Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

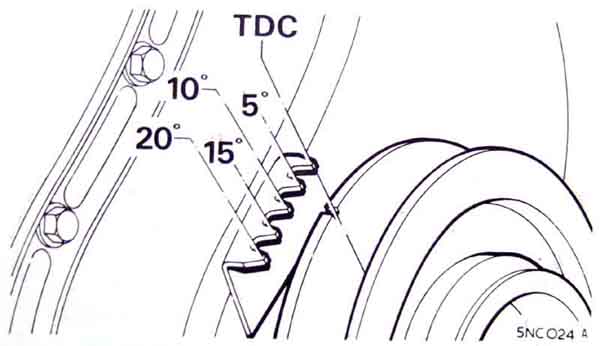

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

Engine

|

The socket for the crankshaft pulley nut is 1 5/16" AF (same as for the Salisbury/tube axle hub nut).

Gasket sealants - don't use silicone-based as they 'go off' very quickly and on large areas will 'skin' before you can get the surfaces together and not spread out to an even thin coating. Use something non-hardening such as Loctite MR5922, and only a thin smear. Great gobs of it will get extruded out into the works and in the screw holes can rip paper/card/cork gaskets as they are tightened. Overtightening screws can cause covers to warp between adjacent bolt holes and leak more, check they are flat before fitting.

Haynes mentions changing the big-end and main bearings periodically irrespective of condition for maximum engine life, presumably to minimise crankshaft journal wear. However it gives 30k for big-ends and 50k for main bearings, which seems a bit daft as after several sets of changes you would be doing one just before or just after the other. But that's only likely to be done on continuously high-mileage engines, and how many of our engines do that these days? Vee was my daily driver for some years travelling up to 150 miles per day, but that must be pretty unusual. Bee used for just pleasure touring has only done 60k in my hands in 30 years. I checked Vee's clearances after getting-on for 100k and all of them were either at or just inside the tolerance for new bearings, with minimal scuffing and no copper showing though, so for 'normal' road use it's not worth bothering with especially if the engine is otherwise running well - "If it ain't broke keep fixing it until it is".

Compression Testing Added July 2010

When performing a compression test the engine should be at normal working temperature, remove all the plugs, and wedge the throttle wide open, then test each cylinder 'dry' noting the results. From the Workshop Manual high-compression engines (8.8:1) should be 160psi and low compression (8.0:1) 130psi for 18G engines. 18V high compression are slightly higher at 9.0:1 and 170psi at 275rpm. However 18V engines to European emission control requirements ECE 15 are quoted as 170 to 190 or 195psi, although some have said that pressure can't be reached with 9.0:1 compression ratio. June 2014 After 25 years I've done a compression test on Bee prior to changing the head gasket due to combustion gases in the radiator. 1, 3 and 4 were 160 to 173psi dry, 173 to 185psi wet (so maybe the WSM '170 to 190' refers to both dry and wet testing). No 2 was 127psi dry and 138psi wet. The dry to wet increase is pretty-much the same for all, so bores look OK, but I need to check the valves to see if that's the cause of 2 being low, or whether it is something else. Compressed air forced into No.2 indicated it was the exhaust valve that was leaking, and head off with petrol poured into each combustion chamber confirmed it. No visible damage to valve or head seat, and mild lapping-in stopped the leak. However by the end of 2017 it was doing it again.

The general rule of thumb is that anything more than 10% difference from the lowest to the highest warrants investigation (or is it?), and in reality they should be closer than that under normal circumstances. 2 and 3 down relative to 1 and 4 could indicate a head gasket leak between 2 and 3, where the gasket width is very narrow. For engines where one or more cylinders are low go round the cylinders again putting a teaspoonful of oil into each immediately before testing it, this is a 'wet' test. If a low cylinder increases significantly from the dry to the wet test, i.e. goes up more than the others, that generally indicates worn bores or ring problems. If a low cylinder doesn't increase from the dry to the wet that indicates valve problems, although this is generally accompanied by a regular beat in the exhaust or intake, indicating an exhaust or intake valve respectively. Disconnecting each plug lead in turn should locate the faulty cylinder, when you get a double beat in the exhaust it's not that cylinder, when you get a single beat but more pronounced it will be that cylinder. A little more difficult to determine which inlet valve is at fault using this method though. This may seem a bit pointless if you are going to remove the head anyway, but if the problem is a sticking valve when hot you do need to know which valve it is likely to be first. Another neat way of diagnosing a sticking valve is with an adjustable timing light. In a dark garage, clipped to each plug lead in turn and pointed at the appropriate valve with the rocker cover removed, by turning the adjuster back and fore you should be able to freeze the valve anywhere from fully down to fully up and so see if it is sticking partly down or not. It will help to raise the back of the car relative to the front during this test, to put the engine fully horizontal, to reduce the amount of oil running down the back of the engine with the cover off.

One tip may be to disconnect the fuel pump and run the carbs dry before starting the test, i.e. once fully warmed. I say this because although I have had my Gunson's compression gauge for about fifteen years I can't have used it more than ten times in that period, and yet when I lent it to a neighbour recently it wouldn't hold the pressure, because the hose had perished right by the brass fitting that screws into the plug hole. It was fine just 1/2" back from there, so I trimmed it back and secured it with a clamp and it is working again, but it did make me wonder if it had sucked fuel in during the test (throttle wide open remember) and that had perished the hose. Emptying the carbs would prevent that, but if you do the wet test some oil is likely to get in anyway.

Funny figures? April 2018 After having the head converted to unleaded the first thing I did after bolting it down was to do a compression check to make sure everything was OK, and that was before fitting the carbs or anything else. Consequently it was a 'cold' test, and with no carbs effectively 'throttle open', and all plugs out. I did the valve clearances very roughly, just making sure there was a gap at the 'Rule of Nine' (RON) point, but not bothering about the value ... and got some unexpected results - 104 136 110 132. Very low, and all over the place. Thinking it may be something to do with the random clearances I set them at the standard RON points and got 125 135 122 150. A bit more consistent, but not much, and still low. So I did them again but this time at the point of maximum gap and got 138 150 124 145. Generally a bit higher, but still quite variable.

By now I was wondering if it was down to the engine being cold, so carried on with the reassembly and got it running. The next tests were when hot and all plugs out - dry 157 157 152 162 and wet 170 170 156 165. Better again, and more consistent, but still quite a bit down on the book figure of 170 which I have always assumed was dry. Then I realised I had done them with the throttle closed, so after another run to get up to full temp I did them again this time with the throttle open, dry and plugs out and got 140 142 150 150. This was lower than the closed dry test, I had expected open to be higher. So on another occasion after a run yet another set of tests, this time doing closed followed immediately by open on each cylinder, all dry, plugs out, and got closed 149 open 152 closed 158 open 153 closed 151 open 153 closed 168 open 169. So some higher open than closed, some the other way round, and some with very little difference! After cylinder 2 I did 3, then back to 2 and got exactly the same result, which indicates to me that individual cylinders aren't varying from moment to moment, only from one round of tests to the next.

By now getting thoroughly confused I consulted Peter Burgess. He wrote back to say that he could never understand how the MGB pressures are as high as they are given the slow cranking speed, and also found that looking for the point of maximum gap was preferable from a tappet noise point of view to the standard RON point. He couldn't offer any suggestions as to the throttle open and closed variations.

Thinking about it and looking at how the valves operated I reckoned that as the inlet valve only closes part way into the compression stroke, the later the valve closes the bigger the effect on compression would be, and the smaller the gap just before it starts to close the later it will close. So I readjusted just the inlet valves, this time so that the clearance was 14 to 16 thou just before it started to move. Another hot dry test all plugs out, and I got 160 170 160 170! So finally up to the book values, and the least variation. However done like that the maximum gap on some of them was much bigger than book, and they clattered like billy-oh. Can't live with that, so spent a long time with a dial gauge on all eight valves determining the maximum gap and adjusted them there, noting the position of other valves to save time in the future, and going round three times to confirm I had the right points. A quick start-up showed the engine to be much quieter, and I await some dry weather to get it fully up to temperature for another compression check.

