Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

Fuel System

|

increased to 10% during summer 2021.

February 2024: Geoff's GT gets its first start for a few months and it's first run - up and down his drive - in two years. All we did was check the fluids, putting a bit of water in the thermostat housing filler and expansion tank, then went for it. Cranked a bit slowly but after a few seconds fired up on all four. The petrol tank last had any fresh fuel in February 2020 - 4 years! - which rather gives the lie to petrol 'going off' when stored, particularly over winter as purveyors of magic additives would have us believe.

Air Filters November 2014

Alternative filters

Decals

V8

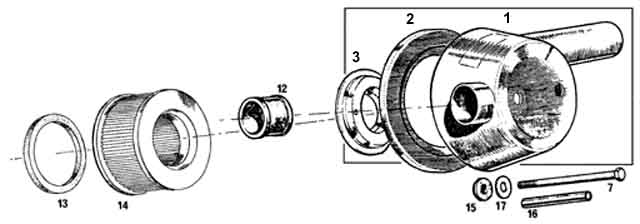

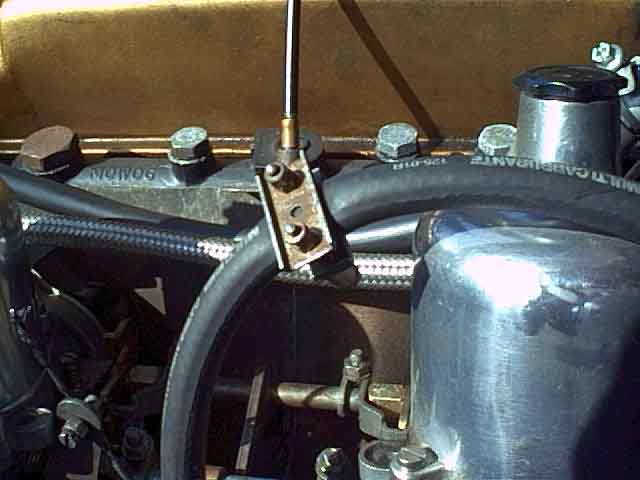

The same basic arrangement was used on twin-carb 4-cylinder MGBs, right through production on RHD cars, LHD changed to single carb at various times. One filter can per carb, with a short interconnecting hose, presumably to equalise air pressure between the two. Each can consists of a body with the air inlet, a pressed steel base, and an alloy plate which butts up against the carb flange with a gasket. The filter element is cylindrical which is clamped between the body and the pressed steel base, and there is a rubber gasket that goes between the base and the alloy plate. Long bolts with oversize steel and rubber washers go through steel tubes inside the body of the can, the centre of the filter, the alloy plate, gasket and the carb flanges. The tubes fit inside stepped rubber washers in the top of the can and prevent it and the filter being crushed from overtightening of the bolts. On HS carbs 5/16" UNF bolts 17H2541 go through the carb flanges into 'U'-shaped brackets with threaded bosses each end. The front bracket (AHH 6371) has an extension finger from one of the bosses projecting upwards between the carbs and is the attachment point for the choke cable inner. The bracket on the rear carb (AHH 6372) is a plain 'U'. HIFs used 5/16" UNC bolts screwed direct into the carb flanges, the carb inner is attached to an extension on the support for the accelerator cable outer.

The same basic arrangement was used on twin-carb 4-cylinder MGBs, right through production on RHD cars, LHD changed to single carb at various times. One filter can per carb, with a short interconnecting hose, presumably to equalise air pressure between the two. Each can consists of a body with the air inlet, a pressed steel base, and an alloy plate which butts up against the carb flange with a gasket. The filter element is cylindrical which is clamped between the body and the pressed steel base, and there is a rubber gasket that goes between the base and the alloy plate. Long bolts with oversize steel and rubber washers go through steel tubes inside the body of the can, the centre of the filter, the alloy plate, gasket and the carb flanges. The tubes fit inside stepped rubber washers in the top of the can and prevent it and the filter being crushed from overtightening of the bolts. On HS carbs 5/16" UNF bolts 17H2541 go through the carb flanges into 'U'-shaped brackets with threaded bosses each end. The front bracket (AHH 6371) has an extension finger from one of the bosses projecting upwards between the carbs and is the attachment point for the choke cable inner. The bracket on the rear carb (AHH 6372) is a plain 'U'. HIFs used 5/16" UNC bolts screwed direct into the carb flanges, the carb inner is attached to an extension on the support for the accelerator cable outer.

Initially, on 18G and GA engines without positive crankcase ventilation, there was a hose leading from a port on the rocker cover to the base of the front air cleaner, on the outside i.e. 'dirty' side of the filter, which acted as one half of a crude form of crankcase ventilation, the other half being an open tube hanging down from the front tappet chest cover. This meant that front and rear 'cans' differed, although I can only see the base being different, not the main part of the can. Nevertheless the Parts Catalogue shows the complete cans as being AHH 7354 for the front and BHH 154 for the rear. These seem to have continued until chassis number 258001 - which was the start of the 1972 model year in Aug 71 - even though the hose to the front can was replaced by the PCV valve in Feb 64, and that was replaced by carb ventilation on 1969 models. That would have meant an open port on the front cleaner which would be unusual, although not out of the question as it was on the dirty side of the filter.

Initially, on 18G and GA engines without positive crankcase ventilation, there was a hose leading from a port on the rocker cover to the base of the front air cleaner, on the outside i.e. 'dirty' side of the filter, which acted as one half of a crude form of crankcase ventilation, the other half being an open tube hanging down from the front tappet chest cover. This meant that front and rear 'cans' differed, although I can only see the base being different, not the main part of the can. Nevertheless the Parts Catalogue shows the complete cans as being AHH 7354 for the front and BHH 154 for the rear. These seem to have continued until chassis number 258001 - which was the start of the 1972 model year in Aug 71 - even though the hose to the front can was replaced by the PCV valve in Feb 64, and that was replaced by carb ventilation on 1969 models. That would have meant an open port on the front cleaner which would be unusual, although not out of the question as it was on the dirty side of the filter.

Dec 71 UK models changed the cans to BHH 548 and BHH 549, the previously straight air inlet tubes changing to curved. Clausager states "to comply with new noise regulations, similar to those found on non-North American models from car number 258001". Normally one would expect that to relate to noise perceived by people outside the car, which would seem odd for air-filters. However a couple of people have said that the straight ones do result in significant intake noise in the cabin from the rear one which points straight at the bulkhead, so maybe it's a case of user comfort rather than 'regulations'. Unless it was the front one directing noise through the grille that was the problem, even though it is behind the radiator diaphragm. Carbs were still HS. For 1972 export models other than North America the can changed to BHH 546 front and BHH 547 rear, which was the same time that the twin carbs changed to the HIF type on those models. As the only part of the filter assembly that touches the carbs is the alloy base, North America also changed for the 1972 model year and HIF carbs - but to BHH 665 front and BHH 666 rear. How these differed from other export cans is not known. All these cans also changed from straight to curved inlet tubes. I can't see any difference between the front and rear cans on my 73.

For 1974 the UK changed to the non-North American export cans i.e. BHH 546 front and BHH 547 rear when they changed to HIF carbs, and stayed that way until the end of production.

None of these cans are currently available from the usual suspects, except ironically the earliest front can AHH 6371 from Brown and Gammons. But apart from that can with the port for the rocker hose, I have not been able to find any difference at all between front and rear cans. Furthermore the only part of the can assembly that touches the carbs is the alloy plate, so one could imagine that changing between HS and HIF carbs. However whilst the usual suspects do list that part (17H 2545) they say it is suitable for all years and don't differentiate between HS and HIF!

None of these cans are currently available from the usual suspects, except ironically the earliest front can AHH 6371 from Brown and Gammons. But apart from that can with the port for the rocker hose, I have not been able to find any difference at all between front and rear cans. Furthermore the only part of the can assembly that touches the carbs is the alloy plate, so one could imagine that changing between HS and HIF carbs. However whilst the usual suspects do list that part (17H 2545) they say it is suitable for all years and don't differentiate between HS and HIF!

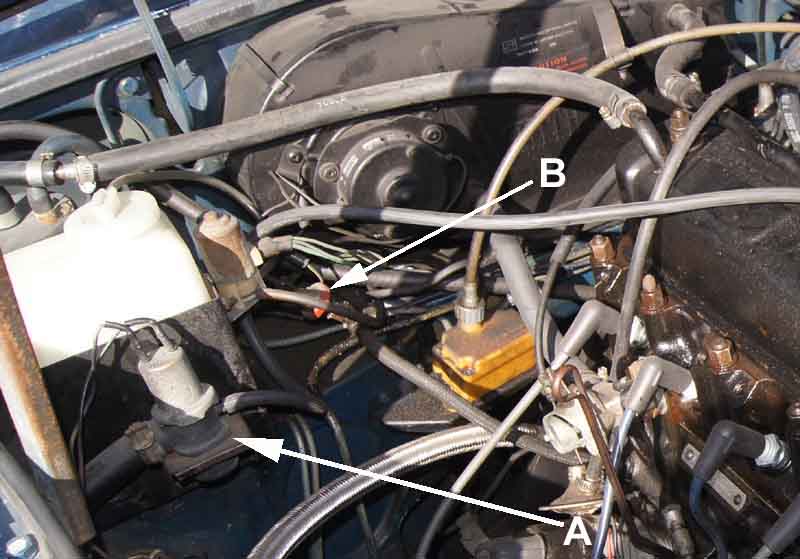

There is also the question of why the inlet tubes changed from straight to curved anyway. It did occur to me that the straight one at the rear could foul the remote servo, and that didn't become standard until 1974 i.e. a year after the cans changed, but it had been optional from Feb 1970. Clausager only shows straight pipes with no servo, or curved pipes with the servo. I googled for images of the engine compartment, did find one that showed straight pipes with the servo, but that was described as a 66 model so obviously modified. I then wondered whether curved pipes were fitted earlier when the servo was factory fitted, not mentioned in the documentation until they became standard in 1972. I did find a picture of a 71 with curved tubes and servo that would fit the bill, but then it had a weird radiator with a centre fill but the top hose on the right (alternator/dynamo) side which was a combination never used by the factory, changing from rear fill right side to centre fill left side with the Mk2 in 1967. Which highlights the caution that must be used when looking at owners photos. Then I was able to compare a straight with a curved side by side, and really the curved projects back almost as far as the straight before the bend, any difference would be marginal.

