having problems fitting new trim rings as part of his restoration because there is insufficient clearance to the wing at the inner edge. I've had the same problem on Vee with what are probably original rings, and so has a PO as the passenger side ring is slightly flattened in that area. Measuring old and new rings - the thickness of the flange where it contacts the rubber gasket - Graham's old rings were 2.8mm and new 4.5mm. I have an old set from Bee replaced 32 years ago and they and the original ones on Vee measure 2.6mm. Bee's 'new' ones measure 2.85mm ... at one point but increasing as you go round the rim to 3.45mm! Originals have a welded seam that has to go in the area of the bottom inner corner limiting scope for placing a thinner part by the wing, but modern ones have no weld so can fitted with the thinnest section in the smallest gap. Graham is handy for the MGOC shop and early CB wings (wide spaced sidelights) have plenty of clearance between rim and wing - 3-4mm, all the later ones had less than 1mm. He also spoke to the workshop who confirmed that they never fit later cars, and they need to grind the wing before painting and reduce the weld size right in the corner too, as well as slotting the holes in the bowl so that can be slid across to make more room. As Graham says - Great! Looking at Bee and Vee here is just enough clearance on Bee - about that 1mm Graham mentioned, and on Vee's driver's side, but on Vee's passenger side there is no clearance even having slid the bowl across as far as it will go without grinding the (freshly painted!) wing, and the ring has been flattened in that area as well.

Graham Moore on the MGOC forum has been having problems fitting new trim rings as part of his restoration because there is insufficient clearance to the wing at the inner edge. I've had the same problem on Vee with what are probably original rings, and so has a PO as the passenger side ring is slightly flattened in that area. Measuring old and new rings - the thickness of the flange where it contacts the rubber gasket - Graham's old rings were 2.8mm and new 4.5mm. I have an old set from Bee replaced 32 years ago and they and the original ones on Vee measure 2.6mm. Bee's 'new' ones measure 2.85mm ... at one point but increasing as you go round the rim to 3.45mm! Originals have a welded seam that has to go in the area of the bottom inner corner limiting scope for placing a thinner part by the wing, but modern ones have no weld so can fitted with the thinnest section in the smallest gap. Graham is handy for the MGOC shop and early CB wings (wide spaced sidelights) have plenty of clearance between rim and wing - 3-4mm, all the later ones had less than 1mm. He also spoke to the workshop who confirmed that they never fit later cars, and they need to grind the wing before painting and reduce the weld size right in the corner too, as well as slotting the holes in the bowl so that can be slid across to make more room. As Graham says - Great! Looking at Bee and Vee here is just enough clearance on Bee - about that 1mm Graham mentioned, and on Vee's driver's side, but on Vee's passenger side there is no clearance even having slid the bowl across as far as it will go without grinding the (freshly painted!) wing, and the ring has been flattened in that area as well.

Whilst only originally provided for North America during the last year of production a number of UK suppliers have the headlamp ring with cut-outs for adjustment meaning removal of the ring is not required. On-car they do look a little 'odd' though.

Whilst only originally provided for North America during the last year of production a number of UK suppliers have the headlamp ring with cut-outs for adjustment meaning removal of the ring is not required. On-car they do look a little 'odd' though.

And now for the adjustment! By comparison with trim-ring removal it is simplicity itself. The adjuster screw at the top tilts the beam up and down, and the one at the side moves it from side to side. You can adjust the beams without the aid of a beam-setter if you have at least 37ft 8 ½ inches (25 ft plus the length of the car!) of flat and level surface back from a vertical surface such as a wall or garage door. Drive the car up to the vertical surface and mark the position of the centre of each headlight e.g. with electrical or masking tape. Now comes the confusing bit. Various sources now say to place two more marks 3" below the centre of the headlight, or 2", or 1" down and 1" to the left, and others just seem to use the original marks. UKMOT.com has a diagram showing that the datum lines should be 0.5% to 2% down, and 2% to the left, which for MGB headlights typically 24" (Vee) off the ground (i.e. less than 850mm or 33.5") equates to 0.12" to 0.48", and 0.48" respectively! Or is that percentage of the screen width and height!? The junction of the two lines ('break' point here) should be between 0.5% and 2% below the headlight centre, and between 0% and 2% to the left. In the past I have set mine using the centres and they have failed the MOT as being too high, and what has passed puts a pool of light just a few feet in front of the car on dipped beam, and still on the road albeit further forward on main beam i.e. to me too low. So probably better to err on the side of lower rather than higher. The MOT should check them with someone sitting in the drivers seat, so if you do yours with the car empty (beautiful/handsome assistant not being available/willing) that will give you a bit of a margin.