For interest the maximum gap points are as follows:

2 - 1 half way up

3 - 4 fully down

4 - 5 half way down

5 - RON point

6 - Just before 5 fully down

7 - 8 just fully down

8 - 1 just started to go down

For No.5 the RON point is suitable as it was at max over a wide range of cam rotation including while No.4 was fully down. For the others, as well as being away from the strict RON point (some of them a long way off) they also needed to be done in a pretty precise location as they weren't at a max for very long. All I need to do now is to order these ideally so as to be able to have done them all in two revolutions, instead of a dozen or more!

Finally (this has to come to a stop sometime ...) another hot, dry, all plugs out, throttle open test gave 168 167 162 169! The highest and most consistent set yet, so I'll leave it at that!

Conclusions?: As 'funny' cams don't seem to be unique to my engine, doing them at the point of maximum gaps does have benefits for engine noise. The gap just before it starts to open has a significant effect on compression pressure, but setting them for maximum compression can result in a noisy engine. The oft-mentioned 'maximum 10% variation' is an ideal and may not be achievable in practice, without perfect matching of piston and bore, and a cam with a perfectly regular profile for each valve. Compression pressures aren't the be-all and end-all of engine condition unless one or more cylinders are way down, so doing compression testing as a 'routine' instead of just when there is an obvious problem when you need to locate the cylinder and/or valve is likely to cause more grief than useful information.

Another test is a leak-down test. On the pukka kit there are two pressure gauges, one either side of a restriction, with the 'inlet' gauge connected to a compressor via a control valve, and the 'outlet' gauge connected to the cylinder. Piston is set to TDC on the compression stroke i.e. both valves closed. You may have to lock the engine i.e. put it in 4th gear with the handbrake firmly applied to prevent the compressed air pushing the piston down. The control valve is adjusted to give, say, 100psi on the first gauge, and the second gauge indicates leakage from the cylinder. If that were 100psi also the cylinder would be perfect, which of course won't happen, it will always be lower. The bigger the difference between the two gauges the faster the air is leaking out of the cylinder. Having the piston at TDC basically checks the valves, head-gasket and the top of the bore, but if you rotate the crank to move the piston down the bore, and get a sudden decrease in pressure on the output gauge, then damage to the bore at that point is indicated.

Crankcase Breathing/Ventilation Added April 2008

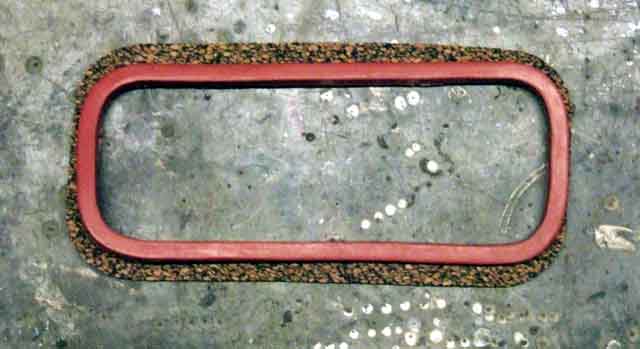

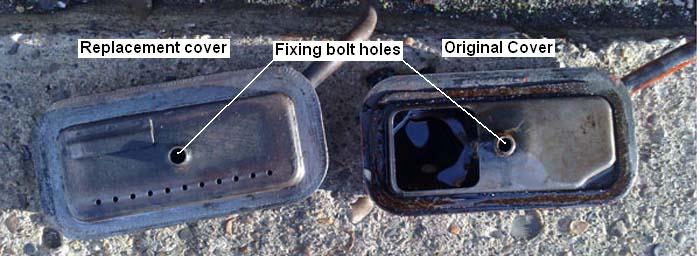

Tappet Chest Covers

Rocker Covers

Carb Ports

Problems

Modifications

V8 Engines

Description:

Originally the MGB used a similar system to the MGA. This was a very basic non-positive system consisting of one hose between the top of the rocker cover and the front air cleaner, and another open-ended hose (often called the 'road draught tube') hanging down from the front tappet chest cover. A non-vented oil filler cap was used. There will be very slight suction on the rocker cover hose from the air cleaner, varying with throttle opening, and when under way there may also be slight suction on the open end of the timing cover hose from the effect of the air passing its open end. The effect from either is minimal, which way any air would flow is a matter of conjecture, and if there is more suction on the rocker cover hose it will be pulling unfiltered and potentially moisture-laden air into the crankcase from the timing cover hose - not ideal. At least any fumes pulled out of the crankcase in that direction would be burnt in the engine, if the flow is the other way they are just pumped out into the atmosphere.

Originally the MGB used a similar system to the MGA. This was a very basic non-positive system consisting of one hose between the top of the rocker cover and the front air cleaner, and another open-ended hose (often called the 'road draught tube') hanging down from the front tappet chest cover. A non-vented oil filler cap was used. There will be very slight suction on the rocker cover hose from the air cleaner, varying with throttle opening, and when under way there may also be slight suction on the open end of the timing cover hose from the effect of the air passing its open end. The effect from either is minimal, which way any air would flow is a matter of conjecture, and if there is more suction on the rocker cover hose it will be pulling unfiltered and potentially moisture-laden air into the crankcase from the timing cover hose - not ideal. At least any fumes pulled out of the crankcase in that direction would be burnt in the engine, if the flow is the other way they are just pumped out into the atmosphere.

In February 1964 with engine 18GA a positive crankcase ventilation (PCV) system was introduced. A PCV valve (13H5191) was fitted to the inlet manifold, and the purpose of this valve is to provide a source of a continuous low-level suction under varying engine operating conditions. The side port on this valve is connected to the front tappet chest cover (in place of the road draught tube) which contains a wire gauze mesh that acts as an oil-trap as well as a flame-trap. The valve itself consists of a diaphragm and valve with a return spring. With the engine stopped the diaphragm is pushed back and the valve is fully open. With the engine running air flow causes a depression in the crankcase and under the diaphragm, which with atmospheric pressure on top of the diaphragm, tends to push the diaphragm down which closes the valve. This reduces the flow, which reduces the depression below the diaphragm and inside the crankcase, which tends to allow the diaphragm to move up again, which opens the valve to give more flow and a greater vacuum and so on. In practice the sprung diaphragm continually balances crankcase pressure with atmospheric pressure to result in a relatively constant flow rate through the valve, and hence the engine, with varying inlet manifold depressions. Clausager refers to this as a 'closed circuit' system but it isn't, it is a 'through-flow' system. A truly closed circuit system would pull its air from after the air cleaner, so any fumes emitted from what is nominally the crankcase inlet, will also be burnt in the engine.

In February 1964 with engine 18GA a positive crankcase ventilation (PCV) system was introduced. A PCV valve (13H5191) was fitted to the inlet manifold, and the purpose of this valve is to provide a source of a continuous low-level suction under varying engine operating conditions. The side port on this valve is connected to the front tappet chest cover (in place of the road draught tube) which contains a wire gauze mesh that acts as an oil-trap as well as a flame-trap. The valve itself consists of a diaphragm and valve with a return spring. With the engine stopped the diaphragm is pushed back and the valve is fully open. With the engine running air flow causes a depression in the crankcase and under the diaphragm, which with atmospheric pressure on top of the diaphragm, tends to push the diaphragm down which closes the valve. This reduces the flow, which reduces the depression below the diaphragm and inside the crankcase, which tends to allow the diaphragm to move up again, which opens the valve to give more flow and a greater vacuum and so on. In practice the sprung diaphragm continually balances crankcase pressure with atmospheric pressure to result in a relatively constant flow rate through the valve, and hence the engine, with varying inlet manifold depressions. Clausager refers to this as a 'closed circuit' system but it isn't, it is a 'through-flow' system. A truly closed circuit system would pull its air from after the air cleaner, so any fumes emitted from what is nominally the crankcase inlet, will also be burnt in the engine.

December 2025: The valve is not immune from failure which can lead to excessive oil consumption. Graham Gilmore asked how this type could be opened up to replace the diaphragm and found a YouTube video showing the spring clip keeping the top in place is removed and an end of the spring inserted into the breather hole of the cap to hook it out. Complete replacements are available at a relatively expensive £25, various bits for less than that. Fine for originality but generic replacements can be had for about £5 and will be more robust, although make sure it is for a similarly sized engine as those for larger engines can result in high oil consumption.

At the same time the oil filler cap was changed to the vented type which lets fresh air into the crankcase via a wire gauze filter and a restriction. The purpose of the filter is obvious, the restriction further limits the flow of air through the engine and PCV valve into the inlet manifold to a low level. This has two purposes - one is to avoid excessive weakening of the mixture, and the other is to provide a slight negative pressure in the crankcase to ensure that under normal conditions i.e. a sound engine, fumes aren't lost to atmosphere from any other place like oil seals and gaskets but are burnt in the engine. It also tends to reduce oil leakage past seals (while the engine is running!).

At the same time the oil filler cap was changed to the vented type which lets fresh air into the crankcase via a wire gauze filter and a restriction. The purpose of the filter is obvious, the restriction further limits the flow of air through the engine and PCV valve into the inlet manifold to a low level. This has two purposes - one is to avoid excessive weakening of the mixture, and the other is to provide a slight negative pressure in the crankcase to ensure that under normal conditions i.e. a sound engine, fumes aren't lost to atmosphere from any other place like oil seals and gaskets but are burnt in the engine. It also tends to reduce oil leakage past seals (while the engine is running!).

In October 1968 with the 18GG engine the system was changed again, replacing the PCV valve with a vacuum source taken from the twin SU carbs. The SU carbs are referred to as 'constant depression' carbs and this refers to the area between the butterfly and the piston. On a running engine as the butterfly is opened the depression in this area tends to increase, but as there is are passages between that area and the top of the piston the higher vacuum appears there also, which tends to lift the piston, which has the effect of lowering the vacuum again between the piston and the butterfly. In practice of course the piston moves up and down with the butterfly opening and closing, and the vacuum between the two remains at a relatively constant low level (see SU Carbs for more information on how the SU carbs work). Each carb has a port that taps into this area, and so provides the same sort of signal as the PCV valve, but with no moving parts (or any parts to fail other than possibly a blocked port) and even more importantly to the manufacturer at no cost! These ports are connected via a Y-pipe to a hose that goes to the front tappet chest cover as before. Both carbs are ported to retain the air-flow and mixture balance between them, and the later HIF carbs are the same as the earlier HS. Again the oil filler cap is of the vented type.

In October 1968 with the 18GG engine the system was changed again, replacing the PCV valve with a vacuum source taken from the twin SU carbs. The SU carbs are referred to as 'constant depression' carbs and this refers to the area between the butterfly and the piston. On a running engine as the butterfly is opened the depression in this area tends to increase, but as there is are passages between that area and the top of the piston the higher vacuum appears there also, which tends to lift the piston, which has the effect of lowering the vacuum again between the piston and the butterfly. In practice of course the piston moves up and down with the butterfly opening and closing, and the vacuum between the two remains at a relatively constant low level (see SU Carbs for more information on how the SU carbs work). Each carb has a port that taps into this area, and so provides the same sort of signal as the PCV valve, but with no moving parts (or any parts to fail other than possibly a blocked port) and even more importantly to the manufacturer at no cost! These ports are connected via a Y-pipe to a hose that goes to the front tappet chest cover as before. Both carbs are ported to retain the air-flow and mixture balance between them, and the later HIF carbs are the same as the earlier HS. Again the oil filler cap is of the vented type.

For UK cars the system remained like that until the end of production, but for North American cars the system changed in October 1969 with the 18GJ engine when the 'evaporative loss control system' was introduced (see North American Emissions Plumbing for more information on this system). From 1977 all LHD cars were to North American spec. The main additional component of this system is the large charcoal canister sitting in the right rear corner of the engine compartment with three ports on the top and one on the bottom. Two of the three ports on the top are connected to the fuel tank and carb float chamber vent ports, and any fumes from expansion of fuel or filling of tank or float chamber are pushed into the canister, adsorbed by the charcoal granules, and fume-free air is vented out of the port at the bottom of the canister. As the level in the fuel tank drops while driving air travels the other way through the canister to replace it. The third port on top of the canister is the important one as far as crankcase ventilation is concerned. On these engines the oil filler cap is replaced with a non-vented type, and a port with a restriction is provide on the back of the rocker cover, this port is connected to the third port on top of the canister. The restriction in the rocker cover port provides the same function as before i.e. preventing excessive weakening and to ensure a small negative pressure in the crankcase. Carb vacuum pulls fresh air through the port at the bottom of the canister, through the granules which purges them of any adsorbed fumes as well as filtering particles out of the drawn-in air, through the engine picking up any oil fumes, any fumes from either source being burned in the engine. When North American spec engines changed from twin SUs to the single Zenith/Stromberg in December 1974 for the 1975 model year the situation remained the same, this carb is also a 'constant depression' type the same as the SUs and has the same breather port, although in this case there is only the one and no Y-piece, of course.

For UK cars the system remained like that until the end of production, but for North American cars the system changed in October 1969 with the 18GJ engine when the 'evaporative loss control system' was introduced (see North American Emissions Plumbing for more information on this system). From 1977 all LHD cars were to North American spec. The main additional component of this system is the large charcoal canister sitting in the right rear corner of the engine compartment with three ports on the top and one on the bottom. Two of the three ports on the top are connected to the fuel tank and carb float chamber vent ports, and any fumes from expansion of fuel or filling of tank or float chamber are pushed into the canister, adsorbed by the charcoal granules, and fume-free air is vented out of the port at the bottom of the canister. As the level in the fuel tank drops while driving air travels the other way through the canister to replace it. The third port on top of the canister is the important one as far as crankcase ventilation is concerned. On these engines the oil filler cap is replaced with a non-vented type, and a port with a restriction is provide on the back of the rocker cover, this port is connected to the third port on top of the canister. The restriction in the rocker cover port provides the same function as before i.e. preventing excessive weakening and to ensure a small negative pressure in the crankcase. Carb vacuum pulls fresh air through the port at the bottom of the canister, through the granules which purges them of any adsorbed fumes as well as filtering particles out of the drawn-in air, through the engine picking up any oil fumes, any fumes from either source being burned in the engine. When North American spec engines changed from twin SUs to the single Zenith/Stromberg in December 1974 for the 1975 model year the situation remained the same, this carb is also a 'constant depression' type the same as the SUs and has the same breather port, although in this case there is only the one and no Y-piece, of course.

In 1978 a second charcoal canister was added in tandem with the original. Logic indicated that the second canister would be on the fresh-air side of the anti-run-on valve as that has a hose from the inlet manifold, with the potential for fumes to escape to atmosphere, but this is not the case. So what benefit it brings is a bit of a mystery. If fumes can escape to atmosphere from the first canister via the valve, then they will escape from the first to the second. So surely fumes can still escape from that to atmosphere via the valve. Maybe less, but.

In 1978 a second charcoal canister was added in tandem with the original. Logic indicated that the second canister would be on the fresh-air side of the anti-run-on valve as that has a hose from the inlet manifold, with the potential for fumes to escape to atmosphere, but this is not the case. So what benefit it brings is a bit of a mystery. If fumes can escape to atmosphere from the first canister via the valve, then they will escape from the first to the second. So surely fumes can still escape from that to atmosphere via the valve. Maybe less, but.

For those confused as to whether a vented or a non-vented oil filler cap should be used on a 4-cylinder car:

- Prior to February 1964 the 18G engine did not have Positive Crankcase Ventilation and a non-vented oil filler cap was used.

- From February 1964 and the 18GA engine Positive Crankcase Ventilation was provided and used a vented and filtered oil filler cap.

- From 1970 (California) or 1971 (rest of North America) all North American spec had a charcoal canister and a non-vented oil filler cap was used. This spec was extended to all LHD markets for the 1977 model year on.

- Markets without the charcoal canister continued with the vented and filtered oil filler cap.

- Whether they had a PCV valve on the inlet manifold or not, and whether they had twin SU or single Zenith carbs, is irrelevant, the type of oil filler cap is as above.

- If a charcoal canister was originally installed but has been removed either the port on the back of the rocker cover should be sealed and a vented oil filler cap fitted, or a small K&N filter can be fitted to the rocker cover port and the non-vented filler cap retained.

- If fixed jet carbs replace SU or Zenith they don't have a PCV port so if not already present a PCV valve should be provided on the inlet manifold plumbed to the front tappet chest cover otherwise internal condensation and corrosion can occur as well as the potential for fumes in the cockpit and increased oil leaks. Definitely so for the 18GA and later engine but the 18G would benefit as well. The type of oil filler cap is as above i.e. depends on the presence or absence of a charcoal canister.

Problems: The original system has enough problems to begin with, drawing unfiltered and wet air in through the front tappet chest cover, and being very haphazard as to whether crankcase fumes are burned in the engine or pumped straight out to the atmosphere. Apart from that all that can happen is either or both hoses get blocked. With either hose - and this is the same for any of the three ventilation systems - a blockage in one hose will prevent any ventilation. The main effect of this is to allow condensation to build up inside the engine, especially in cold conditions or where the engine is only used for short journeys, which will cause corrosion. This is usually visible as a creamy 'mayonnaise' in the oil filler hole and on the bottom of the cap. If both ports get blocked then there is no path for the relief of excess crankcase pressure, which can blow seals and gaskets, however this is more likely to occur on older engines with some blow-by. Note that contrary to often expressed opinion the blocking of one port, whilst it will stop through-flow ventilation, won't allow crankcase pressurisation to occur, as the other, still open, port will relieve that, whether it be via the PCV valve, carb ports, ventilated oil filler cap or charcoal canister. Blockage of one or both of the hoses is also about the only thing that can happen to the later carb ventilation systems. In theory North American spec cars with the canister could get a blockage in that or its fresh-air hose, but in practice this is likely to cause running problems (overflowing carbs and tank vacuum) before it is noticed elsewhere. On positive systems (PCV valve and carb ventilation) the suction-side hose can be checked very easily, as removing the oil filler cap should result in a weakening of the mixture and a slight increase in idle speed as effectively you have created a vacuum leak. If you put the palm of your hand, or a sheet of paper over the oil filler hole, it should be sucked onto the hole with slight pressure. A blockage in hose between the rocker cover and the charcoal canister is more difficult to detect, removing it from the canister will show very little vacuum, although it should pull smoke through i.e. from a cigarette or other smoke source. A blocked ventilated oil filler cap is even more difficult to detect, but these are probably best replaced at 12k intervals anyway. The one that came with the roadster always tended to leak oil past the seal and down the side of the rocker cover, replacing it cured that. With V8s if one carb/rocker cover hose or flame/oil trap gets blocked the crankcase will still get ventilated via the other, but only the one rocker cover.

The PCV valve has a finite life, when it fails it is usually the diaphragm that ruptures, the effect of which is to apply full inlet manifold vacuum to the crankcase, which can pull significant amounts of oil into the combustion chambers fouling the plugs as we as resulting in high oil consumption and oil smoke pollution. If you have a PCV valve and experience stalling when the cap is removed, or a large vacuum is felt, then the valve has probably failed. That is if you haven't already noticed high oil consumption. Other problems can be oil and combustion sludge inside the valve restricting the movement of the diaphragm or blocking the valve. After-market valves and those used on other vehicles often have a plunger instead of a diaphragm which removes the main failure mode of the MGB valve, but they can still stick open or closed and get gunged-up. The advantage of this type over the MGB type is that under crankcase pressurisation from excessive blow-by the valve will close to prevent air being forced into the inlet manifold from this source so weakening the mixture. If this type of valve were used on the MGB the excess pressure would be vented to atmosphere (via the oil filler cap or charcoal canister), but systems with this type of valve tend to have the fresh-air intake inside the air cleaners, so any fumes emitted will still be burned in the engine. This type of system is a closed-circuit system, unlike the MGB, which is through-flow.

Modifications: These range from the simple, like removing the emissions kit from North American cars, to the more complex like replacing the SU or Zenith carbs with something else e.g. Weber. The first thing to say is that unlike the air-injection system (the removal of which isn't covered here) the 'vapour loss recovery system' (aka charcoal canister) has no detrimental effect on performance or economy, and does help to keep the atmosphere a little cleaner than it otherwise would be. The only reason for removing it is to free-up a little space in the engine compartment. And if you have a 73 model or later with the anti-runon valve, interfering with the canister and its plumbing disables the valve, which can be a positive disadvantage. If you do decide to go down that route there are a number of aspects which must be considered. The tank, float chamber and rocker cover vent pipes can be left dangling in that corner of the engine compartment. But if you remove the tank plumbing and separation chamber and seal its vent port you must fit a vented fuel filler cap in place of the standard unvented. Don't remove the pipework running to the front of the car but leave the separation chamber or vent port from the tank open in the boot or it will fill with fumes, and with the electrics in the boot particularly the sparking points of the rubber bumper fuel pump is an explosion hazard. If you remove the existing float chamber vent pipe that runs across the engine compartment you must fit alternatives that run down past the engine and exhaust for safety, neat petrol pouring onto a hot exhaust is not a good idea. With the charcoal canister removed you really ought to provide alternative filtration to prevent the crankcase breathing system pulling dust and moisture into the engine. The best way of doing this is to remove the hose from the rocker cover and fit a small filter to it instead. You could seal off that port and fit a vented oil filler cap instead, but subsequently someone may not realise and fit a non-vented cap again, which will disable the ventilation system resulting the aforementioned condensation and corrosion. Much better and more obvious to leave the cap as standard and fit the filter. If you do all that you might as well remove the anti-runon valve as well as it is no longer doing anything useful, and if you do that you must seal its port on the inlet manifold.

Weber, or not? John Twist: "First of all, Webers make good grills. They shouldn't be on your engine ... the Weber is stupid, dumb, ... I don't think it does as well as SUs." If you fit a fixed-jet carb like a Weber they do not have a PCV port as there is nowhere inside the carb with a constant level of vacuum that SU and Stromberg have so something else should be done. Some revert to the prehistoric non-positive system used on the first MGBs or just leave both rocker cover and front tappet chest cover ports open, but then you are back to condensation and dust in the engine, pumping out oil fumes, and leaks. Weber air-cleaners sometimes have a breather port (like pre-64 MGBs), in which case you could connect the front tappet chest cover port to that. But the suction from that is minimal, as John Twist says in that video you need large bore connections all the way through the system bypassing the very small bore port on the back of North American spec with charcoal canister. Without that you will get will get nothing at all, and even with it ventilation will be hit and miss and likely to be little or none except at high rpm.

Much better to retro-fit a PCV valve and retain the positive ventilation, which eliminated internal condensation, and reduces oil leaks as well as oil fumes in the engine compartment and cabin. After-market PCV valves or one intended for another application are often smaller and neater than the MGB valve (used before carb vacuum in 1968) as well as being more robust not having the diaphragm that fails over time leading to high oil consumption. Whichever, fit that to the inlet manifold and plumb it to the front tappet chest cover as the MGB Positive Crankcase Ventilation systems were. If you don't have a charcoal canister use the original vented oil filler cap, and if you do have a charcoal canister use the original non-vented cap.

V8 Engines:

V8 engines are slightly different. The oil filler cap was always non-vented. Each carb has its own hose, with an oil/flame trap, going to a port on its respective rocker cover. On the back of the block near the right-hand side there is a metal pipe with a restriction pointing upwards, on which is a short length of slightly kinked hose, on top of that a petrol filter held in a clip on the back of the air-cleaner box, and a U-shaped hose on top of the filter (to prevent debris dropping into the filter). In this case the airflow is in the opposite direction to 4-cylinder cars i.e. fresh air goes in via the filter to the crankcase, then up through the engine into the rocker covers, and from there into the carbs and engine. September 2010: There are occasional reports of a V8 valley gasket bulging. This is a thin metal gasket of a large surface area under the inlet manifold, only supported at the edges. Excessive pressure in the crankcase could cause this to bulge up quite easily, as this image from The V8 Owners Forum shows. This could happen on modified engines from a backfire through the carb igniting petrol or even oil fumes in the crankcase, where there is no oil/flame trap as there is (should be!) on factory engines between each rocker cover and its adjacent carb. With the standard three ports on the crankcase i.e. one inlet and two outlets slight blow-by should not cause a problem with the valley gasket, but excessive blow-by may overwhelm the ports and allow pressure to go positive enough to bulge the gasket.

V8 engines are slightly different. The oil filler cap was always non-vented. Each carb has its own hose, with an oil/flame trap, going to a port on its respective rocker cover. On the back of the block near the right-hand side there is a metal pipe with a restriction pointing upwards, on which is a short length of slightly kinked hose, on top of that a petrol filter held in a clip on the back of the air-cleaner box, and a U-shaped hose on top of the filter (to prevent debris dropping into the filter). In this case the airflow is in the opposite direction to 4-cylinder cars i.e. fresh air goes in via the filter to the crankcase, then up through the engine into the rocker covers, and from there into the carbs and engine. September 2010: There are occasional reports of a V8 valley gasket bulging. This is a thin metal gasket of a large surface area under the inlet manifold, only supported at the edges. Excessive pressure in the crankcase could cause this to bulge up quite easily, as this image from The V8 Owners Forum shows. This could happen on modified engines from a backfire through the carb igniting petrol or even oil fumes in the crankcase, where there is no oil/flame trap as there is (should be!) on factory engines between each rocker cover and its adjacent carb. With the standard three ports on the crankcase i.e. one inlet and two outlets slight blow-by should not cause a problem with the valley gasket, but excessive blow-by may overwhelm the ports and allow pressure to go positive enough to bulge the gasket.

Cylinder Block July 2019

Core Plugs

Pal driving down an Autoroute in France when he suddenly lost a lot of power with white and blue smoke pouring out of the back. A blown head gasket was diagnosed and a local place said they could replace it. The oil was contaminated and drained, and before they replaced the drain plug they started refilling the radiator only to find water dribbling out of the sump plug! Repatriation.

Pal driving down an Autoroute in France when he suddenly lost a lot of power with white and blue smoke pouring out of the back. A blown head gasket was diagnosed and a local place said they could replace it. The oil was contaminated and drained, and before they replaced the drain plug they started refilling the radiator only to find water dribbling out of the sump plug! Repatriation.

Back home there is a hole from the lower part of a bore to the water jacket, 1mm in the bore but 3-4mm in the jacket so punched through from the bore to the jacket? What on earth could cause that? Another theory is cavitation where the cylinder wall flexes at high frequency producing bubbles in the coolant, and when they collapse they do so very rapidly directing a jet of coolant at the cylinder walls so eroding them. But most discussions on this refer to Diesel engines, and it being a progressive thing rather than sudden and catastrophic as in this case.

I've asked if they can gauge the thickness of the casting at that point, they are going to sleeve that bore, but one can't help wondering if it is a weak point and there are more elsewhere. Peter Burgess told me that a number of Qualcast blocks were found to be so porous that they had to be sleeved from the outset, these don't appear to be sleeved.

That was in No.1 cylinder, but No.2 piston is completely clean with the others lightly carboned, and is covered with tiny nicks. A clean piston usually means it's been 'steam cleaned' by a leaky head gasket - or cylinder wall porosity? And 10k ago they did find a chunk missing from No.2 exhaust valve so maybe the broken bit had been bouncing up and down inside - the pistons are to be replaced as well. A bit of a 'problem child' this engine as the cam and followers had to be replaced after 20k as they were badly worn and pitted, that quite possibly down to his workshop using 'modern' oil with a low ZDDP.

Core Plugs: May 2021

They seem to have been flat originally, but my Gold Seal has the cup-type and I've been told (by Peter Burgess who has probably seem more MGB engines than anyone else alive today) that Gold Seal blocks were machined as part of the rebuild to accept those. Someone rubbished that statement as his has the flat type so there you are. Mine are flush with the block but another is recessed, so even some variation in the cup-type.. The flat type come dished and have to be flattened when in the block which needs a large enough drift or they can 'dimple' and not press on the sides of the hole firmly enough. By contrast the cup-type just need hammering flush, although I have seen them inserted more than that. The three side ones are easy enough to replace with the engine in-situ, especially the middle one. That leaves the rear one, but a Betson Bolt can be used to replace that. That uses the engine back-plate for a large washer to press against, while the bolt pushes the core plug in. This may be more successful with the dished type than the cup-type. An alternative is this emergency core plug (no personal experience) which can apparently be used to replace any of the four. Also this rubber type.

They seem to have been flat originally, but my Gold Seal has the cup-type and I've been told (by Peter Burgess who has probably seem more MGB engines than anyone else alive today) that Gold Seal blocks were machined as part of the rebuild to accept those. Someone rubbished that statement as his has the flat type so there you are. Mine are flush with the block but another is recessed, so even some variation in the cup-type.. The flat type come dished and have to be flattened when in the block which needs a large enough drift or they can 'dimple' and not press on the sides of the hole firmly enough. By contrast the cup-type just need hammering flush, although I have seen them inserted more than that. The three side ones are easy enough to replace with the engine in-situ, especially the middle one. That leaves the rear one, but a Betson Bolt can be used to replace that. That uses the engine back-plate for a large washer to press against, while the bolt pushes the core plug in. This may be more successful with the dished type than the cup-type. An alternative is this emergency core plug (no personal experience) which can apparently be used to replace any of the four. Also this rubber type.

Dating the engine February 2013

Dating the head

Taking it to the pictures? Not in this case, rather taking pictures of it to work out when block and head might have been made and what type they are.

Dating the block:

Bill Etter from America has asked me about this date code when he lost his engine number plate and wondered whether it could indicate if it was the original engine or not. Originally I was under the impression that all blocks have a date code cast in, immediately below the oil filter, just above the sump mounting flange. However as time has gone by more and more have come to light without these date codes from throughout the production period, and some with a completely different markings which may or may not include a date code. The most common date code seems to be a circular arrangement under the filter mount on blocks and on top of heads. Often referred to as a 'clock', but clock codes have a set of numbers in a ring and an arrow pointing to one of them to indicate a single digit, where as these have three groups of characters arranged in a ring, and all three groups change from example to example. The slot in the middle is simply from the head of the screw used to attach the date code plate to the pattern used to create the sand mould for the casting.

Bill Etter from America has asked me about this date code when he lost his engine number plate and wondered whether it could indicate if it was the original engine or not. Originally I was under the impression that all blocks have a date code cast in, immediately below the oil filter, just above the sump mounting flange. However as time has gone by more and more have come to light without these date codes from throughout the production period, and some with a completely different markings which may or may not include a date code. The most common date code seems to be a circular arrangement under the filter mount on blocks and on top of heads. Often referred to as a 'clock', but clock codes have a set of numbers in a ring and an arrow pointing to one of them to indicate a single digit, where as these have three groups of characters arranged in a ring, and all three groups change from example to example. The slot in the middle is simply from the head of the screw used to attach the date code plate to the pattern used to create the sand mould for the casting.

There is a one or two digit number at the top of the group at 12 o'clock, one or two digits or a letter at 8 o'clock, and a one or two digits at 4 o'clock. After some years pondering these codes and whether they represented an actual date or just a week and year number and a casting mould identifier, Fred Horner in America very kindly sent me a copy of a BL document he found that confirms they are actual dates - from 1970 at least. Apparently dating from 1953 following the introduction of U.S. Federal Regulations on Motor Vehicle Safety, which required all castings to be identifiable by make and by batch. Oddities were a claim that the letter 'I' was not used as it could be confused with the digit '1', and that the letter 'L' was in fact the digit '7'. The former case seems unlikely as if all the other characters in that position are obviously letters what would lead someone to think it was a digit, and what difference would it make? The second case is even more unlikely as to be a '7' it would have to be 'upside down' compared to the others. It turns out that the letter 'I' wasn't used, but the letter L was, so if one could cause confusion why not the other as well? But there we are. Examples show that 60s date codes have two digits for the year and numbers for the month instead of one digit and letters from 1970, so those were probably amendments to this issue of the spec for the 1970s.

There is a one or two digit number at the top of the group at 12 o'clock, one or two digits or a letter at 8 o'clock, and a one or two digits at 4 o'clock. After some years pondering these codes and whether they represented an actual date or just a week and year number and a casting mould identifier, Fred Horner in America very kindly sent me a copy of a BL document he found that confirms they are actual dates - from 1970 at least. Apparently dating from 1953 following the introduction of U.S. Federal Regulations on Motor Vehicle Safety, which required all castings to be identifiable by make and by batch. Oddities were a claim that the letter 'I' was not used as it could be confused with the digit '1', and that the letter 'L' was in fact the digit '7'. The former case seems unlikely as if all the other characters in that position are obviously letters what would lead someone to think it was a digit, and what difference would it make? The second case is even more unlikely as to be a '7' it would have to be 'upside down' compared to the others. It turns out that the letter 'I' wasn't used, but the letter L was, so if one could cause confusion why not the other as well? But there we are. Examples show that 60s date codes have two digits for the year and numbers for the month instead of one digit and letters from 1970, so those were probably amendments to this issue of the spec for the 1970s.

However although it covers the years 1970 to 1981, with a single digit for the year 1970 being '0' and 1981 reusing '1' the same as for 1971, I have found examples of '70' and '71' i.e. two digits as well as numbers for month i.e. same as for the 60s so the change took a while to be implemented at the foundries.

However although it covers the years 1970 to 1981, with a single digit for the year 1970 being '0' and 1981 reusing '1' the same as for 1971, I have found examples of '70' and '71' i.e. two digits as well as numbers for month i.e. same as for the 60s so the change took a while to be implemented at the foundries.

Also there are a number of MGB blocks without these 'clocks', some with seemingly no date code (despite Federal regulations) and others with different markings. There were a number of foundries producing blocks at least, one of which (West Yorkshire Foundries) may have had it's own coding system but I've not found any information as to what that system involves. However I have one example with 'L 5' in a strip that is part of the WYF code and the same in the head clock code which tends to indicate that the WYF strip is the date code. The head day number is 27 whereas the block looks like 'D3' which could be '03', but clock codes didn't use leading zeros, and there are other examples of WYF strips with 'D6', 'D10', 'D16' and 'N22' so the letter probably indicates something else. Also there is an example of a WYF strip using 'X' in what would be the month position, which doesn't fit with the BL spec, and I'm sure it isn't a 'K'. The final digit in the strip does seem to match the year going by the engine and chassis numbers in several examples.

July 2024:

Geoff James has sent me 'The Nuffield and Wellingborough Foundry 1947-1981' by Jon Bolton (a large document in three parts comprising some 400 pages originally published on a Wellingborough Facebook page) containing information about Wellingborough foundry marks including date strips, which are almost identical in appearance to the WYF ones.

Geoff James has sent me 'The Nuffield and Wellingborough Foundry 1947-1981' by Jon Bolton (a large document in three parts comprising some 400 pages originally published on a Wellingborough Facebook page) containing information about Wellingborough foundry marks including date strips, which are almost identical in appearance to the WYF ones.

A side issue has been the elapsed time between casting and build dates. One opinion has been three months would be a likely figure, but going by these engines being used in multiple BMC/BL models and how many cars they were producing - more than 600,000 of all types in one year in the mid 70s - would mean a huge stock-pile of blocks and heads waiting to be machined then assembled, then completed engines, sitting around taking up space, i.e. around 150,000 in any three-month period. Unlikely, I suggest, even for that company! I now have three where cast dates are within a couple of months of the build date. On the one hand that does seem a bit quick, but my Mum bought a new Mini in a January and when it became eligible for Historic status applied feeling sure it must have been built in the previous December if not earlier, only to find that date was also January so it wasn't eligible!

A side issue has been the elapsed time between casting and build dates. One opinion has been three months would be a likely figure, but going by these engines being used in multiple BMC/BL models and how many cars they were producing - more than 600,000 of all types in one year in the mid 70s - would mean a huge stock-pile of blocks and heads waiting to be machined then assembled, then completed engines, sitting around taking up space, i.e. around 150,000 in any three-month period. Unlikely, I suggest, even for that company! I now have three where cast dates are within a couple of months of the build date. On the one hand that does seem a bit quick, but my Mum bought a new Mini in a January and when it became eligible for Historic status applied feeling sure it must have been built in the previous December if not earlier, only to find that date was also January so it wasn't eligible!

A good spot by Fred Horner in America has been that on examples he has with an AF mark on the distributor side, they have the same AF digit on the other side under the 'MOWOG' and wonders if it is a mould identifier on each half and the two have to match before assembly and use. Although the 'MOWOG' only appears on 18G/Gx engines the AF number by itself is on 18V engines - those with the 'clock' date code at least but maybe not WYF blocks.

A good spot by Fred Horner in America has been that on examples he has with an AF mark on the distributor side, they have the same AF digit on the other side under the 'MOWOG' and wonders if it is a mould identifier on each half and the two have to match before assembly and use. Although the 'MOWOG' only appears on 18G/Gx engines the AF number by itself is on 18V engines - those with the 'clock' date code at least but maybe not WYF blocks.

June 2023: In a discussion on the subject with Geoff James in New Zealand he sent me a link to an Aussie site Abingdon Motors with a page on MGB identification. I know Australia had their own arrangements for cars fully assembled there, which included fabrication of the bodies and panels, but the bottom of the document on Decoding Engine Numbers which apparently applies to engines built for all markets is rather confusing with many 'Group 2' suffix letters I've not seen or referred to in practice:

| Bf | Lucas 16ACR or 17ACR alternator with negative earth |

| Ck | Anti-run on valve |

| Pf | Pre-engaged starter motor (when not normally fitted) |

| Re | Exhaust emission control |

| Hl | Meets 1975 US Federal regulations |

| Jl | Meets 1975 Californian regulations |

| Tl | Meets 1975 requirements |

September 2014:

Graham Moore asked me about identifying the engine type i.e. 18Gx or 18V rather than dating it. It should be possible to do this from the casting numbers, even though they are pretty-well concealed by the starter motor. It seems that 18G/GA i.e. 3-bearing engines have a single 12H750 casting number, some 18GB/Gx i.e. 5-bearing engines have three nnHnnn numbers one above the other but late versions may only have a single 12H3243 number, and 18V ('most' of them according to one source) have a single 12H3503 number. But even the 18V can vary as some have the 12H above the 3503, and others have both in a line.

Graham Moore asked me about identifying the engine type i.e. 18Gx or 18V rather than dating it. It should be possible to do this from the casting numbers, even though they are pretty-well concealed by the starter motor. It seems that 18G/GA i.e. 3-bearing engines have a single 12H750 casting number, some 18GB/Gx i.e. 5-bearing engines have three nnHnnn numbers one above the other but late versions may only have a single 12H3243 number, and 18V ('most' of them according to one source) have a single 12H3503 number. But even the 18V can vary as some have the 12H above the 3503, and others have both in a line.

Graham's block seems to have the three rows of 'H' casting numbers, indicating it is an 18GB/D/G of October 64 to August 71, but like the early 3-bearing referred to above, does not have a dating code. Graham's (like mine) is a Gold Seal engine, and his engine number prefix is 48G 739. According to Clausager this was a replacement for the 18GB High Compression manual gearbox engine of October 64 to November 67, but it is the third of three replacement types quoted for that engine. The first was only used for the 18GB, but the second was also used for the 18GD/GG of November 67 to August 71. This engine also had three replacement types, the latest of which was 48G 755. It seems to me that as the original engines developed, the rebuilt engines did so as well, using later components where that did not change the basic specification. The numerical part of Gold Seal suffixes appears to have been issued in numerical order over time, as did the numerical part of the 18V prefixes. And as 739 comes after 737 which was the first (and only) replacement for 18V 584/585 and 18V 672/673 engines produced between August 71 and September 74, it seems to me that 48G 739 could well date to some time between August 71 and September 74, and possibly after August 72 when the 18V 672/673 was introduced. The 48G 755 would have been even later, but presumably before the BHM 1074 which was the replacement for the 18V 836/837 of September 74 to December 74. Another thing to bear in mind is that Gold Seal engines were assembled from good returned blocks etc., which could have been at any time including many years after that block was used originally, so you could well have a 'late' rebuild on an 'early' block.

Another point of confusion concerns the blanking plate for the mechanical fuel pump. Some sources say this was 18V engines only, other sources indicate it was all five-bearing crank blocks i.e. 18GB onwards, yet more indicate that there was a 'lump' on the block of the same size and shape but not pierced, but with a tapped hole for a stud that was used to mount the carb overflow tubes. The Parts Catalogue would seem to be the best guide, and that indicates it was for 18V engines only. Graham's engine has the blanking plate, but the casting numbers indicate it is an 18GB/D/G. This block with a 66 date code, 18GB/D/G casting numbers and an 18GB engine number doesn't have the blanking plate, or unpierced position for it, but another example of unknown date does. More examples required.

Another point of confusion concerns the blanking plate for the mechanical fuel pump. Some sources say this was 18V engines only, other sources indicate it was all five-bearing crank blocks i.e. 18GB onwards, yet more indicate that there was a 'lump' on the block of the same size and shape but not pierced, but with a tapped hole for a stud that was used to mount the carb overflow tubes. The Parts Catalogue would seem to be the best guide, and that indicates it was for 18V engines only. Graham's engine has the blanking plate, but the casting numbers indicate it is an 18GB/D/G. This block with a 66 date code, 18GB/D/G casting numbers and an 18GB engine number doesn't have the blanking plate, or unpierced position for it, but another example of unknown date does. More examples required.

And as for this B-series, what is it from?

And as for this B-series, what is it from?

Cylinder heads seem to be more consistent in that all bar two of the examples I have seen use the same circular code, the other two don't seem to be dated (like some of the blocks). These have been later heads with the off-set oil feed hole in the rear rocker pedestal, and only some of those. The 'clock' codes are the same as blocks i.e. largely two-digit year markers for the 1960s and single digits for the 70s, and month numbers changing to letters.

Dipstick! (and sumps) Added September 2010

Sump plug and washer

Capacities

Auto box

No, not the habitual imprecation invoked by Sheriff Rosco P Coltrane of Hazzard County on his deputies, but seemingly just as liable to cause chaos and confusion regarding engine oil quantity and level.

One of the many things that people get paranoid about is when to check the oil level i.e. just after switch off or after being left overnight or longer. There should be a difference - not only is the oil hot after running a while so may have expanded a bit, but the upper reaches will have a measurable amount that needs time to drain down. But unless you intend to run the level down to Min when cold, i.e. it will be less than that when running, it isn't going to make that much difference. Personally I top mine up when they get about half-way down from Max to Min. Likewise topping up immediately after a hot switch-off is likely to be above Max when cold. It's said that excessive oil is not ideal either, although doing it while still warm will probably aid the oil running down to be measurable on the dipstick sooner so less hanging about.

There were at least three sticks, three dipstick tubes and three sumps over the life of the MGB engine. Each changed at various times, and not all combinations are correct, the wrong ones giving incorrect oil level. Particularly cars with positive crankcase ventilation, where the crankcase is held at negative pressure, need the dipstick and tube to be sealed or the ventilation system will suck in dust and dirt.

There were at least three sticks, three dipstick tubes and three sumps over the life of the MGB engine. Each changed at various times, and not all combinations are correct, the wrong ones giving incorrect oil level. Particularly cars with positive crankcase ventilation, where the crankcase is held at negative pressure, need the dipstick and tube to be sealed or the ventilation system will suck in dust and dirt.

Early sticks dropped right into the sump, the end of the stick sitting on a raised (reinforced?) section at the bottom of the sump. There were two sumps in this period, the difference being associated with the rear main bearing between 3-bearing and 5-bearing, both having the drain plug on the right-hand side in front of the rear corner. The tube is screwed into the lower part of the block. On this type the stick plus the raised portion in the sump determines the oil level, the tube length is largely irrelevant. These sticks have a movable dust-cover sealing the top of the tube which should be pushed down onto the top of the tube. It must not prevent the stick going all the way down or you will be putting more oil in the sump than there should be to reach the MAX mark.

Early sticks dropped right into the sump, the end of the stick sitting on a raised (reinforced?) section at the bottom of the sump. There were two sumps in this period, the difference being associated with the rear main bearing between 3-bearing and 5-bearing, both having the drain plug on the right-hand side in front of the rear corner. The tube is screwed into the lower part of the block. On this type the stick plus the raised portion in the sump determines the oil level, the tube length is largely irrelevant. These sticks have a movable dust-cover sealing the top of the tube which should be pushed down onto the top of the tube. It must not prevent the stick going all the way down or you will be putting more oil in the sump than there should be to reach the MAX mark.

Later sticks have a fixed 'stop' which wedges into the top of a different tube, first screwed then pressed into the block, meaning that both the stick and the tube determine the oil level. When first used the engines still had the sump with the raised portion, but the stick stopped short of it. These sticks do not have a dust-cover as such, the 'stop' seals the top of the tube. Later engines with this stick and tube had a sump without the raised portion below the stick, and the drain plug on these is in the right rear corner.

Engines after that used a different stick, with a stop, the pressed-in tube, and the same sump as previously. Information about exactly what combination of parts was used when is confusing, with different information in the Parts Catalogue to some web sites. I suspect that when looking at examples of original engines you will see when the actual changes took place (incorrect combinations excepted!), whereas later versions of the Parts Catalogue and current parts lists may well show the later of the two (or more) parts that can be used:

| Engine | Stick | Tube | Sump |

| 18G, 18GA | 12H74 no stop | 1B1063 screwed | 12H395 |

| 18GB, 18GD, 18GF | 12H74 no stop | 1B1063 screwed | 12H1426 |

| 18GG RWe H to 22059, 18GG RWe L to 20207 18GG We to 21267, 18GG Rc to 757 18GK RWe to 10072, 18GK We to 10951 | 12H2964 with stop | 12H2966 screwed or 12H3351 pressed | 12H1426 or 12H3541 |

| 18GG RWe H 22060 on, 18GG RWe L 20208 on 18GG We 21268 on, 18GG Rc 758 on 18GK RWe 10073 on, 18GK We 10952 on 18V581H to 1583, 18V581L to 1013 18V582H to 2592, 18V582L to 1207 18V583 to 257, 18V584/585/672/673 | 12H2964 with stop | 12H3351 pressed | 12H3541 |

| 18V581H 1584 on, 18V581L 1014 on 18V582H 2593 on, 18V582L 1208 on 18V583H 258 on, 18V779/780 | 12H3963 with stop | 12H3351 pressed | 12H3541 |

Sumps and gaskets:

5-bearing sumps 12H1426 (18GB) and 12H3541 (18GD on) are interchangeable, the later sump has the corner by the drain plug cut away to give access to the torque converter bolts when used with the automatic gearbox. These have a different bolt pattern to the 3-bearing 12H395 so are not interchangeable with that sump (Chris at Octarine Services). Logically 12H3541 should always have been used with the automatic gearbox at least if not all engines from that time, but logic doesn't always apply with British 'engineering'. I'm sure I originally came across a reference somewhere that this sump was only provided with the 18GG engine whereas the automatic option arrived with the 18GD.

5-bearing sumps 12H1426 (18GB) and 12H3541 (18GD on) are interchangeable, the later sump has the corner by the drain plug cut away to give access to the torque converter bolts when used with the automatic gearbox. These have a different bolt pattern to the 3-bearing 12H395 so are not interchangeable with that sump (Chris at Octarine Services). Logically 12H3541 should always have been used with the automatic gearbox at least if not all engines from that time, but logic doesn't always apply with British 'engineering'. I'm sure I originally came across a reference somewhere that this sump was only provided with the 18GG engine whereas the automatic option arrived with the 18GD.

Also note that the 12H1976 part number specified by Moss for the early 5-bearing sump is not used by anyone else, and the change point to 12H3541 being for the 18V797 engine is completely wrong - the auto option was long gone by then. Other suppliers give a 1965 date i.e. all 5-bearing engines, which is correct for where they can be used, but does not indicate when they were originally used from.

Originally the gaskets were GEG503 for the 3-bearing and GEG504 for the 5-bearing, the part numbers from the usual suspects are now AJM503 for the 3-bearing and AJM504 for the 5-bearing. However the MGOC does not differentiate between the two in its online reference as parts for both types of engine are all listed on one page. Brown & Gammons and Moss Europe split the two types of engine over two pages making it clearer.

Sump plug and washer: The 4-cylinder used plug 88G257 (3/4" AF socket) with washer 6k638 and the V8 plug 554164 (5/8" plug spanner fits these) with washer 213961. The odd thing is that the Leyland Parts Catalogue shows a second plug and washer for the V8 having the same part numbers as for the 4-cylinder, I have no idea where that is, so it may be an error and a hang-over from a list for another usage of the V8.

Over many years I've occasionally read about people re-annealing copper washers to prevent leaks, but I've never done that on any car in the last 55 years and have never had a leak - until changing the oil on Geoff's 78. Tried tightening but no better, so I backed it off a few turns and wrapped some PTFE tape round it so if that stops it. It was only when backing it off I realised how thin and ragged the washer was i.e. it was a single-use crush-washer - I hadn't noticed that on cleaning plug and washer prior to refitting. And Googling the part numbers I see they are all crush-washers now - so these would definitely need to be replaced at each oil change. Both of mine are thick non-crush copper, so the question is ... to keep reusing them as I have for the last 35 years, or replace them each year!

Over many years I've occasionally read about people re-annealing copper washers to prevent leaks, but I've never done that on any car in the last 55 years and have never had a leak - until changing the oil on Geoff's 78. Tried tightening but no better, so I backed it off a few turns and wrapped some PTFE tape round it so if that stops it. It was only when backing it off I realised how thin and ragged the washer was i.e. it was a single-use crush-washer - I hadn't noticed that on cleaning plug and washer prior to refitting. And Googling the part numbers I see they are all crush-washers now - so these would definitely need to be replaced at each oil change. Both of mine are thick non-crush copper, so the question is ... to keep reusing them as I have for the last 35 years, or replace them each year!

Capacities: The GHN4/5 GHD4/5 drivers handbook AKD 7598 4th edition states:

18GG, GD with oil cooler 8.25 Imperial pints (4.5 litres, 9.6 US pints)

18V engines (no oil cooler) 5.25 Imperial pints (3 litres, 6.3 US pints)

18V with oil cooler 6 Imperial pints (3.4 litres, 7.25 US pints)

In other words all 18V engines take less than the 18Gx engines, but this goes against the part numbers and change points stated in the Parts Catalogue which implies later 18Gx engines were the same as 18V, and earlier 18Gx could be either. Other than the change of sump to give access to the torque converter bolts on automatics which was used on all cars, and I can't see that small corner being responsible for 2.25 pints, maybe just the oil level changed, and hence its volume. The BL figures are for a dry engine, hence less will be required for an oil change, although you have to add in the amount required to initially fill a new oil filter. I'm surprised it is as low as 3.4 litres for an 18V with oil cooler, I would have said (but have never measured) mine took more than that to be at the Max mark after running the engine after an oil change, then switching off and leaving a few moments before checking.

February 2013: For what it's worth my 48G 733 Gold Seal (equivalent to the 18V 581/582/583 and 779/780) has the following dimensions:

| A pal's 18V 582 is the same - based on his serial number they should be, so either they are both right or they are both wrong, and in the same way, which seems unlikely! Another pal's 1978 18V 847 is within a couple of mm of all of them. |

Don Hayter in his 'MGB Story' writes that as cars became available in 1962 thoughts turned to competition, and they entered two cars for the USA Sebring event. However the long fast corners caused oil surge in the sump and big-end failures leading the DNFs for both cars. He writes "Sump baffle redesign was quickly on the cards, and the resultant unit built into all (my emphasis) later MGB engines". Maybe he meant all competition engines, as I've never seen a baffle in any other MGB.

V8: My V8 takes a full 5 litres to get back to the Max mark after an oil and filter change. Convenient, as I just chuck the whole container in then leave it to run through for a bit before double-checking. Whereas for the roadster it is a case of pouring in less than you think it needs, waiting for it to run through, then putting progressively smaller amounts in, waiting and checking, until it gradually comes up to the Max mark - takes 3 or 4 iterations.

Auto box:

The auto gearbox takes 10 1/2 pints (6 litres, 12.7 US pints). The dipstick is long and goes into a large tube with a pronounced 'S' shape.

The auto gearbox takes 10 1/2 pints (6 litres, 12.7 US pints). The dipstick is long and goes into a large tube with a pronounced 'S' shape.

Engine Mounts Amended and updated January 2011

Rubber bumper and V8

Restraints

Earth Straps

Chrome bumper: All chrome bumper cars have rectangular engine mounts on the chassis rails, with a right-angle bracket between there and the engine front plate. There are also flat packing plates AHH6992 between the mount and the chassis rail, usually on the left-hand side. Suppliers variously quote this as 'as required', '1', '2', or don't even list it for the MGB as in the case of Brown & Gammons who only show it for the MGA. I've always thought of them as being required to cope with tolerances in the chassis rails, which because of the angled mounts could result in the engine hanging on the bolts and putting the mounts into shear because the holes didn't line up when the engine was fully down, rather than putting the mounts under compression. There has been speculation that it might be to lift the left-hand front corner of the sump a little to prevent it banging into the cross-member on deceleration, but in that case why isn't one needed on the right for acceleration, or on both for when the car went over a bump and crashed back to earth?

Another aspect of these front mounts involves limiting forward engine movement under heavy braking or light impact with some cars having various restraint rods at the gearbox crossmember and some having control brackets at the engine mounts. The usual reason given for these restraints is that without it the engine could move forwards far enough for the fan to chew through the radiator, which would be a bit of a blow. However someone has said that it would be more of a blow if the crank pulley hit the rack bending that, or even worse bend the crankshaft, which may cause the owner to write off the car (surely not?). It's a valid point, as there is only about 3/8" clearance between pulley and rack, whereas there is about 1 3/4" between the fan blades and the nearest part of the radiator (header tank). But an impact large enough to bend rack or crankshaft is going to make a helluva mess of the front of the car anyway, and it is that which is more likely to result in a write-off as much as anything else.

Mk1 roadsters had a restraint rod between the gearbox and its cross-member. Mk1 GTs didn't have this rod, but had a vertical pin and bushes between the gearbox and crossmember (not so positive as the roadster rod), plus control brackets at both front mounts. Mk2 cars had the same arrangement for both roadster and GT - no restraint rod, vertical pin and bushes between gearbox and crossmember, and control brackets on both front mounts. For non-North American cars the right-hand bracket was deleted for the 1972 model year to save a few coppers (in reality one is probably enough), North American cars continued with two. Another change is that when the carbs were changed from HS to HIF (18v export engines during 1971, not until November 1973 for UK cars) the left hand control bracket gained a threaded stud for mounting the clip that held the carb vent/overflow pipes. In Feb 74 a new, longer restraint rod using different components to the Mk1 roadster was added to North American roadsters and GTs, but despite this very positive restraint to fore and aft movement being used again, the vertical pin and bushes and the front mount control brackets were also apparently still provided i.e. three restraint methods. Other markets only got this restraint rod at the start of rubber bumpers production in September 1974 when the engine mounts changed from rectangular to round, keeping the vertical pin and bushes. The control brackets were no longer applicable to the new engine mounts and no alternative was provided.

If you have a Mk2 chrome bumper car without a restraint rod (i.e. all UK and most North American) the crossmember pin and bushes and the front mount control brackets are protecting your radiator from being chewed by the fan in a minor impact, or maybe just a jolt from a pot-hole. My 73 roadster came to me without control brackets, a pals 72 GT doesn't have them either, a situation that seems pretty common by many accounts. In this situation only the pin and bushes are controlling fore and aft movement and going by my V8 they allow a certain amount of movement. I'd been aware these were missing on my roadster for some time, and was pretty sure I had looked but couldn't find anyone stocking them. But at the time of writing MG Parts UK (cheapest, item 14) and both Moss Europe (item 14) and Moss US (item 95) are showing them with a price indicating they are available. If you have the later restraint rod then the front control brackets are superfluous, little trouble to refit if you have them, but not worth retro-fitting. But for cars without the restraint rod they are worth adding, and I have placed my order!