Speedometer

Tachometer

Instrument Voltage Stabiliser

Fuel Gauge

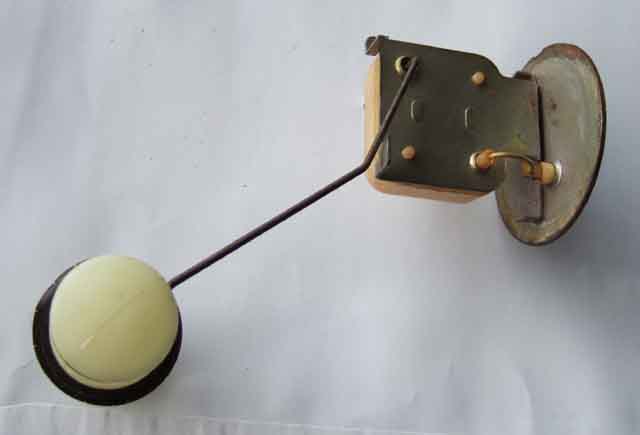

Tank Sender

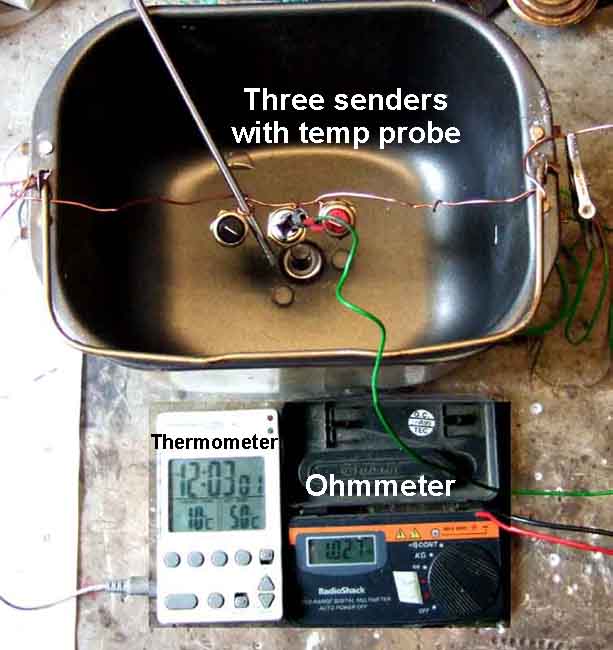

Calibrating the gauge

Dual oil-pressure/temperature

Electric Temperature Gauge

Electric Oil Gauge

Gauge seals

Instrument Lighting

|

|

|

The smaller gauges are secured in the dash with a small 3BA knurled nut (thumb nut) 17H932 and various U-straps. Early gauges have external illumination with strap AJH5185 (fuel) and AJH5186 (dual) that carries the bulb, later gauges with internal illumination use AJH5187.

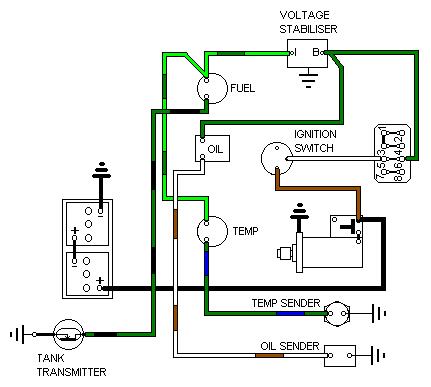

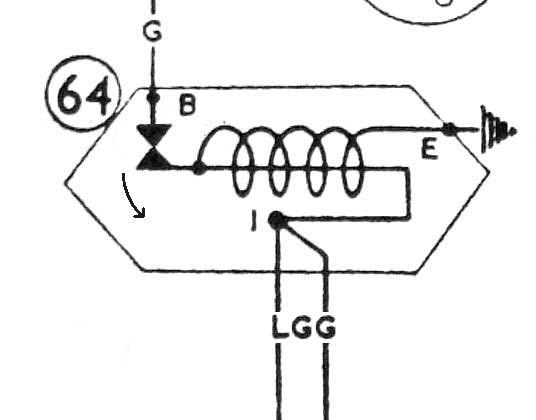

The electric gauges are usually powered from the green circuit (fused ignition), the one exception is the early electric tach from 64-67 which was powered from the white (unfused ignition) as well as having another white coming in to the pickup from the ignition switch and going out to the coil. I have no experience of electric temp and oil gauges in MGBs but the following info on fuel gauges may be of some use in faulting them. What I can give is the wiring colours. All run off the green circuit, either direct or via the voltage 'stabiliser' as follows:

- Fuel: 62-64: green circuit - fuel gauge - green/black - tank unit - black - boot earth

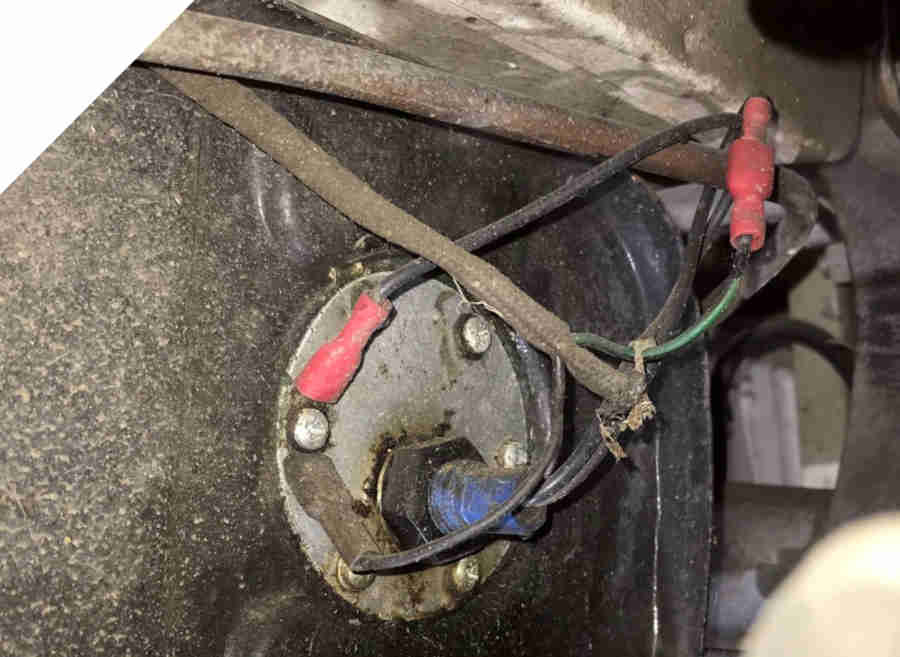

- Fuel: 65-on: green circuit - stabiliser - light-green/green - fuel gauge - green/black - tank unit - black - boot earth. From about 75 on for North America, and 77 on for the UK, there was no longer a wired earth at the tank sender.

- Temp: (North American spec 67-on, UK spec 77-on) green circuit - stabiliser - light-green/green - temp gauge - green/blue - temperature sender

- Oil: North American 67/68: green circuit - stabiliser - light-green/green - oil gauge - white/brown - oil pressure sender

- Oil: North American 69-71: green circuit oil gauge - white/brown - oil pressure sender. From 72-on North American spec reverted to a mechanical gauge

Faults and Repairs

Gearbox Drive Gears

Pinion Housing

Cables and Routing

EGR Valve Service Indicator

Right-angle drives

Decals

Cruise Control

There were many different speedos used over the years (I have found 50 so far!) according to year, market and vehicle spec.

There were many different speedos used over the years (I have found 50 so far!) according to year, market and vehicle spec.

Secured into the dash with two large 3BA knurled nuts 17H1304 and spring-washers, with a U-strap AJH5176 to September 64, separate 'legs' 17H3744 on each threaded stud from then until July 74, and 17H1339 until the 1977 model year. 1977 and later have a much better arrangement where the speedo and tach have three studs in the instrument case, and by turning them clockwise 30 degrees these studs will align with cut-outs in the dashboard to allow the instrument to be withdrawn. Unfortunately LHD only.

Secured into the dash with two large 3BA knurled nuts 17H1304 and spring-washers, with a U-strap AJH5176 to September 64, separate 'legs' 17H3744 on each threaded stud from then until July 74, and 17H1339 until the 1977 model year. 1977 and later have a much better arrangement where the speedo and tach have three studs in the instrument case, and by turning them clockwise 30 degrees these studs will align with cut-outs in the dashboard to allow the instrument to be withdrawn. Unfortunately LHD only.

As well as the obvious physical differences in size and markings the 'turns per mile' (TPM) varied over the years, that is

the number of turns of the speedo cable to register a mile travelled. This has to be matched to the drive gearing in the gearbox output shaft, the rear axle ratio, the wheel size, and to some extent the tyre size. Get the TPM wrong and both speed and distance travelled indications will be incorrect. Speed is relatively easy to compensate for by making internal adjustments but to correct the odometer different gear sets are required. The table below has been developed largely from the Leyland Parts Catalogue and Clausager and examination of many speedos at autojumbles, with additional information from other sites such as NAMGBR, Autochart

and Paul Tegler. However these other sites either don't include TPM figures, are limited in scope, or disagree to some extent with information from other sources.

I am indebted to Ian John of Caerbont Automotive Instruments for supplying me with a list of TPMs for these speedos.

Note that speedos not in the list with the exact reference number, even though they have the correct TPM figure, may have different speedo cable fitments, or night-time illumination/ignition warning lamp/main beam tell-tale or fitting arrangements, making fitting them in an MGB not straightforward.

