What happens inside?

Setting-up

Air Filters

Pistons, Covers and Dampers

Lifting pins

Needles

Jets

Floats and Valves

Butterflies and Spindles

Throttle Pedal and Cable

Return Springs and Linkages

Ports and Vent/Overflow Pipes

Flooding/Overflowing

Vacuum Port June 2017

Hoses July 2015

Flange Gaskets

Heat Shield March 2018

Dates and Codes

Choke Control

Reconditioning

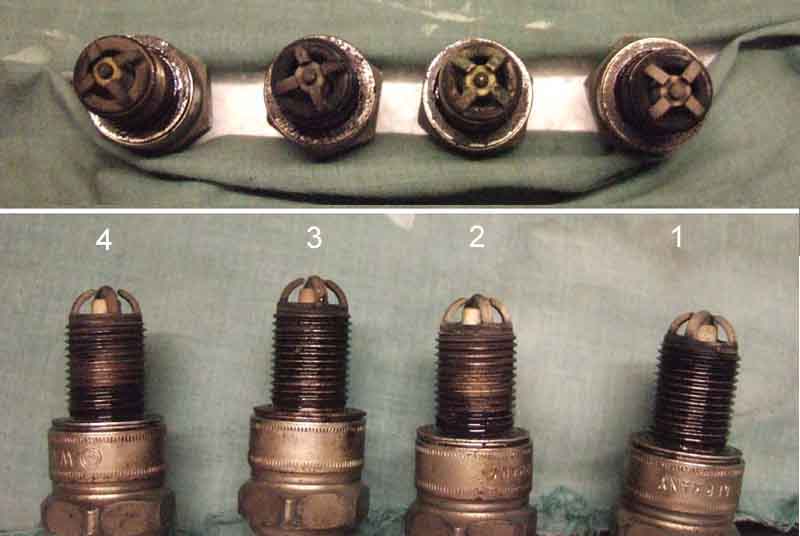

Plug Colour

V8 - which carb feeds which cylinder?

Done properly, and not fiddled with afterwards, SUs will keep their tune for many thousands of miles. A superb quote that I have seen attributed to Lawrie Alexander of British Sportscar Centre is that "90% of the problems with SUs are due to Lucas electrics" i.e. the ignition system. Before setting-up the carbs it is essential that the valve clearances, plug gaps, points gap/dwell and timing including operation of the centrifugal and vacuum advance mechanisms are correct and any defects causing erratic or rough running are fixed.

The MGB was originally provided with HS4 carbs for all markets, the rear having a vacuum advance port above the butterfly. In August 1971 with the then new 18V engine all export markets changed to HIF carbs - 18V584Z for North America, 18V581/582/583Y for other export markets. North American engines now had the vacuum source on the inlet manifold, other markets still from the rear carb but now underneath the butterfly. UK or 'home market' cars stayed with HSs on 18V581/582/583F engines, then in November 1973 they switched to HIFs on 18V779/780F engines (late CB, November 1973) again with a port under the rear carb butterfly, and non-North American export models had the same engines and carbs. With the change to rubber bumpers UK and non-North American export models moved the vacuum source to the inlet manifold. In December 1974 North America changed to a single Stromberg/Zenith carburettor on 18V797/798 engines until the end of production. Other export markets continued with HIFs and the same engines as the UK until the 1977 model year at which point all LHD cars were to North American spec - and only roadsters as North American GTs ceased production in December 1974. There were several additional carb spec changes during production.

The SU carb is brilliantly simple in its design, with very little to go wrong. However the later HIF (which stands for 'Horizontal Integral Float', by the way) is a bit more complex than the earlier HS, which I think stands for 'Horizontal Side float'. Why not HSF then? Who knows? The 'Horizontal' in both cases refers to the direction of air flow into the engine, as opposed to the 'down-draft', or 'semi down-draught' you might see applied to some other designs of carb. Visual identification is simple - on the HIF the float chamber is contained within the main body of the carb and actually surrounds the bottom of the jet whereas on the HS the float chamber is to one side of the main body of the carb and has an external pipe connecting it to the jet. Whilst technically the HIF is an improvement over the HS, for a number of reasons there is no good reason to convert to HIFs if you already have HSs, and if you are converting to SUs from Zenith/Stromberg or an aftermarket conversion and have the choice of HSs or HIFs then HSs would be marginally preferable for their simplicity. The diagrams below are of an HS unless otherwise indicated, click on a thumbnail for a full-size image in a different window.

Put simply the SU carb consists of a butterfly valve on the engine side of the carb connected to the throttle pedal and this controls the volume of air being pulled through the carb and into the combustion chambers. However there is another independent 'valve' in the air passage, and this is the large piston which is on the air-cleaner side of the butterfly. The piston is relatively free to rise and fall depending on how much the butterfly is open or closed as will be seen later. Attached to the bottom of the piston is a tapered needle projecting downwards into the open end of a tube (the jet) containing liquid fuel, the height of which is controlled by a float and valve in the float chamber (not shown). With the butterfly mostly closed i.e. at idle the piston will be at the lower end of its travel so it is blocking most of the air passage through the carb. Also the widest part of the needle is in the jet so blocking most of its opening, and therefore little fuel is being mixed with the air, but the ratio of air to fuel (given correct adjustment of the carb) will be correct. With the butterfly fully open the piston will be fully raised allowing the maximum amount of air to flow through the carb, the needle will have its narrowest portion in the end of the jet, so unblocking most of its opening, and the maximum amount of fuel is being mixed with the air, but again the ratio of air to fuel will be correct. Generally this state of affairs will be obtained for any throttle butterfly opening, and hence any vertical position of the piston in the air passage and the needle in the jet. If you look through the carb it is not the same diameter all the way through. Across the top of the jet there is a raised portion the width of the throat - the bridge. This restricts the diameter of the carb throat at that point, which has the effect of speeding the airflow over it and hence over the top of the jet. This lowers the air pressure above the jet (Bernoulli's Principle) which is what causes fuel to be drawn up into the airflow to produce the mixture. So as well as the thickness of the needle in the jet controlling how much fuel is drawn up, the speed of the air flowing past the jet is also having the same effect. In steady state conditions although the volume of air increases as the butterfly opens and the piston rises, the speed of the air across the top of the jet remains much the same. However as the piston rises the narrowing needle allows more fuel to be drawn up from the jet even though the speed of the airflow is much the same. Later on we will see what happens when the speed of the airflow increases for the same needle position in one case, and the size of the jet orifice is increased for a constant volume and speed of airflow in another case.

Put simply the SU carb consists of a butterfly valve on the engine side of the carb connected to the throttle pedal and this controls the volume of air being pulled through the carb and into the combustion chambers. However there is another independent 'valve' in the air passage, and this is the large piston which is on the air-cleaner side of the butterfly. The piston is relatively free to rise and fall depending on how much the butterfly is open or closed as will be seen later. Attached to the bottom of the piston is a tapered needle projecting downwards into the open end of a tube (the jet) containing liquid fuel, the height of which is controlled by a float and valve in the float chamber (not shown). With the butterfly mostly closed i.e. at idle the piston will be at the lower end of its travel so it is blocking most of the air passage through the carb. Also the widest part of the needle is in the jet so blocking most of its opening, and therefore little fuel is being mixed with the air, but the ratio of air to fuel (given correct adjustment of the carb) will be correct. With the butterfly fully open the piston will be fully raised allowing the maximum amount of air to flow through the carb, the needle will have its narrowest portion in the end of the jet, so unblocking most of its opening, and the maximum amount of fuel is being mixed with the air, but again the ratio of air to fuel will be correct. Generally this state of affairs will be obtained for any throttle butterfly opening, and hence any vertical position of the piston in the air passage and the needle in the jet. If you look through the carb it is not the same diameter all the way through. Across the top of the jet there is a raised portion the width of the throat - the bridge. This restricts the diameter of the carb throat at that point, which has the effect of speeding the airflow over it and hence over the top of the jet. This lowers the air pressure above the jet (Bernoulli's Principle) which is what causes fuel to be drawn up into the airflow to produce the mixture. So as well as the thickness of the needle in the jet controlling how much fuel is drawn up, the speed of the air flowing past the jet is also having the same effect. In steady state conditions although the volume of air increases as the butterfly opens and the piston rises, the speed of the air across the top of the jet remains much the same. However as the piston rises the narrowing needle allows more fuel to be drawn up from the jet even though the speed of the airflow is much the same. Later on we will see what happens when the speed of the airflow increases for the same needle position in one case, and the size of the jet orifice is increased for a constant volume and speed of airflow in another case.

