My temp gauge reading is low

Hotter stat for winter? November 2018

Replacement May 2014

V8 steam pipe

The vast majority of us will need a thermostat to achieve a normal running temperature in as quick a time as possible, only cars in very hot climates may not need one, and see below regarding this. An engine runs more efficiently at it's correct temperature, choke - or more correctly in the case of the SU and Zenith carbs - 'mixture enrichment' will be needed for the shortest time saving fuel, reducing pollution, and giving full performance sooner. Clausager says that initially the standard stat was 82C (180F) with 74C(165F) for hotter countries and 88C(190F) for cold climates. In September 1964 these were changed to 74C for standard to increase oil pressure with 82C for cold climates, but only until March 1969 when they reverted to the original 82C standard with 74C for hot and 88C for cold climates.

The thermostat is a temperature-controlled valve between the head and the radiator. At less than its rated temperature it is closed. As the coolant reaches its rated temperature it should start to open, and after that if coolant temperature continues to rise it will open further. In other words it is not like an electrical switch i.e. either fully on/open or fully off/closed, but variable like a water tap. What follows is the product of many happy hours spent playing with water and basins as a child, much to my parent's annoyance at the amount of time I'd spend in the bathroom: If you plug the outlet of a basin and turn on the tap the basin will fill and you turn off the tap when you have the level you want. If you turn on the tap with no plug the basin probably won't start to fill at all unless your pressure and hence flow-rate is pretty high (I can remember places where with no restrictions at all the flow rate from both taps was such that it would fill the basin, and defeat the overflow outlet, and the basin would eventually overflow onto the floor ... not that I ever left it that long once I had proved the point to my satisfaction). But if you partially block the outlet the basin will start to fill, and you can adjust the tap so that it is letting water in at the same rate as it is escaping from the outlet, and you can maintain a constant level in the basin. Restrict the outlet a bit more, and you will have to close the tap a little to maintain the same level. Open the outlet a bit more and you will have to turn on the tap a bit more to maintain the same level. That's the basis of the thermostat, with the level in the basin equating to coolant temperature.

The thermostat is a temperature-controlled valve between the head and the radiator. At less than its rated temperature it is closed. As the coolant reaches its rated temperature it should start to open, and after that if coolant temperature continues to rise it will open further. In other words it is not like an electrical switch i.e. either fully on/open or fully off/closed, but variable like a water tap. What follows is the product of many happy hours spent playing with water and basins as a child, much to my parent's annoyance at the amount of time I'd spend in the bathroom: If you plug the outlet of a basin and turn on the tap the basin will fill and you turn off the tap when you have the level you want. If you turn on the tap with no plug the basin probably won't start to fill at all unless your pressure and hence flow-rate is pretty high (I can remember places where with no restrictions at all the flow rate from both taps was such that it would fill the basin, and defeat the overflow outlet, and the basin would eventually overflow onto the floor ... not that I ever left it that long once I had proved the point to my satisfaction). But if you partially block the outlet the basin will start to fill, and you can adjust the tap so that it is letting water in at the same rate as it is escaping from the outlet, and you can maintain a constant level in the basin. Restrict the outlet a bit more, and you will have to close the tap a little to maintain the same level. Open the outlet a bit more and you will have to turn on the tap a bit more to maintain the same level. That's the basis of the thermostat, with the level in the basin equating to coolant temperature.

But back to thermostats: The thermostat does not maintain an exact temperature, it varies by a typically 8 to 10 degrees from just starting to open to fully open. In a wax stat the expansion of the wax that is opening the 'valve' is compressing a spring, so each additional milli-meter of movement needs slightly more heat then the previous movement. Furthermore when a stat has partially opened and stabilised, changes of direction don't happen instantly but only after a lag. If the coolant temperature drops to drop after a previous rise the physical properties of the components are such that the temperature can drop 2 or 3 degrees before it starts to close. Likewise if the coolant temperature starts to rise after a previous fall again it takes 2 or 3 degrees of coolant temperature rise before the stat starts to open further. This 'lag' is known as hysteresis, and is very common in mechanical thermostats no matter where they are used. There are many different manufacturers making thermostats for many different applications, and each will design their stats for a given temperature range from just opening to fully open, and the hysteresis, accordingly. Just what state the thermostat is in at its rated temperature also varies between manufacturers and applications.

I was long puzzled by Clausager's statement on p78 that "Weston-Thomson latch-open thermostats were used from 1967". Under what circumstances did it latch open, and why? Googling 'Weston-Thomson' and 'latch-open' revealed nothing at the time, and the Parts Catalogue has no information other than listing the three thermostats used for cold (GTS102), temperate (GTS104) and hot (GTS109) climates. However in November 2018 someone happened to mention thermostats being 'fail-safe' in that if they failed they failed in the open position. To do that the return spring would have to break which doesn't seem very likely. Far more likely is failure of the rubber capsule around the wax, which would cause it to fail closed. But more Googling specifically 'fail safe thermostat' revealed that there are indeed thermostats described as 'fail-safe' around, although they are designed to latch open when some other part of the cooling system has failed, which has caused the coolant temperature to rise higher than normal, which has caused the thermostat to open beyond any normal operating position. Manufacturers say that once the stat has latched open it must be replaced. Whilst it's tempting to reprise the immortal phrase "They would say that, wouldn't they" - it will have to be accessed in any event, why can't one simply 'unlatch' it? But if the stat has been pushed beyond its normal operating range then there may have been other effects on it, and they are cheap enough anyway. The only comments I could find about the thermostats themselves being 'fail safe' were that they didn't exist, and I've never come across one of these 'latch open' type in over 50 years.

I was long puzzled by Clausager's statement on p78 that "Weston-Thomson latch-open thermostats were used from 1967". Under what circumstances did it latch open, and why? Googling 'Weston-Thomson' and 'latch-open' revealed nothing at the time, and the Parts Catalogue has no information other than listing the three thermostats used for cold (GTS102), temperate (GTS104) and hot (GTS109) climates. However in November 2018 someone happened to mention thermostats being 'fail-safe' in that if they failed they failed in the open position. To do that the return spring would have to break which doesn't seem very likely. Far more likely is failure of the rubber capsule around the wax, which would cause it to fail closed. But more Googling specifically 'fail safe thermostat' revealed that there are indeed thermostats described as 'fail-safe' around, although they are designed to latch open when some other part of the cooling system has failed, which has caused the coolant temperature to rise higher than normal, which has caused the thermostat to open beyond any normal operating position. Manufacturers say that once the stat has latched open it must be replaced. Whilst it's tempting to reprise the immortal phrase "They would say that, wouldn't they" - it will have to be accessed in any event, why can't one simply 'unlatch' it? But if the stat has been pushed beyond its normal operating range then there may have been other effects on it, and they are cheap enough anyway. The only comments I could find about the thermostats themselves being 'fail safe' were that they didn't exist, and I've never come across one of these 'latch open' type in over 50 years.