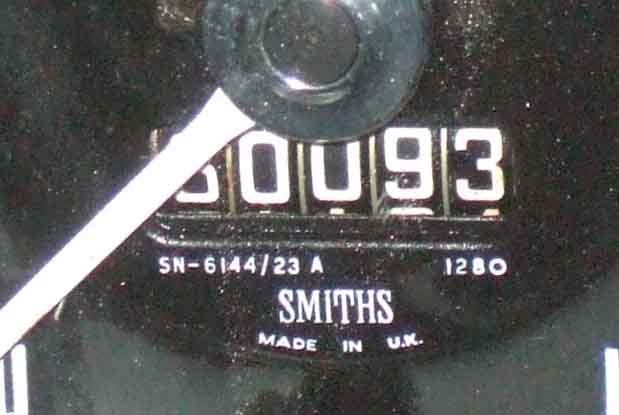

Updated August 2010: Note that 1280 tpm overdrives were used V8s and 4-cylinder chrome bumper cars (the latter having a black label) whereas 1000 tpm ODs were used on 4-cylinder rubber bumper cars and had a blue label. Thus on V8s there seems to be a mismatch between the 1280 tpm overdrive and the 980 tpm speedo, but this is almost exactly counterbalanced by the different axle ratio used on the V8. See here for more information on label colours.

Lights: July 2020

Instrument illumination is at the top, the bulb-holder (single wire, red/white) is push-fit, but usually pretty tight so may need to be pulled to one side to get it free. CB cars main-beam bulb (also single wire, blue) is at the bottom, also push fit but much easier to get out and back in.

Instrument illumination is at the top, the bulb-holder (single wire, red/white) is push-fit, but usually pretty tight so may need to be pulled to one side to get it free. CB cars main-beam bulb (also single wire, blue) is at the bottom, also push fit but much easier to get out and back in.

I've had a copy of a Repairing Jaeger & Smiths Speedometers document by Anthony Rhodes for a long time. That used to be online although harder to find now, it has been rewritten into a web site for Sunbeam Tigers. The Tigers web site has more written information (albeit over 17 pages which is a bit inconvenient), but the original document has more pictorial information and is easier to scroll back and fore, hence both are linked from here.

However with Bee's 4" speedo it was nothing like as easy to get the guts out of the case as Rhodes states. The trip reset protrudes much too far and will not 'push into the case' as described, and it only allows the mechanism to be moved forwards a few mm with the rear screws removed. I did not fancy trying to remove the pointer from that tiny spindle, so removed the screws holding the dial to the mechanism and with that free to move about under the pointer, and pushing the rubber gasket around the rear shaft up into the case, gave me just enough room to manipulate the mechanism out of the case. However trying to replace it the pointer did ping off - fortunately not snapping the spindle as I first feared, but leaving me with the problem of where to reattach it. That was done successfully, and on a subsequent occasion slotted the hole in the case for the reset shaft and that allowed removal without removing the dial screws.

June 2024:

Noticed Vee had clicked over to 30k ... then the next trip it out was just the same! Five minutes saw the speedo out (both cars came to me with only the tach-side mounting leg installed which can be accessed by reaching up behind the tach), another minute it was out of the case, and the main driving wheel was jammed. All the wheels were jammed, including the 10k digit, so it looked like that had failed to complete its turn and jammed all the way back. On the desk upstairs I consulted my previous experiences with the odo and just by removing the blue driving wheel and giving things a wiggle there was a click and everything was free again, and that had taken another five minutes. Back together turning a screwdriver in the cable drive started advancing the tenths wheel, and a drill and end off a broken cable drove the speedo round to 140mph with the tenths advancing merrily. I wanted to put the known 'missing' miles back on, but that way would have taken ages with the drill, so back out of the case again turning the driving wheel beside the tenths with a thumb soon put 75 miles on pending a trip out and refuel to give another estimate of mileage but it was about right so fastened back in the dash. Which took three goes feeling for the stud with the 'leg', earth wire and spring washer on, and a bit of a fiddle to get the knurled wheel started but no more than ten minutes. Will it happen again at 40k? Watch this space ...

Noticed Vee had clicked over to 30k ... then the next trip it out was just the same! Five minutes saw the speedo out (both cars came to me with only the tach-side mounting leg installed which can be accessed by reaching up behind the tach), another minute it was out of the case, and the main driving wheel was jammed. All the wheels were jammed, including the 10k digit, so it looked like that had failed to complete its turn and jammed all the way back. On the desk upstairs I consulted my previous experiences with the odo and just by removing the blue driving wheel and giving things a wiggle there was a click and everything was free again, and that had taken another five minutes. Back together turning a screwdriver in the cable drive started advancing the tenths wheel, and a drill and end off a broken cable drove the speedo round to 140mph with the tenths advancing merrily. I wanted to put the known 'missing' miles back on, but that way would have taken ages with the drill, so back out of the case again turning the driving wheel beside the tenths with a thumb soon put 75 miles on pending a trip out and refuel to give another estimate of mileage but it was about right so fastened back in the dash. Which took three goes feeling for the stud with the 'leg', earth wire and spring washer on, and a bit of a fiddle to get the knurled wheel started but no more than ten minutes. Will it happen again at 40k? Watch this space ...

May 2021:

Guy Renou has written to say he was able to remove the pointer surprisingly easily by putting a cloth over the dial, then using the curved tines of a table fork to gently lever it off! With the dial then removed you should be able to manoeuvre the mechanism out of the case with the rubber gasket pushed inside the case, but it does need to be orientated in a particular way, and again to get it back in. But with the dial off you can remove the small circlip from the reset shaft which allows the shaft to be removed, then the mechanism comes straight out.

Guy Renou has written to say he was able to remove the pointer surprisingly easily by putting a cloth over the dial, then using the curved tines of a table fork to gently lever it off! With the dial then removed you should be able to manoeuvre the mechanism out of the case with the rubber gasket pushed inside the case, but it does need to be orientated in a particular way, and again to get it back in. But with the dial off you can remove the small circlip from the reset shaft which allows the shaft to be removed, then the mechanism comes straight out.

April 2024:

Suddenly had the thought that trim removal tools could be used to remove the pointer ... and they can.

Suddenly had the thought that trim removal tools could be used to remove the pointer ... and they can.

July 2020:

On the way up to the Lake District Vee's speedo started flicking and I wondered whether it was the new cable that had been in about 500 miles. Then it started flicking higher and higher, and when it got to 120, 140 and then the back of the needle stop I knew it had to be the speedo itself. Finally it stayed at the back of the needle stop until we came to a halt when it slowly returned to zero, going round to the stop as we started moving again, confirming it was the speedo. Back home it took about 10 minutes to get the speedo out and opened up (much easier than Bee's) and the problem was immediately obvious - black oil in the mechanism and causing the spinning magnets to pull the needle cup round by much more than the usual magnetic force.

On the way up to the Lake District Vee's speedo started flicking and I wondered whether it was the new cable that had been in about 500 miles. Then it started flicking higher and higher, and when it got to 120, 140 and then the back of the needle stop I knew it had to be the speedo itself. Finally it stayed at the back of the needle stop until we came to a halt when it slowly returned to zero, going round to the stop as we started moving again, confirming it was the speedo. Back home it took about 10 minutes to get the speedo out and opened up (much easier than Bee's) and the problem was immediately obvious - black oil in the mechanism and causing the spinning magnets to pull the needle cup round by much more than the usual magnetic force.

Note that it is not magnetism that drives the needle cup directly but induced eddy currents, as the cup is aluminium which is non-magnetic. What happens is that the spinning magnet induces a current in the aluminium cup, and the effect of that current flowing in the aluminium is to generate an equal and opposite magnetic field which opposes the field created by the spinning magnet. This opposition cannot slow down the spinning disc, so it causes the needle cup to be dragged round. This effect has been used in electricity meters and to control the speed of roller-coasters and high-speed trains for many years. For the roller-coaster all it needs is permanent magnets on the car, and aluminium vanes on the track. No power supply, no moving parts, nothing to go wrong.

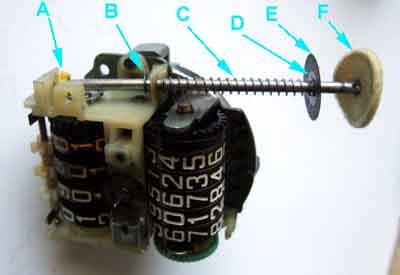

December 2014:  I needed to get into the mechanism in order to modify the mileage reading. Bee's trip odo has been jamming regularly this year, which made following Tulip instructions tricky. Fortunately the tenths was still going round, so I was having to add that to the main odo reading, then add to that the next inter (distance to the next turn) for the Navigator to write down. Bad enough, but because the trip and main odo aren't in synch sometimes I ended up a mile out either way. I was going to send it away over winter to be repaired, there are a couple of people who can then set any mileage you require (ordinarily it would be zeroed), but at £90 it's quite pricey and they take several weeks to do it. I'd got to the point of investigating how much new ones were for insurance purposes if mine should get lost, when I thought of looking for used on eBay. I found two, one was exactly right for Bee going by the reference number on the dial at £40. The other wasn't a very good picture but from what I could see looked right, at £20 in 'good condition and fully functioning', both mileages way different to Bee's of course. No shipping price in the ad, and you don't get that until you commit to buy which isn't helpful. Emailed the seller asking them to confirm the numbers and shipping price, but had to wait several days for a reply. Not exactly right - it was originally used on 74 models, but specified in the Parts Catalogue as being backwards compatible with earlier Mk2 cars so fine for me, and shipping a reasonable £5. By that time the £40 one had gone, so I committed to buy this one, then had to wait another week or so with no further info from the seller as to whether it had been shipped or not, before it turned up. First thing I did was test it with my drill on reverse, and the speedo goes smartly round, but neither bloody odo worked! Annoying, as the face and the numerals were in as-new condition, and the bezel and glass were no worse than Bee's. I could have sent it back of course, but more hassle and aggro, and no further forwards. So for the sake of £20 I decided to use it as a learning experience and open it up and have a look at it. Same problems with getting the guts out as with Bee's, which I'd already tried months earlier in an effort to see what was wrong with her trip. See the full story here on fixing the odometers on both speedos as well as a description of how they work.