There is also the question of why the inlet tubes changed from straight to curved anyway. It did occur to me that the straight one at the rear could foul the remote servo, and that didn't become standard until 1974 i.e. a year after the cans changed, but it had been optional from Feb 1970. Clausager only shows straight pipes with no servo, or curved pipes with the servo. I googled for images of the engine compartment, did find one that showed straight pipes with the servo, but that was described as a 66 model so obviously modified. I then wondered whether curved pipes were fitted earlier when the servo was factory fitted, not mentioned in the documentation until they became standard in 1972. I did find a picture of a 71 with curved tubes and servo that would fit the bill, but then it had a weird radiator with a centre fill but the top hose on the right (alternator/dynamo) side which was a combination never used by the factory, changing from rear fill right side to centre fill left side with the Mk2 in 1967. Which highlights the caution that must be used when looking at owners photos. Then I was able to compare a straight with a curved side by side, and really the curved projects back almost as far as the straight before the bend, any difference would be marginal.

It could have been to move the front intake away from the hole in the radiator surround, which would have allowed more dirt onto the filter element, but also allowed cold air to reach the carbs. Normally a good thing - cold air is denser so carries more fuel with it for a bigger bang, but under cold and damp conditions it can cause carb icing. In the past I've deliberately piped cold air directly into carbs of a daily driver, and so has a pal on his supercharged MGB, neither of us having icing problems. But maybe the factory did get a few complaints in their tens of thousands of cars and decided to make the change. Why change the rear as well? Maybe that is just more confirmation that the two are the same! Then someone with straight pipes complained of noticeable induction noise in the cabin, and I wondered if that is because the rear pipe is pointing straight at the bulkhead and that is the reason for the change!

While looking into this for a pal I took Bee's cans off to compare them side by side from all sorts of directions, and in doing so I discovered a crack where the inlet tube joined the main body, which had extended as far as the flange joining the two halves of the tube together. No big deal from a filtration point of view as it is on the 'dirty' side of the filter, but I took the opportunity to tack-weld it in a couple of places inside.

While looking into this for a pal I took Bee's cans off to compare them side by side from all sorts of directions, and in doing so I discovered a crack where the inlet tube joined the main body, which had extended as far as the flange joining the two halves of the tube together. No big deal from a filtration point of view as it is on the 'dirty' side of the filter, but I took the opportunity to tack-weld it in a couple of places inside.

Remove/Refit: March 2024 Removal easy - don't drop the rear U-bracket on HS carbs as you unscrew the bolt as it may skitter away under the car, you can use one hand under the can with fingers round the back to hold the bracket while you turn the bolts with the other, then use the 'bolt' hand to lift the can and baseplate away while you withdraw the bracket with the other. HIFs without the U-brackets easier. Original cans can be removed one at a time - blingy K&Ns with the flat panel that goes across both filters less-so!

Refitting seems like a job for several hands - especially on HS carbs with the threaded U-brackets behind the carb flanges. Holding the cans with the filters and spacer tubes in, the base plates on, and the bolts in position, with the short rubber hose joining the two cans while positioning the U-brackets. However like removal original cans can be refitted one at a time, I do the front one first. Only insert the bolt tips into the flanges, not all the way through, while you position the U-bracket getting first one bolt started then the other. The front HS carb U-bracket has a finger on one side for the choke cable inner, on mine the correct resting position of the choke is pulling the interconnecting shaft lever up against spring pressure, so get the front bolt started first, then you can lift the finger to position the rear threaded hole for the rear bolt and get that started. With the first can loosely mounted get the rear can and rubber joining hose in position, position that U-clamp and support the can with one hand while you turn the bolts with the other.

When positioning the front HS U-bracket it helps if the bracket puts a slight anti-clockwise twist in the choke cable inner - don't go mad, just a partial turn is enough, and this will apply a bit of clockwise force to the knob which helps the locking mechanism to keep it out when pulled.

Alternative filters: August 2022 The original filters are said to be 'restrictive' at higher throttle openings, so less-restrictive K&Ns are a popular alternative although it's said they only add a couple of BHP and it's also said you can't feel anything less than 5 bhp on the 'seat'o'pants' meter. They also require regular cleaning and re-oiling with the special products, and suppliers web sites indicate that by being less restrictive they will upset the mixture balance across the throttle range and 'richer' needles will be required. Vee has K&Ns (probably from losing the 'lobster-claw' cans when the exhaust manifolds were changed to tubular) and that did need richer needles to cure a noticeable flat-spot when overtaking on a motorway.

There are several styles of alternative filter including K&Ns that fit in the original cans; of a similar size with a top bridging plate (some with 'MG' (or 'MGB') in an octagon and some without) and no cans; K&N 'pancake' style which as the name suggests are very slim and as a consequence are probably more restrictive and maybe more restrictive than the originals; and pancakes from other manufacturers that can be even slimmer and hence even more restrictive. Some of these have a plate going round the edge of the filter with holes drilled - or more importantly areas without holes so blocking air-flow. Such is the power of 'bling' (with the exception of those that fit in the standard cans), although LHD cars that replace the single Zenith/Stromberg carb with twin SUs will have to fit slimmer air filters as the dual-circuit brake master with servo takes up a lot of space that side.

The K&N with the top plate are a different size to the originals and as a consequence need different spacer tubes (should be supplied with the kit) on the bolts that clamp them to the carbs. One person has found that the 75mm tubes that came with the filters were too short and started crushing the filter before the spacer tubes were clamped so they rattled. The original 85mm tubes are too long in that they bolted up tight but the filters were left loose. Another poster said his tightened up snug, so perhaps the original poster has been supplied with non-matching filters and spacer tubes, although this (see rear filter) shows he is not alone. One 'answer' is to cut down the original tubes so they are snug, I wouldn't want to do that, and a better option for me (not that I would ever be tempted to go down the K&N route ...) would be spacer washers with the shorter tubes. This type are also more of a fiddle to fit than the originals as the whole kit and caboodle has to be offered up together.

V8:

The V8 used a completely different arrangement using a single airbox across both carbs, then a 'lobster claw' housing and filter each side. The intake side of the housing has a mounting onto the rocker cover, a metal tube extending forward, and a flexible tube extending down from that to a shroud around the original cast-iron manifold. The metal tube has a thermostatically-controlled flap that is closed when cold so warm air is drawn from around the exhaust manifold when the engine is started. This air warms up rapidly and means you can start pushing the choke in sooner to reduce emissions and consumption. As the temperature of the air from the manifold rises a port in the upper tube starts to open to draw cooler air in, which benefits performance once the engine is at normal running temperature.

The V8 used a completely different arrangement using a single airbox across both carbs, then a 'lobster claw' housing and filter each side. The intake side of the housing has a mounting onto the rocker cover, a metal tube extending forward, and a flexible tube extending down from that to a shroud around the original cast-iron manifold. The metal tube has a thermostatically-controlled flap that is closed when cold so warm air is drawn from around the exhaust manifold when the engine is started. This air warms up rapidly and means you can start pushing the choke in sooner to reduce emissions and consumption. As the temperature of the air from the manifold rises a port in the upper tube starts to open to draw cooler air in, which benefits performance once the engine is at normal running temperature.

See here for information on the gaskets between the air-box and the carbs.

However many V8s will have replaced the cast-iron manifolds with tubular and usually the lobster-claw arrangement is discarded at the same time. There is no real need to discard the air cleaner part, only the flexible tube and shroud, but the temperature-controlled flap then becomes redundant as it is unlikely to open without the heat from the manifold. The original system takes up a lot of space in the engine compartment so in fact probably the majority will have the system removed when changing the manifolds and K&N filters substituted which take up a lot less room. Unfortunately that's not the end of the story as changing both the exhaust manifolds and the air filters results in better breathing which has a negative effect on mixture balance through the throttle range. Vee came to me with tubular manifolds, K&Ns and standard needles and there was a pronounced flat-spot when accelerating from a cruise, it was a case of either flooring it or pulling the choke or you would get nowhere and may even lose speed. Many needles are available including ones with a 'richer' profile which is where the needle starts out the same size at the idle position but reduces in diameter more rapidly than the standard needle as you work towards the tip. The standard needle is BBU which is relatively 'weak' i.e. has a profile that doesn't taper very rapidly and at its tip is about double the diameter of the 'richest' needles. More information on needles and alternatives here.

However many V8s will have replaced the cast-iron manifolds with tubular and usually the lobster-claw arrangement is discarded at the same time. There is no real need to discard the air cleaner part, only the flexible tube and shroud, but the temperature-controlled flap then becomes redundant as it is unlikely to open without the heat from the manifold. The original system takes up a lot of space in the engine compartment so in fact probably the majority will have the system removed when changing the manifolds and K&N filters substituted which take up a lot less room. Unfortunately that's not the end of the story as changing both the exhaust manifolds and the air filters results in better breathing which has a negative effect on mixture balance through the throttle range. Vee came to me with tubular manifolds, K&Ns and standard needles and there was a pronounced flat-spot when accelerating from a cruise, it was a case of either flooring it or pulling the choke or you would get nowhere and may even lose speed. Many needles are available including ones with a 'richer' profile which is where the needle starts out the same size at the idle position but reduces in diameter more rapidly than the standard needle as you work towards the tip. The standard needle is BBU which is relatively 'weak' i.e. has a profile that doesn't taper very rapidly and at its tip is about double the diameter of the 'richest' needles. More information on needles and alternatives here.

