27th July 2020: A sad day, I sell the ZS.

It was a real wrench to hear someone else start it up and drive it away, but still a glorious sound from the engine and exhaust. Unfortunately it did have to go as it was needing more time and effort to find and fit parts now it is fifteen years old and a classic in its own right. I need at least one car that needs minimal attention year on year, and for that reason it has been replaced by a Golf. I don't have the space to keep the ZS as well as it has lived outside the twelve years I have had it, getting either of the MGBs out of the garage was a bit of a 'missing square puzzle', and with four cars both the ZS and the Golf would be used even less than the ZS has been. The ad only appeared on Car and Classic late Saturday or early Sunday and on Sunday night when my phone was in 'quiet hours' and doesn't ring the same chap rang eight times. Ed also sent me an email, and phoned again on Monday morning. Drove up from Gloucester with a transporter mid-day, and bought it without driving it. He said he wanted one to restore and obviously knew what he was talking about so I was happy to accept his offer to go to 'a good home'. It was a brilliant car to drive, I shall miss it.

It was a real wrench to hear someone else start it up and drive it away, but still a glorious sound from the engine and exhaust. Unfortunately it did have to go as it was needing more time and effort to find and fit parts now it is fifteen years old and a classic in its own right. I need at least one car that needs minimal attention year on year, and for that reason it has been replaced by a Golf. I don't have the space to keep the ZS as well as it has lived outside the twelve years I have had it, getting either of the MGBs out of the garage was a bit of a 'missing square puzzle', and with four cars both the ZS and the Golf would be used even less than the ZS has been. The ad only appeared on Car and Classic late Saturday or early Sunday and on Sunday night when my phone was in 'quiet hours' and doesn't ring the same chap rang eight times. Ed also sent me an email, and phoned again on Monday morning. Drove up from Gloucester with a transporter mid-day, and bought it without driving it. He said he wanted one to restore and obviously knew what he was talking about so I was happy to accept his offer to go to 'a good home'. It was a brilliant car to drive, I shall miss it.

Postscript: I've never been a fan of Elvis and only came across 'Always on my mind' from the Pet Shop Boys, but the lyrics are applicable even though it's 'only' a car. It suddenly struck me that although I enjoyed driving the ZS I did really only drive it when we couldn't use either of the MGBs for any reason. In my mind the ZS was a 'long term' car just like the MGBs, and 'We have all the time in the world'. But of course we didn't, and I wish now I had driven it more, particularly on wet Sunday mornings to get the paper when instead of just going to the shop and back I could have made more of a trip of it, like I do with the MGBs, the Golf and subsequently the Mercedes A-Class. 'Use it or lose it'.

Get a birth certificate for your MG Rover ZR/ZS/ZT. There seem to be at least two options - one from the MGOC which has limited information, and another from MG-Rover.org which is more comprehensive. For my car the latter tells me:

- This vehicle was the 23,358th ZS to run off the production line, out of 27,514

- This vehicle was the 6,267th ZS 180 to be made out of 6,876

- This vehicle was the 239th ZS in Mica Blue (Ignition) (code: JGY) to be made out of 999 Mica Blue (Ignition) ZSs

- It came off the assembly line on Thursday, 19th August 2004 @ 00:17:46 and was sold on 1st September 2004.

There is also the 'How many left' web site which gets its data from the DVLA database, but that has to be treated with caution. Searching on 'MG ZS' gets a list of many variants including 'V6', which shows only 61 left on the road as of Q1 2019 plus 44 on SORN. However it shows the peak as 154 cars in Q4 2006, and none before 2004 which is obviously wrong, given that the MG-Rover site says there were 6,876 ZS 180s made from 2001 to 2005, so the vast majority of those must be registered under a different description. Adding up the peak numbers for all those ZS variants (excluding the Chinese cars from 2016 on) I get to 20,496, whereas MG-Rover above says there were 27,514. So 7,000 short, most of which seem to be the ZS 180 which is 6,722 short. However Roger Parker tells me that 5563 ZS were exported, many of which were 180s so wouldn't appear on the DVLA record, but that still leaves over 1000 cars 'missing'.

Nevertheless, the DVLA figure of 61 probably does represent how many face-lift ZS 180s are left on the road.

One year on: Unfortunately our illustrious chancellor in the 2008 budget has seen fit to raise the car tax from £210 to £415 in the interests of ecology. The annoying thing is that I could have a Bentley, Ferrari, Aston, or even a Hummer and only pay £25 more! And what price the resale value now, let alone the insurance valuation?

One year on: I suddenly noticed the right front tyre looked a bit flat, and found it well down at about 15psi! After that I kept an eye on it and found it was losing a few psi per week. Took the wheel off and rolled it down the drive looking very closely for a nail or anything but found nothing, and at that rate of loss dunking it in a bath of water wasn't going to be easy to find it either. Then at the MOT the tester noted 'nail in right front tyre' so I though he must have good eyesight. Took the wheel off again, and immediately noticed a huge silver screw in the middle of the tread sticking out like a, well, huge silver screw in the middle of the tread! Pulled it out and it was only in 1/2" but had obviously been there some time. Dribbled some water into the hole and waited ... and waited ... and eventually after several minutes a tiny bubble of air popped out, and continued to do so once every several minutes. So that is leaking, the question is whether it is the only leak and somehow I missed that screw when I looked last time, or whether it is another more recent leak and the original remains, I don't know. Had it repaired (£17) and whilst the tyre was off the repairer showed me the paint bubbling up on the inner rim which he had to scrape off and repaint to get a good seal. He said MG Rover wheels are the worst for corrosion as they only paid for a minimal coat of paint. He said his scraping and repainting would give a good seal for a very long time now, but when left they eventually start leaking, so that could have been my original non-screw leak. Time will tell.

February 2009:That front tyre repair has been fine, but now I find the left rear is going down. Not consistently like the other, it can lose nothing over two weeks, then suddenly go almost completely flat on a journey of just a couple of miles. Seems unlikely to be a puncture, I suspect inner rim corrosion as mentioned by the tyre chap when repairing the front. But a friend suggested checking the valve first, screwed in very tight so I settled for depressing it as far as I could and letting a good blast of air out, then pumping back up. Since when it seems to have been OK ... Two 'punctures' on the ZS in a few months when I have only had one each on the other MGs over the previous 20 years is most odd though. Subsequently, probably is rim corrosion as I found it completely flat after a bit of exuberant driving, which may well have affected the seal of the bead to a corroded rim.

One year on: However I don't like the pull-pull dip-switch arrangement, when you want to flash the headlights unless you are very careful you also change the beam, so you have to flash them again to switch the beam back again. Why they fiddle with these things I just do not know, what could be simpler than the MGB arrangement? Still, it doesn't have the same arrangement for the indicators, thank goodness, I've driven a BMW with those and they are awful.

Started looking for something to stop the seal sticking to the glass. Of course silicone spray came up, although for the channels, not the seal. Then I came across a recommendation for a German product called Sonax Gummi Pflege which is primarily intended to dress door and seals to stop them sticking in icy conditions, with a couple of mentions of weather stripping. Bought some, and the tube and the stuff inside is just like Pritt Stick ... and then I started wondering if 'Gummi' was German for adhesive! But it spreads over the seals, and can be rubbed in without a trace of stickiness. I subsequently see that the literal translation of 'gummi pflege' is 'rubber maintenance', so I'll see how it goes. Rubbed some on the boot seal as well as the lid usually sticks down when opened with the cabin lever or remote, and see how that goes as well.

June 2020: The middle section needs replacing again having crumbled at the flange for the rear box, when I was trying to remove that to replace the ARB bushes that side! Initially I was a bit peeved as it didn't seem long since it was done, but I see it was 2014 so six years isn't bad I suppose, and I dare say it wouldn't have failed had I used the air-gun on it instead of a socket. Gave up on the middle to back cat connection as I didn't want to do the same thing, so entrusted it to Cranmore Garage to see if they could shift it without collateral damage. In which case I'd get the exhaust done, get it back to do the calipers, then back to Cranmore for another MOT, otherwise scrap it there and then. They did get it off quite easily as it turned out, so ordered all the stuff. Exhaust was a pain with it taking longer than advertised, then forgetting to send the gaskets, then when told about that they sent them and another exhaust!

Cranmore fitted it but said the hangers on the new section were about an inch out, which has pulled the rear section to one side and the tail pipe is very close to the cut-out in the rear bumper.

June 2019: Fails the MOT on the back box leaking: 'Major - repair immediately", together with a list of advisories. I knew it would fail (although not on this as usually you can hear a blowing exhaust) as for some reason I was reluctant to make the appointment at the beginning of the '30 days in advance'. Then a few days later I got a phone call to say their MOT hoist had been condemned and they couldn't do it for two weeks! By this time I'd paid, but I did ponder getting it moved to another branch but dismissed that, and my sense that it was going to fail was reinforced. Back to the fail, and Halfords proceeded to give me my options including scrapping it (!) or taking it somewhere else to get it fixed, but stated that a fail immediately cancelled the existing MOT (which still had a week to run), and if I drove it I could be picked up by ANPR cameras and fined, and my insurance would be invalid, which started the second saga.

I did opt to leave it, but primarily because of the difficulty of getting parts for these cars now (only 66 still taxed as of the end of 2018), which was what I did when I had the central section replaced a while ago, also that if another part was a problem I didn't want to replace just the back box, then bring it back for a retest only for it to fail again. They said they would let me know - this was at 10:30. Nothing by 4pm so I called them, so be told they had taken the back box off and got a replacement! In addition to starting the work without advising me or getting my agreement, they had received the wrong item (too short, so it was one for the hatch and not the saloon which is longer). They expected to get the correct replacement next morning by 11:30 and would let me know. I played my face about not being kept informed and he said they would do the job at cost - £135, which was OK as far as the job went, but still left the 'you can't drive it' statement outstanding. Next day 12:30 comes and goes with no phone call, so I call them to be told it is done and they were just doing the paperwork - another failure to keep me informed. Collect the car, and ask again about his statement regarding the existing MOT, and he is adamant. But subsequent research shows he is telling porkies. So another complaint to head office about what could be construed as lies to get work, and they reduce the charge by a further 50%. I accept that, but it leaves a nasty taste considering I've been using them for multiple cars for 30 years or more, and I decide to take the V8 to another place nearby. I'll see how I feel for the next round of MOTs.

Looking at the new back box it was immediately obvious that it didn't come back quite so far as the old one - barely reaching the trim round the aperture in the bumper. I did wonder whether they had fitted the shorter one with a spacer at the flange, but no. Then when I looked inside the tail-pipe I could see there was a 'chisel' end inside, with an extension piece bolted on, like a tail-pipe trim! Now whether the exhaust came like that, or whether Halfords couldn't get the longer one and decided to add the trim (they don't stock this design online) remains to be seen.

Looking at the new back box it was immediately obvious that it didn't come back quite so far as the old one - barely reaching the trim round the aperture in the bumper. I did wonder whether they had fitted the shorter one with a spacer at the flange, but no. Then when I looked inside the tail-pipe I could see there was a 'chisel' end inside, with an extension piece bolted on, like a tail-pipe trim! Now whether the exhaust came like that, or whether Halfords couldn't get the longer one and decided to add the trim (they don't stock this design online) remains to be seen.

April 2018:

While working on the right rear caliper I noticed the exhaust waggled more than I expected, looked underneath and found the rear hanger rubber broken. Called in at Halfords and got another one of theirs for 91 and later Escort - and it's significantly bigger than the one that has come off! So much so that once on the box bar it doesn't want to point upwards to go on the body bar. The previous one was OK with the after-market box, so it looks like when I had the original box refitted in 2014 Halfords replaced it with the correct item, in which case it's not lasted very well. Do a bit of research and although Rimmers don't list one for the ZS 180, several other places say it is DBP7104 which is the same as for the other MG Rover models on the Rimmer site, and also for many other marques and models, so I order one from a Land Rover site which are showing several pounds cheaper than MG sites. Along the way I spotted this hanger for Fiat and Alpha - with a reinforcing band round the outside, so I'm thinking of doing the same with a cable-tie. Fit the rubber to the long bar on the box, jack up the box so the upper hole is in line with the body bar, and it goes on quite easily despite the corrosion on the box bar. Still jacked up to take a bit of stretch out of the rubber, I fit a cable tie round the rubber which takes some of the load. A cable tie on its own (as it came to me) resulted in a surprising amount of noise and harshness, I'll soon see if this adds any (it doesn't).

While working on the right rear caliper I noticed the exhaust waggled more than I expected, looked underneath and found the rear hanger rubber broken. Called in at Halfords and got another one of theirs for 91 and later Escort - and it's significantly bigger than the one that has come off! So much so that once on the box bar it doesn't want to point upwards to go on the body bar. The previous one was OK with the after-market box, so it looks like when I had the original box refitted in 2014 Halfords replaced it with the correct item, in which case it's not lasted very well. Do a bit of research and although Rimmers don't list one for the ZS 180, several other places say it is DBP7104 which is the same as for the other MG Rover models on the Rimmer site, and also for many other marques and models, so I order one from a Land Rover site which are showing several pounds cheaper than MG sites. Along the way I spotted this hanger for Fiat and Alpha - with a reinforcing band round the outside, so I'm thinking of doing the same with a cable-tie. Fit the rubber to the long bar on the box, jack up the box so the upper hole is in line with the body bar, and it goes on quite easily despite the corrosion on the box bar. Still jacked up to take a bit of stretch out of the rubber, I fit a cable tie round the rubber which takes some of the load. A cable tie on its own (as it came to me) resulted in a surprising amount of noise and harshness, I'll soon see if this adds any (it doesn't).

February 2014: No further problems with exhaust mountings, but other work needed. The original insurance company had no qualms about the modified exhaust, but renewing online elsewhere for a £100 saving there were no questions on the form but perusing the documentation subsequently I noticed a statement about modifications that was pre-filled with 'None'. Rang the company and told them, and they wanted to know how much BHP it added. I said I didn't know, and they suggested I ring the previous owner! I told them I'd had the car six years, and they asked what previous insurance companies had done about it. I told them they had been fine with it, but they insisted on knowing the BHP. I couldn't find out what make it was, and vendors of other after-market systems wouldn't say, saying it depended on all sorts of factors including fuel grade, and even the weather! I made some enquiries about putting it on a rolling road, at about £80, but had no guarantee the insurance company would accept that. It's going to be easier just to replace the back box with the original. Get under the car to start that, and find the nuts between middle and back sections heavily corroded so will need cutting off. Also whereas the original back box has welded studs facing forwards, the middle section appears to have studs facing backwards! And going by the nuts the studs would be equally as bad, so I'd have to cut them off and drill them out, and use nuts and bolts. So maybe it had been a 'cat back' enhancement i.e. both middle and back sections. Another factor is that been aware of a slight blow near the middle of the car for a while, and I found a very small hole in the centre box. No point in swapping the back box without replacing the centre section. But as the weather has been lousy lately, and it would need the ZS up on the ramp i.e. the two MGBs outside, I decided to have someone else do it.

Halfords quoted me £120, I could have got it cheaper at Sh*tFit but wouldn't trust them not to wreck the very expensive cat section, so had it done at Halfords, including swapping the rear boxes. I had the after-market rear box back, with a view to eBay-ing it, but the flange was so heavily corroded even though the rest of the system was pretty-well pristine stainless, I just junked it.

Halfords quoted me £120, I could have got it cheaper at Sh*tFit but wouldn't trust them not to wreck the very expensive cat section, so had it done at Halfords, including swapping the rear boxes. I had the after-market rear box back, with a view to eBay-ing it, but the flange was so heavily corroded even though the rest of the system was pretty-well pristine stainless, I just junked it.

March 2009: The exhaust knocked in slow-speed manoeuvres over dropped kerbs and sleeping policemen right from the start. I did get underneath soon after purchase to see if there was anything I could do, and found a cable tie on the rear support for the back box, even though the proper rubber one was fitted to the body pin. So I removed the cable tie and fitted the rubber, but if anything the knocking was slightly worse, and was probably why the cable tie was there! However whereas before there had been noticeable NVH (Noise, Vibration and Harshness) it had now gone so that was a benefit. I've lived with the knocking for some time now, but with the onset of spring and warmer weather I decided I had to do something about it. If I waggled the tail pipe it knocked up and down as well as side to side, but with a different noise. Getting underneath I discovered the pipe leading into the back box was knocking on the anti-roll bar in side to side movement, but in up and down it was the tail pipe knocking on the bumper trim. I also noticed the refitted rubber support had split one side, so that would need replacing anyway. Down to Halfords to see what they had on the shelf, and they only had one of that style, for a 91 and later Ford Escort. Same distance between mounting holes, same profile, but about 50% thicker. Less than £2 so worth a go. Wondered if the extra thickness would make fitting much harder, but it hardly did at all. I don't know whether the Rover mounts are softer, or mine had gone soft even when I refitted it, but with the new mount the rear box is held much firmer, not hitting either anti-roll bar or bumper. As ever, time will tell.