So how does opening the butterfly cause the piston to rise, and the needle with it? With the engine at idle the butterfly is mostly closed and the piston is mostly lowered. But far from 'idling' in the usual sense of the term i.e. doing nothing, the engine is acting like a large vacuum pump due to the action of the pistons in the cylinders. On the engine side of the butterfly i.e. in the inlet manifold there will be quite a large vacuum, which is measured in inches of mercury (in. Hg.), and can be up to 18 or 20 in. Hg. However between the butterfly and the piston there will only be a few in. Hg., and on the air cleaner side of the piston the air will be virtually at atmospheric pressure i.e. 0 in. Hg. Now consider the instant the driver opens the throttle a significant amount, say to accelerate away from traffic lights. The butterfly opens, but with the piston still mostly closed the large vacuum that existed on the engine side of the butterfly is now present between the butterfly and the piston. The piston has a couple of holes on the butterfly side near its base with passages to the space above the piston and its large skirt, so the vacuum is applied above the skirt. Although there is a gap between the edge of the skirt and the inside face of the piston cover it is a very small gap, so virtually none of the vacuum 'leaks' away. Now below the piston skirt there is a passage way to the two breather holes in the air filter flange, so the whole of the bottom of the skirt is at atmospheric pressure. Vacuum above, atmospheric below, causes the piston to rise. This increases the air flow into the engine and raises the needle out of the jet, which increases the fuel flow into the engine, so more mixture in the cylinders, a bigger bang when the plugs fire, and the engine accelerates the car.

So how does opening the butterfly cause the piston to rise, and the needle with it? With the engine at idle the butterfly is mostly closed and the piston is mostly lowered. But far from 'idling' in the usual sense of the term i.e. doing nothing, the engine is acting like a large vacuum pump due to the action of the pistons in the cylinders. On the engine side of the butterfly i.e. in the inlet manifold there will be quite a large vacuum, which is measured in inches of mercury (in. Hg.), and can be up to 18 or 20 in. Hg. However between the butterfly and the piston there will only be a few in. Hg., and on the air cleaner side of the piston the air will be virtually at atmospheric pressure i.e. 0 in. Hg. Now consider the instant the driver opens the throttle a significant amount, say to accelerate away from traffic lights. The butterfly opens, but with the piston still mostly closed the large vacuum that existed on the engine side of the butterfly is now present between the butterfly and the piston. The piston has a couple of holes on the butterfly side near its base with passages to the space above the piston and its large skirt, so the vacuum is applied above the skirt. Although there is a gap between the edge of the skirt and the inside face of the piston cover it is a very small gap, so virtually none of the vacuum 'leaks' away. Now below the piston skirt there is a passage way to the two breather holes in the air filter flange, so the whole of the bottom of the skirt is at atmospheric pressure. Vacuum above, atmospheric below, causes the piston to rise. This increases the air flow into the engine and raises the needle out of the jet, which increases the fuel flow into the engine, so more mixture in the cylinders, a bigger bang when the plugs fire, and the engine accelerates the car.

So how does the piston know how far to rise? As the piston rises it 'unblocks' the flow of air into the space between the butterfly and the piston, which reduces the vacuum there and above the piston. This reduces the difference in air pressure above and below the piston, which reduces the force causing it to rise. The piston will continue to rise, and continue to reduce the vacuum above the piston, until it reaches the point where the air pressure both sides of the piston and skirt are largely equal again. It will stabilise at a point where the vacuum between the butterfly and piston, and hence above the piston, are more or less at the same level it was before accelerating. It is this feature that causes this type of carburettor to be called a 'constant depression' or 'constant vacuum' carburettor i.e. no matter how big the throttle opening is under steady state conditions the vacuum between butterfly and piston will always be much the same. If you manually raise the piston further than it wants to go, the vacuum between the piston and the butterfly and above the skirt reduces, and when released the piston will fall back to its previous level. Similarly if the piston is manually pushed down the vacuum between piston and butterfly and above the skirt increases trying to pull it back up again, and when released the piston will rise back to its former level, and the amount of vacuum between butterfly and piston will be maintained.

So how does the piston know how far to rise? As the piston rises it 'unblocks' the flow of air into the space between the butterfly and the piston, which reduces the vacuum there and above the piston. This reduces the difference in air pressure above and below the piston, which reduces the force causing it to rise. The piston will continue to rise, and continue to reduce the vacuum above the piston, until it reaches the point where the air pressure both sides of the piston and skirt are largely equal again. It will stabilise at a point where the vacuum between the butterfly and piston, and hence above the piston, are more or less at the same level it was before accelerating. It is this feature that causes this type of carburettor to be called a 'constant depression' or 'constant vacuum' carburettor i.e. no matter how big the throttle opening is under steady state conditions the vacuum between butterfly and piston will always be much the same. If you manually raise the piston further than it wants to go, the vacuum between the piston and the butterfly and above the skirt reduces, and when released the piston will fall back to its previous level. Similarly if the piston is manually pushed down the vacuum between piston and butterfly and above the skirt increases trying to pull it back up again, and when released the piston will rise back to its former level, and the amount of vacuum between butterfly and piston will be maintained.

That is generally the case, but in practise there is a physically large but quite weak coil spring between the top of the piston and the outer cover pressing down on the piston and so restricting its rise somewhat. This is another feature to ensure the correct balance of air to fuel across the range of throttle opening, and means that a progressively larger vacuum is required the higher the piston rises. However the difference in vacuum between idle and full throttle piston heights is relatively small compared to the up to 20 in. Hg or so available in the inlet manifold. The spring strength, carb throat diameter, needle shape and jet size are all chosen to give the correct mixture across the operating range of the carb in any particular application. For a larger or smaller engine, single or multiple carbs, with or without supercharger, etc. the carb throat size, needle shape, jet size, spring strength etc. will all be chosen to give the correct results for that application. You can't just bolt on a bigger carb without doing anything else and expect your car to go faster, indeed it will probably perform worse. Likewise if you make changes to engine capacity, breathing, valve timing etc. you probably won't get the best out of them unless you change the carb parameters as well. What changes to make under what circumstances is a huge subject.

That is basically it. However whenever the throttle is suddenly opened the volume of air passing through the carb is able to increase faster than the volume of fuel can increase coming out of the jet. This has the effect of weakening the mixture, which causes the engine stumble when accelerating. To counteract this on top of the large piston there is a cylinder filled with oil - the damper cylinder. Attached to the outer cover there is a small damper piston sitting in this oil. As the large piston tries to rise the damper cylinder also rises, and because the damper piston is fixed this has the effect of forcing the damper piston further into the cylinder. As the lower end of the cylinder is sealed, and oil is not compressible, the only way the large piston can rise is for oil to be forced past the damper piston. The dimensions of both damper cylinder and damper piston are carefully set to that the oil flows past at a known rate, and hence controls the rise of the large piston. This damps or slows down the rise of the large piston, so that for a short time (a couple of seconds or so) the increased vacuum between butterfly and large piston causes the air flow across the top of the jet to increase in speed, which sucks more fuel out of the jet relative to the volume of air that is flowing even though the needle hasn't yet moved, so enriching the mixture to avoid the stumble. But when the throttle butterfly is closed there is no such need to control the movement of the large piston, so the damper piston is designed to be ineffective when the large piston is falling, so it falls immediately.

