Mounting points

Mounting bolts

Belt Types

Inertia mechanism

Belt guides so you don't have to grovel around behind you to find them

GT rear belts August 2013

Seat-belt warning system

Did the MGB ever have air-bags?

Mounting points: Quite a lot of confusion over seat belt mountings from time to time.

Very very early cars seem to have had two 5/16" studs near the middle of the lower edge of the inner arch. Both these should be used with an adapter plate, one stud is not going to be enough if you really need the belts at any time.

Very very early cars seem to have had two 5/16" studs near the middle of the lower edge of the inner arch. Both these should be used with an adapter plate, one stud is not going to be enough if you really need the belts at any time.

After that a single larger threaded boss was fitted to the rear arch, low down and about mid-way from front to back.

After that a single larger threaded boss was fitted to the rear arch, low down and about mid-way from front to back.

On Mk2 North American roadsters up to December 1971, and on roadsters for other markets from January 1971, mounting points on the tonneau panel were used which necessitated a quick-release device so the belt could be detached each time the hood was raised or lowered or the tonneau cover fitted or removed! The fastening utilised a plastic button, most have probably broken by now and been replaced by inertia reels. When I received my roadster it had inertia reels - but fitted to the tonneau panel. Very inconvenient as these had to be unbolted to raise and lower the hood! This picture was taken on the 2007 New Forest run and shows a metal button which seems to be the only type available now. The Driver's Glovebox Handbook indicates that this quick-release fastening was used on GTs as well as roadsters, with the fastener mounted on top of the rear arch. Quite why isn't known, whilst the roadster did need it to raise and lower the hood that isn't the case for the GT. A friend's 72 GT had these belts but with just a plain bolt on the arch, which meant the belt bracket could come off the bolt without having to depress any locking plate. I first thought this was an error and somehow his car had got roadster belts, but maybe not, maybe it was just the fastener that had broken, and in any event he fitted inertia reels. For those roadsters that have them but unused there is a blanking plug to prevent water ingress.

On Mk2 North American roadsters up to December 1971, and on roadsters for other markets from January 1971, mounting points on the tonneau panel were used which necessitated a quick-release device so the belt could be detached each time the hood was raised or lowered or the tonneau cover fitted or removed! The fastening utilised a plastic button, most have probably broken by now and been replaced by inertia reels. When I received my roadster it had inertia reels - but fitted to the tonneau panel. Very inconvenient as these had to be unbolted to raise and lower the hood! This picture was taken on the 2007 New Forest run and shows a metal button which seems to be the only type available now. The Driver's Glovebox Handbook indicates that this quick-release fastening was used on GTs as well as roadsters, with the fastener mounted on top of the rear arch. Quite why isn't known, whilst the roadster did need it to raise and lower the hood that isn't the case for the GT. A friend's 72 GT had these belts but with just a plain bolt on the arch, which meant the belt bracket could come off the bolt without having to depress any locking plate. I first thought this was an error and somehow his car had got roadster belts, but maybe not, maybe it was just the fastener that had broken, and in any event he fitted inertia reels. For those roadsters that have them but unused there is a blanking plug to prevent water ingress.

It seems that when the tonneau mounting point was provided the wheel arch boss was deleted - but only from roadsters, so these cars from November 67 to December 71 only have the tonneau panel mounting point. Presumably this was only on North American roadsters as UK roadsters didn't get the tonneau mounting point until January 1971, when the arch mounting point was deleted from those as well. To use static belts with a fixed shoulder point where your quick-release type are damaged and you can't get replacements, you will have to provide a mount on the inner arch. Probably the easiest way to do this is with 1/8" steel plates either side of the arch panel and bolted through. The belt should come with a spacer/boss that the belt end will rotate around even when the bolts are fully tightened. Only when North American cars got inertia belts as standard in December 1971 and RHD cars in May 1977 was a mounting point reinstated to the inner arch, however now it is right at the back of the arch and just above the chassis rail. The tonneau panel mounting points were probably deleted at this time.