February 2009: Leaving all the dash vents open but angled away from the occupants seems to have done the trick - mostly. Warms up quicker now, and copes with varying outside temperatures from below freezing to needing the chiller better. But the cabin still gets over-warm to begin with, and on a long run in cold weather it seems to get too cool so one has to up the temperature a degree or two. But overall much better than before, I rarely have to touch anything but the demister button. One spectacularly illogical feature concerns the outside temperature, displayed by pushing a button. The display can show both internal and external temperatures in degrees C or F, and to switch between them you hold a 'temperature' button down for a second. Wouldn't you think this would be the button to switch between internal and external temperatures as well? Oh no - you have to use the demister button!

2018: After eleven years I think I may have cracked it! As well as setting the air flow manually to body, feet, body & face or screen, and the fan speed above or below what the computer thinks is appropriate, there is an 'Auto' button that sets everything back to 'normal', and for direction this is body & face and computer controlled speed. But I've discovered that if I set the direction manually to feet, the temperature sensor 'warms up' much quicker to turn the heat down after starting off, and one's feet don't get cold after running for some time. Only discovered in late Spring, so I'll see what happens over winter.

June 2014: Had the car 7 years now, and the air-con has gradually become less effective over that time. In good weather we are usually using the MGBs, so are well used to being very warm, so for both those reasons it wasn't something I really noticed. However it occurred to me that it probably wasn't a very good idea to let it run out of fluid, if that wasn't good for the system.

I investigated various options - companies large and small, as well as DIY kits, also scanned forum posts. Now the summer is upon us (in season if not weather) companies that were charging £25 or so in winter are charging £49 or more. DIY kits just add more fluid, but by the time you have bought a bottle plus the gauge and connector you are talking about the same money. The other problem with those is that they don't check for leaks, don't add leak detection fluid, and they don't add fluid by weight which is what you are supposed to do, and adding fluid to a pressure reading you can end up with too much or nowhere near enough. So I opted for a local mobile specialist - Roadchill at £20 for a system check and £20 for a recharge if all was good.

First thing was to check the pressure which with A/C off was near normal, although way down with A/C on. Next was to extract the remaining fluid - 140 gm left, so no major leaks. Next evacuate the system as another leak check, then add leak detector for any future problems as well as lubricant. Finally add new fluid by weight - 560 gm. Before the work face-vent temp was 23C, after 6C. Very happy with the job, I can recommend Roadchill.

June/July 2018: Not used the ZS for several weeks while the weather has been so good, until one day for just a very short trip when it wasn't really worth getting the V8 out. Ambient 24C, output didn't seem much cooler than that at max. Later on I put the thermometer in one of the vents - 39C just after switch-on, dropping to 35C ... er, I think it's bust. Back to Roadchill, who said there was still some pressure left so he didn't think it was a major fault, and that four years wasn't bad (despite being 10 years and only a gradual reduction last time). Recharged - temp 3.1C. In those inevitable words - "We shall see ...".

Summer 2019: Barely chilling, not spending any more money on it.

Summer 2020: Not chilling at all, and ditto.

Battery Added May 2009

Cut-off Switch

Battery or Starter Problems?

The ZS tends to stand for a week quite often, longer in the summer when we use the V8 for pottering around. I'd been aware that the battery had been getting a bit soft for a while, but it didn't fail to start the car until this week. As that was just under a week after I had driven the car for an hour or more, and the starter was really whizzing the engine over the day after that, it's time for a replacement. As it was an MG/Rover battery, presumably the original, 4 1/2 years or so isn't bad I suppose. As luck would have it I had a sheet of discount vouchers for National Tyres and Autocare including £10 off batteries. Did some research and Halfords have a 5-year HCB075 with 60Ah at the 20-hour rate and 540 'starting' amps at £85, whereas the original states 63Ah and 570CCA. They also have a 4-year HB075 at £75. National Tyres have a 5-year GTE 075 with 600 'Voltage charge' (presumably CCA!) at £82 and a 4-year version with 540 at £72 so slightly cheaper than Halfords. You also get an 8% discount for ordering on-line from National (specifying the fitting station you want to use, then they tell you when it is in stock), although with my voucher I was able to do even better than that. Straight-forward dropping the new battery in, at the cost of losing the radio tuning and clock time.

Update February 2014: Although I added the cut-off switch in 2009 I generally only use it in the summer when the car could go for several weeks without being used in the better weather. Normally in the winter it got regular runs of 80 miles or so. However this winter for various reasons it's only doing a few miles per week, and I've noticed the cranking speed gradually getting slower, much as it did in 2009. I didn't want to pay-out for a new battery after just five years, when the two MGBs are lasting double that, so I thought I'd try a boost charge. It's always been the case that vehicle charging systems won't put back the full charge if the battery has been significantly discharged, as they are limited to 14.5v or less. These batteries are designed to give a high current for a short period of cranking, not to be noticeably discharged then recharged, unlike 'leisure' batteries for caravans and motor homes. However boost charging - within limits - will restore a battery capacity. So I took the battery off (not without some trauma) and recharged it on the bench with my high power charger. Initially it took just under 6 amps and registered only 13v, but after about five hours it had dropped to 4 amps and registered about 15.5v (on charge, dropped rapidly to just over 13v off-charge). Refitted it, check the car started, then left it overnight with the cut-off switch not turned off. Next morning cranking was significantly faster than previously, and that was after a night of alarm and ECU discharge. Ditto after two more days of not being turned off, and journeys of just a few miles, so the capacity restoration ploy seems to have worked. I shall have to use the cut-off switch as a matter of course from now on.

April 2018: Still using the battery bought in May 2009, and no more boost charges needed, so using the cut-off switch after every trip unless I know I'll be using it the next day seems to work. As a comparison Vee's battery was fitted in January 2004 and still going, that cut-off switch (and Bee) goes off every time I put her away in the garage regardless. This is because to turn off and on just means reaching behind the seat, whereas for the ZS I have to lift the bonnet.

Autumn 2019: Failed to start but as in June I had bought a lithium battery pack following another sudden battery failure in Bee it was only a moment work to get going. After a few short runs here and there it was holding up, but cranking was getting a bit slow after a couple of weeks of non-use, so I gave it another boost charge with the same results as before i.e. left overnight without the cut-off switch being off it cranks over just fine, so battery still OK - 10 years now.

Battery Clamp Problems: Incidentally the trauma in removing the battery was that initially the clamp bolt was quite stiff, then came free with a 'ping'. However nothing so convenient as shearing the clamp bolt, the welded nut under the battery box had broken free, trapping the battery. And of course the battery box fixing bolts are under the battery. However with a strip of metal to protect the battery case I was able to use a large screwdriver to lever the clamping flange on the other side back just enough to get the battery out, which enabled me to remove the battery box and re-weld the nut. This time along all four sides of the (square) nut, rather than tack-welds at each corner. All refitted with copper-grease, and another example of checking you can undo things before you have to, instead of waiting until you need to, find you can't, and are stranded.