That is basically it. However whenever the throttle is suddenly opened the volume of air passing through the carb is able to increase faster than the volume of fuel can increase coming out of the jet. This has the effect of weakening the mixture, which causes the engine stumble when accelerating. To counteract this on top of the large piston there is a cylinder filled with oil - the damper cylinder. Attached to the outer cover there is a small damper piston sitting in this oil. As the large piston tries to rise the damper cylinder also rises, and because the damper piston is fixed this has the effect of forcing the damper piston further into the cylinder. As the lower end of the cylinder is sealed, and oil is not compressible, the only way the large piston can rise is for oil to be forced past the damper piston. The dimensions of both damper cylinder and damper piston are carefully set to that the oil flows past at a known rate, and hence controls the rise of the large piston. This damps or slows down the rise of the large piston, so that for a short time (a couple of seconds or so) the increased vacuum between butterfly and large piston causes the air flow across the top of the jet to increase in speed, which sucks more fuel out of the jet relative to the volume of air that is flowing even though the needle hasn't yet moved, so enriching the mixture to avoid the stumble. But when the throttle butterfly is closed there is no such need to control the movement of the large piston, so the damper piston is designed to be ineffective when the large piston is falling, so it falls immediately.

Another occasion when the ratio of air to fuel has to be altered from the norm is on starting from cold. When everything is cold the fuel doesn't atomise as well and so doesn't combust as well inside the engine, so again you get the effects of a weak mixture and indeed the engine may not start at all. To counteract this we have a choke. Well, it is called a choke but that is a hangover from earlier carbs where the air flow through the carb throat was manually restricted or 'choked' as a way of enriching the mixture. In both types of SU carb it is done by increasing the amount of fuel for a given amount of air (rather than reducing the amount of air for a given amount of fuel as in the other design of carb) and so is an enrichment device rather than a choke. But no matter, 'choke' is the generic term, so that is what we shall use. The HS and HIF types differ in how they enrich. The HS has a very simple mechanism for lowering the jet relative to the needle, so increasing the size of the outlet, which allows a given speed of air passing over the end of the jet to draw out a greater quantity of fuel, so enriching the mixture. In the HIF there is a separate valve which opens and adds more fuel to the air stream via separate passages in the carb body. Both types allow the amount of enrichment to be continuously varied i.e. they are not a simple on/off switch. As mentioned before a mixture that is too rich causes a number of problems so you should endeavour to have the minimum amount of enrichment for smooth running. In practice every car is different and you will have to learn how much yours needs under various conditions. As well as varying from car to car it also various according to the ambient temperature and how long the engine has been switched off. Even though the temperature gauge may show fully cold if the engine has only been off for a couple of hours, as opposed to overnight, it may restart with no choke or only minimal choke, you will have to learn. For example my roadster (HSs) needs full choke to start from fully cold then immediately pushed in about half-way, then gradually pushed in further as the engine warms up. By contrast the V8 (HIFs) needs full choke to start and for the first few seconds, then gradually pushing back in as the engine warms. However a pal's 78 (HIFs) is the same as the roadster and others with 4-cylinder HIFs have said the same. Also it is better to drive off immediately after starting and not let the engine warm through idling, unless you have to defrost windows etc., in which case push the choke back to just enough to keep it running, even if it needs more to actually drive off.

Another occasion when the ratio of air to fuel has to be altered from the norm is on starting from cold. When everything is cold the fuel doesn't atomise as well and so doesn't combust as well inside the engine, so again you get the effects of a weak mixture and indeed the engine may not start at all. To counteract this we have a choke. Well, it is called a choke but that is a hangover from earlier carbs where the air flow through the carb throat was manually restricted or 'choked' as a way of enriching the mixture. In both types of SU carb it is done by increasing the amount of fuel for a given amount of air (rather than reducing the amount of air for a given amount of fuel as in the other design of carb) and so is an enrichment device rather than a choke. But no matter, 'choke' is the generic term, so that is what we shall use. The HS and HIF types differ in how they enrich. The HS has a very simple mechanism for lowering the jet relative to the needle, so increasing the size of the outlet, which allows a given speed of air passing over the end of the jet to draw out a greater quantity of fuel, so enriching the mixture. In the HIF there is a separate valve which opens and adds more fuel to the air stream via separate passages in the carb body. Both types allow the amount of enrichment to be continuously varied i.e. they are not a simple on/off switch. As mentioned before a mixture that is too rich causes a number of problems so you should endeavour to have the minimum amount of enrichment for smooth running. In practice every car is different and you will have to learn how much yours needs under various conditions. As well as varying from car to car it also various according to the ambient temperature and how long the engine has been switched off. Even though the temperature gauge may show fully cold if the engine has only been off for a couple of hours, as opposed to overnight, it may restart with no choke or only minimal choke, you will have to learn. For example my roadster (HSs) needs full choke to start from fully cold then immediately pushed in about half-way, then gradually pushed in further as the engine warms up. By contrast the V8 (HIFs) needs full choke to start and for the first few seconds, then gradually pushing back in as the engine warms. However a pal's 78 (HIFs) is the same as the roadster and others with 4-cylinder HIFs have said the same. Also it is better to drive off immediately after starting and not let the engine warm through idling, unless you have to defrost windows etc., in which case push the choke back to just enough to keep it running, even if it needs more to actually drive off.

Another feature of the choke control on the MGB is that when correctly adjusted the first 1/4" of movement actually only increases the idle speed - the fast idle - and doesn't enrich the mixture. This is very useful if you are scraping frost,

once it will idle at that amount of choke, even though you may have to add more choke once you drive off. In both carbs the choke control turns a cam which is sitting under the fast idle adjustment screw. As the choke is pulled the cam is turned and it gradually lifts the screw, which opens the butterfly a little more than the normal idle setting. Again the amount of choke to fast-idle is a matter of balance - too much fast idle will cause the engine to race before you have enriched the mixture sufficiently for slow running, which makes for difficult slow running in traffic. Insufficient fast idle may cause the engine to tend to stall even though the mixture is enriched,

so you apply more choke until the idle speed is suitable, by which time the engine is over-choked causing the aforementioned problems of plug fouling and oil dilution.

Another feature of the choke control on the MGB is that when correctly adjusted the first 1/4" of movement actually only increases the idle speed - the fast idle - and doesn't enrich the mixture. This is very useful if you are scraping frost,

once it will idle at that amount of choke, even though you may have to add more choke once you drive off. In both carbs the choke control turns a cam which is sitting under the fast idle adjustment screw. As the choke is pulled the cam is turned and it gradually lifts the screw, which opens the butterfly a little more than the normal idle setting. Again the amount of choke to fast-idle is a matter of balance - too much fast idle will cause the engine to race before you have enriched the mixture sufficiently for slow running, which makes for difficult slow running in traffic. Insufficient fast idle may cause the engine to tend to stall even though the mixture is enriched,

so you apply more choke until the idle speed is suitable, by which time the engine is over-choked causing the aforementioned problems of plug fouling and oil dilution.

Piston Balls March 2013

Drop-test

It is vital not to get pistons and covers mixed up. The original part numbers are for a pair matched in the factory to meet a specified drop-test characteristic, and mixing them up can significantly change the operating performance of the carbs.

There are some misconceptions about covers though, one being that you have to mark the cover relative to the carb body to get it back at the right orientation. Incorrect as the fixing holes are not equidistant round the periphery so each cover can only go back in one orientation. Whilst two of the holes are either side of the intake, the third one has to be one side or the other of the port on the engine side otherwise it would project into the port.

Another one is that you must mark each cover and piston so it goes back on the right body. Ideally yes, but not strictly correct as within each era of carb there is only one part number for each cover piston/assembly so they can be fitted to either the front or the rear carb.