I've seen quite heated discussions in the past with one camp saying it sets the minimum temperature, and the other camp saying it sets the maximum. It does neither, and the clue is in the name - 'thermo' i.e. heat and 'stat' from the Greek 'stato' which means standing i.e. it is a device that attempts to maintain a 'standing' or constant temperature. However it can only do that between two extremes, and those extremes are controlled by the heat output of the engine and the cooling effect of the radiator and the air temperature passing through it. Consider driving along in moderate conditions, with the engine output and radiator output balanced, and the thermostat partially open, which should give a 'normal' reading on your temperature gauge.

- Now consider a long downhill into cooler conditions on a trailing throttle. Much less heat output from the engine, but the radiator is cooling at the same rate as before, so the coolant temperature drops, which causes the thermostat to start closing, and the radiator to dissipate less and less heat, to maintain the coolant temperature. But once the thermostat becomes fully closed, it can no longer regulate the temperature, and at that point if engine output reduces still further coolant temperature will start to drop because you cannot reduce the cooling effect any more, and you will see this on the gauge. You may wonder how the thermostat could close fully on a running engine, but read on.

- Now consider the opposite where the engine is slogging up a steepening incline in hot weather, and the engine is outputting more and more heat as you go. The coolant temperature rises, and as it does so the thermostat opens further, and the radiator dissipates more and more heat. But once the thermostat is fully open, any further increase in heat output will cause the coolant temperature to rise without flowing more through the radiator to cool it, and again you will see this on the gauge. But even without more coolant flowing through the radiator, and a rising coolant temperature, the radiator still dissipates more heat due to the difference between coolant temperature and ambient i.e. the air flowing through the radiator, so overall the coolant temperature is still being 'controlled', or managed, just not to a given temperature.

What causes even more 'discussion' is when driving the same roads winter and summer, and seeing a more noticeable change in the temperature gauge reading, which is when people start talking about blanking off the radiator and such-like, with others saying that if the thermostat is working correctly you shouldn't need to. That's true, and if the thermostat isn't working the effects on the gauge will be much bigger - anywhere from barely getting off C in winter if it is stuck open to boiling if stuck closed. Even with a working stat, it will be closed when you first start the engine and drive off, so the radiator isn't doing any cooling anyway, so blanking it off won't do anything ... or will it? Air is generally ducted through the grille and the radiator to get the best cooling from the ram-air effect, with minimal air that has passed through the grill not passing through the radiator. The foam and rubber seals on the radiator and diaphragm contribute to this. So in winter even when the thermostat is fully closed and the radiator doing nothing, there is still the icy blast (when driving along) flowing over the block, head and sump, and through the oil cooler where fitted, and you probably have the heater on which is cooling things still further, and this is where a 'radiator' blind does have a benefit. By reducing the air-flow into the engine compartment you are reducing this surface cooling effect on engine and head at least, and with the over-mounted oil cooler reducing air-flow through that as well. Adjustable blinds were common as an accessory in the UK in the 50s - it was a factory accessory for the MGA, and some countries with very cold winters such as Canada and Sweden still have them. Whether they - in the form of temporary non-adjustable partial covers of the rad or oil cooler - are needed in the UK is highly debatable, how many of us drive our cars in freezing weather with salt on the roads?

Probably the biggest cause of temperature gauge difference between winter and summer is down to the 8 to 10 degrees difference between starting to open and fully open, in a typical thermostat. As we may well be running near the closed end in winter, and near the fully open end in summer, this will directly relate to an 8 to 10 degree difference in coolant temperature, and hence gauge reading. But there may be another effect in play - on pre-77 cars with the capillary temperature gauge. On these a gas or fluid is heated in a bulb in the cylinder head, which expands, increases the pressure in the tube, which acts directly on the gauge. There is gas or fluid the full length of the tube, so this must have the same heat/volume characteristics as that in the bulb, but is subject to the ambient temperature in the engine compartment rather than the coolant temperature in the engine. I know there is a big difference in the relative volumes of gas/fluid in the bulb and the tube, but logic dictates there must be some effect. It would be interesting to monitor the coolant temperature directly and compare with the capillary gauge. This would need a probe in the coolant itself - it's common to have such probes that are part of after-market electric cooling fans, but they are pushed into the top hose, which because of the thermostat controlling flow is not reliable in this instance. So it would have to be the heater hose as it comes out of the valve on the cylinder head. Typical probes on digital oven thermometers will be too big in a small hose to seal properly, unless you can make an adapter of some kind.

Probably the biggest cause of temperature gauge difference between winter and summer is down to the 8 to 10 degrees difference between starting to open and fully open, in a typical thermostat. As we may well be running near the closed end in winter, and near the fully open end in summer, this will directly relate to an 8 to 10 degree difference in coolant temperature, and hence gauge reading. But there may be another effect in play - on pre-77 cars with the capillary temperature gauge. On these a gas or fluid is heated in a bulb in the cylinder head, which expands, increases the pressure in the tube, which acts directly on the gauge. There is gas or fluid the full length of the tube, so this must have the same heat/volume characteristics as that in the bulb, but is subject to the ambient temperature in the engine compartment rather than the coolant temperature in the engine. I know there is a big difference in the relative volumes of gas/fluid in the bulb and the tube, but logic dictates there must be some effect. It would be interesting to monitor the coolant temperature directly and compare with the capillary gauge. This would need a probe in the coolant itself - it's common to have such probes that are part of after-market electric cooling fans, but they are pushed into the top hose, which because of the thermostat controlling flow is not reliable in this instance. So it would have to be the heater hose as it comes out of the valve on the cylinder head. Typical probes on digital oven thermometers will be too big in a small hose to seal properly, unless you can make an adapter of some kind.

But then, does it really matter? I know engines ideally run at an optimum temperature, but we almost never get extreme lows (I remember -26C in Shropshire in the 70s) in most parts of the UK, and most of us don't drive them then anyway. And the kind of variations the rest of us are going to get when we do drive them are not going to have any detrimental effect on the engine, and only a minor discomfort in cabin temperatures for the occupants. And if you don't like that, don't drive them!

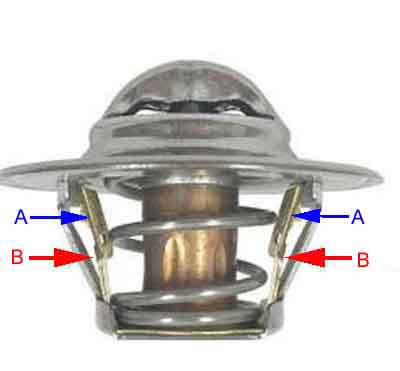

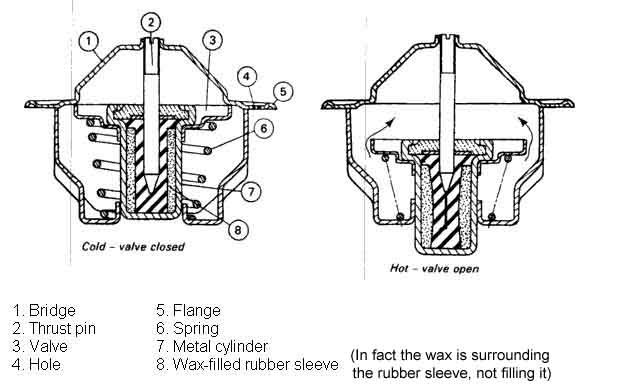

The type of thermostat fitted to MGBs has a metal cylinder containing wax, inside which is a rubber sleeve. Inside the rubber sleeve is a metal pin. When the wax is heated it expands, which presses on the rubber sleeve, which presses on the pin and forces it out of the rubber sleeve. In fact the pin is fixed and it is the metal cylinder that is forced down pulling the disc valve open with it (incidentally against pump pressure). As the coolant temperature is reduced the wax pellet contracts, and a large spring forces the metal cylinder back up and the disc valve closed. The thermostat can actually be installed either way round in the head and thermostat housing, but it must be installed such that the wax pellet is suspended in the head coolant. If it is installed upside down it won't open as the wax pellet will be on the cooler side of the valve, except when sufficient heat has been transferred through by conduction in the thermostat itself.