And now for the adjustment! By comparison with trim-ring removal it is simplicity itself. The adjuster screw at the top tilts the beam up and down, and the one at the side moves it from side to side. You can adjust the beams without the aid of a beam-setter if you have at least 37ft 8 ½ inches (25 ft plus the length of the car!) of flat and level surface back from a vertical surface such as a wall or garage door. Drive the car up to the vertical surface and mark the position of the centre of each headlight e.g. with electrical or masking tape. Now comes the confusing bit. Various sources now say to place two more marks 3" below the centre of the headlight, or 2", or 1" down and 1" to the left, and others just seem to use the original marks. UKMOT.com has a diagram showing that the datum lines should be 0.5% to 2% down, and 2% to the left, which for MGB headlights typically 24" (Vee) off the ground (i.e. less than 850mm or 33.5") equates to 0.12" to 0.48", and 0.48" respectively! Or is that percentage of the screen width and height!? The junction of the two lines ('break' point here) should be between 0.5% and 2% below the headlight centre, and between 0% and 2% to the left. In the past I have set mine using the centres and they have failed the MOT as being too high, and what has passed puts a pool of light just a few feet in front of the car on dipped beam, and still on the road albeit further forward on main beam i.e. to me too low. So probably better to err on the side of lower rather than higher. The MOT should check them with someone sitting in the drivers seat, so if you do yours with the car empty (beautiful/handsome assistant not being available/willing) that will give you a bit of a margin.

Back up so the front of the car is 25ft from the vertical surface and turn on the dipped beam (obviously doing this at night is preferable!). Each dipped beam should have a flat and horizontal top edge on the right-hand side, and the left-hand side should be angled upwards, this upward angling lights up the left-hand side of the road. Note that other European countries don't have this which is why they don't need beam deflectors when driving here like we do when driving there. A typical MGB won't have a sharp cut-off at the top of the beam like many modern cars do, having some upward scatter, but there should be a visible point where the horizontal part joins the angled part - the junction. Adjust the headlamps so that this junction is on your secondary marks. Switch to main beam and the centre of the beam should also be on these secondary marks. Note that if your reflectors are cloudy, bulbs old and blackened inside etc. the junction may not be clear enough and it can fail the MOT. Any misalignment of the bulb, reflector etc. could result in one beam to be correctly adjusted but the other not, with the same result.

Back up so the front of the car is 25ft from the vertical surface and turn on the dipped beam (obviously doing this at night is preferable!). Each dipped beam should have a flat and horizontal top edge on the right-hand side, and the left-hand side should be angled upwards, this upward angling lights up the left-hand side of the road. Note that other European countries don't have this which is why they don't need beam deflectors when driving here like we do when driving there. A typical MGB won't have a sharp cut-off at the top of the beam like many modern cars do, having some upward scatter, but there should be a visible point where the horizontal part joins the angled part - the junction. Adjust the headlamps so that this junction is on your secondary marks. Switch to main beam and the centre of the beam should also be on these secondary marks. Note that if your reflectors are cloudy, bulbs old and blackened inside etc. the junction may not be clear enough and it can fail the MOT. Any misalignment of the bulb, reflector etc. could result in one beam to be correctly adjusted but the other not, with the same result.

Headlamp Mounting: January 2017

The headlamp glass and reflector (a single unit) is clamped into a chrome-plated surround with four small screws. The rear half of the surround has a tab at the top and one on the outer edge for the special beam adjuster screws to slot into. These screw into nylon sockets fitted into the headlamp bowl, and as they are turned move their part of the surround plus headlamp assembly back and fore to get the correct height and side to side adjustment. The back of the reflector should have a tag with a hole, and a spring goes between this and a similar tag inside the bowl, to pull the headlamp assembly plus clamp ring into the bowl, and it is pushed out against spring tension by the adjuster screws to get the correct beam adjustment.

The headlamp glass and reflector (a single unit) is clamped into a chrome-plated surround with four small screws. The rear half of the surround has a tab at the top and one on the outer edge for the special beam adjuster screws to slot into. These screw into nylon sockets fitted into the headlamp bowl, and as they are turned move their part of the surround plus headlamp assembly back and fore to get the correct height and side to side adjustment. The back of the reflector should have a tag with a hole, and a spring goes between this and a similar tag inside the bowl, to pull the headlamp assembly plus clamp ring into the bowl, and it is pushed out against spring tension by the adjuster screws to get the correct beam adjustment.