I needed to get into the mechanism in order to modify the mileage reading. Bee's trip odo has been jamming regularly this year, which made following Tulip instructions tricky. Fortunately the tenths was still going round, so I was having to add that to the main odo reading, then add to that the next inter (distance to the next turn) for the Navigator to write down. Bad enough, but because the trip and main odo aren't in synch sometimes I ended up a mile out either way. I was going to send it away over winter to be repaired, there are a couple of people who can then set any mileage you require (ordinarily it would be zeroed), but at £90 it's quite pricey and they take several weeks to do it. I'd got to the point of investigating how much new ones were for insurance purposes if mine should get lost, when I thought of looking for used on eBay. I found two, one was exactly right for Bee going by the reference number on the dial at £40. The other wasn't a very good picture but from what I could see looked right, at £20 in 'good condition and fully functioning', both mileages way different to Bee's of course. No shipping price in the ad, and you don't get that until you commit to buy which isn't helpful. Emailed the seller asking them to confirm the numbers and shipping price, but had to wait several days for a reply. Not exactly right - it was originally used on 74 models, but specified in the Parts Catalogue as being backwards compatible with earlier Mk2 cars so fine for me, and shipping a reasonable £5. By that time the £40 one had gone, so I committed to buy this one, then had to wait another week or so with no further info from the seller as to whether it had been shipped or not, before it turned up. First thing I did was test it with my drill on reverse, and the speedo goes smartly round, but neither bloody odo worked! Annoying, as the face and the numerals were in as-new condition, and the bezel and glass were no worse than Bee's. I could have sent it back of course, but more hassle and aggro, and no further forwards. So for the sake of £20 I decided to use it as a learning experience and open it up and have a look at it. Same problems with getting the guts out as with Bee's, which I'd already tried months earlier in an effort to see what was wrong with her trip. See the full story here on fixing the odometers on both speedos as well as a description of how they work.

Speedy Cables is often mentioned as a source of speedo repairs, but there have been complaints of these taking several weeks.

I used Speedograph Richfield to recalibrate Vee's speedo as part of a 5-speed conversion. It had to go back a second time as they hadn't replaced dirty odo wheels, and when it refitted it over-read by a full 10% which was annoying, until I reset the pointer on the shaft.

JDO Instruments offers a 48 hour turn round which has been verified by members of the MGOC MGB Technical forum. But for the purposes of balance someone ringing JDO about a repaired speedo that had failed had the phone slammed down on him with the words "I'm 80 years old and I don't need this", and someone else said he had used Speedy Cables with prompt return.

So there you are - your choice.

Speedo Drive Gears: March 2008

Looking at the parts lists there always were different speedo drive gears and pinions, with different ratios, between non-OD and OD. But whereas the ratio difference is nearly 3% for the 3-synch gearboxes, it is only 1% for the chrome bumper 4-synch (I don't have all the ratio information for the rubber bumper cars). 1% is insignificant (given that speedos in the UK are allowed to over-read by up to 10% but not under-read) so having the same tpms for both is reasonable, but why the different speedo part and reference number if everything else is the same? Even 3% difference for the 3-synch is not that significant in the grand scheme of things, but the speedo tpms for non-OD and OD cars did take this into account. Although even that isn't straight-forward, as the information I have is that Jaeger instruments were 1060 for non-OD and 1040 for OD, whereas the later (1964) Smiths were 1040 for non-OD and 1020 for OD! Whilst the change from crossply tyres to radial may have required a change in gearing, radials weren't available until 1965, and crossplies remained standard on UK cars until 1972.

The bottom line is that while changing a non-OD gearbox to an OD gearbox using 3-synch will introduce an error of nearly 3%, on a 4-synch car changing from a non-OD to an OD gearbox of the same era will only introduce a 1% error and can be ignored. The important thing to remember on 4-synch 4-cylinder cars is that the OD units changed from a black label to a blue label between CB and RB so if you put a rubber bumper OD gearbox in a chrome bumper car or vice-versa, and don't change the speedo, you will introduce an error of around 20% which is very significant. However the speedo size changed at the same time so it's not simply a case of fitting the speedo that came from the same car as the gearbox. V8s used a black label on both CB and RB, so no change in speedo tpm and all V8 tach and speedo instruments are 80mm.

Paradoxically using a 3-synch speedo on an RB car or vice-versa would only introduce a 2% to 5% error, unfortunately the speedos are different sizes at 4" and 80mm on RHD cars. One of the great mysteries of life is why LHD cars reverted to 4" from 80mm for the latest plastic dash in 1977 when RHD stayed at 80mm. On the face of it one of those would fit, but RB speedo and tach don't have provision for the ignition and main beam warning lights.

What speedo drive gears and pinions were used, where and when:

| Gearbox | Worm Gear | Starts | Pinion | Teeth | Ratio | |

| Chrome bumper 4-cylinder | 3-synch non-OD (dipstick level/filler) | 1H3369 (white plastic) | 9 | 11G3264 (white plastic) or 22H1420L | 28 | 1:3.111 |

| 3-synch OD (dipstick level/filler) D-type OD | 7H8294 (metal) | 5 | 17H8021 (metal?) | 16 | 1:3.2 | |

| 4-synch non-OD (dipstick level/filler) and Auto | 22B468 (metal) or 22B649 (white plastic) | 10 | 22B654 (white) | 26 | 1:2.6 | |

| 4-synch OD (dipstick level/filler) LH-type OD (black label) | 37H3464 (blue) | 8 | 37H3463 (white) | 21 | 1:2.625 | |

| Rubber bumper 4-cylinder | 4-synch non-OD (side-plug level/filler) | DAM686 (black) | 9 | DAM687 | 30 | 1:3.333 |

| 4-synch OD (side-plug level/filler) LH-type OD (blue label) | 37H8844 (red) | 6 | 37H8845 (red) | 20 | 1:3.333 | |

| All V8s Note 1 | 4-synch OD (side-plug level/filler) LH-type OD (red label but see Note 2) | 37H3464 (blue) | 8 | 37H3463 (white) | 21 | 1:2.625 |

Note 2: Label colours are nominal, with MGC having green according to one source and V8s red, however my V8 is black and Geoff Dunlop's in Australia is green. Ex Laycock people at Sheffield Overdrive Services have told me that if they didn't have the right colour available they used whatever they had to hand albeit stamped with the correct reference and serial numbers.

'Starts' refers to the number of threads on the worm gear fitted to the gearbox output shaft (a standard bolt only has one start). The number of starts is another way of setting the ratio between worm gear and cable drive pinion, the greater the number of starts the faster the pinion turns in relationship to the worm gear. This Wikipedia page explains the principle very well and has an animated graphic demonstrating a 4-start worm gear.

SC Parts Group has exploded diagrams of all the OD components (as well as the gearboxes) for all the MGB variants. All the pinions and drive gears are priced, implying that all are available.

Pinion Housing: August 2020

The LH OD housing (non-OD and D-type are different) has an O-ring seal to the gearbox body and a lip-type seal in the housing to prevent leaks from the pinion shaft. After replacing Vee's cable the new one is drawing oil up the cable to contaminate the speedo, so investigation with a view to seal replacement was called for.

The LH OD housing (non-OD and D-type are different) has an O-ring seal to the gearbox body and a lip-type seal in the housing to prevent leaks from the pinion shaft. After replacing Vee's cable the new one is drawing oil up the cable to contaminate the speedo, so investigation with a view to seal replacement was called for.

Why is this cable drawing oil up when the old one hadn't? There is a seal on the drive spindle, which seemed initially to be missing so I fitted one, but subsequent research indicated it should be well into the housing so one is probably already there. Checking about 50 miles later more oil has worked it's way about one quarter the way up again, so I'm going to have to get the housing and pinion out for inspection and replacing the original seal - probably with yet another new one. That means working with the back of the car as high as possible to limit the amount of oil that can run out, but some is bound to.

Why is this cable drawing oil up when the old one hadn't? There is a seal on the drive spindle, which seemed initially to be missing so I fitted one, but subsequent research indicated it should be well into the housing so one is probably already there. Checking about 50 miles later more oil has worked it's way about one quarter the way up again, so I'm going to have to get the housing and pinion out for inspection and replacing the original seal - probably with yet another new one. That means working with the back of the car as high as possible to limit the amount of oil that can run out, but some is bound to.

Late October after a 200-miler I take the speedo cable inner out ... and it was slathered in oil again right to the top. So oil still getting into the cable somehow, but the inside of the speedo was clear so maybe just caught it in time. Next step will be to disconnect the cable from the gearbox and see if anything drips out, and keeps dripping. Also to check the oil level and colour to see if it is as black as what's in the cable.

Early November I check the gearbox and the oil is clean as it should be, so the standard lubrication of the new cable is what must be blackening it. The level hasn't dropped in fact it's a bit high so I let some trickle out. Started removing the cable and the knurled nut didn't seem to be turning more freely or the cable coming loose in the nut, then I noticed the housing was turning! So out from under and back again with a selection of spanners to tighten the forked clamp that holds the housing in, didn't go fully tight, but after a few flats I tried again and this time the knurled nut came free. No oil came out, but I jacked up one rear wheel and ran it in 1st gear for a few minutes with the cable removed, to find a tiny drop of oil where the pinion exits my extra seal, so the housing will have to come off and the seal and pinion removed, examined and maybe replaced. I could replace just the seal at a few pence, but if the problem is the pinion it'll only happen again, and if I think it's fixed I probably won't know until the speedo packs up again. A pal had an OD rebuilt and the drive flange oil seal leaked straight away, they sent him a new seal and flange, so I'd expect the same.