The type of thermostat fitted to MGBs has a metal cylinder containing wax, inside which is a rubber sleeve. Inside the rubber sleeve is a metal pin. When the wax is heated it expands, which presses on the rubber sleeve, which presses on the pin and forces it out of the rubber sleeve. In fact the pin is fixed and it is the metal cylinder that is forced down pulling the disc valve open with it (incidentally against pump pressure). As the coolant temperature is reduced the wax pellet contracts, and a large spring forces the metal cylinder back up and the disc valve closed. The thermostat can actually be installed either way round in the head and thermostat housing, but it must be installed such that the wax pellet is suspended in the head coolant. If it is installed upside down it won't open as the wax pellet will be on the cooler side of the valve, except when sufficient heat has been transferred through by conduction in the thermostat itself.

The thermostat would normally be closed when filling the system with coolant, and this would lead to an air-lock, so the thermostat usually has a bleed of some kind. Sometimes there is just a hole in the flange, which allows some coolant to circulate via the radiator even when the thermostat is closed, which will extend the warm-up time a little. Others thermostats have a 'jiggle-pin' in this hole, and originally I thought a 'float' on the bottom of the pin lifts it up to block the hole to give quick filling time when in air but zero circulation during warm-up when in coolant. However some turn out to be metal, so there is still some coolant circulation during warm-up, and the pin is only there to keep the hole clear. Yet other thermostats are 'cost reduced' without a hole in the flange and hence no jiggle-pin, but do have a very small notch in the edge of the valve. This also allows air to bleed through and minimal circulation during warm-up. Still others have no hole or notch, and these cause problems when filling from empty, as described below.

The thermostat would normally be closed when filling the system with coolant, and this would lead to an air-lock, so the thermostat usually has a bleed of some kind. Sometimes there is just a hole in the flange, which allows some coolant to circulate via the radiator even when the thermostat is closed, which will extend the warm-up time a little. Others thermostats have a 'jiggle-pin' in this hole, and originally I thought a 'float' on the bottom of the pin lifts it up to block the hole to give quick filling time when in air but zero circulation during warm-up when in coolant. However some turn out to be metal, so there is still some coolant circulation during warm-up, and the pin is only there to keep the hole clear. Yet other thermostats are 'cost reduced' without a hole in the flange and hence no jiggle-pin, but do have a very small notch in the edge of the valve. This also allows air to bleed through and minimal circulation during warm-up. Still others have no hole or notch, and these cause problems when filling from empty, as described below.

May 2014:

Bee's thermostat started sticking closed (or so I thought, turned out to be head gasket) so needed replacement. I noticed that not only did the new one have no jiggle-pin (the old one did), it didn't even have the notch in the valve. I dribbled some water onto the top of the valve, and eventually some trickled through. But whether this was just because of an imperfect seal, or a concealed bleed port I don't know. But on filling after draining the radiator filled very quickly i.e. not much went in, and on running the engine it got almost to the point of opening the thermostat when the level in the rad (I was watching it) dropped like a stone. I immediately switched off and it took half a kettle-full of hot water before the level got above the tubes again, so there had been a massive air-lock under the thermostat. Ran again, and with it warmed up some more I could see when the thermostat opened (coolant flowing across the top of the tubes now) it started to drop slowly. This time I trickled some cold water in - maybe half a litre - to bring it back up to half-way up the header tank. Overnight it had dropped a little more, but still above the tubes, so I added another half-litre. As this was only a test-fill with water after head gasket replacement I knew I was going to have to drain and refill and have the same problem again, so I discussed it with Roger Parker at the MGOC. He said they had recently sourced thermostats with the correct jiggle-pin, but suggested I drill a hole in the flange rather than junking a new stat, which I did.

Bee's thermostat started sticking closed (or so I thought, turned out to be head gasket) so needed replacement. I noticed that not only did the new one have no jiggle-pin (the old one did), it didn't even have the notch in the valve. I dribbled some water onto the top of the valve, and eventually some trickled through. But whether this was just because of an imperfect seal, or a concealed bleed port I don't know. But on filling after draining the radiator filled very quickly i.e. not much went in, and on running the engine it got almost to the point of opening the thermostat when the level in the rad (I was watching it) dropped like a stone. I immediately switched off and it took half a kettle-full of hot water before the level got above the tubes again, so there had been a massive air-lock under the thermostat. Ran again, and with it warmed up some more I could see when the thermostat opened (coolant flowing across the top of the tubes now) it started to drop slowly. This time I trickled some cold water in - maybe half a litre - to bring it back up to half-way up the header tank. Overnight it had dropped a little more, but still above the tubes, so I added another half-litre. As this was only a test-fill with water after head gasket replacement I knew I was going to have to drain and refill and have the same problem again, so I discussed it with Roger Parker at the MGOC. He said they had recently sourced thermostats with the correct jiggle-pin, but suggested I drill a hole in the flange rather than junking a new stat, which I did.

Incidentally this one from Bee had been in at least 25 years. She had always run at around N on the gauge - which is supposed to be 82C, until the second replacement gauge fitted in May 2012 when normal running showed about 7:30 o'clock. Subsequently changing the stat made no difference. I originally thought I had replaced the stat like for like i.e. 82C, but much later subsequently discovered the old one had been 88C. I find I bought two from Leacy in the space of a couple of days, the first being the 'wrong' 88C one, and getting the 'correct' 82C one. Leacy offered to have the wrong one back, but I said for the money I might as well keep it as a spare. Why the change from 88 to 82 made no difference on the gauge is a bit of a mystery (but see this). In Jan/Feb 2018 and having the head off again for conversion to unleaded after the same exhaust valve was leaking as before I have the opportunity to fit the 88C and see what happens. (Didn't think about it again, but as she is used more in hot summers than cold winters it's not an issue).

Incidentally this one from Bee had been in at least 25 years. She had always run at around N on the gauge - which is supposed to be 82C, until the second replacement gauge fitted in May 2012 when normal running showed about 7:30 o'clock. Subsequently changing the stat made no difference. I originally thought I had replaced the stat like for like i.e. 82C, but much later subsequently discovered the old one had been 88C. I find I bought two from Leacy in the space of a couple of days, the first being the 'wrong' 88C one, and getting the 'correct' 82C one. Leacy offered to have the wrong one back, but I said for the money I might as well keep it as a spare. Why the change from 88 to 82 made no difference on the gauge is a bit of a mystery (but see this). In Jan/Feb 2018 and having the head off again for conversion to unleaded after the same exhaust valve was leaking as before I have the opportunity to fit the 88C and see what happens. (Didn't think about it again, but as she is used more in hot summers than cold winters it's not an issue).