Emissions Limits (UK) added November 2012

Updated November 2018: For cars first used before 1st September 2002 and with a non-original engine, test according to which is older - engine or vehicle.

Note this only seems to apply to vehicles first used on or after 1st August 1975, so cars earlier than that should still be exempt even with a later engine.

October 2019: Different in Ireland with the NCT, apparently, where the limit is dependant solely on the age of the car, not the engine. Stephen Elster wrote on the MG Enthusiasts Bulletin Board how his 1981-registered model had failed emissions with 1.3% CO i.e. well within the limit of 4.5% but 1627 HC where the limit is 1000 - a high HC indicating incomplete combustion. This wasn't an isolated instance as it only just scraped through last time, apparently. All the more frustrating as this is the last time it would have to pass emissions, being exempt next year. Some of it concerned another problem with a front damper, but it took nearly 130 posts over 3 weeks to get it resolved. A lot of the suggestions such as plug gaps and tinkering with the carb settings I just didn't feel would have that much effect, and he got nowhere with multiple tests including at garages elsewhere. It wasn't until he went back to basics and checked valve clearances which he discovered had been set to 0.15mm instead of 0.015" (by a so-called professional mechanic), i.e. about 6 thou instead of 15 thou, and discovered he had an intake leak from loose manifold nuts discovered by spraying carb cleaner round the inlet manifold. With both those fixed a retest came in at 1.95 CO and 557 HC. It's a shame we don't know which had the greatest effect - valve clearances or vacuum leak - but I do suspect the latter. He'd previously adjusted the carbs for 3.5 CO, which was probably rich at the carbs compensating for the vacuum leak 'downstream', and maybe not mixing properly for full combustion. So the moral of the story is to go back first principles checking all the basics, before you start throwing parts at it.

Checking prior to MOT: All engines are different and while some always pass emissions when the carbs have been adjusted to the lifting pins, others don't, and the V8 is a case in point. I always have to weaken the mixtures by at least a quarter-turn (both carbs by the same amount in the same direction remember) and put them back afterwards. Many years ago I bought a Gunson's Gastester, and like the curate's egg it has only been good in parts. It's reasonably accurate as far as checking and tweaking prior to the MOT if you have to pass the limit test. However I have found that it gives noticeably different readings if it is sitting on hot tarmac on a warm day compared to about bumper level on a stool or some-such, and also varies according to which way it is tilted! If that wasn't enough although you are supposed to set it to read 2% before the probe is inserted into the exhaust, after many years mine won't go that low even on the minimum. Nevertheless I do find that if it goes up by less than 2.5% between fresh air and the exhaust, it does pass the MOT.

I don't always use it, and I think at least once in the past I have not turned them back to 'normal' after the MOT. The upshot being that whilst in 2016 it was 3.56 CO and 272 HC, in 2017 it was 1.41 CO and 201 HC and in 2018 it was 0.2 CO yes nought point two and 190 HC, and the tester looked at me in astonishment. The amazing thing is that apart from warming up from cold in winter taking a bit longer at weaker mixtures, otherwise she has always run very well with no stumbling or anything else. Paradoxically though given the longer warm-up, she was running noticeably hotter on the gauge when left idling for the duration of the 2018 test. As it was after this test I readjusted to the lifting pins, winter warm-up is now noticeably better, and in future I'll be using the Gastester before and turning her back to 'normal' again afterwards.

The current situation

Theoretical problems

Hot start problems?

Who supplies what?

History

Fuel hose July 2015

February 2024: Another unnecessary worry (in my opinion) is fuel 'going off' over winter. I regularly have the same fuel in the tank of both cars for six months or so with the less decent weather in winter and have never had a problem. After doing various jobs on Geoff's GT for the first start in a long time all we did was check the fluids, putting a bit of water in the thermostat housing filler and expansion tank, then went for it. Cranked a bit slowly but after a few seconds it fired up on all four. The petrol tank last had any fresh fuel in February 2020 - 4 years! - which rather gives the lie to petrol 'going off' when stored, particularly over winter as purveyors of magic additives would have us believe. Funnily enough at the 'first start' it wouldn't fire up, and Geoff said he hadn't heard the fuel pump ticking. Not unknown with points pumps, but being an RB with the electrics end in the boot that's quite easy - once you have lifted the spare wheel cover - which had loads of parts on it awaiting refitting. I did a test lift to see if I could get at the pump but it was too heavy, so I dropped it back down in preparation for shifting everything off and 'tick-tick-tick-tick' - that was even easier! The pump is a Hardi, so they aren't immune from the problem despite their implication that by being electronic it can't happen.

December 2023:

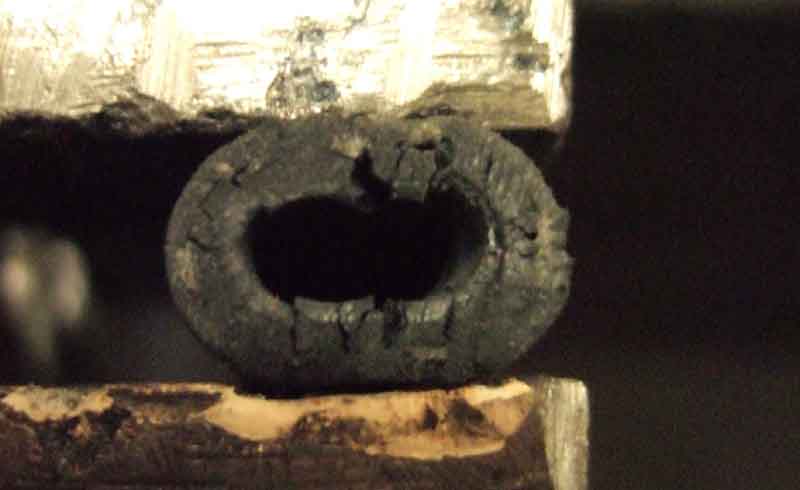

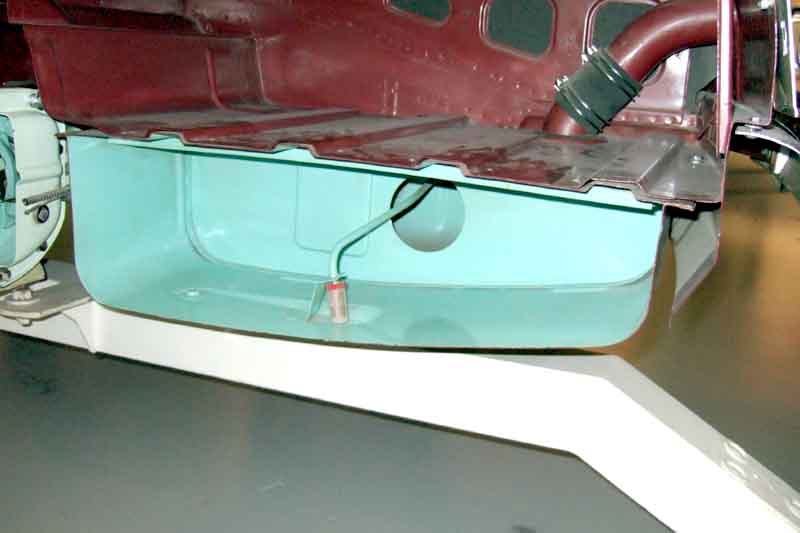

People are worrying - unnecessarily in my opinion - about the effect of ethanol fuel on their tank over winter and wondering if they should 'brim' the tank for a period of non-use (I've seen Americans recommend this) and even hang silica gel bags in the filler (which was new one on me)! The chances of moisture vapour condensing on the roof of the tank are negligible and probably non-existent in a UK winter. It seems to me that as ethanol i.e. oxygenated fuels contain more oxygen molecules than non-ethanol, and can absorb more water vapour, and as we know that both water and oxygen are needed for corrosion to occur, brimming is more likely to increase a problem. In fact there is no problem as the attached from Peter Mitchell of the tank on his 1978 which he has had since 1988 when it had done 34k so is almost certainly the original tank, shows. I know exposure to ethanol has been for a relatively short period in its life, but if the addition of ethanol was going to have such a huge effect as people fear we would know by now with reports from America which have had it for longer than us.

People are worrying - unnecessarily in my opinion - about the effect of ethanol fuel on their tank over winter and wondering if they should 'brim' the tank for a period of non-use (I've seen Americans recommend this) and even hang silica gel bags in the filler (which was new one on me)! The chances of moisture vapour condensing on the roof of the tank are negligible and probably non-existent in a UK winter. It seems to me that as ethanol i.e. oxygenated fuels contain more oxygen molecules than non-ethanol, and can absorb more water vapour, and as we know that both water and oxygen are needed for corrosion to occur, brimming is more likely to increase a problem. In fact there is no problem as the attached from Peter Mitchell of the tank on his 1978 which he has had since 1988 when it had done 34k so is almost certainly the original tank, shows. I know exposure to ethanol has been for a relatively short period in its life, but if the addition of ethanol was going to have such a huge effect as people fear we would know by now with reports from America which have had it for longer than us.