The bowl attaches to the wing with four screws - top, bottom and at each side, with a rubber gasket between bowl and wing. The gasket has sleeves for the adjuster screws, to prevent dirt being thrown forwards onto the headlamp and down the outside of the wing as well as to protect the screws from the worst of road dirt to some extent. The four bowl screws go into a reinforcing/mounting ring which is spot-welded to the back of the main body of the wing. This reinforcing ring does not appear to be separately available for the MGB, but should be the same as the classic Mini item which is part No. 14A6993 from many sources.

The bowl attaches to the wing with four screws - top, bottom and at each side, with a rubber gasket between bowl and wing. The gasket has sleeves for the adjuster screws, to prevent dirt being thrown forwards onto the headlamp and down the outside of the wing as well as to protect the screws from the worst of road dirt to some extent. The four bowl screws go into a reinforcing/mounting ring which is spot-welded to the back of the main body of the wing. This reinforcing ring does not appear to be separately available for the MGB, but should be the same as the classic Mini item which is part No. 14A6993 from many sources.

Halogen

LED

HID

Relays and Fuses:

Main beam/flasher problems

The full current for the headlights is fed through the main and dip switches. Not only does this involve considerable lengths of wire and several connectors, but ageing switches can be less than perfect, all of which produces less light from the lamps and heat in the switches, in extreme cases melting them and causing total loss of lights. Uprated headlights almost certainly take more current which will make the foregoing problems worse, and you will not see the full benefit of the extra power. Always consider fitting relays with uprated lamps, which will result in more power at the lights and less strain on the old switches and connectors. Two relays will be required - one for the dipped beam and one for the main. The difference can be remarkable, as seen with a set I fitted to a car with uprated headlamps. Beforehand when switching from dip to main and back again there was a finite period when there was virtually no light at all! Afterwards the switch was near instant, and the lights were significantly brighter as well.

The next consideration is fusing. The headlights were never fused by the factory. Because you are adding wiring it does make sense to fuse it, but simply providing one main fuse (e.g. the MGOC and Moss kits) could result in total loss of the headlamps if it should fail, so think in terms of providing one fuse per beam as a minimum if not one per filament. This will protect the wiring from just after the relays out to the lamps, but still leaves the relays and wiring to them unprotected. By positioning the relays close to the point at which you pick up the supply from a brown connection point and properly routing and harness-taping you can minimise the risks but some might still want to fuse the main supply as well. In this case you should use a rating at least double that for the filaments, otherwise a problem by one headlight could blow the main fuse and not the filament fuse. I would recommend using 10amps per filament or 15amps per beam, which is about double the typical current flow, and 30amps minimum for the main fuse. That may seem high, but the headlamp flasher needs to be considered. From 1970 when the dip-switch was on the column stalk the headlamp flasher used its own fused supply, but with relays all that circuit does is operate the main beam relay. If the headlights are on dipped beam and the stalk is pulled towards you to flash the main beams, both relays will be operated and all four filaments will be powered, so any main fuse will be carrying getting on for 20 amps, and needs to be in excess of that. If you are not using a main fuse in series with filament or headlamp fuses then the filament and those fuses can be standard 17/35s.