The interesting thing is that HS carbs and early HIF carbs have a breather rib in the cover neck, and that rib faces in different directions - towards the air-cleaner on the front carb and forwards on the rear carb. This is because the fixing holes in the carb body are mirror images with the hole nearest the engine being one side of the port on one carb and the other side of the port on the other carb. So the cover is at one orientation on the front carb and a different orientation on the rear.

The interesting thing is that HS carbs and early HIF carbs have a breather rib in the cover neck, and that rib faces in different directions - towards the air-cleaner on the front carb and forwards on the rear carb. This is because the fixing holes in the carb body are mirror images with the hole nearest the engine being one side of the port on one carb and the other side of the port on the other carb. So the cover is at one orientation on the front carb and a different orientation on the rear.

But later HIFs have the both ribs facing the air cleaners, and that is because instead of the fixing holes being mirror images, the hole nearest the engine is to the rear of the port on both carbs, so the covers are at the same orientation. At first I joked that it must have been someone with OCD not being able to stand seeing the offset any more. But that is highly unlikely, and I think it must have been for emissions reasons. Because they are a matched pair to meet a drop-test, unless the piston and the cover were perfectly circular you will get small difference in the drop-test depending on the relative orientation of the piston in the cover, and so you would get different operating characteristics depending on whether the cover/piston assembly were fitted to the front or the rear carb. With how the emissions limits tightened in later years for North America, maybe that difference was enough to cause problems meeting them. And by moving the position of the engine-side hole to be the same on both carbs, each cover and piston could be tested at a known orientation, and that would be the same when fitted to either carb. Maybe.

But later HIFs have the both ribs facing the air cleaners, and that is because instead of the fixing holes being mirror images, the hole nearest the engine is to the rear of the port on both carbs, so the covers are at the same orientation. At first I joked that it must have been someone with OCD not being able to stand seeing the offset any more. But that is highly unlikely, and I think it must have been for emissions reasons. Because they are a matched pair to meet a drop-test, unless the piston and the cover were perfectly circular you will get small difference in the drop-test depending on the relative orientation of the piston in the cover, and so you would get different operating characteristics depending on whether the cover/piston assembly were fitted to the front or the rear carb. With how the emissions limits tightened in later years for North America, maybe that difference was enough to cause problems meeting them. And by moving the position of the engine-side hole to be the same on both carbs, each cover and piston could be tested at a known orientation, and that would be the same when fitted to either carb. Maybe.

Oil-level

Breather November 2013

Ball-bearing suction chamber

Retaining clips

The damper consists of a brass cylinder on a rod inserted into an oil reservoir in the piston. It has a large clearance to the rod and a small clearance to the walls of the oil reservoir. At the top it is retained by a solid disc, and at the bottom by a circlip, and these two components allow it to damp piston movement when it is going up, but not when it is moving down. When the piston starts to move up the oil in the reservoir lifts the damper up the rod until it reaches the solid disc, which closes off the hollow centre of the damper so no oil can pass through. At that point the piston can only rise further as oil passes through the small clearance between the outside of the damper and the sides of the oil chamber. However when the piston is falling it pulls the damper downwards, opening up the space at the top, and with the circlip at the bottom both ends of the damper are 'open'. Thus oil can move freely through the centre of the damper, allowing the piston to fall without any restriction. Because the damper has to move up a very small distance when the piston starts rising before it starts damping, on very small throttle openings you may detect a slight hesitation as the mixture is not being enriched. On larger throttle opening normal damping covers up this initial hesitation.

The damper consists of a brass cylinder on a rod inserted into an oil reservoir in the piston. It has a large clearance to the rod and a small clearance to the walls of the oil reservoir. At the top it is retained by a solid disc, and at the bottom by a circlip, and these two components allow it to damp piston movement when it is going up, but not when it is moving down. When the piston starts to move up the oil in the reservoir lifts the damper up the rod until it reaches the solid disc, which closes off the hollow centre of the damper so no oil can pass through. At that point the piston can only rise further as oil passes through the small clearance between the outside of the damper and the sides of the oil chamber. However when the piston is falling it pulls the damper downwards, opening up the space at the top, and with the circlip at the bottom both ends of the damper are 'open'. Thus oil can move freely through the centre of the damper, allowing the piston to fall without any restriction. Because the damper has to move up a very small distance when the piston starts rising before it starts damping, on very small throttle openings you may detect a slight hesitation as the mixture is not being enriched. On larger throttle opening normal damping covers up this initial hesitation.

Oil: A lot of opinions on what oil should be used in the damper. The Leyland Workshop Manual lubrication chart shows the same oil as used in the crankcase i.e. 20W/50 for temperate climates but 'thin cycle oil', 3-in-1, SAE 90 gear oil are all mentioned in various quarters. SU Burlen sell their own SAE 20 but at £8 for 100ml (double that from 3rd-party sellers) it's a bit expensive and is yet another product to keep on the shelf when you already have engine oil. Thin oils will give less damping and allow the piston to rise more quickly which will cause flat-spots i.e. stumbling on acceleration. The proponents of SAE 90 gear oil say 'thicker is better' but this is a mis-nomer as the actual viscosity of 20W/50 crankcase oil almost exactly parallels that of SAE 80 to 90 gear oil as this chart from Precision Lubrication shows:

Oil-level: December 2011

Some confusion over this, and the manuals don't help. HS drawings show the oil level being below the top of the oil reservoir, whereas HIF drawings in the same manuals show it above. I have seen a claim that it has to be above so the outside of the reservoir is lubricated where it moves up and down again against the cover, but if HSs didn't need it why do HIFs? If you do try to keep it above, then you will be continually topping-up, and some people do say they have to keep topping-up. I have maintained my HIFs below, the same as my HSs, for around 90k with no ill-effects so far. All I do is unscrew the plastic cap, lift it up, and press it down again. If I can feel the resistance of the oil before the plastic cap reaches the cover, then I have enough, and the distance before tells me how much 'reserve' I have left. I don't have to top up from one year's end to the next. The oil only needs to reach the bottom of the damper piston in the oil reservoir to do its job, not the top, so to maintain it much above that is overkill.

Some confusion over this, and the manuals don't help. HS drawings show the oil level being below the top of the oil reservoir, whereas HIF drawings in the same manuals show it above. I have seen a claim that it has to be above so the outside of the reservoir is lubricated where it moves up and down again against the cover, but if HSs didn't need it why do HIFs? If you do try to keep it above, then you will be continually topping-up, and some people do say they have to keep topping-up. I have maintained my HIFs below, the same as my HSs, for around 90k with no ill-effects so far. All I do is unscrew the plastic cap, lift it up, and press it down again. If I can feel the resistance of the oil before the plastic cap reaches the cover, then I have enough, and the distance before tells me how much 'reserve' I have left. I don't have to top up from one year's end to the next. The oil only needs to reach the bottom of the damper piston in the oil reservoir to do its job, not the top, so to maintain it much above that is overkill.

March 2013: Just having discovered HIFs (and maybe some HSs) have ball-bearing assemblies between the piston and cover, I did wonder whether the higher level would initially drain down and lubricate the bearings, then stabilise, and only be topped-up again at the next service. As long as you only check at the recommended service intervals you will be fine, but if you keep checking weekly then you probably will have to keep topping-up. But as part of my research into the bearings I came across these historic SU technical documents on the SU Burlen site.

The HS document clearly shows the oil level below (a long way below) the top of the hollow rod, and the text states "... pour oil into the hollow piston rod to within about 1/2" from the top of the rod ..." (the text is a bit fragmented, you have to jump from the second line in section 4 to below the drawings in the second column).

The HIF document, Tuning - General page section 4 has three sub-sections depending on whether the suction chamber is 'standard' (i.e. no ball-bearings), has 'early' ball-bearings and the damper retaining clip, or 'later' ball-bearings. Not that it matters, because the two drawings and all three descriptions show the oil level is below the top of the hollow piston rod! So I go back to my Leyland Workshop Manual and Haynes to double-check what they say ... and start to wonder if I should have left well alone!