June 2023: Can't say I have noticed a difference in Vee between Sainsbury's 97 and Tesco's 99 but with the same change for Bee I'm pretty sure she is now running the same as on Shell 99. Another unexpected benefit of the higher octane in Vee is that running as well as she was I tried weakening the carbs by 1/4 turn just to see what happened. No reduction in performance so I just left it there, then at the MOT this week emissions were 3.85% and 189ppm i.e. inside the limits - and I had forgotten to turn them down beforehand! Previously on 95 she always had to be turned down from her normal running level of 5-6% (limit is 4.5%) for the test, then turned back up afterwards otherwise there was a flat spot accelerating from a cruise. Another 220-miler on Tesco 99 - filled immediately before and after and 28 mpg this time, but the forecourt at the first fill pump has a lean to the right so not completely full, and the second (1st pump not available) has a lean to the left so got more in than previously.

August Bank Holiday 2022: A 200 miler, the 100 miles down I was conscious just how well Vee was going. Just a squeeze of the throttle to accelerate past traffic once they had pulled over not even bothering to switch OD out. A harbinger of problems? The journey back was the same ... then I remembered she was running on Sainsbury's 97! Filled up at the same pump on our return, and another 31mpg. I wonder what Tesco 99 will be like ...

July 2022: Given the cost of fuel these days and seeing as how I'm using supermarket E5 in Vee I've decided to give it a try in Bee as well instead of the Shell 99 she's had for a very long time. Having run the tank right down to work on a fuel pump connection I filled up at Sainsbury's (97 octane). Only one run so far, but I did think there was perhaps a little less pep than usual, so next time (when I've used most of this tank) I'll go for Tesco 99.

April 2022: After a 230 miler on 99 E5 in Vee I had about 1/4 tank showing and after two cold starts (petrol shortages again) filling with multiple clicks from the nozzle it took less than 8 gallons and had averaged 31mpg! However again that was on a pump with a favourable lean of the forecourt as that was the only pump with that grade, so jury still out.

August 2021: Appearing at a petrol station near me - Tesco 95 E10. So filled up the V8 with 99 E5, did a 250 miler with noticeably more left in the tank when arriving back home than usual. Filled up next day and had averaged 29mpg which is better than normal, although at a different pump with a favourable (for mpg) forecourt 'lean' so more miles needed. Next fill leaning the other way i.e. getting more in than before hence worsening apparent mpg and only having done short journeys was 16mpg! So the jury is still out. Also only E10 available following the late September supply issues, fortunately only needed half a tank so fairly well watered down.

March 2021: During summer 2021 the standard 95 octane petrol grade in the UK (confusingly called 'Premium') will become E10 and contain up to 10% ethanol. Both the pump and the nozzle should indicate this by 'E10' labelling in place of 'E5'. To avoid this you will have to use the higher octane 97/98/99 ('Super') grades, although smaller petrol stations will not be required to carry it in addition to E10. Note that the earlier proposal for "larger filling stations to continue to stock the standard Premium 95 petrol in an E5 grade (95 E5) alongside 95 E10" has been abandoned, although certain parts of the Highlands, north and west coast of Scotland will be covered by an exemption process and allowed to continue to market the 95-octane E5 grade. General opinion at the time of the introduction of E5 was that classic cars such as the MGB should not have a problem with it, but older vintage and veteran cars could. However the same is not true for E10 and the opinion of the FBHVC is that vehicles built before 2000 (and some from the early 2000s) are not compatible with E10 and should use E5 97/98/99 instead, albeit at a higher price. Government advice that one refuelling of E10 where E5 is not available should not cause a problem (especially where the tank is not completely empty), simply refuel again with E5 when available. More information in this DoT publication.

References:

FBHVC - Introduction of E10 petrol for historic vehicle owners

DoT - E10 petrol explained

February 2021: Another spurious claim in this months Enjoying MG that ethanol is damaging hoses, float tips and other fuel system components, as well as 'going off' and 'attracting moisture'. All 'fake noos' - with E5 at any rate and I've not yet seen any E10, it's crap modern parts particularly rubber. However it does include the information that Esso Synergy Supreme+ Unleaded 97 and Synergy Supreme+ 99 is ethanol-free except in Devon, Cornwall, the Teesside area, NW England and Scotland. However don't expect to see an E0 label at the pump as that is not permitted by the regulations, the pumps are marked 97 or 99 octane and E5 with red labelling. Pumps with 'Unleaded', E10 and blue labelling are 95 octane with up to 10% ethanol. The red labelling could cause confusion because the old leaded pumps had red nozzles, but this isn't leaded petrol, just ethanol-free.

June 2020: People are still blaming ethanol in fuel for problems with hoses even though pretty-well any rubber component is as short-lived these days. Roger Parker writes about the likely introduction of E10 in the UK and it's effects on our cars in the May and June issues of Enjoying MG from the MGOC, but towards the end of the May article on page 19 he writes:

August 2019: The ethanol industry has been kicking off and pressing the Government to introduce E10. The consultation referred to below was updated and the outcome published in February 2019, and the upshot of that is that pump labelling laws will come into force in September 2019. How and when E10 itself will be introduced is still pending, and at the moment is being left up to suppliers. As the Government are proposing to require a continuation of E5 95 in stations that sell E10 95, suppliers may be unwilling to carry the costs of providing both, so may choose not to provide E10. Also because of the low rate of take-up of 97 and higher octanes, changing that to E10 will have little impact on meeting any increased renewables objectives, perhaps meaning 97/99 E10 is less likely to appear. We shall see.

August 2018: I wrote to the Renewable Transport Fuel Obligation government department asking about E10 - whether any was being sold in the UK, and whether there were any plans to sell it. The response was:

2015: From March 2013 retailers have been allowed to sell petrol containing up to 10% ethanol, replacing the previous E5. There had never been a requirement to label pumps that carried E5, and it was by no means clear whether pump labelling would be changed to indicate E10 or not. That was for 95 octane, 97 and higher octane was classified as 'petrol protection grade' which was limited to E5, but that requirement had been due to expire at the end of 2013. The Government confirmed it would continue until the end of 2016, EC proposals to extend it to 2018 were awaiting approval, and the Government as seeking the views of interested parties in this document dated October 2013. Also I had not seen any definitive statement from an authoritative source i.e. Governmental as to exactly what E5 and E10 actually meant in terms of ethanol content.

Eventually I asked the AA these two questions and had the following reply:

"European standards now permit up to 10% bioethanol in petrol. Petrol containing between 5% and 10% must be labelled as E10.

"Technically the assumption is that all vehicles are compatible with E5 while compatibility with E10 (5< >10) must be checked with the vehicle manufacturer.

"Government's regulatory plans are laid out in this response to consultation on a proposed amendment to the motor fuel regulations 1999."

So the upshot is:

- E5 can contain up to 5% ethanol, and E10 anywhere from 5% to 10%.

- Only 95 octane can contain more than 5% ethanol.

- Pumps dispensing E10 must be labelled '95 E10', so potentially can be avoided.

- In answer to a written question in July 2015 the Government stated:

"The ethanol content of petrol supplied in the UK is a commercial matter for fuel suppliers, subject to the Motor Fuel (Composition and Content) Regulations 1999 which set the maximum permissible ethanol content of petrol at ten per cent, known as E10. The Regulations set no minimum ethanol content.

"E10 is not yet on sale in the UK. Petrol sold in the UK today typically contains up to five per cent ethanol, known as E5. The Motor Fuel (Composition and Content) (Amendment) Regulations 2013 ensure that E5 petrol will continue to remain available until the end of 2016, thereby providing a ‘protection grade' of petrol for drivers of those vehicles which would be incompatible with petrol which has a higher ethanol content.

"Should E10 be rolled out by suppliers, we will carefully assess the compatibility of the UK vehicle fleet in determining whether to extend the regulatory requirement for E5 to remain available beyond 2016.

"This Government recognises the concerns of owners of some older vehicles that may not be compatible with E10. The Department is in regular contact with suppliers who in turn have been asked to write to us to give at least three months of notice if they were to plan the introduction of this fuel. As yet none have indicated they have any immediate plans to introduce E10. - Proposed EC legislation would extend the availability of 'petrol protection grade' until the end of 2018, and the Government has said it will review whether UK legislation needs to be altered if the EC directive comes into force.

- Suppliers have indicated they have no plans to introduce E10, but it is a commercial decision and certain suppliers in certain areas could introduce it at any time. So if you habitually use 95, study that pump!

February 2015: More scare tactics. Moss claims:

The end result of water in the fuel is phase separation. The fuel separates into two distinct layers: a thick layer of gasoline mixed with a little ethanol on top, and a thinner layer on the bottom consisting of water mixed with most of the ethanol. And it doesn't take much water for this to happen - phase separation occurs in a gallon of 10 percent ethanol blend with just 3.8 teaspoons of water.

A gasoline/ethanol blend absorbs water until it triggers phase separation. The blend has a 90-day product life in a closed tank, but lasts just 30 to 45 days in a vented tank often found in classic cars. With 10 percent ethanol blends, owners are supposed to replace the fuel in vented tanks about once a month by driving or draining, taking into consideration the humidity in the atmosphere and temperatures.

Water phase separation in any gasoline is most likely to occur when liquid water comes in contact with the fuel. (Water in the form of moisture in the air will generally not cause phase separation.) Water which is in solution with gasoline is not a problem in any engine, but as a separate phase it can prevent an engine from running or even cause damage. Since oxygenated gasolines, however, can hold more water than conventional gasoline, phase separation is less likely to occur with oxygenates present.

Hot start problems? Vaporisation? Highly unlikely!

June 2014: Some people are beginning to experience odd hot-starting problems and are wondering if ethanol is the cause. Vee had two bouts of this recently, near the end of the tank i.e. not a recent fill (Tesco 95), and the second time was barely warm. I checked the mixture balance and it was slightly off, but no more than it had been in the past without this problem, but since correcting the mixture it hasn't reoccurred, with the same tankful, so who knows?