Cut-off Switch:

Given the experience with the V8 some years ago when I stopped using that every day, and having to replace the battery every 18 months or so, I didn't want the same thing to happen with the ZS so I have been disconnecting the earth strap unless I know I'm going to be using it next day. Ironically my son has just bought (another) classic BMW (M3 E30 limited edition) with the same problem and a new battery so he is doing the same thing. The ZS is fairly convenient in that the clamps have a top nut instead of a side nut and I happened to find a socket on a tommy-bar that is a perfect fit for the nut, courtesy of some self-assembly furniture we bought years ago ("If you haven't found a use for something yet, you haven't kept it long enough"), so it is relatively easy to remove and refit. The BMW needs a spanner, but the tool-tray is right beside the battery so again no big deal. I had eventually fitted a battery cut-off switch (with a bypass fuse direct to the clock to avoid having to continually reset it) to the V8 which has solved it's battery problems, so have been looking at ways of making things easier on both the ZS and the BMW. I'll have the same problem with the clock (and the radio) in the ZS. Fortunately F8 in the engine compartment fusebox feeds both them both, so if I remove that and connect a separately fused supply direct from the live-side of the cut-off switch to the load side of that fuse holder, they will stay powered when the cut-off switch disconnects everything else. One minor inconvenience is that I'll have to lock the three passengers doors with their buttons, and the drivers door with the key. The cable doesn't run past a convenient panel in the passenger compartment like it does with the V8, so I will have to suspend the switch in the cable and lift the bonnet each time, unless I can find a convenient place to mount the switch in the firewall under the dash somewhere, which would mean running longer cables to battery and fusebox. That in itself should be no big deal, as there are two cables coming off the battery post - one going direct to the solenoid for cranking which I shall leave as is, and the other connecting to the alternator and remainder of the cars electrics, which carries much less current than the cranking cable. Standard starter cable (likewise the switch) will have no problem carrying these non-cranking loads and cause negligible volt-drop even on longer cables, which would still be shorter than the cranking cables in the MGB or BMW. If I didn't want to keep the radio and clock alive in theory there would be a very slight benefit in putting the switch in the earth cable, but as there are three cables coming off the clamp it would have to cut off all three, which would mean attaching all those three to the switch then a single cable from the switch to the battery. The switch and battery cable would then be carrying all the load, i.e. including cranking, so cable length would start to become relevant. In order to be able to provide a bypass circuit for the clock and radio, I must switch the 12v supply and not the earth, or I'd have to get to the back of the dashboard, find and remove all existing earth paths, then provide new wiring to the clock and radio, no mean task.

Given the experience with the V8 some years ago when I stopped using that every day, and having to replace the battery every 18 months or so, I didn't want the same thing to happen with the ZS so I have been disconnecting the earth strap unless I know I'm going to be using it next day. Ironically my son has just bought (another) classic BMW (M3 E30 limited edition) with the same problem and a new battery so he is doing the same thing. The ZS is fairly convenient in that the clamps have a top nut instead of a side nut and I happened to find a socket on a tommy-bar that is a perfect fit for the nut, courtesy of some self-assembly furniture we bought years ago ("If you haven't found a use for something yet, you haven't kept it long enough"), so it is relatively easy to remove and refit. The BMW needs a spanner, but the tool-tray is right beside the battery so again no big deal. I had eventually fitted a battery cut-off switch (with a bypass fuse direct to the clock to avoid having to continually reset it) to the V8 which has solved it's battery problems, so have been looking at ways of making things easier on both the ZS and the BMW. I'll have the same problem with the clock (and the radio) in the ZS. Fortunately F8 in the engine compartment fusebox feeds both them both, so if I remove that and connect a separately fused supply direct from the live-side of the cut-off switch to the load side of that fuse holder, they will stay powered when the cut-off switch disconnects everything else. One minor inconvenience is that I'll have to lock the three passengers doors with their buttons, and the drivers door with the key. The cable doesn't run past a convenient panel in the passenger compartment like it does with the V8, so I will have to suspend the switch in the cable and lift the bonnet each time, unless I can find a convenient place to mount the switch in the firewall under the dash somewhere, which would mean running longer cables to battery and fusebox. That in itself should be no big deal, as there are two cables coming off the battery post - one going direct to the solenoid for cranking which I shall leave as is, and the other connecting to the alternator and remainder of the cars electrics, which carries much less current than the cranking cable. Standard starter cable (likewise the switch) will have no problem carrying these non-cranking loads and cause negligible volt-drop even on longer cables, which would still be shorter than the cranking cables in the MGB or BMW. If I didn't want to keep the radio and clock alive in theory there would be a very slight benefit in putting the switch in the earth cable, but as there are three cables coming off the clamp it would have to cut off all three, which would mean attaching all those three to the switch then a single cable from the switch to the battery. The switch and battery cable would then be carrying all the load, i.e. including cranking, so cable length would start to become relevant. In order to be able to provide a bypass circuit for the clock and radio, I must switch the 12v supply and not the earth, or I'd have to get to the back of the dashboard, find and remove all existing earth paths, then provide new wiring to the clock and radio, no mean task.

Update July 2009: Not long after writing this section I came across this Battery Brain which automatically disconnects the battery if it drops below 12.1v. There are a number of models - all can be manually reset using a button on the unit, the Type II can be reset using a remote, and the Type III can be disconnected and reset using a remote, making it the most convenient, at the expense of another fob hanging around. The Type IV offers a manual switch which can be fitted inside the cabin for disconnection and reconnection instead of a plipper. This does away with the extra key fob (and a saving of £10) at the slight expense of having to manually open the door to reconnect the power if, as seems sensible, you have the switch inside the cabin. However a significant inconvenience is having to manually lock all the doors after turning the unit off, as none of them lock with a door open i.e. before I flip the cabin switch to disconnect the power. £60 for the Type III version with full remote is a bit pricey, even £45 for the basic version is expensive and still results in the same drain until it comes into play, so I think I'll opt for a mechanical under-bonnet switch as the doors will lock with the bonnet up, albeit at the expense of a polite warning beep from the horn. Subsequently realised the following points:

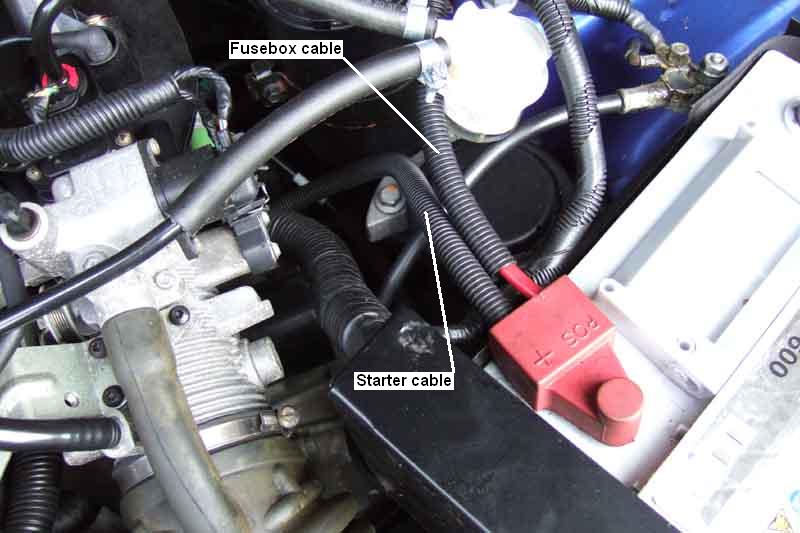

There is a completely separate cable from the battery to the starter which only carries current when the starter is operating, so I only need to interrupt the cable from the battery to the main fusebox, for which the smallest battery cut-off switch will be more than adequate. I looked at a DisCarNect which mounts on the battery post, but the two +ve cables on the ZS are crimped into a special battery connector and I don't want to have to cut that off and solder new lugs onto each cable. So I'm going for the same type of switch as I've used on the MGBs, which inserts into the a cable run. I could cut the existing cable and solder two new lugs but again I don't want to do that so a bit of lateral thinking is called for. The battery cable attaches to the fusebox with a conventional lug, so if I unbolt that and connect that to one side of my switch, then get another ready-made cable for between the other side of the switch and the fusebox I am sorted, and it can be restored to normal very easily. That leaves the clock and radio memory to be reset each time we use the car, but again that is solvable the same way as on the V8. Cut-off switches often come with bypass fuses, but all they do is prevent someone cranking the car when the switch is off, it doesn't stop the drain as all the electrics are still powered as normal. The answer is to remove the existing fuse (F8) and take a new in-line fuse (15A) from the live side of the cut-off switch into the fusebox, terminated with a male spade connector, and insert that into the load side of F8! Remember before doing any work on the electrics to disconnect the earth cable, not the 12v cable, and reconnect it last.

There is a completely separate cable from the battery to the starter which only carries current when the starter is operating, so I only need to interrupt the cable from the battery to the main fusebox, for which the smallest battery cut-off switch will be more than adequate. I looked at a DisCarNect which mounts on the battery post, but the two +ve cables on the ZS are crimped into a special battery connector and I don't want to have to cut that off and solder new lugs onto each cable. So I'm going for the same type of switch as I've used on the MGBs, which inserts into the a cable run. I could cut the existing cable and solder two new lugs but again I don't want to do that so a bit of lateral thinking is called for. The battery cable attaches to the fusebox with a conventional lug, so if I unbolt that and connect that to one side of my switch, then get another ready-made cable for between the other side of the switch and the fusebox I am sorted, and it can be restored to normal very easily. That leaves the clock and radio memory to be reset each time we use the car, but again that is solvable the same way as on the V8. Cut-off switches often come with bypass fuses, but all they do is prevent someone cranking the car when the switch is off, it doesn't stop the drain as all the electrics are still powered as normal. The answer is to remove the existing fuse (F8) and take a new in-line fuse (15A) from the live side of the cut-off switch into the fusebox, terminated with a male spade connector, and insert that into the load side of F8! Remember before doing any work on the electrics to disconnect the earth cable, not the 12v cable, and reconnect it last.

Just connected to two lengths of cable the switch would flap about quite a bit, so a mounting bracket is called for. The switch needs to be easily accessible, not block access to anything else as far as possible, and be clear of the bonnet. There is a nice triangular space between the fusebox and an air-con pipe that fits the bill, so next I need a couple of mounting points. There is a what is probably a suspension mounting stud with several threads clear of the nut, which should be suitable with a second nut, and I can use one of the fusebox mounting points. I cut, shape and trim a card template to suit, then use that as a pattern for cutting a bracket out of a sound section off an old MGB wing, with additional flanges for strength. Cut, drill, bend and weld the bracket into shape, then paint. My previous two switches I have bought at the annual Stoneleigh spare show in February but I don't want to wait that long. Halfords have the identical item at about £12, but that is more than double what I paid, so I look around on the web. Several ads on eBay for silly money (like 99p!) which I just don't trust, plus some others at various prices all plus postage of course. Then I think of Min-Its only a couple of miles from me, a classic Mini specialist from which I've bought 20W/50 oil and some headlight parts recently. They have the same switch, and at less than £6 and no postage that gets my vote. The switch is actually intended to mount on the front of a panel, but that requires a large and irregular hole which would take most of the strength out of the panel, so I opt to mount the switch from the back which only needs a much smaller round hole. I don't want to leave the lugs and nuts on the bottom of the switch bare and risk shorting, so a couple of rubber covers at the princely sum of 44p each fits the bill. Min-Its didn't have these, nor a couple of local auto electricians, so they did have to come from the web and its postage charges, but very quickly (less than 24 hours) from Auto Electric Supplies Ltd. Halfords have a selection of ready-made battery cables in both red and black (£4 for 18"), and I have a spare inline blade fuseholder. I also have some split ribbed tubing to protect the switched cable and bypass wire, and some large diameter heat-shrink to seal that to the cables at the fusebox end as per the original, which gives an element of moisture sealing. I did find I had to open out the end of the original cable being moved from the fusebox to the switch to fit the switch studs, and also the switch end of the additional cable. I also had to trim a male spade slightly to fit in place of the original clock and radio memory fuse, as the spades on those are slightly thinner and narrower. There is still the drain of the clock and radio of course, but that is only about 9mA, and a significant chunk of that is the flashing LED in the radio (visible with the face-plate off and ignition off to act as a deterrent) which is off half the time reducing the current still further. Not long enough for me to see on my analogue meter, but it is less than 5mA. Original drain is about 27mA to 30mA (pulsing between them) so a useful saving.

Just connected to two lengths of cable the switch would flap about quite a bit, so a mounting bracket is called for. The switch needs to be easily accessible, not block access to anything else as far as possible, and be clear of the bonnet. There is a nice triangular space between the fusebox and an air-con pipe that fits the bill, so next I need a couple of mounting points. There is a what is probably a suspension mounting stud with several threads clear of the nut, which should be suitable with a second nut, and I can use one of the fusebox mounting points. I cut, shape and trim a card template to suit, then use that as a pattern for cutting a bracket out of a sound section off an old MGB wing, with additional flanges for strength. Cut, drill, bend and weld the bracket into shape, then paint. My previous two switches I have bought at the annual Stoneleigh spare show in February but I don't want to wait that long. Halfords have the identical item at about £12, but that is more than double what I paid, so I look around on the web. Several ads on eBay for silly money (like 99p!) which I just don't trust, plus some others at various prices all plus postage of course. Then I think of Min-Its only a couple of miles from me, a classic Mini specialist from which I've bought 20W/50 oil and some headlight parts recently. They have the same switch, and at less than £6 and no postage that gets my vote. The switch is actually intended to mount on the front of a panel, but that requires a large and irregular hole which would take most of the strength out of the panel, so I opt to mount the switch from the back which only needs a much smaller round hole. I don't want to leave the lugs and nuts on the bottom of the switch bare and risk shorting, so a couple of rubber covers at the princely sum of 44p each fits the bill. Min-Its didn't have these, nor a couple of local auto electricians, so they did have to come from the web and its postage charges, but very quickly (less than 24 hours) from Auto Electric Supplies Ltd. Halfords have a selection of ready-made battery cables in both red and black (£4 for 18"), and I have a spare inline blade fuseholder. I also have some split ribbed tubing to protect the switched cable and bypass wire, and some large diameter heat-shrink to seal that to the cables at the fusebox end as per the original, which gives an element of moisture sealing. I did find I had to open out the end of the original cable being moved from the fusebox to the switch to fit the switch studs, and also the switch end of the additional cable. I also had to trim a male spade slightly to fit in place of the original clock and radio memory fuse, as the spades on those are slightly thinner and narrower. There is still the drain of the clock and radio of course, but that is only about 9mA, and a significant chunk of that is the flashing LED in the radio (visible with the face-plate off and ignition off to act as a deterrent) which is off half the time reducing the current still further. Not long enough for me to see on my analogue meter, but it is less than 5mA. Original drain is about 27mA to 30mA (pulsing between them) so a useful saving.

The first time I reconnected the power using the switch the alarm went off, something it hadn't done when I had been removing the earth connection. I think the problem is that I had used the key fob to lock the doors for convenience while I still had the bonnet up, which sets the alarm, but when I reconnected power the doors were unlocked and one of them open as well as the bonnet. I recalled that the alarm 'remembers' its state even after a battery disconnection for security, so I'm not going to be able to lock the doors with the key fob before switching off the power, but will have to go back to locking the doors manually i.e. alarm not set before I switch off. I may be able to use the central locking from the key in the drivers door which doesn't set the alarm instead, before switching off and closing the bonnet, but will have to wait to test that for something other than a Sunday morning! And in that event locking the door with the key with the power on means it has to be unlocked with the plipper or the alarm goes off.

Body February 2020

It's a bit of a mystery, although the back of the car faces south-east it's the vertical surface not the horizontal which one might expect to suffer more from sun damage. Also why now, in winter, when the summer before last was more notable for hot sun than last year? I've sent off for some spray paint, it's not worth spending any money on a full strip and repaint at a body-shop. Next day after more wind and rain more lifting edges are showing, so how extensive the problem will be is anyone's guess.

Bonnet Badge Added November 2012

Where the ZS was parked at the previous house the bonnet faced due south and the badge had faded almost completely to silver. I remembered Roger Parker describing in the MGOC magazine that this happened, and having prised up the old badge carefully from the front as it is stuck on with double-sided sticky tape and the back is inaccessible. The problem is that the badge sits in a recess and there is very little space to get a blade under without damaging the painted grille. Subsequently I saw a reference to using fishing line to cut through the double-sided sticky-tape, which seemed to make more sense. In any case there was little point in doing anything about it while the car was still parked in the same place.

Where the ZS was parked at the previous house the bonnet faced due south and the badge had faded almost completely to silver. I remembered Roger Parker describing in the MGOC magazine that this happened, and having prised up the old badge carefully from the front as it is stuck on with double-sided sticky tape and the back is inaccessible. The problem is that the badge sits in a recess and there is very little space to get a blade under without damaging the painted grille. Subsequently I saw a reference to using fishing line to cut through the double-sided sticky-tape, which seemed to make more sense. In any case there was little point in doing anything about it while the car was still parked in the same place.

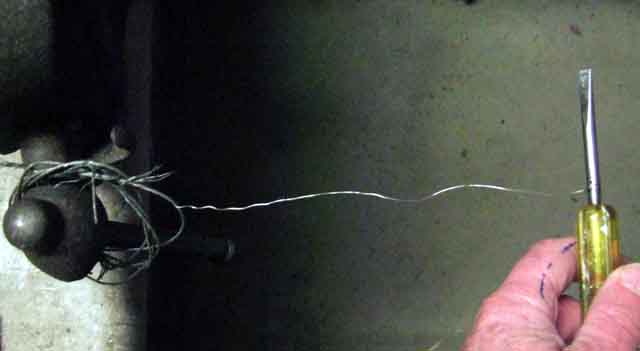

Then we moved house and now the front of the car is only in sun for a short time each morning, so when I eventually get round to getting some new covers for Vee's tailgate props from Brown and Gammons I get a new badge as well. I'm not a fisherman, but scrounged some line off a pal of a pal. However that didn't seem to make any impression on the tape before breaking, maybe the cold weather is making the tape harder. I've got an old bicycle brake cable inner, so I peel a strand of that off, and being steel should be much stronger. Pull it back and fore over the shaft of a screwdriver to straighten out the spiral, and tie a loop in each end so I can use two screwdrivers as handles - and realise I have made myself a garrote!

Then we moved house and now the front of the car is only in sun for a short time each morning, so when I eventually get round to getting some new covers for Vee's tailgate props from Brown and Gammons I get a new badge as well. I'm not a fisherman, but scrounged some line off a pal of a pal. However that didn't seem to make any impression on the tape before breaking, maybe the cold weather is making the tape harder. I've got an old bicycle brake cable inner, so I peel a strand of that off, and being steel should be much stronger. Pull it back and fore over the shaft of a screwdriver to straighten out the spiral, and tie a loop in each end so I can use two screwdrivers as handles - and realise I have made myself a garrote!

It slides under the badge easy enough, and with relatively little pressure cuts through the bottom half of the tap and partly up the sides. There are two pegs on the back of the badge which stop it coming up all the way. But with that much done it's easy to get a fingernail under the bottom of the badge, and the top half comes away. The tape on the top half has peeled off the grille completely, but the bottom half where the garrotte cut through is shredded with some stuck to the back of the badge and some to the grille, but again peels off easily with a fingernail, and I clean up the recess ready for the new badge. The garrotte had put a couple of fine scratches on the edge of the recess, so silver or grey was showing through. With the badge offered up you would have to look very closely to see them against the silver badge surround, but the dealership mixed some paint for touching-up when I bought the car, and that was still liquid even though it was in a plastic mixing cup with a lid, and it was five years later! A fine brush soon covered the scratches.

It slides under the badge easy enough, and with relatively little pressure cuts through the bottom half of the tap and partly up the sides. There are two pegs on the back of the badge which stop it coming up all the way. But with that much done it's easy to get a fingernail under the bottom of the badge, and the top half comes away. The tape on the top half has peeled off the grille completely, but the bottom half where the garrotte cut through is shredded with some stuck to the back of the badge and some to the grille, but again peels off easily with a fingernail, and I clean up the recess ready for the new badge. The garrotte had put a couple of fine scratches on the edge of the recess, so silver or grey was showing through. With the badge offered up you would have to look very closely to see them against the silver badge surround, but the dealership mixed some paint for touching-up when I bought the car, and that was still liquid even though it was in a plastic mixing cup with a lid, and it was five years later! A fine brush soon covered the scratches.

I play a heat-gun onto the recess and the back of a badge to warm them up (holding the badge on my palm so I can be sure I'm not going to damage it or the grille), peel off the backing, and stick it in place. Don't go by the writing on the back of the badge, that is upside down compared to the logo on the front! Apply some pressure around the badge and job done, about half an hour.

I play a heat-gun onto the recess and the back of a badge to warm them up (holding the badge on my palm so I can be sure I'm not going to damage it or the grille), peel off the backing, and stick it in place. Don't go by the writing on the back of the badge, that is upside down compared to the logo on the front! Apply some pressure around the badge and job done, about half an hour.

However since moving house the bulk of the sun is now on the offside rear quarter and the boot, and fading the badges there!

Discs

Dust Shields

Calipers

ABS, and Speedo

Brake Pads Added June 2011

After an advisory on brake pads at the MOT a couple of years ago I bought a set (pukka MG Rover) but found there was plenty of meat still on them. Pleased to see springs, piston shims, and even four new bolts as part of the kit. Same last year, so thought I would have a look at them this year. Book specifies 3mm minimum friction material, mine have 4mm plus, and there are wear indicators so I decide to leave them in, no point in changing them too soon given the mileage I do. However Haynes is not correct in its instructions for pad changing. It says to remove the lower caliper bolt and pivot the caliper upwards, but the caliper only moves a few degrees before it runs out of brake hose! This is because the caliper hose comes off the strut and not the body, so only needs to be just long enough as the two ends have a fixed relationship to one another. So both bolts have to come out and the caliper tied up out of the way. June 2016: At least ... they did until I realised that if you detach the clip securing the hose to the strut (arrowed here), it does give you enough hose to pivot the caliper upwards and fully off the pads.

After an advisory on brake pads at the MOT a couple of years ago I bought a set (pukka MG Rover) but found there was plenty of meat still on them. Pleased to see springs, piston shims, and even four new bolts as part of the kit. Same last year, so thought I would have a look at them this year. Book specifies 3mm minimum friction material, mine have 4mm plus, and there are wear indicators so I decide to leave them in, no point in changing them too soon given the mileage I do. However Haynes is not correct in its instructions for pad changing. It says to remove the lower caliper bolt and pivot the caliper upwards, but the caliper only moves a few degrees before it runs out of brake hose! This is because the caliper hose comes off the strut and not the body, so only needs to be just long enough as the two ends have a fixed relationship to one another. So both bolts have to come out and the caliper tied up out of the way. June 2016: At least ... they did until I realised that if you detach the clip securing the hose to the strut (arrowed here), it does give you enough hose to pivot the caliper upwards and fully off the pads.

Updated June 2012: MOT looming so decided to change the pads anyway. Still plenty of meat, I reckon at least as much again from the wear indicator touching the disc, but I might as well. All pretty straight-forward, I just had to clean a bit of corrosion off the carriers before I could get the new springs in, but that's all. One initial concern on pushing the pedal afterwards to push the pistons back out before driving off (I don't want a repeat of the V8 where I forgot once and had no brakes when rolling off my sloping drive!), engine running, was that the pedal went a long way down even after having reset the pistons, and under heavy pressure seemed to be sinking. However it stopped before reaching the floor, and driving even when pressing the pedal quite heavily to bed the pads in it didn't seem to go down anywhere near as far, and in normal driving it felt the same as before. The thing is I've never sat with the engine running and pressed the pedal very hard before, so I don't know what it was like before, could just be hose expansion. However the following year it failed on front brake balance, the discs had always been ropey, so had to change them ... and consequently the pads again.

Rears

Fronts: June 2013 Annoyingly failed the MOT on front brake balance - 34% and 19%. Absolutely no pull on the steering, which tends to confirm my theory that modern suspension alignment is such that the king-pin and tyre contact patch relationship prevents it, otherwise ABS would fling you one side or the other unless tyre grip was equal both sides, certainly not something to be depended upon. One thing I had noticed was a faint pulsing at the pedal, although only since I changed the pads, from the calipers as it slows with road speed i.e. not the ABS, which I've only ever activated on snow and ice and then only rarely. I had also been aware that the outer surface of the right-hand disc wasn't polished right across and had been like that since the pad change at least, but it was only when looking at the left-hand disc and finding that polished right across that I could see the reason for the imbalance. The calipers were fine when I changed the pads, i.e. piston movement and carrier movement, so whilst I shall have to spring for new discs and another set of new pads I'm hoping the caliper is OK. I'm very light on brakes, keeping my distance on motorways so I can usually control my speed just with the throttle, and on minor roads using anticipation to lose speed through deceleration except for the final stop. Sudden hard braking is rare. A pal says I need to be more of a hooligan and use them more, the Navigator would not agree!

New discs and pads ordered, I'm expecting problems freeing the discs from the hubs. They have counter-sunk screws like MGB rear drums, and just as unnecessary in use as the wheels clamp the discs to the hubs. However I see from a photo when I changed the pads that the screws and the area of the discs where they are (one side at least) was clean and shiny then, so may come undone OK, but the centre hole may be a different matter as that is a snug fit to centralise the disc on the hub and is showing rust. Before ordering the parts I need to check the calipers are free both in terms of the piston and the sliding carrier on each, which they are and is a relief. And while I'm doing that I might as well see how much of a problem I'm going to have getting the discs off. Right side screws come off just with a screwdriver, the disc needs a couple of taps with a wooden mallet so easy enough. The left side screws were tighter so before I damaged the slots I used my impact driver on them and they came undone ... and that disc just fell off. Ordering the parts it was a toss-up between MG Rover stuff from Rimmer at about £170 plus P&P, or Mintex from eBay at £115 inc P&P and I opt for the latter - noting that discs and pads for the MGB would be less than that. With these discs having to be replaced in 9 years and 40k miles, whereas the V8 discs are originals at nearly 40 years and over 200k miles, I don't think the extra cost is warranted. Maybe change my mind if these discs have to be replaced in 4 years!

Parts ordered Friday pm and arrive Monday am, good service from Motor Spares Dewsbury. Discs (Mintex) have some sharp edges, so watch your fingers, I wiped the surfaces off with brake/carb cleaner and a clean cloth to remove surface oil from manufacturing. The pads (also Mintex) have huge chamfers on the leading and trailing edges maybe removing as much as a third of the initial contact patch, which will increase as the pads wear down, probably not reaching the full contact surface until they are one third worn. One thing to note is that these are bare pads, if yours have been on a long time then I'd recommend getting MG Rover pads as these come with anti-squeal shims for both the pads and the pistons, anti-chatter springs for the carriers, and even new caliper bolts. Changing mine last year the caliper bolt heads had rusted quite a bit, one needing an under-sized socket hammered on before it could be undone.

Parts ordered Friday pm and arrive Monday am, good service from Motor Spares Dewsbury. Discs (Mintex) have some sharp edges, so watch your fingers, I wiped the surfaces off with brake/carb cleaner and a clean cloth to remove surface oil from manufacturing. The pads (also Mintex) have huge chamfers on the leading and trailing edges maybe removing as much as a third of the initial contact patch, which will increase as the pads wear down, probably not reaching the full contact surface until they are one third worn. One thing to note is that these are bare pads, if yours have been on a long time then I'd recommend getting MG Rover pads as these come with anti-squeal shims for both the pads and the pistons, anti-chatter springs for the carriers, and even new caliper bolts. Changing mine last year the caliper bolt heads had rusted quite a bit, one needing an under-sized socket hammered on before it could be undone.

Removal was easy as everything came undone easily this time, it took more time fiddling the pads into the anti-chatter springs on the right-hand caliper than anything else. Copper grease on centre hole of the discs, and the locating screws, as well as the caliper bolts. If I thought the outside of the right-hand disc was bad, the inside surfaces of both were dire. As well as being different amounts of clean metal on each, giving the unbalanced braking, I can also see that the amount of clean metal varies around one of the discs, which will give the pulsed braking I have increasingly been able to feel. Back together a static test showed much less sinking of the pedal than with just the pad change. A short drive and several moderate braking checks from about 50mph has good feel and retardation, and back home both discs show even initial marking from the pads so hopefully not much bedding-in required. Next day the MOT retest is successful, even though I can see slight imbalance between the sides on the braking machine when both are checked together, possibly just needs fully bedding-in.

Removal was easy as everything came undone easily this time, it took more time fiddling the pads into the anti-chatter springs on the right-hand caliper than anything else. Copper grease on centre hole of the discs, and the locating screws, as well as the caliper bolts. If I thought the outside of the right-hand disc was bad, the inside surfaces of both were dire. As well as being different amounts of clean metal on each, giving the unbalanced braking, I can also see that the amount of clean metal varies around one of the discs, which will give the pulsed braking I have increasingly been able to feel. Back together a static test showed much less sinking of the pedal than with just the pad change. A short drive and several moderate braking checks from about 50mph has good feel and retardation, and back home both discs show even initial marking from the pads so hopefully not much bedding-in required. Next day the MOT retest is successful, even though I can see slight imbalance between the sides on the braking machine when both are checked together, possibly just needs fully bedding-in.

Rears: September 2013 Last MOT there was an advisory that the right rear was grabbing slightly. Nothing this year but a couple of weeks ago I noticed some brown staining on that wheel, then a couple of days after that it was squeaking when going backwards. Thought it might be the wear indicator so had a squint at the outer pad and it seems to be worn down to the backing, whereas the left outer has bags of meat left on it - I wonder if the right caliper is sticking ... Order a pair of discs and pads from the same place I got the fronts and they arrive in a couple of days.

Get the right rear wheel off, and the first thing I do is check that the disc screws will undo. A bit tighter than the fronts were, but still came undone with my impact screwdriver and a mallet. Next was to push the piston back in, as you can never get pads off the edge of old discs as they are thicker there as well as being rusty. Piston doesn't want to move, maybe the caliper is seized. Oh well, see if I can get them off anyway.

Next was to remove the carrier complete with caliper and pads from the hub, and compared to the fronts that is a bit of a fiddle. My socket only just goes on the lower bolt - really it needs a slim-line socket as it is very close to the suspension arm, and I have to try various extensions before I can undo both. Try and remove the assembly from the disc, but it jams before it has got half-way, that piston simply isn't moving. If it is the caliper then the other one might be as bad, so refit that side and have the same battle with the other side, with the same result. Hmmm, both calipers seized? I refit it and get the navigator to pull the handbrake on and off, and press and release the foot brake while I turn each wheel, and both wheels are braked and released as they should be, so what's going on?

Off to the internet to have a browse, and I discover that because the handbrake acts on the pads via the caliper piston, there is a ratchet mechanism behind the piston that acts as a self adjuster for the handbrake as the pads wear, and you have to wind the pistons back in with a special tool, you can't just press them back in! So that's what going on. Haynes doesn't say anything about that in disc replacement, but it does in pad replacement. It also says to remove the caliper, carrier and pads complete when changing the disc, but as I've discovered that is unlikely to be possible with old discs. It looks like I'll have to disconnect the caliper from the carrier and lift that out of the way, and then remove the carrier with pads, before I can get the disc off. But as one has to press the piston in while turning it, I may have to remove the caliper, remove the pads, remove the carrier, remove the disc, refit the carrier, and refit the caliper so as to hold it firmly while I press and turn the piston! Then remove the caliper again, remove the carrier, fit the new disc, refit the carrier, fit the new pads, and refit the caliper - quite a palaver. One of the internet sources I browsed has a link to a source for the rewinder. They are just a couple of miles from me, but as they do free postage and I have run out of time anyway I opt to order online and it arrives in a couple of days.

This time I remove the caliper from the carrier. Top bolt is fine but the bottom bolt is shrouded by the hydraulic pipe, that would have to be disconnected with the inevitable need for bleeding in order to get a socket on it. I do have a 12mm ring spanner, but it is a ratchet ring and I don't like using those for the initial undoing of a nut, but I don't have any solid metric rings. Nevertheless I give it a go, and a few taps with a mallet shift that one on both sides. Caliper comes off quite easily, and can be suspended from the rear box bracket on the drivers side, and a hole in the inner wing (for the fuel pipe cover that was fitted to early cars) for the passenger side. I remove the pads from the carrier while that is still attached to the suspension arm as they are quite tight and need to be drifted out. If had removed that first I would have had to clamp it in a vice. Drivers outer pad completely worn out, inner pad nearly so. Passenger pads well down. Next the carrier comes off - for some reason it was much easier to get a socket and short extension on the two bolts this time, and finally the disc.

This time I remove the caliper from the carrier. Top bolt is fine but the bottom bolt is shrouded by the hydraulic pipe, that would have to be disconnected with the inevitable need for bleeding in order to get a socket on it. I do have a 12mm ring spanner, but it is a ratchet ring and I don't like using those for the initial undoing of a nut, but I don't have any solid metric rings. Nevertheless I give it a go, and a few taps with a mallet shift that one on both sides. Caliper comes off quite easily, and can be suspended from the rear box bracket on the drivers side, and a hole in the inner wing (for the fuel pipe cover that was fitted to early cars) for the passenger side. I remove the pads from the carrier while that is still attached to the suspension arm as they are quite tight and need to be drifted out. If had removed that first I would have had to clamp it in a vice. Drivers outer pad completely worn out, inner pad nearly so. Passenger pads well down. Next the carrier comes off - for some reason it was much easier to get a socket and short extension on the two bolts this time, and finally the disc.

I had wondered if I would need to reattach the carrier to the suspension arm, and the caliper to the carrier, to hold it firmly enough to be able to screw the piston back into the caliper with the rewinder, but it turned quite easily. The rubber dust-seal did start to snag a bit as the piston was nearly fully in as the edge of the piston was quite rusty, so I wound it out again and used a small file around the edge to clean it up which allowed the piston to bottom without twisting the seal.

Clean up the new disc with brake cleaner and fit that. Refit the carrier to the suspension arm, with a smear of copper-grease on the faces of the retainer spring that butt up against the edge of the pads. Fit the pads, the outer goes in fine, but the inner goes so far then stops. Peering round the back I realise it is the wear indicator spring, the free end has to be lifted up with a screwdriver so it fits over the edge of the carrier. The biggest potential problem is that these Mintex pads are bare pads i.e. no springs, shims, and sliding pin bolts that the pukka MG Rover front pads came with. I discovered that when I changed the front discs and pads, but there the 'missing' items had only been fitted a couple of years previously so bare pads were fine. I had forgotten that for the rears, I should have got just the discs and got pukka pads elsewhere even at the higher price. Fortunately the springs are fine, the shims for the backs for the pads are pretty corroded but are just about OK to reuse. Copper grease on both sides of the shims, and the caliper slides over them - I had wondered if there would be enough clearance with the corrosion on the shims. Then it's just a matter of refitting the sliding pin bolts, tightening them and the carrier bolts, and refitting the wheel. The handbrake comes up a helluva long way to begin with after doing the second side (didn't seem much different after the first), but after a couple of pumps on the foot-pedal and raising and dropping the handbrake a couple of times it settled back down to a more normal position. Quick test-drive round the block, footbrake is fine, but the handbrake is (still) pretty poor, but then again the pads need to bed-in. About 2 hours for both sides, including setting up i.e. jacking under the boot floor before putting axle stands under the sill supports just in front of the wheels, then packing everything away. All-in-all easier than I was expecting.

Dust Shields: January 2020

February 2020: Roger Parker advises that SEC100120 was superseded to SEC000100 way back, SEC000100 fits MG and Rover. Circa £25 each from All Car Parts Fast and MG Rover Genuine

Brake Calipers June 2016

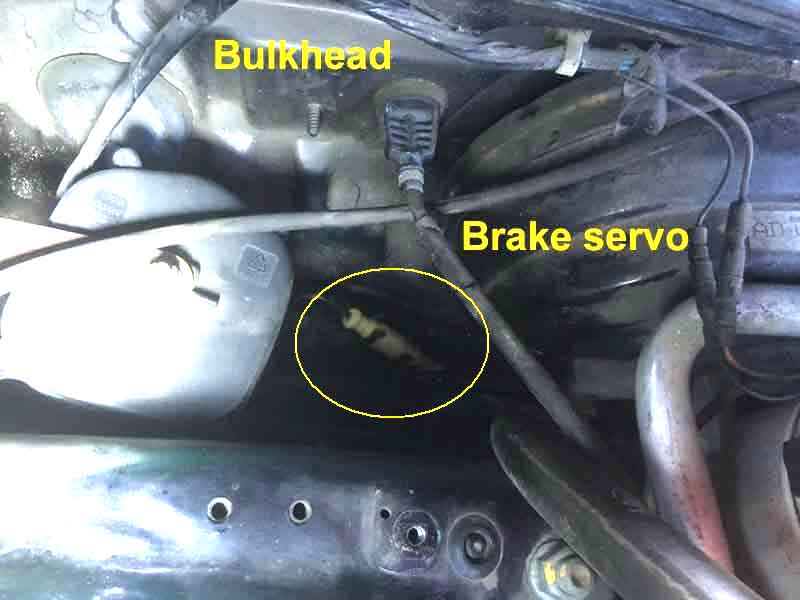

June 2020: MOT failure on O/S front and N/S rear dragging, and advisory on N/S front, which surprises me as I checked them two days before and although the off-side rubbed a bit (probably the dust shield as per the near-side previously) both seemed to turn OK. I did notice the N/S rear which will need a replacement and disc and pads as done to the off-side in 2018, but didn't do it before the MOT as I wanted to know what else it was going to fail on! Exhaust centre section also damaged during replacement of the rear ARB bushes, so I'm debating whether to do all of it to give me some breathing space to get a replacement, or effectively scrap it and get something else. NS rear and OS front (the failures) came off surprisingly easy, cleaned up the pads in the carriers so they were moving OK, but the pistons in both seized.

Couldn't undo the centre to back cat joint so gave it to Cranmore Garage to try, if they damaged the back cat then I'd scrap it there and then, but it came off OK with their specialist kit so ordered the exhaust (nightmare!) and both calipers. B&G have the front but not the rear saying they aren't getting them back in exchange for new ones, and Rimmers have the rear but not the front, albeit at the huge price of £124 plus £66 surcharge against return of the old unit. B&G surcharge is only £12 (for the front, £36 for the rears) - probably why they don't get them back, and as the cheapest carrier to send one back is £5 they won't be getting mine back either! I find another source - Spareto - at half the price of Rimmer and no surcharge so go for that, to discover they are in Estonia and it is shipped via Poland! B&G item arrives next day, Spareto takes a week but with all the faffing with the exhaust it's not an issue.

Once the exhaust has been done I get the car back and next day start on the calipers - rear first, then the front. Rear a bit of a fiddle, front very straightforward, both done less-bleeding in not much more than an hour. Left hose clamps in place on both. I left the bleeding until after I had changed both as the Navigator has to do the pedalling, not having an EeziBleed cap to fit the master, and she was shopping. Not ideal as if they still don't feel right you won't know which one has the problem. Rears seemed to take a few strokes to get what seemed like the tiniest bubbles out, front only took a couple of strokes, but pedal left spongy and long. So did them again, rear first this time with the handbrake released (an info sheet that came with the caliper indicated that the handbrake shouldn't even be connected until after bleeding). Did several strokes starting with a few quick jabs to 'pump them up' then the long hard stroke for maximum pressure, before opening and shutting the bleed nipple, and seemed to get more tiny bubbles out. Ditto the front but that seemed completely clear. Still seems a bit long under hard pressure - much harder than I need to press when driving, but didn't pump up, and a test drive felt completely normal. So MOT booked, and I'll see what comes from that.

Front:

June 2020: Replacement very straightforward having shifted all the bolts previously. Had to reuse the copper washers for the hose banjo as although this caliper came with a carrier, sliding pin bolts and the three stainless pad shims those washers weren't included.

June 2018: Another advisory about the OSF wheel binding, verbal this time otherwise it would have been a fail under the new rules! The caliper came off the pads surprisingly easily, whereas I had to drift the pads out of the carrier! So this time it looks like the pads binding in the carrier, much as the OSR were, although in that case the piston was failing to retract after the handbrake had been used as well. With the caliper off and the pad out I took the carrier off and over to the bench, and scraped/filed the corrosion off from under the stainless shim that 'ears' of the pads press down on. Lightly copper-greased all metal to metal contact points and the pads slide back in easily. Refitted the caliper, applied the brakes, released, and could press piston back by levering between the disc and the carrier on the outer pad side, so all looks well. After a drive and normal braking, on a barely perceptible incline, within about a second from stopping and releasing the brakes the car started creeping, so that looks fine.

Some years earlier: Advisory at the MOT said the 'o/s/f brake was dragging slightly'. Took both front wheels off and levered the outer pad back from the disc, and whilst the near-side moved OK the off-side was reluctant, so that will need looking at, although both wheels were turning equally freely. Then a couple of weeks later coming home from a trip away I became aware of quite a loud wittering noise intermittently, that was definitely me and the off-side, that went as soon as I touched the brake pedal. I then started to notice it pulling to the left very slightly on braking, so definitely needs looking at sooner rather than later.