The upshot? The Workshop Manual and Haynes do largely seem to agree with each other, in that the text indicates HS carbs with a hole in the damper cap have it above and those without below, whereas HIF carbs have it above regardless. However they are not without their contradictions and both disagree with the SU documents which show and state that it is always below for both carbs. If you do decide to top it up to above, then don't expect it to remain there for very long. Only put it to that level at each recommended service interval, allowing it to drop below the top of the hollow rod (but still be high enough to perform the damping action) in between services.

There is currently a long thread on a BBS about plugs oiling, and oil pooling on top of pistons, and after many posts the person who started it all said he has just noticed that there is oil in the throat of the carbs while they have been sitting on the bench, and wondering whether it could be from the carb damper, saying he did top up the dampers recently. At the moment we don't know to what level he filled them, and if they are HSs or HIFs, but there is another possible cause of complete draining of the oil from an HIF, rather than just what is above the top of the reservoir. And that is that while the reservoir on HSs seems to be blind-drilled, that on HIFs seems to be through-drilled, then plugged. If the plug is faulty or gets dislodged somehow, then that carb could drain completely.

Breather November 2013

As the piston rises and falls inside the suction chamber the damper oil chamber also rises and falls. Unless there is some way of equalising the pressure above the oil reservoir increasing air pressure will resist the rise of the piston in addition to the resistance of the damper, and resist its fall which should be immediate. Originally there was a breather hole in the damper cap which allowed the space above the damper to be kept at atmospheric pressure. However in dusty environments this would draw dust into the carb on each fall of the piston which when mixed with the oil makes a very effective grinding paste as well as clogging up the works and progressively restricting the free rise and fall of the piston.

As the piston rises and falls inside the suction chamber the damper oil chamber also rises and falls. Unless there is some way of equalising the pressure above the oil reservoir increasing air pressure will resist the rise of the piston in addition to the resistance of the damper, and resist its fall which should be immediate. Originally there was a breather hole in the damper cap which allowed the space above the damper to be kept at atmospheric pressure. However in dusty environments this would draw dust into the carb on each fall of the piston which when mixed with the oil makes a very effective grinding paste as well as clogging up the works and progressively restricting the free rise and fall of the piston.

Subsequently a web was moulded into the side of the piston cover, which was drilled into the suction chamber above the main piston skirt. These carbs had a non-drilled damper cap and were termed 'dustproofed'. This internal drilling results in suction chamber vacuum being placed above the damper as well as above the piston. This is not a problem if the spring and other components take account of the probable increased 'lift'. Incidentally SU Burlen state in their description of a damper cap that "... some are externally vented (hole in the top) and some are internally vented (angled hole in the Suction Chamber) these are termed dustproof and non-dustproof respectively." Surely they have the terminology the wrong way round - the externally vented being non-dustproof and the internally vented being dustproof?

However the situation is very confused regarding webs or no webs, drilled or not drilled, and vented cap or not vented cap. My 73 roadster has the webs, but they are not drilled. They also have vented damper caps, so probably are correct. But the V8 has no webs, no drilling, and non-vented caps - so how is the space above the damper vented? They also have the ball-bearing arrangement between the piston cover and the outside of the damper oil chamber, instead of the plain and very close-fitting earlier arrangement. So perhaps the ball-bearing arrangement has a larger clearance that supplies sufficient venting. This will also result in piston lift vacuum being above the damper as well as above the piston.

Another thought is that if a vented cap is fitted to carbs with one of these internal venting arrangements, that would introduce an air-leak into the suction chamber, which could limit its rise as the throttle is opened, and definitely upset the mixture.

Ball-bearing suction chamber March 2013

Whereas originally the hollow rod of the piston slid in the cover directly, metal to metal, at some point SU started fitting two ball bearing assemblies, each containing six balls, to reduce friction and sticking as part of their emission reduction developments (see "Ball Bearing Suction Chamber Assembly" here). No clear indication of when, but it has to be in the late 60s/early 70s, and whilst it was definitely applied to the HIF it could also have been in late HSs as well. Originally the balls might have been loose as the V8 Register published a note about the risk, and Geoff Allen also mentioned it in a talk on the development of the V8. Later the balls were held in a plastic sleeve which retained them when the cover and piston were separated, this SU technical article does talk about two types of ball bearing assembly in the section on damper oil level. I have had my V8 HIF covers off and pistons out a number of times and never even noticed them, let alone had ball bearing dropping out, so wondered if I even had them. I found a picture of the cover on the Rimmer site which clearly shows the sleeve and lower balls, and whilst not wishing to remove my covers just for this I did remove the damper cap and peering inside can see the top of the same plastic sleeve between the piston and the cover. This does seem to indicate that mine have the later arrangement, but the same SU document describes that the early arrangement has retaining clips so the damper can only be lifted, not fully removed, whereas the later arrangement does not have the clip and the damper can be completely removed. And mine have the retaining clip! So maybe I've just been lucky not to lose my balls ...

Whereas originally the hollow rod of the piston slid in the cover directly, metal to metal, at some point SU started fitting two ball bearing assemblies, each containing six balls, to reduce friction and sticking as part of their emission reduction developments (see "Ball Bearing Suction Chamber Assembly" here). No clear indication of when, but it has to be in the late 60s/early 70s, and whilst it was definitely applied to the HIF it could also have been in late HSs as well. Originally the balls might have been loose as the V8 Register published a note about the risk, and Geoff Allen also mentioned it in a talk on the development of the V8. Later the balls were held in a plastic sleeve which retained them when the cover and piston were separated, this SU technical article does talk about two types of ball bearing assembly in the section on damper oil level. I have had my V8 HIF covers off and pistons out a number of times and never even noticed them, let alone had ball bearing dropping out, so wondered if I even had them. I found a picture of the cover on the Rimmer site which clearly shows the sleeve and lower balls, and whilst not wishing to remove my covers just for this I did remove the damper cap and peering inside can see the top of the same plastic sleeve between the piston and the cover. This does seem to indicate that mine have the later arrangement, but the same SU document describes that the early arrangement has retaining clips so the damper can only be lifted, not fully removed, whereas the later arrangement does not have the clip and the damper can be completely removed. And mine have the retaining clip! So maybe I've just been lucky not to lose my balls ...

I then started wondering whether this explained why the manuals show the HS damper oil level as being below the top of the hollow rod, whereas the HIF shows it above. I.e. at each service interval you fill it above, the excess runs down to lubricate the bearings, then you top it up again at the next service interval. It could also explain why there are periodic complaints about the HIF 'losing all its oil' if people are trying to maintain the oil level above the top of the hollow rod all the time, and not just at the service interval. But more of this in Damper Oil Level.

Retaining clips March 2013

These only seem to have been fitted to HIF carbs, and only for a period. Originally the piston and cover assembly was much like the HS in that the hollow rod of the piston slid in the cylinder inside the cover. Then as part of emissions reduction two ball-bearing assemblies were fitted between the two, to reduce sliding friction and hysteresis. It is these that have the retaining clip, which means the damper can only be raised and tilted to one side for topping-up, not completely removed. Subsequently there was a version without the clip, although whether this used a different ball bearing assembly or just did away with the clip, isn't known. The only purpose I can see is to avoid mixing up pistons and dampers, which could result in different rise-times during acceleration for each piston. This SU Technical document (4 Check the piston damper oil level) emphasises that the bearing retainer is not to be displaced from the piston rod, but I accidentally pulled mine out many years ago and it didn't seem to make any difference to anything. Nevertheless after reading this I decided to re-fit it. There are two ways to do this, and if you have the 4-cylinder this is probably the easiest way: Remove the air cleaner, unscrew the damper cap, lift the piston as high as you can with a finger-tip, and hopefully that will lift the top of the hollow rod far enough for you to press the clip back in again. On the V8 it's a bit of a fiddle to remove the air-box then grope around the back of the carbs to lift the piston, reaching across the engine to reinsert the clip, so it's probably easier to remove the cover and piston from the carb body. Then unscrew the damper cap, lift the piston up inside the cover compressing the spring, until the top of the hollow rod has been raised high enough to reinsert the clip. Despite refitting it came out again the next time I went to top-up, so I left it out, and again it doesn't seem to have made any difference.