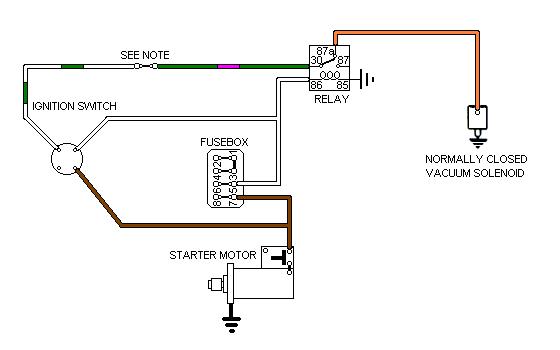

August 2014: Two tankfuls (one Esso, one Tesco) caused no problems despite the hottest weather of the year, but a subsequent Tesco tank did on a pretty warm day. After repeated cranking I could smell petrol so I know it wasn't fuel starvation i.e. vapour lock. It could have been flooding due to fuel expansion, but the usual treatment of flooring the throttle had no effect (although that's usually done when it is cold flooded), and it restarted after about 10 minutes with the bonnet up. The coil was very hot, I wasn't sure about the spark, and subsequent testing showed the coil boost circuit on the ballasted 6v ignition system wasn't working - and never had been with this starter. see here for the responses, which summarised indicate so far that apart from possibly lay-ups over winter - and none of those in cars, there have been no problems.

Who supplies what? September 2016: This TR-Register page contains information on ethanol in petrol including the following:

| BP | Ethanol is added at 5% to unleaded petrol at all sites across the UK. BP Ultimate (super unleaded petrol) does not have Ethanol added, except in the South West of England. |

| Esso | Ethanol is added at 5% to unleaded petrol at most sites in the UK. Esso Super Unleaded petrol does not contain Ethanol, except in the South West of England (Devon & Cornwall) |

| Shell | Shell has repeatedly refused to answer the question. It is therefore an assumption only, that all Shell petrol should be considered to contain 5% Ethanol. |

| Texaco | Ethanol is added at 5% to unleaded petrol. Texaco Super Unleaded petrol does not contain Ethanol. |

| Total | Ethanol is not added to any Total fuel (including standard unleaded petrol). Except in the North West and South East of England. |

It includes a link to download a list of TOTAL E0 sites, which can also be found here, sorted by Postcode. Bear in mind that any or all of the information above could change at any time.

My own research came up with the following:

Petrol sold in the UK must conform to BS EN 288 British Standards. This allows up to 5% ethanol in petrol. Tesco fully complies with these standards with the ethanol content of our fuels varying from 0 - 4.8% depending on the location and supplier.

Also this Ethanil page which contains a league table compiled from users testing petrol they have purchased, using a testing kit available from Ethanil. Interestingly Shell V-Power 99 from Durham tested at 5%, whereas 95 in Hampshire and Cornwall tested at 3%, and Sainsbury's 97/98 in West Mids tested at 1%. Also interesting is that Morrison's 95 in Humberside tested at 5.25%, which if correct should have the pump labelled 'E10 95'.

Update October 2012:The FBHVC site was updated on 25th April 2012. Permitted ethanol content in petrol will rise from 5% to 10% in 2013. i.e. unlabelled pumps will increasingly contain up to 10%. The FBHVC have endorsed three products that protect against corrosion (although confusingly they are described as 'stability' products), although be aware this only covers corrosion of mild steel e.g. tanks and lines, they were not tested as regards damage of other materials in the fuel systems e.g. plastics and rubbers. They are:

Update September 2011: Currently UK petrol can contain up to 5% ethanol without any additional labelling, anything more than 5% must be labelled "Not suitable for all vehicles: consult vehicle manufacturer before use" The Biofuel (Labelling) Regulations 2004. There is currently a proposal to increase the amount to 10% before labelling is required Targeted Consultation on Proposed Amendments to the Biofuel (Labelling) Regulations 2004. The FBHVC is on the case - see The Changing Nature of Fuels.

The main problems of E10 for carburettor equipped engines are:

Given the problems listed for E10 I don't think I want to use even E5 in my cars. Update May 2010: I understand UK fuels can contain up to 5% without labelling on the pumps, and even Shell V-Power may now contain it. Car warranties may state only E5 can be used and nothing higher. E10 becoming more common in Europe, and forces in America are pushing for E20.

Update July 2011: Amal Carbs states:

Frost Restoration are selling Ethomix additive at £12 per bottle. The advert mentions nothing about protection against ethanol, it seems to be a fuel system cleaner more than anything, but modern fuels don't need additional detergents. The data sheet linked from that page does mention that it protects against ethanol-based acids and corrosion, however the FAQ page includes:

Zinc and galvanised materials, Brass, Copper, Lead / tin coated steel. (Aluminium), Buna-N (seals), Neoprene (seals), Urethane rubber, Acrylonitrile-butadiene hoses, Polybutene terephthalate, Polyurethane, Nylon 66, Fibreglass-reinforced polyester and epoxy resins, Shellac, Cork.

References:

Fault Diagnosis January 2018

For cutting-out and misfiring while under way, always look at the tach before doing anything i.e. while the momentum of the car is still spinning the engine. If the tach is jumping about or has dropped to zero while the engine is still spinning and the ignition is still on then it's an ignition LT problem.

If the tach is still registering the appropriate engine revs then try and get in a position where it is safe to turn off the ignition while the problem is apparent i.e. while the car is still rolling, and bring the car to a halt. Then, when things are quiet enough turn on the ignition while listening to the pump. If the pump makes no sound, and it won't restart, then do a delivery check. But if you get a spurt of fuel when the delivery pipe is removed from a carb fuel is reaching the carbs at least, so if it still won't start it's probably an HT problem, or possibly a failed condenser.

If the pump chatters away before slowing and stopping and when turning the key to crank the engine restarts, or if there was no spurt of fuel, then the problem is fuel starvation, either because the pump is intermittently cutting out or dead, or there is a blockage in the plumbing between pump and carbs. With an intermittent pump the cutting-out or misfiring is also likely to be intermittent, or you will find that sometimes when turning on the ignition there is no chattering and no start, but on another occasion there is both chattering and starting. If the pump always chatters, and it always restarts, then it is a delivery problem which should be confirmed by the delivery check here. If you find you are getting one click each time you turn the ignition on and one click when you turn it off again, then the points are stuck closed.

Delivery Check August 2020

The standard check of the delivery system up to the carbs is to remove a pipe from a carb - watching out for a spurt of fuel if the ignition has been in recently, directing it into a container and switching on the ignition. The pump should deliver a minimum of one Imperial pint per minute and in practice double that, in a continuous series of pulses with minimal bubbling. Less than that indicates a restriction; intermittent pulses indicates a pump problem - electrical if the pump is audibly stopping and starting, mechanical if it chatters faster sometimes than others but the delivery rate reduces; if lots of bubbles then either fuel is running out or sucking in air on the tank side of the pump, which can be from a perforated pick-up pipe inside the tank.

The new possibility is the jet blocked, and Ian on the MGOC forum found this on one of his HSs from the rubber seal at the float chamber end of the jet pipe having broken up and restricted the flow. Visible in this case, but it could be concealed inside the pipe or jet. So maybe an extension to the delivery check is to remove the jet part from the jet carrier and direct that into the container. I don't know if the jet (once the screw to the choke lever has been removed) can be pulled out of the carrier with the pipe still connected to the float chamber, if not then it's probably easier to blow through it in the reverse direction, although how much back-pressure from the normal dimensions can be expected I don't know.

The new possibility is the jet blocked, and Ian on the MGOC forum found this on one of his HSs from the rubber seal at the float chamber end of the jet pipe having broken up and restricted the flow. Visible in this case, but it could be concealed inside the pipe or jet. So maybe an extension to the delivery check is to remove the jet part from the jet carrier and direct that into the container. I don't know if the jet (once the screw to the choke lever has been removed) can be pulled out of the carrier with the pipe still connected to the float chamber, if not then it's probably easier to blow through it in the reverse direction, although how much back-pressure from the normal dimensions can be expected I don't know.

HIFs don't have such a seal, but debris could still get through to the float chamber. Unfortunately quite a bit more work to get at, the main drawback of the HIF over the HS.

November 2019: in the last couple of years there have been complaints of rough running and cutting-out in hot weather, or failure to start a hot engine in hot weather, with people blaming ethanol for vapour-lock or vaporisation. These people should take a step back and look at the bigger picture: For a start you need to consider just how many people get this - a tiny number. Also that these cars have run in desert states from new without these problems, and America has had ethanol at double our level (and more) and weird brews for far longer than we have and don't report these problems.

Secondly I just don't see how you can get 'vapour-lock' with our fuel system - the pump pressurises the fuel, and if the float chamber needs fuel the float valve opens and the pump will push fuel forwards. If there is any air in the fuel that will simply be pushed out of the float chamber vent and the pump will keep pumping until the float chambers become full.

Thirdly because the pump is at the back pushing fuel forwards it is pressurising the fuel, which will make vaporisation less likely. Indeed fitting an electric pusher pump at the back in place of an engine-driven mechanical pump is a recognised method of solving vaporisation problems in America at least.

The most likely cause - if it IS fuel and not ignition - is probably fuel expansion, possibly forcing the float valves open and raising the level in the float chambers and hence the jets, and that plus expansion of the fuel in the float chambers and jets possibly overflowing into the inlet manifold giving a overly rich mixture. So flooding, not fuel starvation.

Fuel Filter Updated October 2015

Replacement filters seem to be GFE7004 some the old style with 5/16" ports both end and some with a transparent body with dual ports at both ends starting off at 1/4" and expanding to 5/16". For the 5/16" supply hose I wouldn't cut the 1/4" section off in case bits go inside, you should be able to push both the 1/4" and the 5/16" sections inside the 5/16" hose and apply the clamp over the 5/16" section. Personally I wouldn't have anything to do with blingy glass and chrome filters, they have been known to come apart ... but then I suppose a poor weld on a plastic could as well.