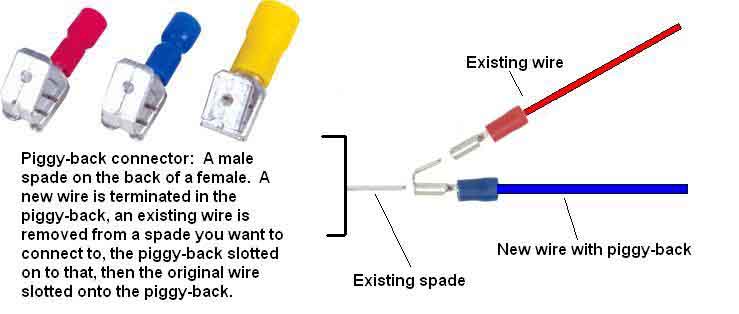

Click on the link for the schematic ![]() and suggested layout. The standard wiring on most MGB has two double bullet connectors by the right-hand headlight one for dip and one for main. These have three wires - a supply wire and another wire in the main harness that goes across to the left-hand headlight, the third wire from a tail going to the right-hand headlight. At the left-hand headlight there are two single bullet connectors each with a wire from the end of the main harness and a tail leading to the headlight. Early cars have this junction in the middle of the car with two long tails - one to the left and one to the right. Position the fuses close to the relays. One fuse per filament will see four fuses on the output of the two relays, one fuse per beam will see two fuses feeding power to the relay. To avoid cutting into the harness, and to make the changes easily reversible if required, make up a sub-harness that picks up the blue/white and blue/red wires from the main harness via two single connectors and routes them to the relays, two wires from the relays to the fuses, and four wires from the fuses back to four single bullet connectors to join up with the wires to the headlamps.

and suggested layout. The standard wiring on most MGB has two double bullet connectors by the right-hand headlight one for dip and one for main. These have three wires - a supply wire and another wire in the main harness that goes across to the left-hand headlight, the third wire from a tail going to the right-hand headlight. At the left-hand headlight there are two single bullet connectors each with a wire from the end of the main harness and a tail leading to the headlight. Early cars have this junction in the middle of the car with two long tails - one to the left and one to the right. Position the fuses close to the relays. One fuse per filament will see four fuses on the output of the two relays, one fuse per beam will see two fuses feeding power to the relay. To avoid cutting into the harness, and to make the changes easily reversible if required, make up a sub-harness that picks up the blue/white and blue/red wires from the main harness via two single connectors and routes them to the relays, two wires from the relays to the fuses, and four wires from the fuses back to four single bullet connectors to join up with the wires to the headlamps.

October 2016: Relay kits are available from MGOC and Moss Europe (with the latter being a lot more expensive!) or Moss US. Both kits only seem to include a single main supply fuse, which should it blow will kill both dipped and main beams. Daniel Stern Lighting recommends one per relay, and this kit from Advance Autowire has one per filament, but no main supply fuse, so opinions obviously vary! For both MGOC and Moss kits it would be easy to add a second fuse and have one per relay, and not much more work to add one per filament, just by adding in-line fuses with the appropriate spades and bullets. However note that the Moss and Advance kits use relays plugged in to sockets. There are two configurations of relay terminal, and with sockets you have to use the correct configuration, more info here.

November 2020: In the space of a couple of days I was asked for advice about improving the electrics with relays and fuses from two separate people, and a pal in America sent me a picture of heat-damaged wiring at his lighting switch. All of which set me off thinking about Vee's headlights as we do occasionally use her at night.

But first I decided to see just how much difference a relay might make. I took a length of the heavier gauge wire that is used for headlights, put a bullet on one end and fitted that to the spare hole in the main-beam bullet connector by the right hand headlight, and positioned the other end (which happened to have a ring terminal) by the battery terminal post in the engine compartment. Turned on the headlights as normal, then tapped the ring connector on the battery terminal post. Not only did they brighten significantly, but the connection even sparked confirming that significantly more current was flowing, and the voltage at the headlight bullet increased from 9v to 11.5v (engine not running), and that despite my 'ring main' wiring of the brown circuit. So Something Should Be Done.

Relays are simple enough, but what to do about fuses? Two relays plus four fuses is going to take up quite a bit of space on the inner wing, all need mounting, and I don't like drilling holes. You can get sockets for plug-in relays so I looked for a socket for a pair of relays with a single mounting point without success. But along the way I found this dual relay with single mounting point from 12v Planet which is just the ticket - or so I thought. These are unfused and whilst I could get fused relays for individual sockets they take modern blade fuses which means carrying spares. In the end I decided to go with in-line holders that take standard fuses, 20 amp rated with spade terminals also from 12v Planet, and use just one per relay i.e. one for the dipped beams and one for the main, and expect to have the presence of mind to switch beams if the one should fail. I'm planning on having only about 6" of wire from the relay to an existing brown circuit connection. Four of these fuses could be used one per filament if you prefer but you would have to join two together to connect to the relay output, in which case the 'bare ended' type would probably be better for you to attach your own terminals.