These only seem to have been fitted to HIF carbs, and only for a period. Originally the piston and cover assembly was much like the HS in that the hollow rod of the piston slid in the cylinder inside the cover. Then as part of emissions reduction two ball-bearing assemblies were fitted between the two, to reduce sliding friction and hysteresis. It is these that have the retaining clip, which means the damper can only be raised and tilted to one side for topping-up, not completely removed. Subsequently there was a version without the clip, although whether this used a different ball bearing assembly or just did away with the clip, isn't known. The only purpose I can see is to avoid mixing up pistons and dampers, which could result in different rise-times during acceleration for each piston. This SU Technical document (4 Check the piston damper oil level) emphasises that the bearing retainer is not to be displaced from the piston rod, but I accidentally pulled mine out many years ago and it didn't seem to make any difference to anything. Nevertheless after reading this I decided to re-fit it. There are two ways to do this, and if you have the 4-cylinder this is probably the easiest way: Remove the air cleaner, unscrew the damper cap, lift the piston as high as you can with a finger-tip, and hopefully that will lift the top of the hollow rod far enough for you to press the clip back in again. On the V8 it's a bit of a fiddle to remove the air-box then grope around the back of the carbs to lift the piston, reaching across the engine to reinsert the clip, so it's probably easier to remove the cover and piston from the carb body. Then unscrew the damper cap, lift the piston up inside the cover compressing the spring, until the top of the hollow rod has been raised high enough to reinsert the clip. Despite refitting it came out again the next time I went to top-up, so I left it out, and again it doesn't seem to have made any difference.

Drop-test: April 2019

The drop-test measures how long the cover takes to fall from the piston, while holding both inverted, and is performed as follows:

|

|

|

|

The SU Burlen pages for both HS and HIF say: "For carburetters 38.0 mm (1.5 in) to 47.6 mm (1 7/8 in) bore, the time taken should be 5 to 7 seconds.". Other sources give slightly different timings, but I'd rather go by the SU information

Note: There seem to be different views about leaving the dampers in place, some remove them but SU Burlen specifically says to fit it, with its washer where provided. If you find one of yours takes too long to drop, then try the test again on both carbs but this time with the damper removed. If the two are now very close (albeit dropping faster) then the damper on the slow one is at fault - maybe the shaft is bent, or the (damper) piston not free on its spindle. However that would also be revealed by removing the air cleaners and lifting each piston fully up against damper pressure, then releasing, where both should drop sharply and at the same rate. That check should have been done way before you get into the drop-test.

Ports and Vent/Overflow Pipes: There is often confusion about which hose goes on which port of SUs. If you get the inlet and vent hoses reversed for example, the carb will flood petrol out of one of the ports and/or the jet.

HS carbs are a mirror image of each other (except for the jets which are NOT handed), each with its own fuel inlet and vent/overflow ports. The main fuel feed pipe has a T-piece which feeds the rear carb from a side tapping, the straight-through tapping feeding the front carb. From October 1969 and the 18GG/GH/GJ/GK engines the carbs also had a crankcase ventilation port which removed the need for a separate PCV valve. These are joined together by a Y-piece and connected to the front tappet chest cover port. Click on the thumbnails to see which port is which but basically non-NA cars have the fuel inlet ports pointing straight across the car to the rocker cover, and the vent/overflow ports are the same size pointing straight across the car in the opposite direction i.e. to the left-hand wing. The ventilation ports are larger and point diagonally upwards, towards the front of the car on the front carb and the rear of the car on the rear carb.

HS carbs are a mirror image of each other (except for the jets which are NOT handed), each with its own fuel inlet and vent/overflow ports. The main fuel feed pipe has a T-piece which feeds the rear carb from a side tapping, the straight-through tapping feeding the front carb. From October 1969 and the 18GG/GH/GJ/GK engines the carbs also had a crankcase ventilation port which removed the need for a separate PCV valve. These are joined together by a Y-piece and connected to the front tappet chest cover port. Click on the thumbnails to see which port is which but basically non-NA cars have the fuel inlet ports pointing straight across the car to the rocker cover, and the vent/overflow ports are the same size pointing straight across the car in the opposite direction i.e. to the left-hand wing. The ventilation ports are larger and point diagonally upwards, towards the front of the car on the front carb and the rear of the car on the rear carb.

North American emissions-controlled vehicles may have a different arrangement with a three-port float chamber lid on the front carb although this is not listed in the Parts Catalogue. One of the ports is the fuel inlet from a filter on the inner wing, another is a fuel outlet that goes to the rear carb, and the third is the overflow going to the charcoal canister. The rear carb should have a conventional 2-port with fuel inlet and overflow.

North American emissions-controlled vehicles may have a different arrangement with a three-port float chamber lid on the front carb although this is not listed in the Parts Catalogue. One of the ports is the fuel inlet from a filter on the inner wing, another is a fuel outlet that goes to the rear carb, and the third is the overflow going to the charcoal canister. The rear carb should have a conventional 2-port with fuel inlet and overflow.

The vent/overflow ports are connected with a short length of rubber hose to two individual steel pipes which carry any overflow safely down past the exhaust. Bee came to me with them just dangling, so I looked closely at a concourse winner of the same year (and colour!) which had them retained by one of the rear engine mount to chassis bracket bolts, so that is how I fixed Bee's. However this means that as the engine rocks the carb end of the pipes moves up and down, but the clipped part stays still, which stresses the short piece of rubber hose connecting them to the carbs. Subsequent research has shown that these run side-by-side to the rear of the engine mount and originally were attached with a P-clip to a bracket (AHH7382 was NLA), which mounts to the side of the block on the lower engine mount bolt. Used until the introduction of the 18V engine in 1971 for export cars, and until November 1973 for UK cars i.e. until the change to HIF carbs when the P-clip was mounted using the mechanical fuel pump blanking plate rear bolt. With the bracket NLA at the time (and access to the lower engine mount bolt restricted with the engine in-situ) I eventually changed Bee to use the engine restraint bracket (also missing when she came to me) which has a convenient hole for a bolt and P-clip to hold the pipes, which allows them to move with the engine.

The vent/overflow ports are connected with a short length of rubber hose to two individual steel pipes which carry any overflow safely down past the exhaust. Bee came to me with them just dangling, so I looked closely at a concourse winner of the same year (and colour!) which had them retained by one of the rear engine mount to chassis bracket bolts, so that is how I fixed Bee's. However this means that as the engine rocks the carb end of the pipes moves up and down, but the clipped part stays still, which stresses the short piece of rubber hose connecting them to the carbs. Subsequent research has shown that these run side-by-side to the rear of the engine mount and originally were attached with a P-clip to a bracket (AHH7382 was NLA), which mounts to the side of the block on the lower engine mount bolt. Used until the introduction of the 18V engine in 1971 for export cars, and until November 1973 for UK cars i.e. until the change to HIF carbs when the P-clip was mounted using the mechanical fuel pump blanking plate rear bolt. With the bracket NLA at the time (and access to the lower engine mount bolt restricted with the engine in-situ) I eventually changed Bee to use the engine restraint bracket (also missing when she came to me) which has a convenient hole for a bolt and P-clip to hold the pipes, which allows them to move with the engine.