Replacement filters seem to be GFE7004 some the old style with 5/16" ports both end and some with a transparent body with dual ports at both ends starting off at 1/4" and expanding to 5/16". For the 5/16" supply hose I wouldn't cut the 1/4" section off in case bits go inside, you should be able to push both the 1/4" and the 5/16" sections inside the 5/16" hose and apply the clamp over the 5/16" section. Personally I wouldn't have anything to do with blingy glass and chrome filters, they have been known to come apart ... but then I suppose a poor weld on a plastic could as well.

There is frequent concern about how empty or full these filters should been and from observations of my own V8 and from others with 4-cylinder HIF it matters not how full it is. I have seen mine virtually empty, at other times virtually full, and it seems to make no difference whatever to the running of the car either way. So if your car is running well ignore an empty fuel filter. If it isn't running well then seeing the filter empty or very nearly so is necessarily proof of fuel starvation, the only way to verify that is to do a delivery check.

Do NOT fit a filter on the tank side of the pump. As Dave Dubois says the existing filters in the tank and the pump are designed to stop rocks and small birds and will pass fine rust particles which have no effect on SU pumps or SU (particularly HS) carbs. But in a fine filter they can clog it, stall the pump and burn it out.

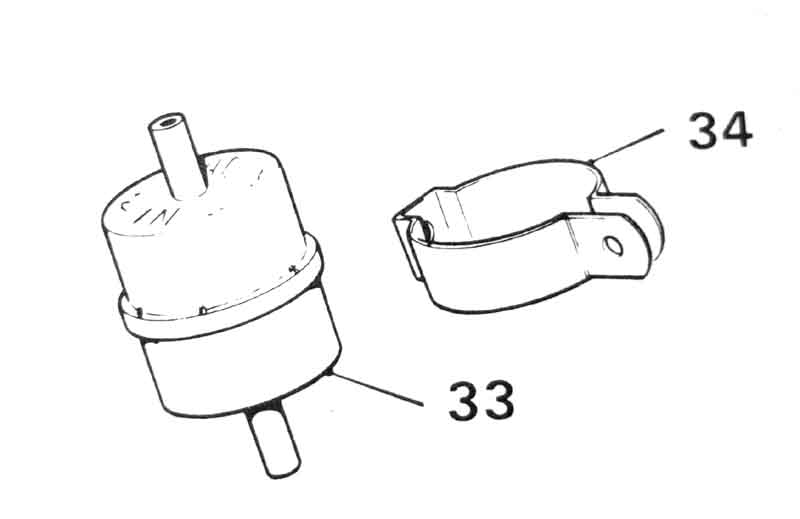

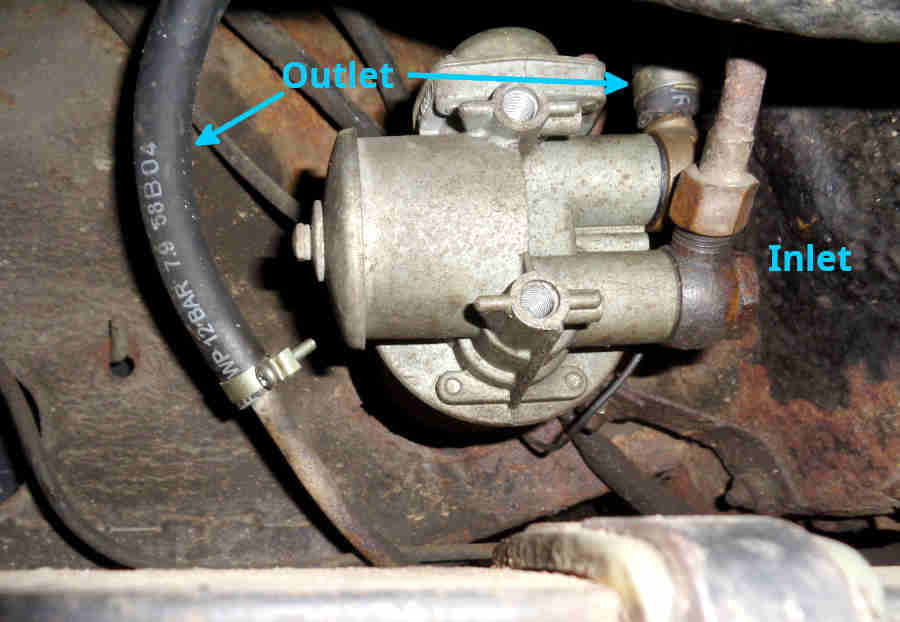

V8 Filter:

However whilst the V8 did come to me with a filter there was no bulkhead clip for it and it was hanging in mid-air between the supply-pipe and the near-side carb. I did change it and the hoses on getting the car, from the original style where the outer casing is two identical halves bonded together in the middle, to what Halfords had available which has a cup-shaped body with a lid. Another difference between the two is that the original has short 5/16" ports both ends, which is fine for the supply pipe, but the carb port takes a 1/4" hose. How original it was I don't know - it's not shown in the parts catalogue - but there was a 5/16" to 1/4" reducer between the filter and the carb, to cope with this difference. The new filter (as most seem to now) had dual 1/4" and 5/16" ports both ends, so didn't need it, and in to the Misc Prts box the reducer went.

However whilst the V8 did come to me with a filter there was no bulkhead clip for it and it was hanging in mid-air between the supply-pipe and the near-side carb. I did change it and the hoses on getting the car, from the original style where the outer casing is two identical halves bonded together in the middle, to what Halfords had available which has a cup-shaped body with a lid. Another difference between the two is that the original has short 5/16" ports both ends, which is fine for the supply pipe, but the carb port takes a 1/4" hose. How original it was I don't know - it's not shown in the parts catalogue - but there was a 5/16" to 1/4" reducer between the filter and the carb, to cope with this difference. The new filter (as most seem to now) had dual 1/4" and 5/16" ports both ends, so didn't need it, and in to the Misc Prts box the reducer went.

As the car is now 40 years old and on its third time round the clock I had decided to change the fuel pump hoses, as they were almost certainly original, and some people have been getting hot under the collar about ethanol and rubber. In the event they were in perfect condition, but that's another story.

As part of that job I had occasion to remove the filter hose from the carb, and noticed it had some internal longitudinal splitting at the cut end. I cut an inch or so off and opened it out but the splitting didn't extend under where the clamp had been, so I reckoned the rest was OK. However what I did notice was where the end of the carb port had been positioned in the hose there was some radial damage, and I wondered whether it had been caused by the unsupported filter flapping around for 20 years and nigh-on 100k. That started me looking at filter clips.

The original clip (BHH1212, confusingly on the fuel tank page of the Parts Catalogue) is symmetrical in that it mounts to the bulkhead behind the filter, and two ears are clamped together in front of the filter. However all the suppliers show this as having been superseded by clip 603185, which is a completely different P-shape, and is used for the crankcase breather filter on the back of the engine, albeit for the same filter. The mounting point on this clip is offset significantly to one side, which would put the filter itself to one side or the other by a significant amount, blocked on the one side by the heater, and on the other by the brake pipes that go to and from the servo. Much research later I found this capacitor clip, which looked identical in shape and style to the original, albeit at 40mm diameter which is slightly smaller than the filters which seem to be about 45mm. Cheap enough at £2, but by the time VAT and P&P had been added on it had risen to £6.43. Still, not much dearer than one of the wrong clips from the usual suspects.

The original clip (BHH1212, confusingly on the fuel tank page of the Parts Catalogue) is symmetrical in that it mounts to the bulkhead behind the filter, and two ears are clamped together in front of the filter. However all the suppliers show this as having been superseded by clip 603185, which is a completely different P-shape, and is used for the crankcase breather filter on the back of the engine, albeit for the same filter. The mounting point on this clip is offset significantly to one side, which would put the filter itself to one side or the other by a significant amount, blocked on the one side by the heater, and on the other by the brake pipes that go to and from the servo. Much research later I found this capacitor clip, which looked identical in shape and style to the original, albeit at 40mm diameter which is slightly smaller than the filters which seem to be about 45mm. Cheap enough at £2, but by the time VAT and P&P had been added on it had risen to £6.43. Still, not much dearer than one of the wrong clips from the usual suspects.

It had to be opened up to fit round this filter, but by pinching the right-angle corners, flattening the sides a little and bending the clamping ears it has ended up a good fit, albeit with the ears slightly further apart than they were originally. But since there wasn't a clamping screw and nut supplied I've just had to ferret a longer one out of my tin of bits than I otherwise would have for an original clip.

It had to be opened up to fit round this filter, but by pinching the right-angle corners, flattening the sides a little and bending the clamping ears it has ended up a good fit, albeit with the ears slightly further apart than they were originally. But since there wasn't a clamping screw and nut supplied I've just had to ferret a longer one out of my tin of bits than I otherwise would have for an original clip.

Although there was no trace of muck in the filter while installed, there was a very small amount of sediment visible once I had removed it. Still, that is after nigh-on 100k, so very little.

Although there was no trace of muck in the filter while installed, there was a very small amount of sediment visible once I had removed it. Still, that is after nigh-on 100k, so very little.

With the hoses removed from the filter there is very clear cracking in the ends. OK, they are 20 years old, but bear in mind the 40 year-old pump hoses showed no cracking whatsoever. It does beg the question of how long 2015 hose is going to last.

With the hoses removed from the filter there is very clear cracking in the ends. OK, they are 20 years old, but bear in mind the 40 year-old pump hoses showed no cracking whatsoever. It does beg the question of how long 2015 hose is going to last.