To fit inertia reels to roadsters built prior to the above dates you will need this fitting kit (item 2) from the MGOC (maybe other sources). This shows Bee's inertia reels fitted to the later position using the kit, which entails drilling a hole in the panel. Fitted in this position they do not prevent the hood from folding fully, as some have complained. Securon reels can bolt directly to the vertical panel and be adjusted for correct operation, but this means the belt exits vertically and has to twist through 90 degrees between there and the shoulder and can suffer retraction problems with other stuff in the area, and they cannot be fitted to the top of the GT arch without additional bracketry which compromises security in an impact.

To fit inertia reels to roadsters built prior to the above dates you will need this fitting kit (item 2) from the MGOC (maybe other sources). This shows Bee's inertia reels fitted to the later position using the kit, which entails drilling a hole in the panel. Fitted in this position they do not prevent the hood from folding fully, as some have complained. Securon reels can bolt directly to the vertical panel and be adjusted for correct operation, but this means the belt exits vertically and has to twist through 90 degrees between there and the shoulder and can suffer retraction problems with other stuff in the area, and they cannot be fitted to the top of the GT arch without additional bracketry which compromises security in an impact.

GTs kept the boss in the lower position, but did they always have one on top of the arch as well? It is classed as a four-seater, and late Mk1 shells at least had them, but perhaps not very early models. I've also heard of the roadster-type quick-release static belts attached to those points in a UK GT, but that may have been done by an owner.

GTs kept the boss in the lower position, but did they always have one on top of the arch as well? It is classed as a four-seater, and late Mk1 shells at least had them, but perhaps not very early models. I've also heard of the roadster-type quick-release static belts attached to those points in a UK GT, but that may have been done by an owner.

If that wasn't enough the tunnel mounting position also seems to have moved, being further back on early cars compared to later. The earlier position can cause problems with inertia belts with a fixed-length tunnel stalk, being almost behind the seat. Some suppliers do have longer stalks to overcome this.

If that wasn't enough the tunnel mounting position also seems to have moved, being further back on early cars compared to later. The earlier position can cause problems with inertia belts with a fixed-length tunnel stalk, being almost behind the seat. Some suppliers do have longer stalks to overcome this.

Various tunnel stalk types - floppy (statics) and stiff of various types to enable one-handed fastening.

Various tunnel stalk types - floppy (statics) and stiff of various types to enable one-handed fastening.

From Feb 72 there was what Clausager describes a 'New seat belt parking cover instead of parking buckle'. However it looks like a socket that the tongue would slot down into, although I can imagine an inertia reel belt could pull it out.

From Feb 72 there was what Clausager describes a 'New seat belt parking cover instead of parking buckle'. However it looks like a socket that the tongue would slot down into, although I can imagine an inertia reel belt could pull it out.

Another fabled gadget - the seat belt hook, fitted from Feb 77 to roadsters and GTs with new Kangol inertia reel belts. This is on a GT, mounted on the rear waist rail, with an enlargement of the actual hook inset. On a roadster the hook was mounted much lower down on the trim panel, below the folded hood frame.

Another fabled gadget - the seat belt hook, fitted from Feb 77 to roadsters and GTs with new Kangol inertia reel belts. This is on a GT, mounted on the rear waist rail, with an enlargement of the actual hook inset. On a roadster the hook was mounted much lower down on the trim panel, below the folded hood frame.

Types: As well as static and inertia types, and different locking features of the latter, there have been a number of different fastening arrangements on both.

As far as inertia belts are concerned Vee came to me with the original belts, and the tunnel part is a fixed length of webbing in plastic sheath that holds the buckle in a relatively fixed position to enable easy one-hand fastening. However over the past 43 years the plastic by the buckle has gradually been breaking away. This isn't a safety issue as long as the belt itself is still sound, but it does mean the buckle flops about and recently one-handed fastening has been getting more of a fiddle. By contrast Bee came to me with PO-fitted inertia reels replacing the original statics. I suspect they came off a late model i.e. 77 and later as the tunnel parts have wires for the seat-belt warning system. But these tunnel parts are a semi-stiff cable encased in plastic, which can be bent and twisted into various positions, and once positioned it more-or-less stays put making one-handed fastening very easy. Interestingly both sets are Kangol Magnet ... without the magnet arrangement used on the statics.