Fabrication went well but with five headlight-grade wires going to the two relays I discovered the individual relays were getting dislodged in the dual case during installation. They are 'skeleton' relays, the only casing is the dual case, and they are only 'clicked' in. As well as the risk of mechanical damage I can't see anything stopping moisture getting in and causing problems, so I decided to super-glue them in ... and of course ran out of adhesive and had to order more. But the biggest headache by far was getting them working properly. You need to find the supply wire to the 4-way bullet connector at the right-hand headlight and pull that out, as that becomes the relay 'operate' wire, and the output wire from the relay goes back into the 4-way bullet connector to power both headlights. In theory one pulls one of the main harness wires out, and if both sides stop working you know you have pulled out the supply wire, so you put that into a new 2-way bullet connector with the relay 'operate' wire. But if only the left-hand headlight goes out you have the wrong wire, so put that one back and pull the other one out. Easy, no? No! I just couldn't get them to work right - one beam worked but not the other, sometimes one of the relays buzzed, if the dips were on and pulled the stalk back to flash the dips went out and all sorts. Thinking I had the wrong wires I juggled them about which just confused the issue. Resorted to a 12v jumper lead to operate the relays and power the lamps directly to try and work out what was wrong to no avail. Got a meter to measure the voltages and got some very strange readings. Eventually I used the jumper wire to connect an earth to the relays on top of the existing earth wire, and suddenly they started working. When I removed the front fog/spot lights for painting and decided not to put them back I left the relay in place with just the earth wire connected having removed the other three wires. Mounting the dual relay in place of the single I simply swapped the earth wire over to the new relays 'assuming' it was a good earth ... and of course it wasn't! Testing it with an ohmmeter it drifts about a bit, it comes out of additional wrap on the harness so where it goes back to I have no idea. All I can say is that the old lights worked - probably because it was just one relay, but two sharing a poor earth get unwanted interactions. Anyway, I abandoned that wire and fabricated a new one to go under the relay fixing screw. Phew.

At the same time I've decided to uprate the H4 bulbs to Osram Night Breaker Silver which are claimed to be about 100% uprated (see below). Incidentally, one person reviewed these bulbs and complained about them giving an 'amber' light instead of 'silver' as on the tin. The word 'dipstick' comes to mind.

Main beam/flasher problems: October 2021 Note that if your speedo contains the main-beam tell-tale as well as the panel light bulb the speedo must be properly earthed. Brian Wall on the MGOC forum reported a strange problem affecting the headlamp flasher after doing some work on his relays. It took a couple of goes to ascertain what was happening but I suspected speedo earthing affecting the main-beam tell-tale. The first symptom was that if the tell-tale was unplugged the headlights worked as they should, and if the tell-tale bulb holder was earthed with a separate wire that also worked as it should. Subsequently Brian wrote "when I turn on headlights it will show main beam and allow me to change to dip beam, but then will not change back to main or even flash the lights (unless I) turn lights off, then on again and same sequence all over again, until I disconnect the telltale and let it hang free and then the headlights and flasher work as normal". This confirmed speedo earthing as the problem to me, and connecting an earth to the speedo allowed everything to work as it should, The problem occurred for the following reasons:

- With the parking lights on, the lack of earth to the speedo means that the panel light is trying to earth backwards through the main-beam tell-tale bulb.

- Without relays the two bulbs in series would earth through the headlamp main beam filaments, but the current is so low you would not notice it at the headlights. Both panel and tell-tale bulbs would only glow dimly - unlikely to be noticed especially in daylight.

- With relays the relays only supply power to the headlamps themselves, the main-beam tell-tale is powered from the dip-switch/headlamp flasher switches as before, which are also powering the main-beam relay, hence there is a connection between the tell-tale and the relay winding.

- When the main beam is turned off there is enough current flowing from the parking light circuit through the panel light bulb and backwards through the tell-tale bulb in series to the relay winding to keep the relay operated ... unless the panel light dimmer is turned off!

- This keeps the main beam illuminated, but again you would have to look closely to realise it unless you were in the dark, especially if the dipped beam was illuminated.

- The headlamp flasher used on its own, i.e. with the main lighting switch off, would almost certainly work normally. Even the tell-tale would work almost normally as current from the headlamp flasher switch would flow through the tell-tale bulb and backwards through the panel light bulb to the parking light circuit, and from there to earth through all the parking light bulbs in parallel, again unless the panel light dimmer switch is turned off.

- LEDs used in panel lights and/or the tell-tale would change the symptoms because they will only pass current in one direction, not both like a filament bulb. LED headlamps were in use on this car but I don't think they would have an effect, and relays shouldn't be needed with LED headlamp bulbs anyway as the current is much lower.

Halogen: If you have sealed beams currently you will need an H4 conversion which includes the headlamp unit as well as bulbs, the connector should be the same. One would hope that these kits are correct for the MGB but some headlamp units are too deep to fit in the bowls.

Uprated halogen: There are H4 halogen bulbs available with claimed 20% to 200% more brightness for the same wattage as originally e.g. 60/55W, all road legal. There are also 100/80W and 130/100W versions for sale, but unless they were original equipment on your car they are not road-legal. The 'brighter for the same wattage' bulbs achieve that by a different design of filament which draws the original current, and hence are the same wattage (Watts being Volts multiplied by Amps), but as with anything else you don't get owt for nowt and the 'cost' (in additional to higher price) is a shorter life. For example the 150% is said to have half the life of the 130%, which itself will have a reduced life from the 110%, and so on comparing 110%, 50% and standard. When buying these make sure they are dual-filament for main and dipped beams, as there are single-filament variants which have the same H4 fitting. They are for cars with dual headlights such as the ZS which has main and dip in the outer headlight, and an additional main beam only in the inner headlight. As ever shop around, for example Halfords has a single 50% brighter at £17 (although you may get a BOGOF offer), whereas Euro Car Parts has pairs of Osram 115% at £15, Phillips 130% at £18, and Phillips 150% at £21 (although with these last two there is no written indication of whether they are single- or dual-filament). Standard halogen dual-filament are typically £3!

November 2020: As part of installing relays and fuses I also purchased a pair of '+100%' uprated bulbs but as the detailed text says 'up to' that can mean anything or nothing. After fitting just one it's true they are a bit brighter - but not as much improvement as from the relays, I doubt you would notice the difference with two in and on the road. But they were reduced from £17 to £12 so I can live with that.

But before considering a change such as this, it would be best to investigate your switches and wiring to see how much voltage is being lost before it gets to the bulb, if not fit relays and fuses. Clean bullets and connectors always help, and you should consider replacing the connectors at the front of the car, polishing the bullets with fine wet-and-dry or emery cloth, and reassembling with Vaseline. I did that on Vee as a matter of course towards the end of her restoration, as well as polishing all the bullets by the pedal box and in the boot, and found the indicator flashing rate afterwards was noticeably faster and more consistent even though the switches and wiring were as before. To measure the volt drop connect a meter between the brown at the fusebox, and the back of each of the bullets by the off-side headlight, for each beam when powered. No need to run the engine, although the voltages you will see will be higher the relative differences will be the same, and it is those we are interested in. There should be two wires from the harness, and one wire from the sub-harness going through the inner wing to the headlight. Any difference in voltage between the three bullets shows that voltage is being lost in that connector. And the difference between the highest of those and the brown at the fusebox is what is being lost in the main lighting switch, dip-switch, and their wiring. You can also unplug the alternator, and move the meter probe from the brown at the fusebox to the thick brown in the alternator plug, and the difference between that and the fusebox reading will tell you if any is being lost in the connections at the solenoid. Unless you have brand-new wiring and switches, and perfect connections, you are bound to see some voltage being lost, in which case your headlights would benefit from having relays and fuses installed. I fitted relays and fuses for someone with (illegal) 100w bulbs, he said before that as well as not being very bright before, when switching between dip and main the 'new' beam only gradually came up after the 'old' beam went out, leaving him momentarily in the dark. Afterwards he said they switched almost instantly, as well as being noticeably brighter. Checking Vee main beam lost volts is about 1.8v and dipped about 1.5v, with Bee (old bullet connectors at the front) a couple of tenths higher. There is only about 0.1v difference between the fusebox and the alt plug on both. Powered normally, then adding a thick jumper wire between the fusebox and the connectors (simulating a relay), there was a visible increase in brightness. Pondering.

LED:

March 2023: The wording changes again to remove the confusion caused by the use of the word 'halogen', now conversion to LED or HID of any type of headlamp on cars first used before 1st April 1986 is legal.

March 2021: Ink barely dry and they change the rules again. From 22nd March halogen to LED conversions on cars first used before 1st April 1986 will be legal. But then they go and mess it up by writing:

"Vehicles presented with converted halogen headlamp units first used on or after 1 April 1986 will continue to be failed."

Also by specifying 'halogen' it's implying converted sealed beam installations will continue to be failed, surely 'halogen' should read 'incandescent' or 'filament' i.e. treat sealed beam and halogen the same. Even more complicated where sealed beam have already been converted to halogen!

Even more interesting is that HID conversions will also be legal, and having been disappointed with an LED conversion I'll be looking at HIDs.

1st January 2021: MOT rules have been changed to fail cars with LED headlamp conversions:

4.1. Headlamps

4.1.4. Compliance with requirements

"Existing halogen headlamp units should not be converted to be used with high intensity discharge (HID) or light emitting diode (LED) bulbs. If such a conversion has been done, you must fail the headlamp."

October 2020: Information on legality or otherwise from Classic Car LEDs and the Federation of British Historic Vehicle Clubs here.

September 2020: Brian Wall on the MGOC forum asked about his club-supplied LED headlights and why the headlamp flasher wasn't working when the dipped beams were on. I wondered whether this was something to do with having LEDs and asked if the tell-tale was coming on. It is, so yet another undocumented feature of dual 'filament' LEDs. However Brian raised this again in November 2021 after having rewired the relays, and this time I suggested he double-check that the dip relay is remaining operated and the main relay operates as well when the control is pulled to flash. And he discovered that he had cross-connected the two some how, and correcting that they work as they should.

Intrigued by an advert in Enjoying MG I did some research and found some with the same manufacturers designation elsewhere at about half the price. They turned out to be slightly different physically as the driver module is integral with the lamp, which has a short cable terminating in a 3-pin plug which is compatible with the harness socket. There is quite a large 'lump' on the back of the 'bulb' which made me wonder if it would all fit in the bowl, but it did. The MGOC items are shown with an external driver module, as well as having the lump on the back and cable with plug so even more to fit in.

Intrigued by an advert in Enjoying MG I did some research and found some with the same manufacturers designation elsewhere at about half the price. They turned out to be slightly different physically as the driver module is integral with the lamp, which has a short cable terminating in a 3-pin plug which is compatible with the harness socket. There is quite a large 'lump' on the back of the 'bulb' which made me wonder if it would all fit in the bowl, but it did. The MGOC items are shown with an external driver module, as well as having the lump on the back and cable with plug so even more to fit in.

One issue with installation is that you install the H4 adapter to the reflector/lens assembly, then slide the 'bulb' into the adapter, and twist it to get the correct beam pattern with a ball-bearing dropping into a hole to hold it in the selected position. This is so that one kit can be used for both RHD and LHD with the upsweep on the correct side ... but there are a whole series of holes all round the adapter meaning you can select any of about a dozen positions, including with the beam vertical instead of horizontal! The 'issue' was with the rubber seal that fits round the base of a halogen bulb and pushes up against the back of the reflector. With the LED items you fit the rubber seal to the back of the reflector after the H4 adapter, then push the LED 'bulb' through the hole in the seal into the adapter. However the seal is too deep to allow the 'bulb' to go in far enough for the ball-bearing to engage with one of the holes, meaning it (the seal) would have to be cut down. I didn't do this, pending further enquiries.

As far as adjusting the rotational position of the 'bulb' goes this has to be done with it powered, but before the lens/reflector is clamped into its carrier. The flat and angled cut-offs of the dipped beam can be clearly seen in the glass, and as my glass has similar moulded lines, it is a simple matter of turning the 'bulb' until the edges of the beam line up with the mouldings in the glass. Bear in mind that when looking at the glass, everything is reversed compared to how the light strikes the road, i.e. the light is at the top of the glass instead of the bottom, and the angled section is on the off-side instead of the near-side.

As far as adjusting the rotational position of the 'bulb' goes this has to be done with it powered, but before the lens/reflector is clamped into its carrier. The flat and angled cut-offs of the dipped beam can be clearly seen in the glass, and as my glass has similar moulded lines, it is a simple matter of turning the 'bulb' until the edges of the beam line up with the mouldings in the glass. Bear in mind that when looking at the glass, everything is reversed compared to how the light strikes the road, i.e. the light is at the top of the glass instead of the bottom, and the angled section is on the off-side instead of the near-side.

That gives rise to another 'issue', and that there is a distinctive 'dead' area in the light at the top of the glass, which means there will be a similar 'dead' area on the road right in front of you. This can be seen in YouTube demonstrations of other LED installations on other vehicles, and isn't apparent with halogen bulbs or sealed-beam units. The light is very white, and makes the filament pilot light in the rubber-bumper headlamp assembly look like an orange neon. A brief test at night in lit streets didn't seem to give that much better actual visibility, it was more the whiter reflection.