A 2BA screw and lock washer secures it to the bulkhead, then the supply pipe has to be repositioned towards the bulkhead and the heater a bit to sit under the clip with the open end vertical, as it had been pointing forwards quite a bit for how the filter was previously fitted. I bought a length of 1/4" hose for between filter and carb, partly because the filter is now sitting further back so that needs to be longer, but also as a replacement anyway given the existing condition, and I still had some 5/16" left over from the pump hose replacement to fit between the supply pipe and filter. I cut the 5/16" with a small hacksaw as that was before the filter which would catch any bits, but the smaller 1/4" I was able to cut with a pair of tin snips and hopefully leave no bits.

A potential problem with these later filters with the dual size ports is of course that each port is now at least twice as long as the original, which means the unwanted 1/4" section on the supply side of the filter stops the filter going as low in the clip as it otherwise might. Not a problem in itself, but the outlet side of the filter has another double-length port pointing vertically upwards, that the hose has to fit onto then curve over and down under the closed bonnet. I cut the 1/4" section off the supply side of the filter, as again the filter would trap any bits left behind.

A potential problem with these later filters with the dual size ports is of course that each port is now at least twice as long as the original, which means the unwanted 1/4" section on the supply side of the filter stops the filter going as low in the clip as it otherwise might. Not a problem in itself, but the outlet side of the filter has another double-length port pointing vertically upwards, that the hose has to fit onto then curve over and down under the closed bonnet. I cut the 1/4" section off the supply side of the filter, as again the filter would trap any bits left behind.

After that it was just a case of fitting a short length of new 5/16" hose onto the supply side of the filter with two Jubilee clips - the lower supply side one loose of course, and dropping the filter down through the clip and onto the supply pipe. Well, I say 'just', but getting the hose onto the pipe was easier said than done as its bore slightly smaller than the OD of the supply pipe, and there is very little room to grasp, twist and push. So I eased the supply pipe forwards and up until I had enough room to work the filter hose onto the supply pipe, then opened up the clip so I could push the hose with its Jubilee clips back through between the clamping ears, then pushed the filter body down through the clip. The pipe moved back and fore quite easily, so sat happily in the clip, although not fully down at this point, and I fitted the clamp screw and nut. This only needs enough tightening to grip the filter body gently, you don't want to risk cracking it by overtightening. I'd already fitted the new 1/4" hose to the filter, as it was easier off the car to push it over the thickened section at the open end, the other end slid onto the carb port very easily, and I tightened all four Jubilee clips.

After that it was just a case of fitting a short length of new 5/16" hose onto the supply side of the filter with two Jubilee clips - the lower supply side one loose of course, and dropping the filter down through the clip and onto the supply pipe. Well, I say 'just', but getting the hose onto the pipe was easier said than done as its bore slightly smaller than the OD of the supply pipe, and there is very little room to grasp, twist and push. So I eased the supply pipe forwards and up until I had enough room to work the filter hose onto the supply pipe, then opened up the clip so I could push the hose with its Jubilee clips back through between the clamping ears, then pushed the filter body down through the clip. The pipe moved back and fore quite easily, so sat happily in the clip, although not fully down at this point, and I fitted the clamp screw and nut. This only needs enough tightening to grip the filter body gently, you don't want to risk cracking it by overtightening. I'd already fitted the new 1/4" hose to the filter, as it was easier off the car to push it over the thickened section at the open end, the other end slid onto the carb port very easily, and I tightened all four Jubilee clips.

Now for a leak check. Turned on the ignition, got the initial rapid clicking as expected while it recharged the filter and hoses, then a steady click - click - click every couple of seconds or so - not so good. No visible leaks, so perhaps a carb float valve has got some debris in it. Even though I was careful to cut the hose that side of the filter with blades rather than saw, maybe there was something inside the new hose. Took the overflow hoses off and sure enough it was pulsing out of the near-side carb i.e. the first one to get fuel. So instigate ploy No.1 which is to remove the fuel pump fuse and run the engine until it empties the carbs and stops, then reconnect the fuse. Much chattering as it refilled the now empty carbs, hopefully flushing out any debris from the now wide-open float valves. The chattering slows and stops, then silence - no more clicking. It's perhaps something I shall have to keep an ear on for a while, turning on the ignition and listening to the pump before starting the engine, in case any more remains to cause a problem subsequently.

Finally I do order the 'correct' filter i.e. the one with two identical halves bonded together, but then realise that because of that central flange, and the longer dual ports, it isn't going to sit down in the clip as far as the filter I have now, which means the outlet hose is going to be that much closer to the bonnet. However despite the photo on the website showing the original style albeit with dual ports I get the later version i.e. the same as I fitted 20 years ago! But with the magic of Photoshop and doing a side-by-side comparison I see that with the central flange of the earlier style filter fitted below the clip, the ends of the shortened inlet port and the dual length outlet port end up in almost exactly the same places as each other. I can't track down a dual-size version of the original filter body, so will stick with the current style.

Finally I do order the 'correct' filter i.e. the one with two identical halves bonded together, but then realise that because of that central flange, and the longer dual ports, it isn't going to sit down in the clip as far as the filter I have now, which means the outlet hose is going to be that much closer to the bonnet. However despite the photo on the website showing the original style albeit with dual ports I get the later version i.e. the same as I fitted 20 years ago! But with the magic of Photoshop and doing a side-by-side comparison I see that with the central flange of the earlier style filter fitted below the clip, the ends of the shortened inlet port and the dual length outlet port end up in almost exactly the same places as each other. I can't track down a dual-size version of the original filter body, so will stick with the current style.

Fuel Hose July 2015

HS carb hose supports

Warning: Fuel hose specification from sources may not be adequate. SAE J30 seems to detail the standards for fuel and oil hose, with R6 and R9 being the specific types relevant to us. R6 (and R7 and R8) is the specification for 'low pressure' i.e. carb hose, and R9 for 'high pressure' i.e. injection hose, R6 is stated as having has a max external temp of 100C and R9 of 135C. MGOC engine compartment hose is specified as conforming to "DIN 73379-2A rated to withstand ... a working temperature range of -30°C to +50°C" (confirmed on other sites), but I have measured my roadster engine compartment at 50C and the V8 at 58C, and someone on the forum has had a failure of a club hose after just six months. So be warned! DIN 73379-3E would have been preferable as that is specced at 110C, but that seems to be multi-layer like R9 and the thin inner layer may cause problems. Do not buy braided! You can't see what is happening inside.

Moss Europe have Gates Barricade 'ethanol-proof' in 1/4" dia and 5/16" dia which are the two sizes needed on the MGB, rated at +125C. If these are an easy fit to the ports you should be OK, but if it is a tight fit over ribbed ports then the inner layer is easily damaged as below and debris will block your carbs. The strange thing is that these 5-layer hoses are cheaper than the standard 2-layer!

A pal went to a great deal of trouble to import some Barricade, but on fitting it he had no end of problems with rubber bits blocking his float valves and jets. Barricade is a 3-layer hose, with a very thin internal layer, and that was shredding as he pushed it onto his pipes and ports. And that was caused by the next issue - sizing differences between metric and imperial. There are plenty of suppliers of R9 by the metre on eBay, but I have only been able to find metric sizes - although occasionally they will show an Imperial measurement as well, although that is just a 'near equivalent'. The two sizes the MGB needs are 5/16" at the pump end, and 1/4" carb end, with a conversion from the larger to the smaller on cars with HIF carbs, done with a reducer, or a modern plastic filter that has a two-stage spigot on each end. The exact equivalent of 5/16" is 7.9375mm, so 8mm would be fine, but only 7.3mm or 9.3mm are typically available. The exact equivalent of 1/4" is 6.35mm, but again the available sizes are 5.5mm and 7.3mm. It's forcing on smaller hose that caused pal No. 2's problem. Holden lists Imperial sizes, but at £50 plus for a metre of each by the time you have added on P&P.

A pal went to a great deal of trouble to import some Barricade, but on fitting it he had no end of problems with rubber bits blocking his float valves and jets. Barricade is a 3-layer hose, with a very thin internal layer, and that was shredding as he pushed it onto his pipes and ports. And that was caused by the next issue - sizing differences between metric and imperial. There are plenty of suppliers of R9 by the metre on eBay, but I have only been able to find metric sizes - although occasionally they will show an Imperial measurement as well, although that is just a 'near equivalent'. The two sizes the MGB needs are 5/16" at the pump end, and 1/4" carb end, with a conversion from the larger to the smaller on cars with HIF carbs, done with a reducer, or a modern plastic filter that has a two-stage spigot on each end. The exact equivalent of 5/16" is 7.9375mm, so 8mm would be fine, but only 7.3mm or 9.3mm are typically available. The exact equivalent of 1/4" is 6.35mm, but again the available sizes are 5.5mm and 7.3mm. It's forcing on smaller hose that caused pal No. 2's problem. Holden lists Imperial sizes, but at £50 plus for a metre of each by the time you have added on P&P.

The bottom line is that problems with fuel hose on our cars are solely down to the quality of the rubber and not ethanol. I've had to replace the V8 engine compartment hoses more than once, I did eventually change the pump hoses but only as a precaution as it looked original with the braiding having crumbled away. Slit lengthwise and opened out it was perfect both inside and out, Roger Parker has also found replacement hoses failing before originals. After replacing the roadster engine compartment hoses early on for appearance with OE-style they eventually failed under the shiny braiding which is why I won't use braided anywhere.

Hose Replacement: September 2015:

Bee's hoses

The pump hoses on the V8 were 'old' when the car came to me 20 years ago, with the metal braiding crumbling away, but what I could see of the rubber gave me no qualms. I did replace the hoses at the carb end when I got the car as I wasn't happy with them. But since then I've had to replace them again and there are more and more complaints about fuel hoses, with ethanol being blamed for deterioration (it's not, it's rubbish rubber), I thought I had better do something about them. As mentioned above I had decided upon R6 unbraided to keep an eye on the external condition of the rubber.