As far as inertia belts are concerned Vee came to me with the original belts, and the tunnel part is a fixed length of webbing in plastic sheath that holds the buckle in a relatively fixed position to enable easy one-hand fastening. However over the past 43 years the plastic by the buckle has gradually been breaking away. This isn't a safety issue as long as the belt itself is still sound, but it does mean the buckle flops about and recently one-handed fastening has been getting more of a fiddle. By contrast Bee came to me with PO-fitted inertia reels replacing the original statics. I suspect they came off a late model i.e. 77 and later as the tunnel parts have wires for the seat-belt warning system. But these tunnel parts are a semi-stiff cable encased in plastic, which can be bent and twisted into various positions, and once positioned it more-or-less stays put making one-handed fastening very easy. Interestingly both sets are Kangol Magnet ... without the magnet arrangement used on the statics.

Eventually I'd had enough of groping around trying to orientate the buckle and push the two parts together with one hand. Looking around on eBay I did find the odd tunnel part of the same type, but zooming-in it looked as bad as mine, so I decided to replace the tunnel parts with stiff stalks the same as Bee's. Something to be aware of is that the lengths of the stalks vary, and also the tunnel mounting position was further back on earlier cars meaning they need a longer stalk. Get the wrong length and they will either be too short on earlier cars and hidden beside the seat back, or too long on later cars and the hard plastic socket will be lying across your hip. Found a pair of those OK, the length was given in the advert and was the same as both Bee's and Vee's existing belts (32mm) so I knew they would be correct. But when they arrived I 'discovered' the tongue is different - the originals are rectangular with a square hole and the replacements take a longer narrower one! I should have realised as the differences between Bees and Vees have been staring me in the face for 24 years, but there we are.

Eventually I'd had enough of groping around trying to orientate the buckle and push the two parts together with one hand. Looking around on eBay I did find the odd tunnel part of the same type, but zooming-in it looked as bad as mine, so I decided to replace the tunnel parts with stiff stalks the same as Bee's. Something to be aware of is that the lengths of the stalks vary, and also the tunnel mounting position was further back on earlier cars meaning they need a longer stalk. Get the wrong length and they will either be too short on earlier cars and hidden beside the seat back, or too long on later cars and the hard plastic socket will be lying across your hip. Found a pair of those OK, the length was given in the advert and was the same as both Bee's and Vee's existing belts (32mm) so I knew they would be correct. But when they arrived I 'discovered' the tongue is different - the originals are rectangular with a square hole and the replacements take a longer narrower one! I should have realised as the differences between Bees and Vees have been staring me in the face for 24 years, but there we are.

So more eBaying found a single belt with the correct tongue. Complete with bracket for mounting on top of the GT rear arch which is just as well as the existing one is completely different. This is L-shaped as the bolt into the reel is horizontal, whereas the new reel needs one that is basically flat as the bolt through a tab on the real into a boss on the bracket is vertical. Both types of bracket are handed with a slight angled kink to position the reel horizontally in both orientations, as the bolt into the rear arch is at a slight angle from the vertical in two planes. Get the angle wrong and the pendulum device that is one of the two locking mechanisms on these belts will be such that if the car is parked other than on a level surface the belt may lock when you try to pull it out. Although the bracket was marked 'RH' in red felt-tip it was shaped incorrectly for the right-hand side, but a moment in a vice with large grips soon altered that. The original GT brackets were never listed separately, but several suppliers list BMH9514/5 which is a different design and only suitable for the later reels with black plastic housings and not the earlier hammered grey metal housings, and are sometimes supplied as part of a new full belt kits. BHI UK have a number of brackets of various types including flat and angled. They look flat, but also look thinner than either of the brackets I have so will bend easily enough - hopefully not too thin.