HIF carbs:

HIF carbs are mostly a mirror image of each other, but this time both the floats and the jets are handed, and the fuel feed arrangements are different. The jets are colour-coded black and white according to which carb they go in, and I think the black one goes in the front carb. The right-angled pick-up pipe should more-or-less face the butterfly, and the adjuster mechanism engages with a tab on the body of the jet. It might be possible to install the wrong jet with the pick-up pipe facing the other way, but it may also be the case that the cover plate then won't fit correctly. Note that although the manuals and SU Burlen's web site show the jet bearing having a washer above it, a phone call to Burlen elicited the information that later versions did not have it! The fuel feed pipe connects to the front (4-cylinder) or left-hand (V8) carb only, which as well as feeding the float valve in that carb goes straight through the carb body to an 'outlet' port on the other side. A short (very short in the case of the V8) length of rubber hose goes straight across from that port on the front/left-hand carb to a mirror-image inlet port on the rear/right-hand carb. There is a matching outlet drilling on the other side of the rear/right-hand carb, presumably for triple carb setups, but it is plugged on MGB carbs. The crankcase ventilation ports are connected individually via a flame/oil traps to the associated rocker cover. Click on the thumbnails for details of which port is which, but basically the fuel inlet and outlet ports are at the back of the carbs pointing straight across the car, with the inlet on the left-hand carb immediately above its mixture screw, and the blanked-off outlet port of the right-hand carb the same. The vent/overflow ports are immediately in front of those, also pointing straight across the car, and the same size as the fuel inlet/outlet ports. The crankcase ventilation ports are in front of those, are larger, and pointing diagonally upwards as well as across the car. On 4-cylinder chrome bumper cars the vent/overflow ports and crankcase ventilation ports are plumbed similar to HS carbs, but the former are held by a retaining clip bolted to a stud on the engine restraint bracket. On 4-cylinder rubber bumper cars the pipes are clipped to one of the studs for the mechanical fuel pump blanking plate on the block. The V8 has hoses from the vent/overflow ports going being the carbs to a T-piece behind the right-hand carb, then a single down-pipe clipped to a bolt on the bell-housing.

HIF carbs are mostly a mirror image of each other, but this time both the floats and the jets are handed, and the fuel feed arrangements are different. The jets are colour-coded black and white according to which carb they go in, and I think the black one goes in the front carb. The right-angled pick-up pipe should more-or-less face the butterfly, and the adjuster mechanism engages with a tab on the body of the jet. It might be possible to install the wrong jet with the pick-up pipe facing the other way, but it may also be the case that the cover plate then won't fit correctly. Note that although the manuals and SU Burlen's web site show the jet bearing having a washer above it, a phone call to Burlen elicited the information that later versions did not have it! The fuel feed pipe connects to the front (4-cylinder) or left-hand (V8) carb only, which as well as feeding the float valve in that carb goes straight through the carb body to an 'outlet' port on the other side. A short (very short in the case of the V8) length of rubber hose goes straight across from that port on the front/left-hand carb to a mirror-image inlet port on the rear/right-hand carb. There is a matching outlet drilling on the other side of the rear/right-hand carb, presumably for triple carb setups, but it is plugged on MGB carbs. The crankcase ventilation ports are connected individually via a flame/oil traps to the associated rocker cover. Click on the thumbnails for details of which port is which, but basically the fuel inlet and outlet ports are at the back of the carbs pointing straight across the car, with the inlet on the left-hand carb immediately above its mixture screw, and the blanked-off outlet port of the right-hand carb the same. The vent/overflow ports are immediately in front of those, also pointing straight across the car, and the same size as the fuel inlet/outlet ports. The crankcase ventilation ports are in front of those, are larger, and pointing diagonally upwards as well as across the car. On 4-cylinder chrome bumper cars the vent/overflow ports and crankcase ventilation ports are plumbed similar to HS carbs, but the former are held by a retaining clip bolted to a stud on the engine restraint bracket. On 4-cylinder rubber bumper cars the pipes are clipped to one of the studs for the mechanical fuel pump blanking plate on the block. The V8 has hoses from the vent/overflow ports going being the carbs to a T-piece behind the right-hand carb, then a single down-pipe clipped to a bolt on the bell-housing.

October 2020:

The 4-cylinder HIF vent/overflow arrangement is much the same as for HS carbs but the V8 is quite different. Hoses from the carbs go under the air-box to a plastic washer tee GWW401 behind the off-side carb. Another short piece of hose goes down to metal pipe BHH1570 which has a support bracket under the top off-side bell-housing bolt, then a longer section of hose goes down past the off-side of the bell-housing. Vee had none of that when she came to me and I had no idea what was supposed to be there, didn't fancy fuel running down onto the exhausts, so I did basically the same with hoses and tee and in the same position, but without the metal pipe to support it all. Apparently these pipes are very rarely seen in the wild, and I can imagine that unless someone remembers to attach the metal pipe to the bell-housing bolt when the engine and gearbox are reassembled out of the car, they won't go back on at all as you can't access that bolt once the two are back in the car!

The 4-cylinder HIF vent/overflow arrangement is much the same as for HS carbs but the V8 is quite different. Hoses from the carbs go under the air-box to a plastic washer tee GWW401 behind the off-side carb. Another short piece of hose goes down to metal pipe BHH1570 which has a support bracket under the top off-side bell-housing bolt, then a longer section of hose goes down past the off-side of the bell-housing. Vee had none of that when she came to me and I had no idea what was supposed to be there, didn't fancy fuel running down onto the exhausts, so I did basically the same with hoses and tee and in the same position, but without the metal pipe to support it all. Apparently these pipes are very rarely seen in the wild, and I can imagine that unless someone remembers to attach the metal pipe to the bell-housing bolt when the engine and gearbox are reassembled out of the car, they won't go back on at all as you can't access that bolt once the two are back in the car!

Flange gaskets March 2017

The air-filter gaskets (HS and HIF are the same) are handed and must be installed the right way up. The flange has breather holes that maintain the underside of the piston at atmospheric pressure, so when inlet manifold vacuum is applied above the piston it can rise correctly to deliver the correct mixture. V8 HIFs are different in that there are no less than nine holes in the carb flanges. Again the gaskets must be installed the right way up to leave the breather and fixing holes clear, and that cover the other holes.

The air-filter gaskets (HS and HIF are the same) are handed and must be installed the right way up. The flange has breather holes that maintain the underside of the piston at atmospheric pressure, so when inlet manifold vacuum is applied above the piston it can rise correctly to deliver the correct mixture. V8 HIFs are different in that there are no less than nine holes in the carb flanges. Again the gaskets must be installed the right way up to leave the breather and fixing holes clear, and that cover the other holes.

While doing the clutch change on a friend's 78 I found these gaskets, which have holes in both upper and lower positions, and so cannot be fitted the wrong way round. However! You still have to fit the base-plate for the air filter the right way round or the holes will be blocked whichever gasket you use or how you install it! It wasn't obvious from the running of the car that they were blocked, but Keith's car failed it's emissions test this year having passed just a year earlier, done very little mileage since, no changes other than a new choke cable (which was fully releasing the choke) even during the clutch change apart from having the air-filters removed. When I went to setup the carbs for air-balance and mixture I found the filter bases upside down, hence the auxiliary ports were blocked. In the end the balance and mixture were just about spot-on, only the balance under choke was out, which wouldn't have affected the emissions test anyway, so I can only assume I put the filter cans on the wrong carbs hence the bases upside down, and that was enough to affect the reading. Correcting that and a precautionary weakening of the mixture by just 1/8th turn to show 3.8% on my Gastester passed the retest at almost the same figure.

While doing the clutch change on a friend's 78 I found these gaskets, which have holes in both upper and lower positions, and so cannot be fitted the wrong way round. However! You still have to fit the base-plate for the air filter the right way round or the holes will be blocked whichever gasket you use or how you install it! It wasn't obvious from the running of the car that they were blocked, but Keith's car failed it's emissions test this year having passed just a year earlier, done very little mileage since, no changes other than a new choke cable (which was fully releasing the choke) even during the clutch change apart from having the air-filters removed. When I went to setup the carbs for air-balance and mixture I found the filter bases upside down, hence the auxiliary ports were blocked. In the end the balance and mixture were just about spot-on, only the balance under choke was out, which wouldn't have affected the emissions test anyway, so I can only assume I put the filter cans on the wrong carbs hence the bases upside down, and that was enough to affect the reading. Correcting that and a precautionary weakening of the mixture by just 1/8th turn to show 3.8% on my Gastester passed the retest at almost the same figure.