The pump hoses on the V8 were 'old' when the car came to me 20 years ago, with the metal braiding crumbling away, but what I could see of the rubber gave me no qualms. I did replace the hoses at the carb end when I got the car as I wasn't happy with them. But since then I've had to replace them again and there are more and more complaints about fuel hoses, with ethanol being blamed for deterioration (it's not, it's rubbish rubber), I thought I had better do something about them. As mentioned above I had decided upon R6 unbraided to keep an eye on the external condition of the rubber.

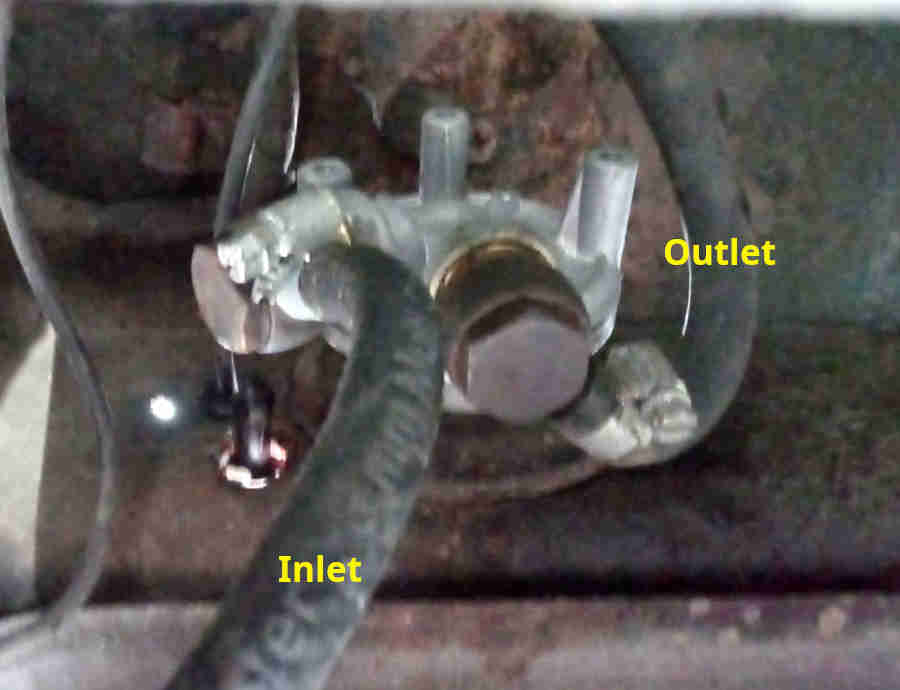

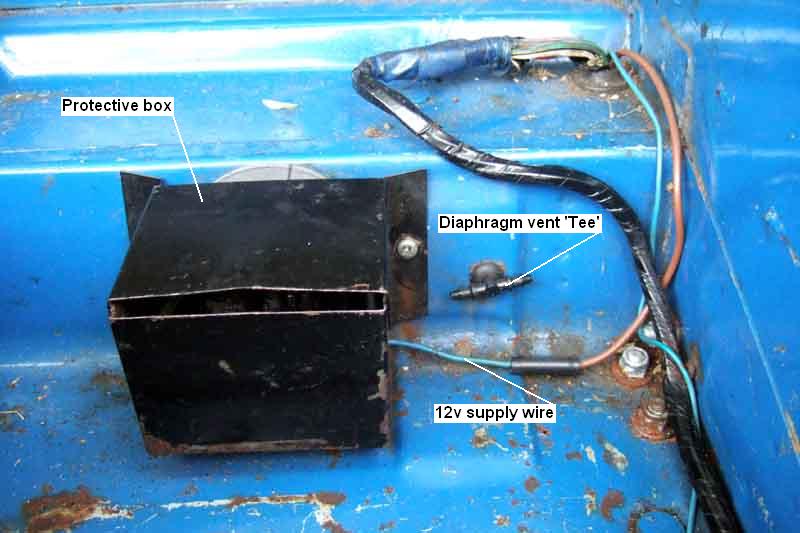

The RB pump has two hoses, and the clamps were the flimsy 'metal strap with screw and nut' type. I didn't think I stood any chance of unscrewing them, so opted for cutting them off with a Junior hacksaw, for which despite the after-market anti-roll bar and everything else in the vicinity there was just enough space at the right angle to get at both and each only took a couple of minutes work.

The RB pump has two hoses, and the clamps were the flimsy 'metal strap with screw and nut' type. I didn't think I stood any chance of unscrewing them, so opted for cutting them off with a Junior hacksaw, for which despite the after-market anti-roll bar and everything else in the vicinity there was just enough space at the right angle to get at both and each only took a couple of minutes work.

I had run the tank down to not much more than a gallon to reduce siphoning problems, and had considered undoing the pipe to tank fitting joint to break the siphon. But with the high position of the pump on the RB, the join between the tank pipe and the hose is level with the top of the tank anyway, so easing the hose off the pipe let air in to break the siphon and only a few of drops came out. The pump hose to carb pipe was more of a problem as having reversed the car onto the ramps just minutes before there was still pressure in that line. But several sheets of newspaper scrunched up and held under the join as I eased the hose off caught most of that.

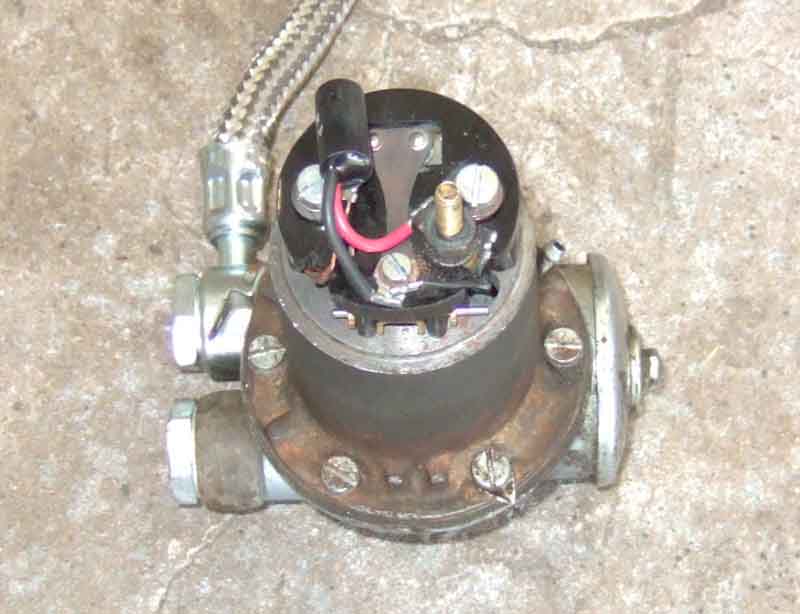

After that it was only a few minutes work to remove the earth wire and diaphragm-end vent tube from the pump body, then remove the metal cover in the boot, remove the 12v feed, and slacken the clamp round the large grommet and pump body, and the pump complete with hoses came out from under the car after less than an hours work. I had chosen to do it that way rather than undoing the banjo unions on the in-situ pump for two reasons - one was to avoid breaking yet another seal, and the other is that being able to grasp the pump body with one hand it was relatively easy to work the hoses off the banjo fittings with a pair of grips.

With both hoses off I measured them at 170mm, so cut two sections off the metre length I had bought. They needed a bit of a push onto the banjo ports which have a single rib, which may well have been enough to rupture the thin inner layer of Gates Barricade hose that Peter Ugle had had so many problems with. They were an easier fit onto the plain ends of the pipes. I probably spent as much time slackening the four new Jubilee clips right off before painting them with Waxoyl, part-tightening them, fitting, orientating for convenience then fully tightening as much as anything else, but even so had probably only spent a couple of hours so far.

With both hoses off I measured them at 170mm, so cut two sections off the metre length I had bought. They needed a bit of a push onto the banjo ports which have a single rib, which may well have been enough to rupture the thin inner layer of Gates Barricade hose that Peter Ugle had had so many problems with. They were an easier fit onto the plain ends of the pipes. I probably spent as much time slackening the four new Jubilee clips right off before painting them with Waxoyl, part-tightening them, fitting, orientating for convenience then fully tightening as much as anything else, but even so had probably only spent a couple of hours so far.

I connected up the pump but before fully mounting it turned on the ignition to test the joints. As expected the pump chattered, but then kept chattering, and eventually I switched off. Pondered a bit, I was sure I had got the hoses the right way round but checked the roadster and a spare pump to make sure, and they were. Then I wondered if, because I had refurbed this pump which originally failed on the roadster, and used it to replace the problematic Moprod pump that the car came to me with, I had got the one-way valves round the wrong way and the hoses had been the other way round ever since fitting. But checked some photos I had taken at the time, and they were correct. More pondering.

I had run the tank down, but there should be at least a gallon left, and I've never had a problem picking up with previous tank and pump changes. So I took the filler cap off and pressed the end of the filler pipe against my face round my mouth to form a seal, and blew. It pressurised, and released from the filler when I moved away. So I tried that again this time with the ignition on, chattered again, chattering rate increased slightly as I blew, but didn't stop. Switched off again and more pondering.

Suddenly it struck me. I'd driven the car onto the ramps immediately before I started, engine still cold, so the float chambers were full hence the float valves closed, and so the pump couldn't pump anything through, hence couldn't suck up any fuel! So I did a delivery check. The pump chattered rapidly initially, then slowed as it picked up fuel and started to pump it into my container. Whilst the non-return valve in the pump is good enough to prevent pressurised fuel in the pump chamber from flowing back it can't stop air. Phew! Whilst I was at it I decided check the rate to find it delivered just over an Imperial pint in 30 secs which is correct.