So more eBaying found a single belt with the correct tongue. Complete with bracket for mounting on top of the GT rear arch which is just as well as the existing one is completely different. This is L-shaped as the bolt into the reel is horizontal, whereas the new reel needs one that is basically flat as the bolt through a tab on the real into a boss on the bracket is vertical. Both types of bracket are handed with a slight angled kink to position the reel horizontally in both orientations, as the bolt into the rear arch is at a slight angle from the vertical in two planes. Get the angle wrong and the pendulum device that is one of the two locking mechanisms on these belts will be such that if the car is parked other than on a level surface the belt may lock when you try to pull it out. Although the bracket was marked 'RH' in red felt-tip it was shaped incorrectly for the right-hand side, but a moment in a vice with large grips soon altered that. The original GT brackets were never listed separately, but several suppliers list BMH9514/5 which is a different design and only suitable for the later reels with black plastic housings and not the earlier hammered grey metal housings, and are sometimes supplied as part of a new full belt kits. BHI UK have a number of brackets of various types including flat and angled. They look flat, but also look thinner than either of the brackets I have so will bend easily enough - hopefully not too thin.

As received the belt was fully in the reel, which it normally never is of course, and it just wouldn't pull out when trying it before fitting. With repeated attempts sometimes it would work then lock, and sometimes not at all, which was rather annoying. After much pondering and trying I realised that in my hands, even though I was holding it in the correct orientation it wouldn't work, but held down on a flat surface it did. So even slight wobbling about when hand-held was enough to lock it.

Then onto the main event - the stalks. Went to fit them and realised there is a stepped spacer on the old belts which fits into an oversized hole in the original belt tab, but the hole in the new stalk is only just big enough for the bolt. I didn't want to fit it like that as it would mean several less threads engaged, and if I left it out altogether the bolt bottomed before tightening onto the stalk. Cut the flange off? Or enlarge the hole? For better or worse I enlarged the hole. Fully fitted it pulls out easily, lock with only a slight yank, and more importantly one-handed fastening is now a doddle.

You may well decide to go for a new set complete rather than messing about as I did, but there are several things to watch out for:

- Some come with floppy belts for the tunnels, others come with stiff stalks which as above are much easier to live with.

- There are roadster versions with an angle-bracket for mounting the reel low down on the side of the rear arch, others for the GT with 'straight' brackets for mounting on top of the arch. Many reels can only be installed in one orientation or the pendulum locking device will do its stuff, and the original MGB belts of either type have to be mounted horizontally. Even a slight angle could cause the belt to repeatedly lock when you are trying to pull it out to fasten it if the car is not on a level surface.

- Whilst reels from most manufacturers only function correctly i.e. pull out smoothly if they are mounted in one specific orientation, others can be mounted in two or more orientations and have adjustments so the locking action operates correctly such as Securon. Although these can be mounted in pretty-well any orientation normally without brackets they are best avoided on both roadsters and GTs for the following reason. They have a large additional section on one side of the reel that contains the orientation adjustment. This is fine on the left-hand GT arch, but on the right-hand it means the reel has to be positioned further inboard by quite a margin. It will not fit without a bracket, or even the usual GT bracket, unless you add a second straight bracket between the arch and the original bracket to make a right-angle. Fine in normal use, but if ever they are needed in anger the reel will move forwards as there is no way the two brackets at right angles to each other will resist the force. In the roadster you can't mount them using the standard right-angle bracket as again the extra lump on one side means they will not fit the right-hand arch. You can mount them vertically and use the adjustment feature, but this means the belt exits the reel vertically and has to twist through 90 degrees to go over your shoulder which compromises the retraction, especially with other gubbins in the way such as windstops, non-standard seats, and belt-guides.

When first looking I only found one belt of the type I wanted, but the day the first one arrived I Googled again and spotted another, so went for that as well. Basically the same shape and complete with bracket, this time definitely for the right-hand side. The only difference seems to be that it does not have the plastic cover that clips over the top of the reel between the two plastic sides. No big deal, I may leave it like that, or may take the cover off the first one if they are identical underneath, or I may make one (I did). Checking Bee's I find they don't have covers either, but are usually hidden by the hood.

When first looking I only found one belt of the type I wanted, but the day the first one arrived I Googled again and spotted another, so went for that as well. Basically the same shape and complete with bracket, this time definitely for the right-hand side. The only difference seems to be that it does not have the plastic cover that clips over the top of the reel between the two plastic sides. No big deal, I may leave it like that, or may take the cover off the first one if they are identical underneath, or I may make one (I did). Checking Bee's I find they don't have covers either, but are usually hidden by the hood.

In any event these reels are much smaller, neater and less obtrusive than Vee's originals. But at the end of the day you can pay nearly as much putting together second-hand parts of variable condition as for new. The MGOC M061 (available singly) come with the stiff stalk (not shown, but they have confirmed it) and fitting kits for roadster and GT are available. Watford Classics shows a kit (pair with brackets) for the GT, and Chase MG one for the roadster (pair with brackets, albeit with red belts), both with stiff stalks.

In any event these reels are much smaller, neater and less obtrusive than Vee's originals. But at the end of the day you can pay nearly as much putting together second-hand parts of variable condition as for new. The MGOC M061 (available singly) come with the stiff stalk (not shown, but they have confirmed it) and fitting kits for roadster and GT are available. Watford Classics shows a kit (pair with brackets) for the GT, and Chase MG one for the roadster (pair with brackets, albeit with red belts), both with stiff stalks.

Belt guide:

Added April 2010:

The Navigator has always moaned she can't find the belts every time she gets in Bee (personally I just feel around on the floor behind the seat, but what do I know?). Many years ago we met up with a couple who had some very neat purpose-designed clips attached to the seat, but he knew nothing about them. Browsing on the web showed some for the new MINI at about £60 (and break, apparently) and for BMW and Mercedes at a couple of hundred (what's that about pricing things for what you can get for them?). Pondered it on and off for years, and this Spring decided to do something about it.

The Navigator has always moaned she can't find the belts every time she gets in Bee (personally I just feel around on the floor behind the seat, but what do I know?). Many years ago we met up with a couple who had some very neat purpose-designed clips attached to the seat, but he knew nothing about them. Browsing on the web showed some for the new MINI at about £60 (and break, apparently) and for BMW and Mercedes at a couple of hundred (what's that about pricing things for what you can get for them?). Pondered it on and off for years, and this Spring decided to do something about it.

All it really needs is a flat strip under the headrest, turned back at the end to retain the belt when released, but allow it to be unhooked easily if needs be. After a bit of thought I realised I could attach the clip to the bottom of the headrest using the tube and one of the screws. Experimenting with card templates showed that something following the curve of the seat back was the most pleasing and effective. I'd been cutting up some square drain down-pipe recently to use as cladding for my wooden garage door frame and had some left over, which seemed as good a material as any. 60mm sides, I shaped and angled the template to fit into a length of that, the end is angled to line up with the main piece when turned back. Using a block of wood either side and clamped in a vice, and a heat-gun, it's quite easy to get a reasonably tight bend for the turned back end, using another block of wood on the back to press it down (it gets hot!), then when you have got it to 90 degrees whip it out of the vice and press it back a further 30 degrees or so.

It certainly holds the belts up and makes them easy to find over one's shoulder, but with the hood folded it does need to be lifted up and fed through as you remove the belt as the inertia reel isn't strong enough to pull it round the folded hood, and without feeding it back it drops over the sill when the door is opened. The opinion of the Navigator is awaited!

June 2010: Showing a roofer pal the garage door cladding made out of guttering down-pipe I happened to mention I had used offcuts to fabricate the belt hooks but was planning to paint them black. He just happened to have replaced some guttering that morning, in black square-section, and dropped me off an offcut so I made two more from that which look much better.

November 2017:

Up till now Vee's belts have always stayed on the shoulders of the seats without any guide, but since recovering them they slip off while parked. So I make another pair, having an offcut of black down-pipe of the perfect length to hand. However it's needed a couple of iterations to get them to the right shape, as with the higher reels on the GT they were being lifted up out of them while being worn.

Up till now Vee's belts have always stayed on the shoulders of the seats without any guide, but since recovering them they slip off while parked. So I make another pair, having an offcut of black down-pipe of the perfect length to hand. However it's needed a couple of iterations to get them to the right shape, as with the higher reels on the GT they were being lifted up out of them while being worn.

GT rear belts: August 2013

One couldn't possibly contemplate seating anyone in the rear of a roadster, but children in a GT using a static lap-belt is a distinct possibility. Presumably because the GT is classed as a 'four-seater' the factory had to provide rear mounting points, although from when I don't know.

One couldn't possibly contemplate seating anyone in the rear of a roadster, but children in a GT using a static lap-belt is a distinct possibility. Presumably because the GT is classed as a 'four-seater' the factory had to provide rear mounting points, although from when I don't know.

There are two mounting points centrally behind the rear seat back which can only be for rear belts.

There are two mounting points centrally behind the rear seat back which can only be for rear belts.

However the side mounting points are not so straightforward. There are bosses on the side of the wheelarch, but these were originally used for the shoulder strap of static belts on both roadsters and GTs. Originally they were quite near the front of the arch, then on roadsters (like my 73) they moved right to the back, but not on GTs (like my 75 V8). Whilst they are usable for a rear lap belt, that half would only go across the front of a child and not curve round them like the central belt, so may allow them to move forwards more in the event of a frontal impact. I think I would prefer to provide another mounting point further back.

However the side mounting points are not so straightforward. There are bosses on the side of the wheelarch, but these were originally used for the shoulder strap of static belts on both roadsters and GTs. Originally they were quite near the front of the arch, then on roadsters (like my 73) they moved right to the back, but not on GTs (like my 75 V8). Whilst they are usable for a rear lap belt, that half would only go across the front of a child and not curve round them like the central belt, so may allow them to move forwards more in the event of a frontal impact. I think I would prefer to provide another mounting point further back.

Make sure you use the correct stepped spacer so the bolt (7/16" UNF/20, it seems) can be tightened but still allow the belt ends to swivel, and use a wavy washer to stop the ends rattling. Both fit over the narrower section of the spacer. The wheel-arch boss isn't a through-fitting like the central mounting points (for obvious reasons I hope) so check the bolt will go in far enough to tighten onto the stepped spacer before it bottoms. If it bottoms first then shorten it by the minimum amount. If the buckle half belt-end is angled (like on the Securon) then even though it might seem more logical to angle it into the car, angle it the other way i.e. towards the side of the car so it doesn't jut out and stick in junior's side.

Make sure you use the correct stepped spacer so the bolt (7/16" UNF/20, it seems) can be tightened but still allow the belt ends to swivel, and use a wavy washer to stop the ends rattling. Both fit over the narrower section of the spacer. The wheel-arch boss isn't a through-fitting like the central mounting points (for obvious reasons I hope) so check the bolt will go in far enough to tighten onto the stepped spacer before it bottoms. If it bottoms first then shorten it by the minimum amount. If the buckle half belt-end is angled (like on the Securon) then even though it might seem more logical to angle it into the car, angle it the other way i.e. towards the side of the car so it doesn't jut out and stick in junior's side.

Only a few minutes and a neat installation, to help bring the next generation of enthusiasts along. Strictly speaking the buckle half should be adjusted such that the buckle lies against the hip of the passenger on the buckle side, and the tongue half is adjusted to reach round the front of the passenger. But using the original boss would probably put the buckle across the lower abdomen which is not a good idea, so that half should be adjusted to reach around the passenger and the tongue half adjusted to be much shorter. If a new mounting point for the buckle half is provided at the back of the arch, or even behind the seat back like the central points, the buckle half could be positioned correctly.

Only a few minutes and a neat installation, to help bring the next generation of enthusiasts along. Strictly speaking the buckle half should be adjusted such that the buckle lies against the hip of the passenger on the buckle side, and the tongue half is adjusted to reach round the front of the passenger. But using the original boss would probably put the buckle across the lower abdomen which is not a good idea, so that half should be adjusted to reach around the passenger and the tongue half adjusted to be much shorter. If a new mounting point for the buckle half is provided at the back of the arch, or even behind the seat back like the central points, the buckle half could be positioned correctly.

Grade 8.8 is required, 7/16" UNF, either a stepped bolt or a plain set screw used with a shouldered spacer so that when tightened the anchor on the belt end pivots on the spacer, and a wavy washer to prevent it rattling. If the sill or tunnel point should become damaged it may be possible to replace it with a purpose-made nut and strengthening plate welded appropriately. Be aware that some sources of these components state they are M10 even though the vehicle compatibility list includes the MGB and many other BMC/BL vehicles.

Grade 8.8 is required, 7/16" UNF, either a stepped bolt or a plain set screw used with a shouldered spacer so that when tightened the anchor on the belt end pivots on the spacer, and a wavy washer to prevent it rattling. If the sill or tunnel point should become damaged it may be possible to replace it with a purpose-made nut and strengthening plate welded appropriately. Be aware that some sources of these components state they are M10 even though the vehicle compatibility list includes the MGB and many other BMC/BL vehicles.

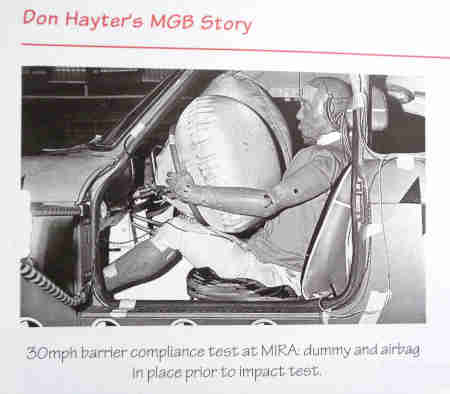

Did the MGB ever have air-bags? January 2017 It's fairly well documented (although the ARONLINE site that originally carried a summary of all the SSV vehicles has gone offline, it can be found here) that the MGB SSV shown at the Washington DC road safety conference in 1972 had air-bags as well as a wide range of other safety features, less so that they were crash tested in at least one North American spec car. A pal recently sent a link to a 1995 film about the MGB produced by the MG Car Club of Holland in which there is an MG film clip (with Dutch commentary) showing just such a test. You may be surprised to see just how far forwards the 'driver' is thrown - knocking out the screen, but it has to be remembered that originally in the USA air-bags were designed to be used as a stand-alone restraint device, and not in conjunction with seat belts as they have always been in the UK.

Don Hayter in his 'MGB Story' writes about taking an MGB 'tourer' to an American company Eaton Corporation in Turin where an air-bag system "was fitted and wired up in two days, before returning to MG to prepare for a test at Mira. The airbags were inflated at 3500psi by a compressed nitrogen cylinder activated by a speed deceleration sensor (set above 14mph) on the bulkhead. Similar tests determining air bag size, inflation pressures and the effects of deceleration on the crash dummy eventually resulted in a successful system. A film of this development work was made by the BBC's Raymond Baxter and called Safety in Numbers".

He also has this picture of a MIRA test, this time of a GT with no door so different to the video above. Earlier in the above chapter on Safety Legislation he writes that because of possible rollover problems they had decided to take a GT to the American Transpo72 along with many other European manufacturers to demonstrate various safety systems, in the shape of the MGB GT SSV1. Consequently it seems odd to have taken a 'tourer' to have air-bags fitted, perhaps faulty memory.

He also has this picture of a MIRA test, this time of a GT with no door so different to the video above. Earlier in the above chapter on Safety Legislation he writes that because of possible rollover problems they had decided to take a GT to the American Transpo72 along with many other European manufacturers to demonstrate various safety systems, in the shape of the MGB GT SSV1. Consequently it seems odd to have taken a 'tourer' to have air-bags fitted, perhaps faulty memory.