Still under guarantee from the rebuilder (who sent the OD elsewhere) and he says if I can get them out to see what needs replacing he will contact the OD rebuilder. That's complicated as it may take a while to get the parts, I could get them locally but why should I? Also the back of the car would need to be raised quite a bit to prevent oil running out from the housing hole - OK for a removal and replacement with parts to hand, but I don't want to leave it like that. So it'll need draining. But unless I can catch it in a clean container for reuse that means another £40 for oil - which is almost twice the parts! I can use an empty oil can from an engine oil change earlier in the year as they are clean. But that will need a funnel or it could be very messy, and the funnel needs to be bigger than the drain hole or the funnel will overflow! Also the car needs to be high enough to get the can and funnel underneath and still leave space for me to remove the drain plug, without dropping it, for if that goes in the funnel it will block it and overflow!! But up on my full-length ramps it should be high enough, and will be level so safe to leave with the housing out for a while if needs be, but I'll need an oil change drain bucket to hand just in case, which will mean losing the oil. So much to think about and plan for, and yet another saga.

Late November: I decide to drain the oil so I can get the car up on the full-length ramps for ease of working underneath. I have an almost empty plastic 5L engine oil can with a short flexy spout. That and its housing can be levered off to leave a large hole in the can, which an old 1L gear oil container with the spout removed fits neatly inside to act as something of a funnel - I don't fancy unscrewing the drain plug and trying to get the sudden flow in the can otherwise without making a right mess. Underneath the drain plug moves easier than I expected - I don't think I checked its tightness on reinstallation! Too much room now, I'm going to have to hold the can and 'funnel' up closer to the gearbox while I'm undoing the plug. Do it over one of my large plastic drip-trays - just as well as some does run down the outside, but at least I don't drop the drain plug in as well, which was another fear. Drains in a few minutes so refit the plug - tightly! Only 2.25L in the can with 3.4L capacity quoted in the manual, something that figures as after draining and up-ending the gearbox after removal, then laying back down again, I did get quite a bit more out. Hope the remainder doesn't run out of the OD with the pinion housing removed!

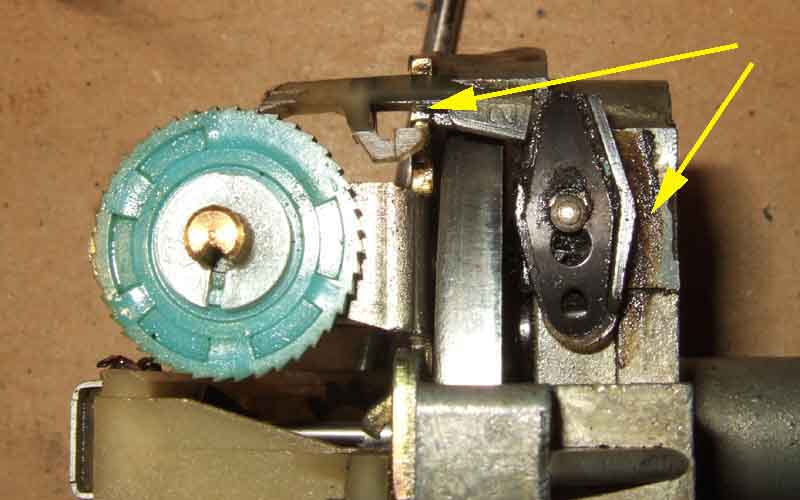

7/16" spanner to remove the bolt holding the forked clamp for the housing, and the housing starts sliding out on its own. Get the drip tray underneath while I fully remove it, thankfully no more oil. On the bench I remove the O-ring that seals the housing to the OD casing and the pinion slides out. A long fine scratch the length of the shaft i.e. passing through the oil seal - source of the leak? Closer examination shows witness marks from the seal round the shaft, but there is a definite gap part way round which indicates that part of the shaft was not in contact with the seal, and so a more likely source of the leak. My extra seal comes out easily enough, and is a good fit to the pinion shaft in terms of the resistance I can feel, but with the pinion back in the housing there doesn't seem to be any extra resistance from the original seal than there is from the housing itself. Now how to remove the original seal, which is well recessed in the housing?

7/16" spanner to remove the bolt holding the forked clamp for the housing, and the housing starts sliding out on its own. Get the drip tray underneath while I fully remove it, thankfully no more oil. On the bench I remove the O-ring that seals the housing to the OD casing and the pinion slides out. A long fine scratch the length of the shaft i.e. passing through the oil seal - source of the leak? Closer examination shows witness marks from the seal round the shaft, but there is a definite gap part way round which indicates that part of the shaft was not in contact with the seal, and so a more likely source of the leak. My extra seal comes out easily enough, and is a good fit to the pinion shaft in terms of the resistance I can feel, but with the pinion back in the housing there doesn't seem to be any extra resistance from the original seal than there is from the housing itself. Now how to remove the original seal, which is well recessed in the housing?

Really it needs some kind of puller that goes in from the speedo cable end, with fingers that go through the seal and can lock behind the metal surround. Then the housing would need to be held firmly while the seal was pulled out - back in the OD!? I opt for bending the end of an old flat-blade screwdriver towards a right-angle, and rounding the ends, to put in from the pinion end and drift it out rather than be pulled, and after a bit of tweaking that does the trick. While writing this I Googled 'small oil seal puller' and found someone else had done exactly that! Someone on that thread mentioned drilling and putting in a sheet-metal screw and pulling it out with that which I know can be done with larger seals but I think this is too small. However it did occur to me that a large screw through the centre of the seal biting into the metal surround might do the same job, but you would have to avoid damaging the part of the housing the pinion shaft runs in which is very close to the seal. Other possibilities were a pick with the tip partly curled back on itself, and other gadgets too complicated to explain and a lot more expensive. Anyway, it's out now.

Two problems immediately apparent - one is a fine scratch the length of the pinion shaft which may well be too fine to cause a problem, but the other concerns the witness mark of the seal on the shaft. There is a distinct gap in the witness mark, as if the pinion shaft has a slight flat at that point and isn't touching the seal, and I can definitely imagine that resulting in a leak. I email pics of both those areas to the gearbox man, together with a phone call, asking for replacements of pinion and both seals from the OD rebuilder, so Vee is out of action for the time being. If they refuse to cough up at least I can get them from Leacy's when I collect the front screen.

Two problems immediately apparent - one is a fine scratch the length of the pinion shaft which may well be too fine to cause a problem, but the other concerns the witness mark of the seal on the shaft. There is a distinct gap in the witness mark, as if the pinion shaft has a slight flat at that point and isn't touching the seal, and I can definitely imagine that resulting in a leak. I email pics of both those areas to the gearbox man, together with a phone call, asking for replacements of pinion and both seals from the OD rebuilder, so Vee is out of action for the time being. If they refuse to cough up at least I can get them from Leacy's when I collect the front screen.

Time to ponder fitting the new seal - fill the (small) gap between seal and housing with grease as an additional measure? At the very least it would lubricate the new seal and pinion shaft before oil works its way down. A second seal again but pushed all the way down if there is enough plain shaft left on the pinion spindle?

Tony at Geartech gave me the number for David at Overdrive Spares in Rugby who overhauled the OD and he sent me a new pinion, seal and O-ring with no quibble. When they arrived I tried the new seal on the new pinion and it seemed a much better fit than the old pinion had been in the old seal. Prior to fitting the seal I injected some grease in the seal end of the housing then pressed the seal into the housing using a suitably-sized socket. I then fitted the old pinion just into the seal from the 'wrong' end, and fitted the new pinion from the correct end, the intention being to squeeze the grease between the two pinions to fill the cavity between the seal and the shoulder in the housing, which worked well. Otherwise the end of the pinion would have pushed the grease straight out of the seal without spreading it round to fill the gap. Fitted the O-ring and bagged the assembly up prior to refitting tomorrow. The question then, will be whether to run the gearbox and overdrive after putting the oil back but before refitting the speedo cable ... or just to go for it. I wasn't bothered about doing that jacked up with one wheel removed when the car was on the ground and the wheel ramps, but doing that on the full-length ramps is a less attractive proposition.

Tony at Geartech gave me the number for David at Overdrive Spares in Rugby who overhauled the OD and he sent me a new pinion, seal and O-ring with no quibble. When they arrived I tried the new seal on the new pinion and it seemed a much better fit than the old pinion had been in the old seal. Prior to fitting the seal I injected some grease in the seal end of the housing then pressed the seal into the housing using a suitably-sized socket. I then fitted the old pinion just into the seal from the 'wrong' end, and fitted the new pinion from the correct end, the intention being to squeeze the grease between the two pinions to fill the cavity between the seal and the shoulder in the housing, which worked well. Otherwise the end of the pinion would have pushed the grease straight out of the seal without spreading it round to fill the gap. Fitted the O-ring and bagged the assembly up prior to refitting tomorrow. The question then, will be whether to run the gearbox and overdrive after putting the oil back but before refitting the speedo cable ... or just to go for it. I wasn't bothered about doing that jacked up with one wheel removed when the car was on the ground and the wheel ramps, but doing that on the full-length ramps is a less attractive proposition.

What a pain in the backside that was! It's bad enough that the housing is above the fixed crossmember with the bulge of the OD one side and the narrowing tunnel the other, so even with a smallish hand I can barely get two fingers on the head of the bolt from behind, and with another finger on the other hand from in front I can't see the hole I'm trying to get the bolt in. Not that I can see the hole with the Y-clamp in the way, to know I'm in the right place to start turning the head. I tried using a long screwdriver to position the head and allow me to see but it flapped about all over the place, and I can't feel when the end of the screw is in the hole, let alone lined up. The threaded end of the screw is recessed from flat which makes it worse, so I file the edges off to make it slightly rounded, but still no go. So housing out and try the bolt without the Y-clamp and it goes in straight away. Try the bolt and the Y-clamp and still no go, but try a 7/16" 1/4" drive socket as a 'holder' for the bolt and eventually it goes in, after packing the socket with paper so enough threads protrude and to wedge the bolt. At some point during all this the bolt slips out and falls onto my neck while lying horizontally underneath, then goes into my shirt so I have to crawl out from under and delve in my clothing to find it. Back under again and I realise I'm missing the lock washer, so back out again and more delving to find that. I then come to the realisation that the problem is caused by the housing flange coming right up to the edge of the bolt hole, so whilst I can tilt the bolt in most directions to help align the threads there is a good 90 degrees or more where I can't tilt the bolt towards the housing, so it has to be dead on square while I'm turning it up to a full rotation to pick up the thread. I'm sure it's easy enough off-car where you can use a nut driver on the bolt head and attack it square on, but in-situ it would make it so much easier if the flange on the housing were an 1/8" or so smaller, it's not as if it needs to be as wide as it is. Eventually I do manage to get it started using the socket as a holder, but it has to be spannered in the whole way as it must be right up against the flange on the housing. I found the same when removing it but didn't think much of it, whereas without the housing in place the bolt went in easily with finger-tips. Another few minutes fiddle saw the speedo cable connected, and that 2 hours was more than enough for the morning session!

After lunch it's refill with oil, I have a 1L bottle with flexy tube with about 500mL left over from filling it after the rebuild, plus the 2.25L I drained out this time in a clean 5L 'can'. So about half a dozen trips under the car after filling the 1L container to squeeze in as much in the side filler as I can which is about half a litre each time, before crawling out again to top up. Eventually I empty the big container and oil starts running out of the side filler so refit the plug, and there is a shade over 500ml in the 1L bottle so not quite as much in now as before. I'll leave it to settle then try again another day after having run the gearbox and OD to be sure oil has got everywhere, but that means getting it off the big ramps which means getting both cars out which needs a dry day! Not that I mind as I'm pretty knackered after what should have been no more than a few minutes to fit the housing and attach the cable. Subsequently checked and all OK.

March 2021: Only a few dozen miles done because of the poor winter weather, but worth a check to see if any more oil is being drawn up. Some at the top which isn't surprising as the inside of the outer would have been coated all the way up and excess would have beef driven upwards as before, but nothing more than what would seem like 'normal' lubrication the rest of the way down and particularly at the bottom, so hopefully problem resolved. I've not refixed the speedo back in the dash yet though until I've done a good few more miles, hopefully a 200-miler to son's and back ... when it's allowed!

April 2021: An Easter trip to son's sees said 200-miler sees the inner out next day. Only a little more than I would expect at the top and 'normal' at the bottom so it looks like the seal has done the trick, but I still only put the speedo back temporarily. Just as well as when I went out in the car the speed wasn't registering but miles were ... odd. Took it out, spinning a screwdriver in the cable drive registered on the speedo, so back in, but still no speed. Waggled it in the dash and the needle went up a bit ... then stuck there! Back out again needle has returned, took the mechanism out of the case and can't find anything wrong. Back in the car,. and at some point a light-bulb moment - literally. I suddenly remembered that when fitting LEDs to the instruments I had to put a sleeve on the speedo holder to stop it going in as far as the longer LED 'bulb' was interfering with the needle disk! Somehow each time I had put the LED back in I had contrived to push it in too far, and withdrawing it a little solved the problem. Phew! Still haven't fully refixed it back in the dash though.

Speedo cables March 2010

Erratic readings

Cable Replacement

Cable Routing

| Chassis No. | Gearbox | Cable | Length | Notes

| 101-9402 | (May 62-Mar 63) 101-138400 (May 62-Oct 67) RHD | LHD non-OD | GSD103 | 1143mm | (45") It seems highly unlikely, if not impossible, for RHD and LHD cables to be the same length | 101-10611 | (May 62-Apr 63) RHD | OD | GSD116 | 1422mm | (56") Not listed, some suppliers show GSD115 as 57", but GSD117 at 60" allows the speedo to be pulled forwards far enough to remove/refit that end in front of the dash rather than behind. | 101-138400 | (May 62-Oct 67) 10612-138400 (Apr 63-Oct 67) LHD | RHD OD | GSD117 | 1542mm | (60") It seems highly unlikely, if not impossible, for RHD and LHD cables to be the same length. | 9402-138400 | (Mar 63-Oct 67) RHD | non-OD | GSD111 | 1219mm | (48") | 138401-410000 | (Mk2-Jun 76) RHD | non-OD | GSD249 | 991mm | (39") | OD | GSD116 | 1422mm | (56") Not listed, some suppliers show GSD115 as 57", but GSD117 at 60" allows the speedo to be pulled forwards far enough to remove/refit that end in front of the dash rather than behind. | 138401-153877 (Canada) | (Mk2-Aug 68) 138401-187210 (roadster) (Mk2-Oct 69) 138401-187840 (GT) (Mk2 - Sep 69) LHD | non-OD | BHA4596 | 1270mm | (50") not USA, Sweden, Germany | OD | GSD151 | 1829mm | (72") not USA, Sweden, Germany | 138401-282419 (USA) | (Mk2-May 72) 153878-282419 (Canada) (Aug 68-May 72) LHD | non-OD | GSD104 | 1373mm | (54") North America, Sweden, Germany, without service indicator | 138401-410000 (USA) | (Mk2-Jun 76) 153878-410000 (Canada) (Mk2-Jun 76) LHD | OD | GSD151 | 1829mm | (72") North America, Sweden, Germany, without service indicator | 187211-328800 | (Oct 69-Aug 73) RHD | Auto | GSD103 | 1143mm | (45") | LHD | Auto | GSD116 | 1422mm | (56") not USA, Sweden, Germany. | Not listed, some suppliers show GSD115 as 57", but GSD117 at 60" allows the speedo to be pulled forwards far enough to remove/refit that end in front of the dash rather than behind. GSD117 | 1542mm | (60") North America, Sweden, Germany, without service indicator. | 282420-410000 | (May 72-Jun 76) LHD | non-OD | GSD145 | | North America, Sweden, Germany, without service indicator | 360301-386600 (Canada) | (Sep 74-Sep 75) 360301-422791 (Sep 74-Jan 77) LHD | non-OD | BHA5351 | | North America, Sweden, Germany, gearbox to service indicator | OD | BHA5360 | 1016mm | (40") North America, Sweden, Germany, gearbox to service indicator | all | BHA5359 | 584mm | (23") North America, Sweden, Germany, service indicator to speedo | 410001 on | (Jun 76-on) Whilst all previous cars seem to have the same sized fitting at the speedo end, RHD cars from this date, and from what I can tell LHD cars as well, have a bigger fitting so are not compatible with earlier cables, and vice-versa. RHD (all) | OD | GSD315 | 1450mm | (57") | LHD | non-OD | AAU3868 | 1200mm | (47") without service indicator | OD | AAU3870 | 1700mm | (67") without service indicator | All V8 | RHD | OD | GSD116 | 1422mm | (56") Not listed, some suppliers show GSD115 as 57", but GSD117 at 60" allows the speedo to be pulled forwards far enough to remove/refit that end in front of the dash rather than behind. | |

Speedo Fitting: May 2021:

Someone having problems with erratic readings which JDO said might be because the cable inner is pressed into the speedo too far. Cables do vary, with 77 and later appearing to project much further than previously, so I've taken some measurements, see the detail from clicking the attached thumbnail.

Someone having problems with erratic readings which JDO said might be because the cable inner is pressed into the speedo too far. Cables do vary, with 77 and later appearing to project much further than previously, so I've taken some measurements, see the detail from clicking the attached thumbnail.

Under reading of both the speedo and odometer can be caused by the gearbox drive flange nut not being tight enough (the drive gear is not splined into the shaft), D-type OD should be 100 to 130 ft lb, LH OD 55 - 60 ft lb, non-OD 150 ft lb. See here for how to hold the flange still while tightening (or undoing) the nut.

Regular downward pulsing of the needle, if coincides with the ODO tenths wheel moving, can be caused by a dry cable or speedo input shaft, a single drop of oil on the end of the shaft will cause no harm. If it flicks more frequently than that it is probably broken strands in the inner.

Cable Replacement: March 2020

Vee breaks her cable and as well as the turmoil created by Coronavirus and companies trying to keep going with people working from home, the part numbers and lengths are very variable between suppliers, which led to some head-scratching.

Vee breaks her cable and as well as the turmoil created by Coronavirus and companies trying to keep going with people working from home, the part numbers and lengths are very variable between suppliers, which led to some head-scratching.

Eventually resolved that, then about 150 miles later on our way up to the Lake District in July the speedo started flicking - damned new cable, I thought. But the flicks were upwards, getting higher and higher, until eventually the needle went all the way round to hit the back of the stop. Until we came to a halt, when it slowly went back to zero again, only to move all the way round again as soon as we started moving. That's got to be the speedo itself, and proved to be oil having worked its way up the cable and into the mechanism, acting as a viscous coupling between the spinning magnet and the needle disc. Eventually got that cleared, but not without damaging the main ODO in the process although I was able to replace it with the one from Bee's old speedo. Cleaning the cable an a few more miles showed more oil - so why not with the old cable? But all I can do is investigate the pinion housing.

Eventually resolved that, then about 150 miles later on our way up to the Lake District in July the speedo started flicking - damned new cable, I thought. But the flicks were upwards, getting higher and higher, until eventually the needle went all the way round to hit the back of the stop. Until we came to a halt, when it slowly went back to zero again, only to move all the way round again as soon as we started moving. That's got to be the speedo itself, and proved to be oil having worked its way up the cable and into the mechanism, acting as a viscous coupling between the spinning magnet and the needle disc. Eventually got that cleared, but not without damaging the main ODO in the process although I was able to replace it with the one from Bee's old speedo. Cleaning the cable an a few more miles showed more oil - so why not with the old cable? But all I can do is investigate the pinion housing.

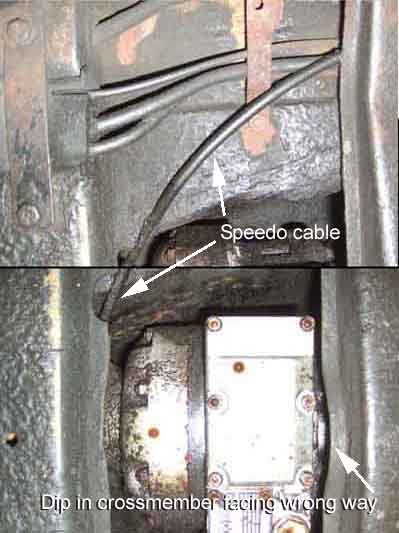

On OD gearboxes the cable attaches further back on the output of the OD and above the fixed cross-member. This cross-member on 4-synch cars has a notch which together with the connection being angled slightly forwards allows the cable to leave the gearbox at almost a right-angle, the bulk of the curve turning forwards being in front of the cross-member and under the floor. Early cars do not show this notch (Clausager p76), but 3-synch gearboxes with the earlier D-type OD do seem to offer more space to allow a right-angle drive to be used. However if a broken right-angle drive on a non-OD gearbox was not replaced (they are expensive) this may need a slightly longer cable to avoid a tight turn.

On OD gearboxes the cable attaches further back on the output of the OD and above the fixed cross-member. This cross-member on 4-synch cars has a notch which together with the connection being angled slightly forwards allows the cable to leave the gearbox at almost a right-angle, the bulk of the curve turning forwards being in front of the cross-member and under the floor. Early cars do not show this notch (Clausager p76), but 3-synch gearboxes with the earlier D-type OD do seem to offer more space to allow a right-angle drive to be used. However if a broken right-angle drive on a non-OD gearbox was not replaced (they are expensive) this may need a slightly longer cable to avoid a tight turn.

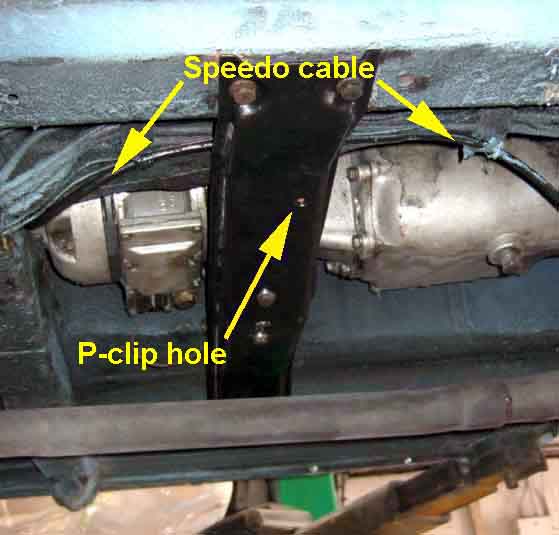

It should then pass under the removable cross-member and be supported by a P-clip, however both Bee and Vee have theirs above and cable-tied to the other cables and pipes. In Bee's case the cross-member is the wrong way round so the tapped hole is on the other side. And whilst Vee's is correct, and I could have fitted it in the correct position, where they are is more protected from any rocks, traffic-calming measures etc. and as neither have exhibited any problems in my ownership where they are I've left them be (until I replaced the cable).

It should then pass under the removable cross-member and be supported by a P-clip, however both Bee and Vee have theirs above and cable-tied to the other cables and pipes. In Bee's case the cross-member is the wrong way round so the tapped hole is on the other side. And whilst Vee's is correct, and I could have fitted it in the correct position, where they are is more protected from any rocks, traffic-calming measures etc. and as neither have exhibited any problems in my ownership where they are I've left them be (until I replaced the cable).

Clausager shows a clip holding it to the tunnel wall by the clutch slave on a Mk1, no reason to assume it isn't the same on later cars although neither Bee nor Vee have it.

Clausager shows a clip holding it to the tunnel wall by the clutch slave on a Mk1, no reason to assume it isn't the same on later cars although neither Bee nor Vee have it.

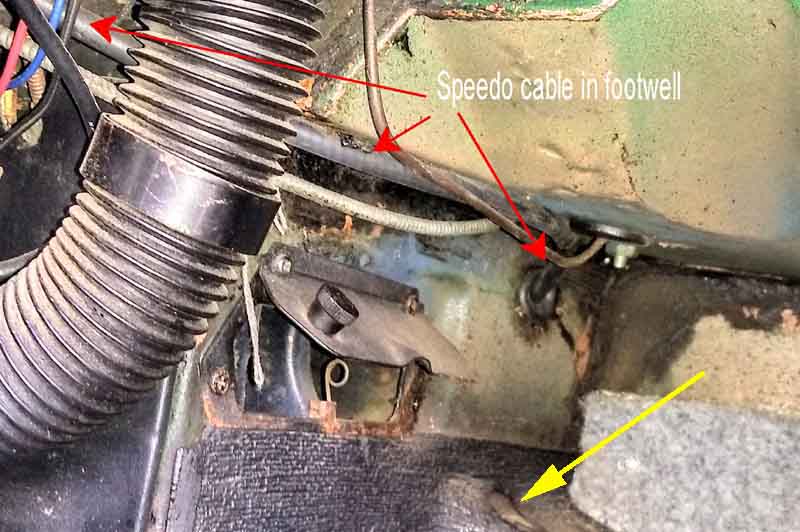

On RHD cars it passes through the bulkhead via a hole in the top of the drivers footrest, and from there makes a graceful turn up and back into the RHD speedo head.

On RHD cars it passes through the bulkhead via a hole in the top of the drivers footrest, and from there makes a graceful turn up and back into the RHD speedo head.

There is also the question of right-angle drives.

The Parts

Catalogue doesn't show or list one with the 3-synch standard box but does show and list 13H2567 (120694) with the D-type OD. The drive on the 3-synch standard box exits pointing slightly backwards, and on the D-type OD comes out at a right-angle to the line of the gearbox, which means especially for the non-OD gearbox a right-angle drive allows the speedo cable to run straight forwards and makes sense.

The Parts

Catalogue doesn't show or list one with the 3-synch standard box but does show and list 13H2567 (120694) with the D-type OD. The drive on the 3-synch standard box exits pointing slightly backwards, and on the D-type OD comes out at a right-angle to the line of the gearbox, which means especially for the non-OD gearbox a right-angle drive allows the speedo cable to run straight forwards and makes sense.

It lists but doesn't show the same item for 4-synch non-OD boxes but lists and shows it for the LH-OD but is completely unsuitable for both. The drive is angled forwards, which not only makes it difficult to attach a right-angle drive and cable especially on the OD with its casting bulge right next to it, but the fixed crossmember has a notch to allow a longer cable to make a smooth turn direct off the gearbox or OD, and the removable crossmember has provision for a clip to support the cable closer to the chassis rail.

It lists but doesn't show it for the automatic box, but exiting at right-angles similar to the 3-synch it does need one.

An important factor on BL gearboxes at least is the provision of copper spacer washer 3H550 between the angle-drive and the gearbox, usually listed in the Parts Catalogue with the angle-drive. Without that there are excessive end-loads on the angle-drive resulting in premature failure, possibly from the square drive shaft protruding too far.

An important factor on BL gearboxes at least is the provision of copper spacer washer 3H550 between the angle-drive and the gearbox, usually listed in the Parts Catalogue with the angle-drive. Without that there are excessive end-loads on the angle-drive resulting in premature failure, possibly from the square drive shaft protruding too far.

What about the speedo end?

The Parts Catalogue indicates one for the speedo as well - BHA 4794 - for Sweden and Germany from chassis number 187211 (1970 model year), North America from 258001 (1972 model year) to 282419 (May 1972), then 13H2567 for apparently all 1977 and later LHD cars. It would have been needed where the cable came up into the right-hand footwell as for RHD cars (which is at the top of the clutch foot rest) then across the car behind the dash. This would have resulted in too tight a turn behind the LHD speedo in the limited space available, hence the second unit. A number of people with LHD cars have said their cable comes up past the RHD entry point, across the engine compartment at the heater shelf, then in through the bulkhead in front of the driver direct to the speedo, rendering a speedo head right-angle drive unnecessary. This includes 3-synch cars using the large hole under the hinge slot, although Clausager appears to show a 74 car routed in this manner but using a smaller hole further above and towards the centre of the car than the large hole (which contains the heat control cable?).

The Parts Catalogue indicates one for the speedo as well - BHA 4794 - for Sweden and Germany from chassis number 187211 (1970 model year), North America from 258001 (1972 model year) to 282419 (May 1972), then 13H2567 for apparently all 1977 and later LHD cars. It would have been needed where the cable came up into the right-hand footwell as for RHD cars (which is at the top of the clutch foot rest) then across the car behind the dash. This would have resulted in too tight a turn behind the LHD speedo in the limited space available, hence the second unit. A number of people with LHD cars have said their cable comes up past the RHD entry point, across the engine compartment at the heater shelf, then in through the bulkhead in front of the driver direct to the speedo, rendering a speedo head right-angle drive unnecessary. This includes 3-synch cars using the large hole under the hinge slot, although Clausager appears to show a 74 car routed in this manner but using a smaller hole further above and towards the centre of the car than the large hole (which contains the heat control cable?).

The question is what happened on LHD cars prior to the 1970 model year? Did they run across the bulkhead in the engine compartment like post-May 72 cars and hence not need one? If so it seems odd that they then brought it inside the cabin for two years, needing a second drive, but a different part to the gearbox one. But this 1968 model has the cable inside the cabin in the right-hand footwell, and has a right-angle drive on the speedo.

The question is what happened on LHD cars prior to the 1970 model year? Did they run across the bulkhead in the engine compartment like post-May 72 cars and hence not need one? If so it seems odd that they then brought it inside the cabin for two years, needing a second drive, but a different part to the gearbox one. But this 1968 model has the cable inside the cabin in the right-hand footwell, and has a right-angle drive on the speedo.

North American rubber bumper cars had an EGR valve service indicator from 1975 which was a warning light triggered every 25,000 miles. A resettable counter intercepted the speedo cable, and was positioned on the bulkhead as shown here on Bill Etter's car. The warning light was illuminated each time the car was started as a lamp test facility. The service indicator was deleted for Canada from 1976 on, and for the rest of North America from 1977 on, which ties in with one of the speedo cable changes listed above.

North American rubber bumper cars had an EGR valve service indicator from 1975 which was a warning light triggered every 25,000 miles. A resettable counter intercepted the speedo cable, and was positioned on the bulkhead as shown here on Bill Etter's car. The warning light was illuminated each time the car was started as a lamp test facility. The service indicator was deleted for Canada from 1976 on, and for the rest of North America from 1977 on, which ties in with one of the speedo cable changes listed above.

Prior to the electronic tachometer a mechanical rev counter was used which was cable driven from the engine block. According to the Parts Catalogue the rev counter ended at chassis number 48765 and the electronic tach started at 48766. The engine changed from 18GA to 18GB at that time, but there was a short period when either engine could have been fitted. According to Clausager the 5-bearing was fitted intermittently from chassis number 47112 with all cars having them at chassis number 48767. This means that cars from 47112 to 48765 that got the 5-bearing would have had the electronic tach as well as there was nowhere on the 18GB to connect the rev counter cable. However 3-bearing engines could have had the rev counter port blanked off and a tach fitted at any time, with suitable wiring changes.

Prior to the electronic tachometer a mechanical rev counter was used which was cable driven from the engine block. According to the Parts Catalogue the rev counter ended at chassis number 48765 and the electronic tach started at 48766. The engine changed from 18GA to 18GB at that time, but there was a short period when either engine could have been fitted. According to Clausager the 5-bearing was fitted intermittently from chassis number 47112 with all cars having them at chassis number 48767. This means that cars from 47112 to 48765 that got the 5-bearing would have had the electronic tach as well as there was nowhere on the 18GB to connect the rev counter cable. However 3-bearing engines could have had the rev counter port blanked off and a tach fitted at any time, with suitable wiring changes.

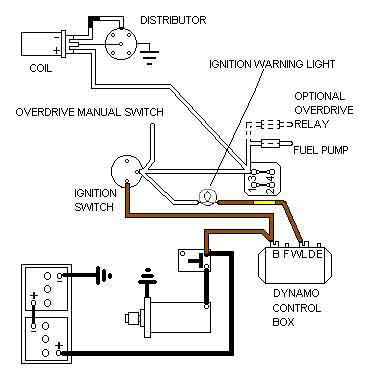

Schematics ![]()

Description

Problems

Electronic ignition

Testing October 2013

Internal and external seals

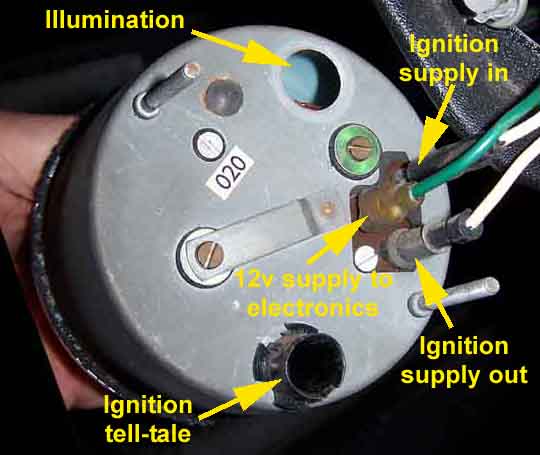

Description: There have been two types of electronic tachometers - the earlier RVI inductively-coupled type (which came in two versions - positive earth and negative earth) and the later RVC directly connected type. The inductively coupled type uses the white wire that goes from the ignition switch via the tach to the coil for triggering. The wire is looped round the tach pick-up and will only work the right way round. The RVC directly connected type was only used on negative earth cars and uses a black/white from the coil -ve (the same terminal as the points wire from the distributor) which terminates on a bullet-type connector at the tach rather than a flat spade. 1962-64 cars used a mechanical rev-counter.

Secured into the dash with two large 3BA knurled nuts 17H1304 and spring-washers, with a U-strap AJH5176 to September 64, separate 'legs' 17H3744 on each threaded stud from then until July 74, and 17H1339 after that until the 1977 model year.

Secured into the dash with two large 3BA knurled nuts 17H1304 and spring-washers, with a U-strap AJH5176 to September 64, separate 'legs' 17H3744 on each threaded stud from then until July 74, and 17H1339 after that until the 1977 model year.

1977 and later have a much better arrangement where the tach and speedo have three studs in the instrument case, and by turning them clockwise 30 degrees these studs will align with cut-outs in the dashboard to allow the instrument to be withdrawn. Unfortunately LHD only.

1977 and later have a much better arrangement where the tach and speedo have three studs in the instrument case, and by turning them clockwise 30 degrees these studs will align with cut-outs in the dashboard to allow the instrument to be withdrawn. Unfortunately LHD only.

The tach is powered from the white (unfused) ignition circuit on Mk1 cars, then for Mk2 cars onwards from one of two green (fused) circuits. Until 1978 this was the green circuit in the fusebox, but when the ignition relay circuit on RHD cars was modified sometime in 1978 and a second in-line fuse between brown/white and green wires was added under the fusebox, the tach is powered from one of these - the one with the thinner wires, the other with thick wires being for the cooling fan. For more information see the ignition schematics.

Tachometers were marked with the original polarity - positive and negative - from inception, at least until they changed from chrome bezels to plastic for the 1977 model year. But bear in mind that a PO may have changed the internal wiring of a positive earth tach and not changed the legend on the dial.

Tachometers were marked with the original polarity - positive and negative - from inception, at least until they changed from chrome bezels to plastic for the 1977 model year. But bear in mind that a PO may have changed the internal wiring of a positive earth tach and not changed the legend on the dial.

Serial numbers (on the faceplate) were as follows:

| Year | Chassis Nos. | Market | Battery Earth/Ground | Sensing | Pickup Location | Size | Reference No. |

| 1964-67 | 48766-138360 | All | Positive | Current | External | 4" | RVI/2401/00B |

| 1968 | 138401-153877 | Canada | Negative | Current | Internal | 80mm | RVI/2430/00 |

| 1968-71 | 138401-256646 | USA | Negative | Current | Internal | 80mm | RVI/1433/00 |

| 1968-71 | 153878-256646 | Canada | Negative | Current | Internal | 80mm | RVI/1433/00 |

| 1968-72 | 138401-294250 | Not North America | Negative | Current | Internal | 4" | RVI/2430/00 |

| 1972 | 258001-294250 | North America, Sweden, Germany | Negative | Current | Internal | 80mm | RVI/1439/00 |

| 1973-74 | 294521-360069 | not North America, Sweden, Germany | Negative | Voltage | N/A | 4" | RVC/2415/00AF |

| 1974.5-76 | 360301-409401 | not North America, Sweden, Germany | Negative | Voltage | N/A | 80mm | RVC/1410/00AF |

| 1973-76 | 294251-409401 | North America, Sweden, Germany | Negative | Voltage | N/A | 80mm | RVC/1410/00AR |

| 1977-80 | 410001-on | RHD | Negative | Voltage | N/A | 80mm | RVC/1414/00F |

| 1977-80 | 410001-on | LHD | Negative | Voltage | N/A | 4" | RVC/2432/00F |

| All | All | V8 | Negative | Voltage | N/A | 80mm | RVC/1810/00 |

Note 2: The change to 1968 Canadian models occurred part way through the year.

Note 3: There were gaps in chassis numbers. From November 1967 with the advent of the Mk2, most model years thereafter started at a 'round number' e.g. the last 1971 model was 256646 (a GT) and the first 72 model was 258001 (a roadster).

The RVI with external pickup either uses a white wire from the harness through the pickup, or may have a short section of white wire with bullet ends already in the pickup. In the former case there may be a long length (4 ft has been mentioned) of white coming out of the harness with a spade on the end, and this goes through the pickup then connects to an 'ignition on' spade on the ignition switch. This makes it easy to determine which way the wire has to go through the pickup. In the latter case the harness may have two separate whites with bullet ends, but it's an easy job to swap them over if at first the tach doesn't work. These tachs will only work with the current going through the pickup in one direction and you have to reverse it if you convert a positive-earth car to negative as well as reversing the 12v and earth connections. You will not harm the tach if the pickup is wired the wrong way round, but may do if the 12v supply is incorrect.

The RVI with external pickup either uses a white wire from the harness through the pickup, or may have a short section of white wire with bullet ends already in the pickup. In the former case there may be a long length (4 ft has been mentioned) of white coming out of the harness with a spade on the end, and this goes through the pickup then connects to an 'ignition on' spade on the ignition switch. This makes it easy to determine which way the wire has to go through the pickup. In the latter case the harness may have two separate whites with bullet ends, but it's an easy job to swap them over if at first the tach doesn't work. These tachs will only work with the current going through the pickup in one direction and you have to reverse it if you convert a positive-earth car to negative as well as reversing the 12v and earth connections. You will not harm the tach if the pickup is wired the wrong way round, but may do if the 12v supply is incorrect.

The RVI with internal pickup has male and female bullets on the back of the case, and corresponding bullets on two white wires from the harness. Note that these seem to be smaller than the standard wiring bullet and connectors at 4.5mm instead of 5mm (Malc Gilliver). The spade for the 12 supply to the tach electronics is close by the bullet connectors. The harness now has separate white wires with female and male respectively bullet connectors, meaning incorrect connection is not possible. Both RVI type tachs sense coil current and respond to the current pulses through the coil as the points open and close. If that circuit breaks the engine stops, if it shorts to earth you fry the harness! The earth wire for both the electronics and the instrument lighting is under one of the knurled wheels holding the tach into the dash.

The RVI with internal pickup has male and female bullets on the back of the case, and corresponding bullets on two white wires from the harness. Note that these seem to be smaller than the standard wiring bullet and connectors at 4.5mm instead of 5mm (Malc Gilliver). The spade for the 12 supply to the tach electronics is close by the bullet connectors. The harness now has separate white wires with female and male respectively bullet connectors, meaning incorrect connection is not possible. Both RVI type tachs sense coil current and respond to the current pulses through the coil as the points open and close. If that circuit breaks the engine stops, if it shorts to earth you fry the harness! The earth wire for both the electronics and the instrument lighting is under one of the knurled wheels holding the tach into the dash.

See here for a description of the external pickup type from Mark Olsen's Sunbeam Tiger pages, and here for the later 2430/00 RVI with internal pickup by Herb Adler. However neither say much about the thermistor, this thread from The Sunbeam Owners Club of America states the original should have a value of 150 ohms at room temperature, but items in the 200 to 500 ohms should be able to be used successfully. A negative temperature coefficient (NTC) item is required, there are positive temperature coefficient (PTC) items around which are not suitable. Unfortunately suppliers in the UK only seem to stock items in the thousands of ohms, not hundreds of ohms.

With the RVC voltage-operated type the ignition current does not go via the tach, instead a wire from coil -ve/points connection goes to the tach on a white/black wire, which responds to the voltage changes as the points open and close. If this circuit breaks the tach ceases to register and the engine continues to run. If it should happen to short to earth the engine will stop, but not fry the harness. (In fact this makes a nifty anti-theft device using a hidden normally open switch connected to the wire at the tach rather than in the engine compartment.) Since the current flowing through the coil has a direct relationship with the voltage at the coil CB or -ve terminal it follows that the two types indicate the same thing.

With the RVC voltage-operated type the ignition current does not go via the tach, instead a wire from coil -ve/points connection goes to the tach on a white/black wire, which responds to the voltage changes as the points open and close. If this circuit breaks the tach ceases to register and the engine continues to run. If it should happen to short to earth the engine will stop, but not fry the harness. (In fact this makes a nifty anti-theft device using a hidden normally open switch connected to the wire at the tach rather than in the engine compartment.) Since the current flowing through the coil has a direct relationship with the voltage at the coil CB or -ve terminal it follows that the two types indicate the same thing.

See here for information about the RVC tach by Herb Adler, Franz Hubl and Rick Astley.

Typical problems are sticking, wavering, or simply not working at all. Sticking, where a rap with a knuckle on the glass fixes it, and it only occurs after being parked for a while or at certain times of year, is almost certainly a mechanical problem with the movement itself.

Wavering or flicking about, if accompanied by changes in the idle speed, have a good chance of being caused by bad connections in the ignition LT circuit that is ignition switch - coil (via tach where appropriate) - points - earth.

Wavering or flicking about not accompanied by changes in idle speed, randomly dropping to zero for longer periods, or not working at all, could be either the 12v supply to the tach, the connection between coil and tach on the later voltage-operated types, or electronic problems inside the tach itself. From 64 to 67 the tach was powered from a third white (unfused ignition) wire and black earth but after that it was from a green (fused ignition) and black earth for both current- and voltage operated types. In no case is the tach powered from the instrument voltage stabiliser as the output from this is 12v switched on and off about once a second and so is unsuitable for the tach for obvious reasons. Get a multi-meter with an rpm range, connect it to the points-side of the coil, and compare that with the cars tach. If they shows similar variations then there is a problem in the ignition LT circuit through the ignition switch, coil and points. If it is steady when the cars varies, and you have the voltage operated tach, then connect the multi-meter to the white/black at the tach. Variation here but not before would indicate problems with the white/black wire or connections between tach and coil. If that is steady too, or if it was steady at the coil and you have a current-operated tach, monitor the 12v supply and earth at the tach. If these are steady too then the problem must be inside the tach itself.

If it works normally with the lights off, but doesn't work at all with them on, then the earth supply is probably missing. Early tachs have the earth connection as a tag under one of the knurled securing nuts (as on the other gauges). Later cars have a spade spot-welded to the back of the case, as well as the insulated 12v spade. A similar problem can affect headlights where relays have been installed when the speedo earth is missing and the main-beam tell-tale is in the speedo.

Very occasionally there are reports of the tach shooting up when the ignition is turned on but before the engine is started, or swinging right round to max with the engine running. About all you can do here is to unplug the illumination bulb and disconnect the trigger wire or wires, and see what happens with just the green 12v supply wire (white on Mk1 cars) and black wires connected. If you have 12v between the spade the green (or white) is connected to and the case, and zero volts between the case and a known good earth elsewhere on the car, and the tach is still registering incorrectly, then it is an internal problem. If it has suddenly happened it is quite likely to be a dry joint or cracked PCB track which may be visible, or a component fault which probably won't be. If you have less than 12v between the green (white) and the case, or any voltage at all between the case and a known good earth elsewhere, then the 12v supply or earth is faulty.

See here for information on companies that repair instruments.

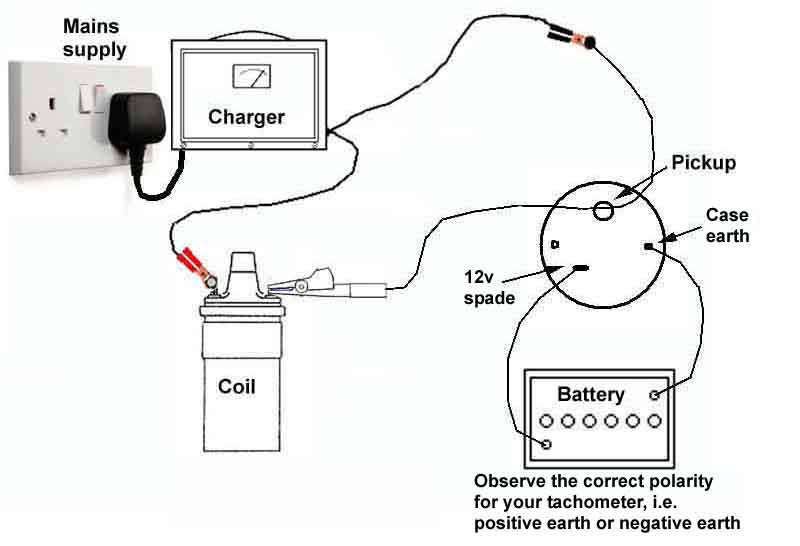

There are several sites around showing how the original tach circuit can be replaced with one using a 555 timer - two examples here and here, and another example using a different IC here. All can be done to both RVI and RVC tachs, although in the first and third cases this would effectively convert an RVI to an RVC and would need a trigger wire from the coil CB or -ve instead of sensing the current pulses in the white wire going to the coil SW or +ve. Initial testing and calibration can be done using a basic battery charger as described here, then comparison with a separate instrument such as in a strobe light or automotive multi-meter which are likely more accessible.

July 2024: If you are not into building circuits there are also a couple of options to convert faulty RVI tachs to RVC using a pre-built circuit board from here and here which looks like the same module but cheaper for slower delivery. The modules may or may not fit into an RVC case.

This Easyfit module keeps the tach as an RVI avoiding wiring changes.

Electronic ignition: July 2011: If your RVI tach (64 to 72) doesn't work with your shiny new electronic ignition system, there are a couple of things you can try, depending on whether you have a positive earth car or a negative. Originally the 'fix' was to try changing the wire going through the pickup from two passes (one turn) to one pass (half a turn) and recalibrating. You will need to dismantle the tach to do that on later versions with the pickup coil inside. Subsequently Herb Adler reported that a 123 used with an RVI tach on a negative earth car (67 to 72) caused problems when following the instructions to connect the red (power) lead of the 123 to the Batt (+12v) terminal of the coil. He found that connecting this to an alternative 12v ignition source that didn't come through the tach pickup, e.g. the white at the fusebox, solved the problem. This shouldn't be necessary with the later RVC tachs, but is worth trying if you have other electronic ignition systems and tach problems. Note that this alternative connection is often recommended when putting electronic ignition on rubber bumper cars (i.e. with the ballasted ignition system), as the electronics are then fed with the full 12v and not the reduced and varying voltage.

Herb also reports that an RVI tach he had modified for 6-cylinders has R6 (see the above Tiger pages) at 820 ohms instead of 470 ohms.

Positive earth cars: June 2021

Pertronix/Aldon positive earth Ignitors are wired completely differently to negative earth in that the Ignitor is in the 12v supply to the coil (SW) instead of replacing the points, and the points side of the coil (CB) is taken direct to earth. This means that the alternative source of 12v for the Ignitor to allow the tachometer to work correctly cannot be used, and Aldon for example say that the tach might have to be converted to the later RVC (which at the time of writing is an additional £42). But this Lotus Elan site suggests an additional wiring change which should - in theory! - work. That is to remove the existing white wire from the tach pickup and run a new black earth wire from the coil CB terminal round the tach pickup (in the same direction as the original white wire) and then to the tach earth.

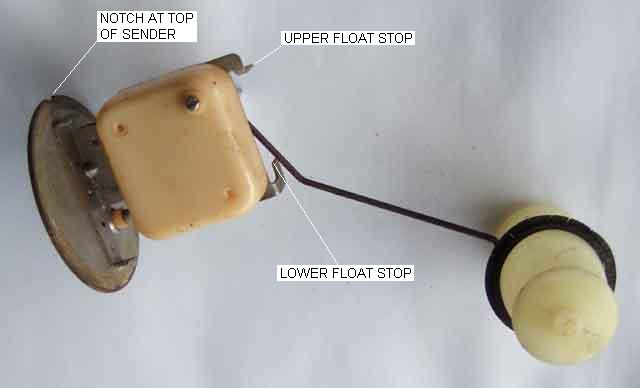

Pertronix/Aldon positive earth Ignitors are wired completely differently to negative earth in that the Ignitor is in the 12v supply to the coil (SW) instead of replacing the points, and the points side of the coil (CB) is taken direct to earth. This means that the alternative source of 12v for the Ignitor to allow the tachometer to work correctly cannot be used, and Aldon for example say that the tach might have to be converted to the later RVC (which at the time of writing is an additional £42). But this Lotus Elan site suggests an additional wiring change which should - in theory! - work. That is to remove the existing white wire from the tach pickup and run a new black earth wire from the coil CB terminal round the tach pickup (in the same direction as the original white wire) and then to the tach earth.