The head has a bypass port below the valve which allows coolant to return from head to block without going via the radiator. This is important to get an even heating of head and block during warm-up to avoid hot-spots which can cause unequal expansion, warping and head gasket failure, and also to ensure heated coolant can circulate round the lower part of thermostat that contains the wax pellet. If this didn't happen the thermostat wouldn't open until sufficient heat had transferred through the metal to warm the static coolant round the thermostat. Incidentally the heater circuit performs the same 'even heating' function when the heater valve is open. The V8 has an additional bypass route, see the steam pipe below, which allows a small amount or coolant to bypass the thermostat and circulate via the radiator at all times.

The head has a bypass port below the valve which allows coolant to return from head to block without going via the radiator. This is important to get an even heating of head and block during warm-up to avoid hot-spots which can cause unequal expansion, warping and head gasket failure, and also to ensure heated coolant can circulate round the lower part of thermostat that contains the wax pellet. If this didn't happen the thermostat wouldn't open until sufficient heat had transferred through the metal to warm the static coolant round the thermostat. Incidentally the heater circuit performs the same 'even heating' function when the heater valve is open. The V8 has an additional bypass route, see the steam pipe below, which allows a small amount or coolant to bypass the thermostat and circulate via the radiator at all times.

MGA stats had a cylindrical sleeve which moved as the stat opened to block this bypass port, and causes the vast majority of circulation to be via the radiator and virtually none via the bypass port. These are sometimes referred to as 'bellows' stats, however this refers to the technology used to open and close the stat, and not the presence or otherwise of this cylindrical sleeve. This type of stat is no longer available. Later wax-pellet stats as used in the MGB don't have this sleeve, meaning that some of the coolant still recirculates once the stat has opened. MGA engines are said to suffer from inadequate cooling in high ambient temperature conditions if a later wax-pellet stat is installed, but it doesn't appear to be a problem with MGBs.

MGA stats had a cylindrical sleeve which moved as the stat opened to block this bypass port, and causes the vast majority of circulation to be via the radiator and virtually none via the bypass port. These are sometimes referred to as 'bellows' stats, however this refers to the technology used to open and close the stat, and not the presence or otherwise of this cylindrical sleeve. This type of stat is no longer available. Later wax-pellet stats as used in the MGB don't have this sleeve, meaning that some of the coolant still recirculates once the stat has opened. MGA engines are said to suffer from inadequate cooling in high ambient temperature conditions if a later wax-pellet stat is installed, but it doesn't appear to be a problem with MGBs.

Competition engines don't usually have a thermostat fitted, but then they are used under very different conditions to road cars. They are generally carefully warmed up before being driven, so any stat will be open anyway, and it is unlikely to close again during use. As stats can fail closed occasionally (which can cause severe overheating and engine damage) not having one in a competition engine is one less thing to go wrong. Usually these engines will have a cylindrical blanking sleeve fitted in place of the thermostat, which greatly restricts the bypass port as the sleeve only has two very small holes in the side. This gets maximum coolant flow through engine and radiator and minimum recirculation, hence maximum cooling. But on some engines even this can be a problem. If you scan around the web you will find recommendations that too much circulation can cause as much of a problem as too little, due to turbulence and local recirculation in the head and block, again leading to localised overheating. In these case it is recommended that a restrictor is fitted instead, to reduce the aperture to the same size as an open thermostat. The easiest way to achieve this is to remove the wax pellet, spring and moving disc from a standard stat. In some cases you might want to fit a blanking sleeve and a restrictor to get both minimum recirculation and turbulence.

Competition engines don't usually have a thermostat fitted, but then they are used under very different conditions to road cars. They are generally carefully warmed up before being driven, so any stat will be open anyway, and it is unlikely to close again during use. As stats can fail closed occasionally (which can cause severe overheating and engine damage) not having one in a competition engine is one less thing to go wrong. Usually these engines will have a cylindrical blanking sleeve fitted in place of the thermostat, which greatly restricts the bypass port as the sleeve only has two very small holes in the side. This gets maximum coolant flow through engine and radiator and minimum recirculation, hence maximum cooling. But on some engines even this can be a problem. If you scan around the web you will find recommendations that too much circulation can cause as much of a problem as too little, due to turbulence and local recirculation in the head and block, again leading to localised overheating. In these case it is recommended that a restrictor is fitted instead, to reduce the aperture to the same size as an open thermostat. The easiest way to achieve this is to remove the wax pellet, spring and moving disc from a standard stat. In some cases you might want to fit a blanking sleeve and a restrictor to get both minimum recirculation and turbulence.

The advice on what to do if not fitting a stat is very confused and confusing. Moss says "The thermostat can be removed to aid cooling but it is essential that a blanking sleeve is fitted in its place or the change in water flow may cause local overheating in the cylinder block" i.e. they are talking about the need for restriction. With a fully open stat and no blanking sleeve the bypass port is uncovered and so some coolant will be recirculating, and even an open stat results in a restriction to the main flow, both of which reduce the maximum cooling that can be achieved. But with a blanking sleeve and no stat the bypass-port is restricted so the whole of the coolant flow is via the radiator, the main coolant flow isn't restricted, both of which result in maximum cooling (assuming no turbulence and localised hot-spots due to the greater flow). Without either warm-up will be slightly quicker as there is some recirculation via the bypass which will reduce the likelihood of localised hot-spots during warm-up, but maximum cooling will be slightly reduced for the same reason. Therefore having neither puts you somewhere between having a just stat on one hand, and just a blanking sleeve on the other, but closer to having just a blanking sleeve. Moss's statement doesn't make sense, and with a blanking sleeve you would have to be careful warming the engine up to make sure it did so evenly. This Mini site also says to fit a blanking sleeve in place of the thermostat, then describes and shows a restrictor. And this one says to fit a blanking sleeve, but it says it is necessary to prevent overheating in certain parts of the engine i.e. they are talking about the need for a restrictor. They show a blanking sleeve, but say to cap-off the bypass ports as well which has already been achieved by the blanking sleeve!

The advice on what to do if not fitting a stat is very confused and confusing. Moss says "The thermostat can be removed to aid cooling but it is essential that a blanking sleeve is fitted in its place or the change in water flow may cause local overheating in the cylinder block" i.e. they are talking about the need for restriction. With a fully open stat and no blanking sleeve the bypass port is uncovered and so some coolant will be recirculating, and even an open stat results in a restriction to the main flow, both of which reduce the maximum cooling that can be achieved. But with a blanking sleeve and no stat the bypass-port is restricted so the whole of the coolant flow is via the radiator, the main coolant flow isn't restricted, both of which result in maximum cooling (assuming no turbulence and localised hot-spots due to the greater flow). Without either warm-up will be slightly quicker as there is some recirculation via the bypass which will reduce the likelihood of localised hot-spots during warm-up, but maximum cooling will be slightly reduced for the same reason. Therefore having neither puts you somewhere between having a just stat on one hand, and just a blanking sleeve on the other, but closer to having just a blanking sleeve. Moss's statement doesn't make sense, and with a blanking sleeve you would have to be careful warming the engine up to make sure it did so evenly. This Mini site also says to fit a blanking sleeve in place of the thermostat, then describes and shows a restrictor. And this one says to fit a blanking sleeve, but it says it is necessary to prevent overheating in certain parts of the engine i.e. they are talking about the need for a restrictor. They show a blanking sleeve, but say to cap-off the bypass ports as well which has already been achieved by the blanking sleeve!

Bob Muenchausen has a comprehensive page on cooling and thermostats and reports that Neil Cotty in Australia fitted a standard wax-pellet stat and a blanking sleeve to a road car (although it's not clear which car this was done to) to get reduced circulation through the bypass port and slightly better cooling. Hopefully the reduced temperature difference between his ambient and normal running temperature eliminates the risk of hot-spots during warm-up. Neil professed himself happy with the result, but wondered if this arrangement in cooler countries would prevent the engine ever reaching its normal temperature. I can't see why that would be if a stat is fitted as seems to be the case. Bob in Idaho and its colder winters tried the same thing in his 68 MGB and reports that it does take slightly longer, but as I say I can't see how, unless the blanking sleeve reduces recirculation so much it prevents the hottest coolant reaching the gauge sensor, i.e. there is uneven heating. But surely the fitting of a blanking sleeve in cooler countries is unnecessary anyway, and with the bigger temperature difference between ambient and normal you run the risk of damage from localised hot-spots for no gain.

In extremely cold conditions and even with a correctly functioning stat the temperature may never reach normal, due to the 'surface cooling' effect of freezing air passing over the sump, block, hoses, and use of the heater. As a point of interest it is this surface cooling that led to there being 'summer' and 'winter' thermostats. In winter a higher rated stat was fitted as more of the cooling would come from surface cooling of the block and sump. In summer a lower rated stat was fitted as the surface cooling effect would be lower. The effect of this surface cooling can be reduced by partially blocking the air-flow through the radiator and oil cooler. Contrary to popular belief this doesn't stop the coolant in the radiator from being cooled too much, as the thermostat closes anyway when the coolant temperature drops below the rated temperature, it simply reduces the amount of surface cooling. Blanking-off will however make the coolant too hot if you blank off too much or the weather doesn't warrant it.

Michael Beswick has pointed out that the typical 13" x 6" (excluding the bump on the top) rally plaque frequently issued on organised runs in the UK tied on with string makes an excellent oil cooler blind for cold weather running, for those cars with the oil cooler above the apron at any rate.

Updated May 2008: Early in 2008 there was a heated discussion about thermostats where one person insisted that the stat controlled the maximum temperature, whereas everyone else myself included said it controlled the minimum. On consideration I changed my view, but to one that says the thermostat maintains a given temperature, rather than a maximum or a minimum. But like any thermostat it can only do this between certain upper and lower limits. If the ambient temperature is below a certain point surface cooling of the block, sump, oil cooler and use of the heater will prevent the coolant getting hot enough to open the stat at all but the engine will still be running below temperature. This is when people in cold areas talk about 'blanking off the radiator'. And if the ambient temperature is above a certain point the radiator won't be able to dissipate as much heat as normal, the stat will be fully open, but the engine will still be hotter than normal. The fact is that more of us experience the latter i.e. higher temp gauge readings in summer than low readings in winter, which is why most people say it controls the minimum temperature. Even giving this interpretation the 'maximum' man refused to acknowledge it and stuck to his guns, so there it was left.

So under a wide range of ambient conditions the running temperature is set by the stat. Below the minimum is relatively easily dealt with by blanking off the radiator, but above the maximum will inevitably result in a higher temp gauge reading than normal. Even in a typical UK summer with temperatures in the high 70s and low 80s the temperature gauge will read higher than normal under some driving conditions. This isn't the end of the world, it just means that the coolant temperature will have to be higher than normal before the radiator can get rid of the usual amount of heat. Mid-way between N and H is no problem at all, and is actually about where the electric cooling fans cut in at 90C, whereas a standard stat is 82C. 'H' on the gauge represents about 110C/230F, which is above boiling point but you should be able to get right up to the H zone without any loss of coolant or steaming because of the pressurised system. Using a typical 33% anti-freeze solution a 12lb cap raise the boiling point to 123C/253F which is well above H on the gauge. I've seen my V8 inside the red zone without problems, other than for my nerves, although by that time you should be thinking about whether you are pushing it too hard for the conditions, or there might indeed be a problem. In either case turning on the heater full-blast can buy you a bit more time - at the expense of comfort!

As mentioned before there are two main reasons why coolant temperature can rise more than it should - either the engine is pushing out more heat than it should or the radiator isn't getting rid of it. In the former case this can be head gasket blown, timing too advanced or retarded, drag on the engine from tight bearings e.g. just after a rebuild all of which can result in a significant increase in heat output, binding brakes (usually accompanied by a smell of them burning), underinflated tyres (slight effect) etc. In the latter case the radiator can be partially blocked either eternally by debris or internally by sludge, restricted airflow through the grille from additional lights, rally plaque, number plate etc. Flow can also be reduced by a thermostat not fully opening, water pump vanes corroded away, and I understand there may be an incorrect combination of engine and pump that results in reduced coolant flow. There is also another possible cause of engine overheating where the coolant temperature coming out of it isn't necessarily raised, and possibly not even an indication on the gauge, and that is when there is sludge in the block and heads restricting coolant flow across parts of the metal surfaces resulting in localised overheating and possibly gasket or head warping problems. Internal sludge when still soft can often be shifted by repeatedly forward and reverse flushing of the engine and radiator until the water runs clear, but hardened deposits may not respond to this and still remain even though the water is clear. There are some DIY radiator flush additives around but they are probably of marginal benefit, both from the safety of DIY use point of view and attacking rubber and alloy parts. Still worth a try before the next step, though. Hard deposits are bad enough in the radiator, but at least this can have the header or footer tank removed, the tubes rodded-out and the tank resoldered, or at worst the radiator replaced. But in an engine often complete dismantling and 'hot-tanking' will be required Hot-tanking is dunking in hot chemical solution to hopefully dissolve any deposits before it dissolves the engine! These chemicals can be pretty caustic and not only dangerous to handle but often destructive to alloy parts.

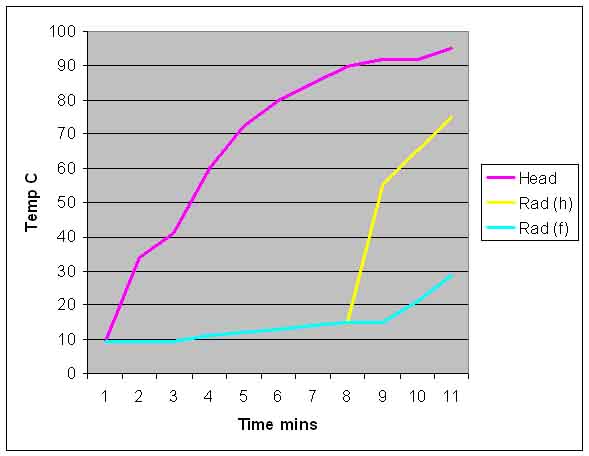

If the thermostat is stuck open, or not even fitted, the engine won't reach normal temperature in anything other than hot weather. This is bad for the engine, the environment and your wallet as well as causing low heat output from the heater. You can check the stat by warming the car up from cold and periodically feeling the radiator. As the temp gauge rises the header tank should stay relatively cool. As the temp gauge gets near N the header tank should suddenly get very hot (!) as the stat opens, and this indicates a normally functioning stat. If the header tank gradually warms up as the temp gauge rises with no sudden increase there is no stat or it is stuck open. You can see this on the temp gauge as a very slow rise, probably not getting anywhere near 'N' until you are stopped in traffic. Don't forget a low temperature gauge reading may also be due to problems with the gauge (capillary and electric) or sender (electric).

If the thermostat is stuck open, or not even fitted, the engine won't reach normal temperature in anything other than hot weather. This is bad for the engine, the environment and your wallet as well as causing low heat output from the heater. You can check the stat by warming the car up from cold and periodically feeling the radiator. As the temp gauge rises the header tank should stay relatively cool. As the temp gauge gets near N the header tank should suddenly get very hot (!) as the stat opens, and this indicates a normally functioning stat. If the header tank gradually warms up as the temp gauge rises with no sudden increase there is no stat or it is stuck open. You can see this on the temp gauge as a very slow rise, probably not getting anywhere near 'N' until you are stopped in traffic. Don't forget a low temperature gauge reading may also be due to problems with the gauge (capillary and electric) or sender (electric).

Thermostat Replacement: May 2014

First job is to drain at least some of the coolant out, which entails removal of the bottom hose. This came to me with the car 25 years ago, although I have replaced the water pump, and I think I've also had it off the rad for flushing, both many years ago. Because the bottom rad pipe faces upwards it's a struggle to remove the bottom hose from that first, but if you remove the pump end first water will go everywhere, whereas at least removing the bottom end first you can catch most of it in a bucket. Before this happened I was planning to drain and flush the system anyway, and replace the coolant, as when hot the coolant in the rad is quite orange, but not when cold, implying that a lot of sediment is being stirred up when in use. I was going to do it by repeatedly filling with water, running up to temp, then draining hot or nearly so, but given the difficulties getting the hose off that's not really an option.

Next day as repeated filling and draining hot wasn't going to be an option, for the sake of four bolts I removed the rad so at least I could agitate that and rinse it out. The two struts that go from the top two bolts to the wing bolts have to be slackened at the wing end so they can be swung out of the way far enough to angle the rad forwards so the top connection clears the mounting panel (and my foam seal). When replacing these struts, remember to position them over the welded nuts on the rad flange as you are screwing the long bolts in, otherwise you will have to undo them again!

Replacement stat arrives. Decide to test it in a pan of water just in case. But that is not as straightforward as it might be as we have an induction hob which means using one of SWMBO's shiny pans. She's OK with it, but I find my digital oven thermometer is being confused by radiation or something from the hob, so I have to keep turning the hob off to read the correct temp. It seems to be opening a shade after 82C, but I had tested the old stat earlier using a blow-lamp on a tin (which took ages hence doing the new one - clean - differently) and that seemed to be about 90 or 92C. Not as high as I was expecting, the temp gauge was going higher than that - maybe to 105C on a Centigrade gauge, and my gauge reads a few degrees low.

What to do about the bottom hose is a bit of a conundrum. As this one is still supple, shiny and smooth do I refit it? Or use the spare that I bought years ago? Given the quality of hoses these days a 'new' one could well fail before my 25+ year-old one. I've had my spare for nearly that long, so is that now perished? Or did I buy it long enough ago before the quality got so bad? I decide to put the original on first, fill it with water and run it up to temperature first to check that there is nothing else wrong and it was the stat before draining and refilling with anti-freeze. I'll fit the new hose and clip at that point.

When it stops raining I get the cars out to do a test run. No leaks, but I'm slightly concerned to see the temp gauge goes to about mid-way between N and H before it comes back down again. No coolant loss, but then I've only just refilled an empty system so the level is probably low anyway. Switch off and it is well down, and takes about 1.5 litres from a just-boiled kettle. Let it cool down to about 70 degrees, and run it again. This time the temp only gradually creeps up from mid-way between C and N to it's normal position. Initially the rad was cooler than the thermostat housing which indicates the stat was closed, then it obviously opened. Switched off, checked the level which was as I had left it. So nothing more to do but put it back in the garage (it had started raining again anyway) until it has fully cooled down overnight and try again.

Next day coolant level still good so run it again. This time I film the temp gauge while monitoring the temperature on the head just above the temp gauge sensor with my infra-red thermometer and the rad header tank with my hand. The rad only warms slightly to begin with, then rapidly got hot as it should. At that point the thermometer indicated about 78C. Replayed the video to see that the temp gauge simply rose to it's normal running position and stopped there, which is a relief. Coolant level still good, and nothing chucked out of the overflow. So the final job once it has cooled down is to drain the plain water which I have put in to start with, and refill with anti-freeze.

The odd thing is that ever since I've had the roadster it's warm-up has been totally consistent in that the temp gauge would always go slightly above N, then come down quite a bit as the stat opened, then go up and down less and less until finally stabilising on its normal running position. When I got the V8 that was exactly the same so I took no notice. Then after many years and tens of thousands of miles it developed a cooling system problem that resulted in coolant loss, but after fixing that the temp gauge stopped oscillating during warm-up and now just rises to its normal running position and stays there.

In the event it was a week or so later that I removed the bottom hose to drain some water out prior to adding antifreeze. This should be done by adding the required amount of neat glycol first - 1.9 litres for 33% with a heater for example - then top up with plain water as that takes account of any old coolant or plain water left in the system, which can be quite a bit. How you get on with replacing glycol with ForLife I don't know, but I do know that with Evans waterless you have to go through several flushing cycles first. I had completely removed the bottom hose as I had decided to be rash and fit my new spare. I smeared Vaseline round the first half inch or so of the inside of the new hose, as dry it was proving difficult to get the hose on any of the three pipes, and the heater return pipe was still quite hard, and tightened up the clamps. Put 2 litres of neat glycol in and that was enough to fill the radiator to above the tops of the tubes, which was a surprise, I had expected to be adding some water as well.

Started it up to hear a load drumming noise so immediately switched off. As suspected the fan was hitting the new hose, hadn't even considered that when fitting it. There is only about 1/4" clearance each side of the hose to both the fan and the timing cover, so it has to be positioned quite carefully. I had noticed the old hose had been rubbing on the timing cover. Fortunately lost no coolant - which would have been neat coolant - when adjusting the hose.

Restarted and let it warm up, looking round for any leaks and keeping an eye on the rad level with the cap off, feeling the thermostat housing, and looking at the gauge. Got maybe half-way from C to N (bearing in mind this gauge reads low) when the rad level suddenly dropped like a stone. Immediately switched off, boiled a kettle (neat water!) to top up with, and it took most of a full kettle. This must be due to the new thermostat having no jiggle valve, not even a notch in the main valve, so it traps air beneath it until it opens, even though it has coolant on top of it from filling the rad. This must be why when I first filled and ran it with the rad cap on, the temp gauge went up quite a way above N before it came back down, and I subsequently found the rad 'empty' needing quite a bit to bring it above the tubes again.

Restarted, no movement in the header tank for a while, then suddenly started flowing across the tops of the tubes and turning blue. I hadn't noticed that it was clear to begin with, even though I had only put neat fluid in. I suppose it is 'heavier' and had displaced the water that was left in the bottom of the rad. At the same time the level started dropping again, but quite slowly, so I just trickled in some cold water to keep it above the tubes, perhaps half a litre. All this is best done with the front of the car slightly higher than the rear to aid bleeding, particularly of the heater, the tap for which should be open. Left it overnight and gave it another test in the garage, and all was well, no oscillation, and no coolant loss.

However next day I took it round the block, to find the wild oscillations had come back. Got back home and found it had lost about half a litre. The same happened again next day, with a catch bottle on the overflow tube. This has to be more than simple purging of air left in the system. By now we were only a couple of days away from the Arden Run, so nothing I could do about it. But as it seems only to chuck some out if filled more than 1/4" above the tubes when cold, and only as the stat opens, it should be OK, and it was.

I'm wondering if it's the pump sucking in air, as seemed to be the case with the V8. I changed the pump almost on getting the car in 1990 as the bearings on the original had gone. It was a pig to fit - an alloy after-market item, with one of the holes having to be ovalled to get all the bolts in, even though the gasket from the same source fitted as it should, and one of the bosses ground down as otherwise the bolt was too short. After a few years I noticed that started weeping on warm-up, so got a pukka cast-iron pump prior to a trip to France and put it in the boot waiting for the weep to get worse - that was 17 years ago and it's still in the boot! It could also be a problem with the bypass passages in the head and/or block not circulating coolant while the stat is closed, but the pump is easier to change as a first go.

Warmed up on the drive and no problems at all, gauge just rose to its 'normal' point, stat opened, pressure up to about 6psi - higher than I was expecting given the V8 pressures. Thermometer on the stat and temp gauge sensor housing showed about 80C. Blocked off the rad, allowed the temp to rise till the gauge was right over the N and the housing temp was 88C. Let it rise to between the two little dots i.e. on the edge of the H zone, temp was 107C, pressure about 9.5 psi, so the 10lb cap is basically OK.

Switched off and the rad cap was hissing, and the pressure started slowly dropping, even though the temp gauge was actually going higher due to heat soak. So although the cap does seem to be 'maintaining' just under 10 psi, it seems there is a small leak from somewhere associated with the cap or the rad fitting, that is allowing pressure to leak away even after it has dropped to below 10 psi. Removed the 10lb cap and fitted a 20lb I had from when I was investigating the V8, ran it again with rad blocked and the pressure got up to about 15psi. Switched off no hissing - faulty 10lb cap seal?

Refitted the 10lb cap and let it cool right down for about 3 hours with bonnet up and cool draught through the garage so the temp gauge was on the end stop and the pressure gauge zero. Drove round the block and I was surprised how quickly the pressure rose, to about 12psi. Temp gauge did its usual thing of rising towards H - but not reaching it this time, and oscillating before it settled back down to its 'normal' but low point. Pressure gauge steady. Got back home, no coolant in catch bottle, and cap not hissing this time!

When I had the V8 cooling system problem that would always rise to cap pressure. Afterwards it only rose to 11psi (15lb cap fitted) when the fans cut in i.e. mid-way between N and H. When the fans cut out it was 6psi, and running in free air on the motorway only 3psi. So I'm pretty sure the roadster system is pumping up just like the roadster was. But whether it is down to the pump sucking in air, or a leaking head gasket, only time will tell. As the pump is easier to change, I did that first.

Unfortunately things were just the same. Before I'd got to the end of the road the pressure was up to 5psi with the temp gauge still on C. As the temp rose the pressure went up to about 12 psi )10 psi cap), temp went up to just over N before coming back down. Pressure dropped to about 5psi, and crept back up to 10 again on the way back home. Perhaps about 250mL in the catch bottle, and the rad cap hissing. I suspect the pressure drop just as the temp dropped was the stat opening, and either localised boiling or something else chucking out some coolant. Looks like the head gasket then, but really I need to do a combustion leak test of the coolant, a compression test and a leak-down test to get as much diagnostic info as possible before doing anything about the gasket.

The combustion leak test proved the head gasket was leaking, and replacing that had the same effect on the gauge as the V8 top-end rebuild, i.e. the gauge now just rises during warm-up and stops, very little if any oscillation, and the rad cap no longer hisses.

This thermostat is original to me so the housing hasn't been off in over 25 years, and I know they can be problematic. The problem is that crud and corrosion builds up on the studs which makes them an interference fit in the holes in the housing, and with three studs there is not much scope for wiggling it, it has to be more or less a straight pull upwards. If I can get any studs out first it should be easier. I can get one out using double-nuts - the one at the front of the engine which is in a blind i.e. a dry hole, but the other two go down into the coolant space and can corrode - can't shift those. Dribble WD40 round the studs the night before. With the top hose and one stud removed I can get a pair of grips in the outlet and wiggle to see the housing is moving, so pull up while wiggling and gradually work it off.

This thermostat is original to me so the housing hasn't been off in over 25 years, and I know they can be problematic. The problem is that crud and corrosion builds up on the studs which makes them an interference fit in the holes in the housing, and with three studs there is not much scope for wiggling it, it has to be more or less a straight pull upwards. If I can get any studs out first it should be easier. I can get one out using double-nuts - the one at the front of the engine which is in a blind i.e. a dry hole, but the other two go down into the coolant space and can corrode - can't shift those. Dribble WD40 round the studs the night before. With the top hose and one stud removed I can get a pair of grips in the outlet and wiggle to see the housing is moving, so pull up while wiggling and gradually work it off.

Very orange underneath, although the thermostat itself doesn't seem to be damaged in any way. With the housing off and more space I can get double-nuts on the other two studs and get those out as well, so I can clean up the head face. I'd delayed ordering a new stat until I got the housing off in case I damaged it - I hadn't, but it was heavily corroded including the sealing face by one of the stud holes which can lead to leaks up the studs, so ordered one anyway with stat and gasket. This is one of the rare occasions when I can't start and finish a job on one of my cars in the same session.

Very orange underneath, although the thermostat itself doesn't seem to be damaged in any way. With the housing off and more space I can get double-nuts on the other two studs and get those out as well, so I can clean up the head face. I'd delayed ordering a new stat until I got the housing off in case I damaged it - I hadn't, but it was heavily corroded including the sealing face by one of the stud holes which can lead to leaks up the studs, so ordered one anyway with stat and gasket. This is one of the rare occasions when I can't start and finish a job on one of my cars in the same session.

I ran a file round the plain shank of the studs, and would have lightly filed out the holes in the old housing if I had been refitting it, and will use copper grease on them anyway. I was surprised to see the head end was coarse thread whereas the nut end is fine. Inlet manifold studs for example are fine thread both ends but rocker pedestal studs are also coarse threads in the head, as are cylinder head studs in the block.

I ran a file round the plain shank of the studs, and would have lightly filed out the holes in the old housing if I had been refitting it, and will use copper grease on them anyway. I was surprised to see the head end was coarse thread whereas the nut end is fine. Inlet manifold studs for example are fine thread both ends but rocker pedestal studs are also coarse threads in the head, as are cylinder head studs in the block.

Parts arrive, and I immediately realised I have ordered an 88C stat instead of an 82C - so another delay. After refitting the rad I reattached the bottom hose, but unfortunately 'stripped' the Jubilee clip, and don't have a spare of that size. And of course when ordering the correct stat a couple of hours later I forget to ask for one of those at the same time! The housing is an alloy copy rather than a steel original as they are quite a bit cheaper. Time will tell if that's a false economy.

Parts arrive, and I immediately realised I have ordered an 88C stat instead of an 82C - so another delay. After refitting the rad I reattached the bottom hose, but unfortunately 'stripped' the Jubilee clip, and don't have a spare of that size. And of course when ordering the correct stat a couple of hours later I forget to ask for one of those at the same time! The housing is an alloy copy rather than a steel original as they are quite a bit cheaper. Time will tell if that's a false economy.

But I really have no choice but to go for it. I had left a rag stuffed in the hole in the head so I didn't drop anything down it. When I first removed the stat the space underneath was full of coolant, despite having removed the bottom hose from the rad. Now all the coolant has gone and I can see inside the head - not pretty! You can see why stripped engines are hot-tanked.

But I really have no choice but to go for it. I had left a rag stuffed in the hole in the head so I didn't drop anything down it. When I first removed the stat the space underneath was full of coolant, despite having removed the bottom hose from the rad. Now all the coolant has gone and I can see inside the head - not pretty! You can see why stripped engines are hot-tanked.

So I reinstall the studs with copper grease, pop the stat in, smear a thin layer of non-setting flange seal on one face of the cork gasket, noting it is handed for both top/bottom and rotational position as it has a notch to clear the rocker cover. Put a smear of seal on the new housing and fit that, then the hoses. A spare Jubilee clip is a little large, but tightens down just before the 'threads' run out, but I've ordered a couple of the correct size and will fit one later.

So I reinstall the studs with copper grease, pop the stat in, smear a thin layer of non-setting flange seal on one face of the cork gasket, noting it is handed for both top/bottom and rotational position as it has a notch to clear the rocker cover. Put a smear of seal on the new housing and fit that, then the hoses. A spare Jubilee clip is a little large, but tightens down just before the 'threads' run out, but I've ordered a couple of the correct size and will fit one later.

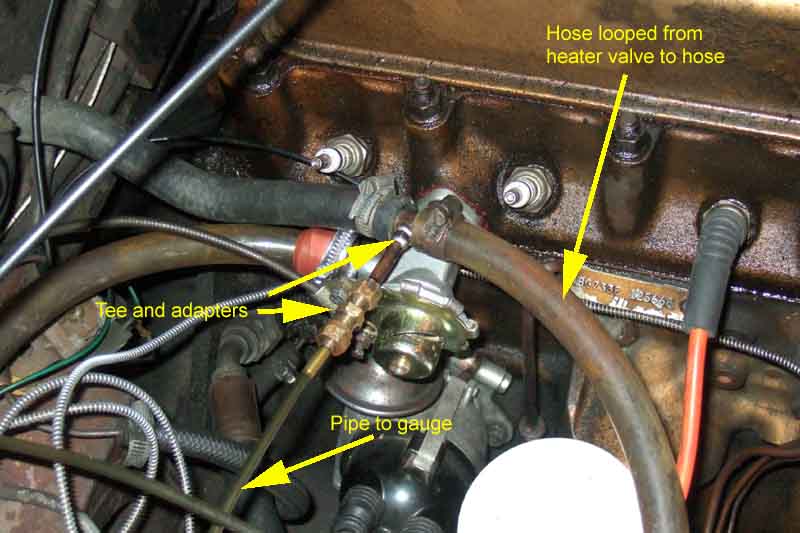

But before that I decide to do some pressure checks. I'd put a gauge Tee in the heater tap hose some time ago when I was investigating the radiator cap, albeit with the gauge under the bonnet as I couldn't come up with the necessary adapters to fit the gauge tubing. But this time I persevered and made a thick spacer washer to take up the slack that was left in one fitting after the tapered threads had tightened as far as was sensible.

But before that I decide to do some pressure checks. I'd put a gauge Tee in the heater tap hose some time ago when I was investigating the radiator cap, albeit with the gauge under the bonnet as I couldn't come up with the necessary adapters to fit the gauge tubing. But this time I persevered and made a thick spacer washer to take up the slack that was left in one fitting after the tapered threads had tightened as far as was sensible.

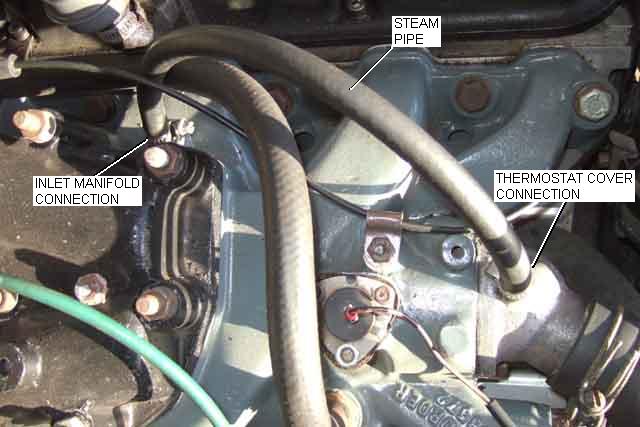

However note that the factory V8 has a 'steam pipe' which connects the inlet manifold i.e. the engine side of the thermostat, with the radiator side of the thermostat, which effectively bypasses the thermostat for a noticeable amount of flow. This means that the inlet manifold and the header tank will start to warm up at the same rate, then the inlet manifold will heat up faster than the header tank, until it gets hot enough to open the stat, then the header tank will suddenly get very hot as with the 4-cylinder engine. This performs the same function as bleed holes in thermostats - either from the manufacturer or owner drilled to prevent air-locks on refilling, which also cause a bleed of warm water into the radiator before the stat opens.

However note that the factory V8 has a 'steam pipe' which connects the inlet manifold i.e. the engine side of the thermostat, with the radiator side of the thermostat, which effectively bypasses the thermostat for a noticeable amount of flow. This means that the inlet manifold and the header tank will start to warm up at the same rate, then the inlet manifold will heat up faster than the header tank, until it gets hot enough to open the stat, then the header tank will suddenly get very hot as with the 4-cylinder engine. This performs the same function as bleed holes in thermostats - either from the manufacturer or owner drilled to prevent air-locks on refilling, which also cause a bleed of warm water into the radiator before the stat opens.