Originally the air-filter cans were clearly handed and as long as you kept them, the bases, bolts and gaskets together as two assemblies you are unlikely to get them on the wrong carbs. But at some point they seem to have been modified so the cans are identical, so if you keep them assembled but mixed up and fit them to the wrong carbs you will get the bases upside down. The Parts Catalogue shows different part numbers for the front and rear cans for all years, but you can definitely fit the later ones on the wrong carbs and it isn't immediately obvious. Originally common to all markets they changed for the 72 model year (from straight intakes to curved?) to three different sets for UK, North America, and the rest of the world (export cars changed to HIF the previous year so it wasn't to do with that). UK changed to use the 'rest of the world' set in November 73 with the 18V 779/780 engines and all twin carb engines had those to the end.

Inlet Manifold:

Together with the spacer blocks 12H712 between heat shield and carbs there are three gaskets AEC2083 per carb to secure the carbs and heat shield to the inlet manifold. These gaskets are also handed but with these it's not a case of blocking holes but simply aligning the outline with the carb flanges and distance pieces. I think these were originally fitted dry (no fluids normally) but I use a smear of copper-grease on all the gasket surfaces in preference to conventional sealants, both hardening and non-hardening.

Together with the spacer blocks 12H712 between heat shield and carbs there are three gaskets AEC2083 per carb to secure the carbs and heat shield to the inlet manifold. These gaskets are also handed but with these it's not a case of blocking holes but simply aligning the outline with the carb flanges and distance pieces. I think these were originally fitted dry (no fluids normally) but I use a smear of copper-grease on all the gasket surfaces in preference to conventional sealants, both hardening and non-hardening.

North America single carb used induction heater AUD9148 as the spacer block.

North America single carb used induction heater AUD9148 as the spacer block.

February 2023: Something to watch out for with replacement valves. Father Ted on the MGOC forum sent his carbs away to SU Burlen to be rebuilt, but when they came back even though the fuel pump clicked then stopped while filling the float chambers, as soon as he started the engine both started overflowing. It turns out they had fitted the larger V8 float valves which are available in two types - one with an internal spring and one without, and they had used the unsprung. It's my belief that the spring helps keep the valve shut if the float should vibrate. FT sent them back at his own cost and they replaced them with the smaller valve which are sprung, and no overflow. More info on float valves here.

One of the biggest benefits of the HS carb over the HIF is that the floats and valves are so easy to access on the HS compared to the HIF, which really need to be removed from the car. The bottom cover on the HIF is also submerged in fuel, and any weakness in the seal can cause significant seepage, enough to drain the float chamber while parked. The HS float chamber lid does have a gasket, but it is above the level of the fuel, so really only protects against seepage if the fuel is sloshing about inside, or if the float chamber should flood due to a faulty valve or float as the overflow port is above the join between chamber and lid.

January 2026: A pal in America has been experiencing intermittent flooding on his 76 with HS carbs despite swapping sundry parts (his 72 had the opposite problem of pump chattering away but no fuel is delivered - but that is a whole other story). Overflowing can be caused by several things including floats not rising (punctured or binding), float valves not closing (worn or contaminated with dirt), float valves being overwhelmed by excessive pump pressure, or even float chamber lid/carb body faults where fuel can bypass a closed valve. An incorrect float height may not cause overflowing but can cause hot-start problems (too high) or cold start problems (too low). It's relatively easy to keep swapping parts (on HS, less so on HIF) but that can be expensive and frustrating when the problem continues, and even with an apparent fix the fault can return. At the end of the day you may need to resort to fault diagnosis from first principles:

- As two float/valve assemblies are unlikely to resist exactly the same pressure block off the feed pipe to each carb in turn and see if the non-overflowing carb now overflows as well. If so then the problem is excessive pump pressure.

- With HS carbs whilst the front and rear float lids are mirror images it should be possible to swap them over complete with floats and valves by re-routing the inlet hose just for testing. With the lids removed check for dirt in the float bowls as this could be causing weeping valves, and you can compare the fuel levels in each float bowl. With HIFs check for dirt on the bottom cover.

- If the fault moves with the HS lid try blowing through the inlet whilst raising the float with a finger and note how much pressure is needed to stop the flow. You can use the other lid as a comparison, and maybe further check by lowering the lid with float into a container while connected to a pump.

- With HIFs you are limited to lifting the float with the bottom cover removed, although I suppose you could lower the whole carb into a container of petrol!

- It may now be time to swap HS floats over - HIF are 'handed', but both types can be checked for fuel sloshing round inside, drop them in water and check they float to the same level, or weigh them but bear in mind volume is also a factor of buoyancy and hence fuel level.

- With both HS and HIF you can swap valve inners (check for wear ridges on the tips), then valve outer (check it is tight) one at a time between the two lids or carbs and see if the fault remains with the component just moved. Note that having moved one or two components over i.e. they are working with different partners you may find that the overflowing has stopped, or indeed now happens on both! Either situation implies that the problem is with one or more of those components.

- Note the Leyland Parts Catalogue depicts a sealing washer for the HIF but not the HS, the Workshop Manual depicts it with 'as required' so presumably to adjust the float height with solid plastic floats. Suppliers don't show them for either. Check any washer is undamaged and if there is no washer check the closing surfaces of lid/carb body and valve body are undamaged.

- If, having moved components over the fault stays with the lid (HS) or carb body (HIF), it sounds like fuel is bypassing the closed valve somehow. If HS and the problem only occurs when the lid is fitted to the carb the float could be fouling the walls of the float chamber.

Bear in mind that on the HS4 at least the overflow port is significantly higher than the jet bridge so even with a stopped engine and the choke control pushed home (i.e. minimal clearance between needle and jet) excess fuel will come up the jet and run into the inlet manifold before it comes out of the overflow. Only if the rate of fuel leaking through or past the float valve is greater than that coming up the jet will the the fuel level in the float chamber continue to rise and eventually come out of the overflow, this could take a long time especially with the North American charcoal canister system. Because of that the test for any seepage has to be how frequently the fuel pump clicks with the ignition on but engine stopped - the factory limit for this is that is should not click more frequently than once every 30 seconds. If it clicks less frequently then the valve could still be seeping but it won't cause a problem in normal use as the engine at idle will be using more fuel than is seeping so the correct float chamber level will be maintained. When doing this test for extended periods you should disconnect the coil to prevent it overheating.

Also bear in mind that (like incorrect float height) if the seepage is enough to raise the fuel level in the float chamber but not overflow it will be resulting in a rich mixture and possible hot-start problems.

See here for a bench test of a float chamber.

Floats:

Float Height

All HS carbs used the same float for both front and rear carbs - originally AUD9904, currently it seems to be WZX1300.

North American 4-cylinder HIF carbs used AUD3571 in the front carb and AUD3570 in the rear, currently WZX1510 and WZX1509 respectively.

UK HIF and V8 carbs used CUD2774 in the front/left carb (as viewed from the driving seat) and CUD2773 in the rear/right, however these also seem to use WZX1510 and WZX1509 respectively now.

There are also 'StayUp' float kits for all versions which have a closed cell construction and Burlen claim they are unsinkable. However on one forum someone had one sink, returned it to Burlen, who said it must have been damaged during handling ... which surely makes it no different to any other float ... apart from being nearly twice as expensive!

January 2026: A pal in America has been experiencing intermittent flooding for a while on an HS carb despite replacing sundry parts and swapping things round. The problem moved with the float and weighing the two StayUp type one weighed 7.8gm whilst the other weighed 14.5gm (see Ship Displacement and Archimedes Principle) which is a huge discrepancy in percentage terms. I contacted Joe Curto the reknowned carb specialist in America asking if he could possible weigh both original and StayUp types for me and he promptly replied with the following information: