Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

Body and Fittings

|

From Lyndsay Porter's 'Guide to Purchase and DIY Restoration of the MGB',

republished as 'The MGB Restoration Manual', both by Haynes.

Fancy a reshell? Manufacturing an MGB bodyshell from British Motor Heritage

Front wing manufacture by British Motor Heritage

A frequent question in MGB circles is "How do I get to the aerial when it is mounted on a front wing?". After Martin Kennedy wrote and asked me that very question, having looked here for the answer and not found it, it prompted me to add this section.

Behind each front wheel there is a 'splash' or closing panel which seals the gap between the front outside edge of the footwell and the front wing, having a rubber seal between it and the wing. There is also a small panel and seal for the gap between the top of the box-section visible from the engine compartment at the rear of the inner wing and the top of the wing.

Behind each front wheel there is a 'splash' or closing panel which seals the gap between the front outside edge of the footwell and the front wing, having a rubber seal between it and the wing. There is also a small panel and seal for the gap between the top of the box-section visible from the engine compartment at the rear of the inner wing and the top of the wing.

The main splash panel is bolted to the footwell with seven bolts, the lowest one being up into the front of the floor pan and not visible in these pictures. Particularly the lower ones can corrode into the nuts welded to the panels, and shear off. In bad cases the corner of the footwell can crumble away.

With the splash panel removed you have access to the aerial, and also the hidden nuts for the door hinges. You can also examine the front section of the sills and the lower edges of the front wings for corrosion, and dribble oil down the very narrow gap between the two as described in 1/4 panel replacement above.

Added October 2008:

One thing to consider when adding an aerial to a front wing is the box-section that is immediately below it and behind the inner wing - see the accompanying thumbnail. There should be one or two large holes in the inner wing to enable you to see inside this box section, and the main harness and accelerator cable go to the cabin via it. If you drill the hole in the outer wing too close to the seam between the wing and the panel at the base of the screen you will also have to drill a hole in this box-section. Even then if you have a manually fully retractable aerial it may foul the bottom of the box-section, and a motorised aerial probably won't be able to be installed at all. The box section goes all the way forward to the splash-panel, and then there is a tapered 'trumpet' section in front of that, so you would have to go all the way forward to just about the front axle before you get a clear space under the wing if you are too close to the inner edge.

One thing to consider when adding an aerial to a front wing is the box-section that is immediately below it and behind the inner wing - see the accompanying thumbnail. There should be one or two large holes in the inner wing to enable you to see inside this box section, and the main harness and accelerator cable go to the cabin via it. If you drill the hole in the outer wing too close to the seam between the wing and the panel at the base of the screen you will also have to drill a hole in this box-section. Even then if you have a manually fully retractable aerial it may foul the bottom of the box-section, and a motorised aerial probably won't be able to be installed at all. The box section goes all the way forward to the splash-panel, and then there is a tapered 'trumpet' section in front of that, so you would have to go all the way forward to just about the front axle before you get a clear space under the wing if you are too close to the inner edge.

However by positioning the aerial close enough to the outer edge of the wing there is plenty of room between the side of the box-section and the side of the outer wing for any likely aerial. This means mounting the aerial on a curved and angled surface rather than a flat and horizontal surface, but all the aerials I have seen have a fitting that can cope with this kind of location.

However by positioning the aerial close enough to the outer edge of the wing there is plenty of room between the side of the box-section and the side of the outer wing for any likely aerial. This means mounting the aerial on a curved and angled surface rather than a flat and horizontal surface, but all the aerials I have seen have a fitting that can cope with this kind of location.

July 2022: Mark Denny has sent me this PDF from Radiomobile showing dimensions for positioning a front wing aerial on both roadster and GT.

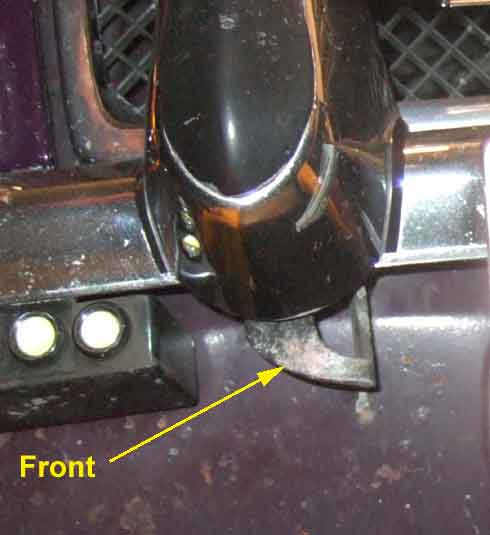

These pictures from Paul Tegler show a motorised aerial in the process of being installed behind the splash panel.

These pictures from Paul Tegler show a motorised aerial in the process of being installed behind the splash panel.

Arm-rest Cubby & Centre Console Added July 2009

1972 models for all markets got a modified centre console incorporating a hinged arm-rest with storage space underneath. There is a plastic peg attached to the lid, and a spring clip on the base, but the way they have been installed results in frequent breakages of the plastic peg unless you are very careful to align the peg in the slot in the clip before pressing down. Because there is just a simple hinge at the back of the lid it allows a lot of sideways movement of the front of the lid, but the peg and clip were fitted such that this sideways movement puts the greatest stress on the plastic peg in its weakest direction. If peg and clip had been turned through 90 degrees the weakest direction of the peg would then be to fore and aft movement of the lid, of which there is very little if any.

1972 models for all markets got a modified centre console incorporating a hinged arm-rest with storage space underneath. There is a plastic peg attached to the lid, and a spring clip on the base, but the way they have been installed results in frequent breakages of the plastic peg unless you are very careful to align the peg in the slot in the clip before pressing down. Because there is just a simple hinge at the back of the lid it allows a lot of sideways movement of the front of the lid, but the peg and clip were fitted such that this sideways movement puts the greatest stress on the plastic peg in its weakest direction. If peg and clip had been turned through 90 degrees the weakest direction of the peg would then be to fore and aft movement of the lid, of which there is very little if any.

Fortunately it is quite easy to turn the peg and clip through said 90 degrees. The peg is easiest as it has a square fitting, just squeeze the lugs on the back with a pair of pliers and push it out, and it will snap back in after turning (it's actually a fraction off-square but will go in the new way with just a bit of a push). The clip requires a bit more work. It's a little bit rectangular, which means the sides of the slot have to be filed out slightly. The overall width of the clip is greater than the length of the hole in the console, so will cover the sides of the hole if you are careful in your filing. Only file the minimum width needed for the clip, and in the middle of the sides of the hole, which will stop the clip sliding fore and aft and revealing the edges of the old hole (as well as nullifying the point of the exercise by putting the peg out of alignment with the clip again).

Fortunately it is quite easy to turn the peg and clip through said 90 degrees. The peg is easiest as it has a square fitting, just squeeze the lugs on the back with a pair of pliers and push it out, and it will snap back in after turning (it's actually a fraction off-square but will go in the new way with just a bit of a push). The clip requires a bit more work. It's a little bit rectangular, which means the sides of the slot have to be filed out slightly. The overall width of the clip is greater than the length of the hole in the console, so will cover the sides of the hole if you are careful in your filing. Only file the minimum width needed for the clip, and in the middle of the sides of the hole, which will stop the clip sliding fore and aft and revealing the edges of the old hole (as well as nullifying the point of the exercise by putting the peg out of alignment with the clip again).

Also only file enough to just be able to get the clip pressed into the new hole, if you file too much the clip will be pulled out of the console on the end of the peg.

Also only file enough to just be able to get the clip pressed into the new hole, if you file too much the clip will be pulled out of the console on the end of the peg.

However even if you did that (as I did on the roadster many years ago) all is not lost. There is a depression in the console that looks as if it were designed to take a mounting plate for the clip, complete with two blocked-off holes for fixing screws. It's a simple matter to cut a plate to fit this depression, drill through the plastic console and use countersunk screws to attach it, and it is much easier to get a tight-fitting hole for the clip in the plate than it is in the plastic.

However even if you did that (as I did on the roadster many years ago) all is not lost. There is a depression in the console that looks as if it were designed to take a mounting plate for the clip, complete with two blocked-off holes for fixing screws. It's a simple matter to cut a plate to fit this depression, drill through the plastic console and use countersunk screws to attach it, and it is much easier to get a tight-fitting hole for the clip in the plate than it is in the plastic.

June 2021: An enquiry about this on the MG Enthusiasts forum and Stephen Strange comes up with "The simplest solution is to glue on two strips of Velcro, one on the underside of the armrest, and the other over the hole in the console." A different kind of 'lateral' thinking!

May 2022 Another enquiry about repeated breakage of the peg on the MGOC forum, despite the poster already having turned peg and socket through 90 degrees. He must be pretty ham-fisted with it, or the hinge is very sloppy in the fore and aft direction as well as from side to side, but there we are. Someone suggested Velcro but another opined it would be difficult to lift the whole strip away in one go as usually they are peeled apart. That's true, but then it depends on how long the strip is. Another suggested a rare earth magnet and a metal plate (which is already in the lid) but going by the ones I have that would be even more difficult to pull apart, unless you recessed the magnet well down in the base to give a significant air-gap. I have a couple of stacks of 15mm discs and the only way I can pull them apart is to 'break' them like you would a stick. One disc would be less of course, but it would need some pretty strong glue, or more likely it would need to be under a metal plate (with a hole) screwed to the base. In the end the poster made a peg out of a screw, filed down to the correct shape and size, and held to the lid plate with a nut.

Herb Adler describes making and fitting an arm-rest cubby to a pre-72 model.

Centre Console: July 2022

Originally the centre switch and radio console for roadsters only had a cigar lighter in the middle, with a rectangular and a circular blank either side, GT's had the heated rear window switch and warning light to the right of the cigar lighter. V8s and RHD RBs (North America had them with the Mk2) gained a hazard warning switch, which didn't have an additional warning light (unlike North America) so one circular blank remained. Bee being a 1973 roadster came to me with four blanks (until I added hazards) but one of the circular ones was missing (which no one seemed to list) and for many years I covered it up with a small greetings card. But that got tatty and kept coming unstuck, so did some Googling. The existing blank measures about 3/4", and I spotted ACH9373 for classic Minis which is classed as a switch blank. Googling that Rimmers came up with that part for the ignition switch blank on MGBs with toggle switches when they got combined steering locks and ignition switches, and several places including MGOC came up with the same number for banjo brake drums! The MGOC item was an eBay listing for two for £2.50, which although it had a postage charge it was about half what supplier websites (including MGOC) were quoting, so that gets my order. They are chrome whereas the existing one is black, but that isn't a problem. When they arrive they are a loose fit in the hole, but as they (and the one I have) consist of a number of springy legs round the back that go through the hole it's a moments work to bend four of them out a little, and Hey-Presto, a good fit. They also have a very slightly domed face whereas the original is flat, but I don't think that will be an issue - if I don't like it I'll fit both and keep the original as a spare!

Originally the centre switch and radio console for roadsters only had a cigar lighter in the middle, with a rectangular and a circular blank either side, GT's had the heated rear window switch and warning light to the right of the cigar lighter. V8s and RHD RBs (North America had them with the Mk2) gained a hazard warning switch, which didn't have an additional warning light (unlike North America) so one circular blank remained. Bee being a 1973 roadster came to me with four blanks (until I added hazards) but one of the circular ones was missing (which no one seemed to list) and for many years I covered it up with a small greetings card. But that got tatty and kept coming unstuck, so did some Googling. The existing blank measures about 3/4", and I spotted ACH9373 for classic Minis which is classed as a switch blank. Googling that Rimmers came up with that part for the ignition switch blank on MGBs with toggle switches when they got combined steering locks and ignition switches, and several places including MGOC came up with the same number for banjo brake drums! The MGOC item was an eBay listing for two for £2.50, which although it had a postage charge it was about half what supplier websites (including MGOC) were quoting, so that gets my order. They are chrome whereas the existing one is black, but that isn't a problem. When they arrive they are a loose fit in the hole, but as they (and the one I have) consist of a number of springy legs round the back that go through the hole it's a moments work to bend four of them out a little, and Hey-Presto, a good fit. They also have a very slightly domed face whereas the original is flat, but I don't think that will be an issue - if I don't like it I'll fit both and keep the original as a spare!

Rubber

Lashing brackets

Chrome Bumpers: Just a warning that there have been some poor copies of chrome bumpers from some sources - incorrect in shape as well as poor in quality. Whilst the latter is not always easy to confirm before purchase, you can at least check that the basic shape is correct. One problem has been in the ends of the rear bumpers. Originals are tapered in towards the wing leaving a very small gap as further back, whereas copies have them chopped off short leaving an open hole facing forwards. That's the biggest and most obvious, there are other more subtle differences such as the part facing forwards is shorter, perhaps in an effort to correct the first problem. I'm not aware that this also occurs with front bumpers, even though the ends are very similar. Bob Muenchausen has some useful comparative photos here.

Mounted on 'springs' bolted to the chassis rails at the front, at the rear the springs were bolted to 'irons' that were bolted to the chassis rails and protruded through the rear valance.

Over-riders:

Originally front over-riders were optional for the UK until 1966, standard elsewhere, although Clausager says it is rare to find a UK car without them. Many changes detailed in Clausager, but basically they were plain chrome until 1970 or 1971 and were the same each side, then had rubber facings and became handed. The all-chrome (AHH6916 front, AHH6489/90 rear) have a welded bracket with nut inside for a standard bolt that comes through from the other side of the mounting 'spring'. Originally the rubber-faced type (BHH377 front, BHH378/9 rear) used a long special bolt with the head under the rubber facing going through the mounting spring with nut screwed on from the other side of that. Some suppliers have these with the long bolt and facing strip already fitted, some a kit of parts including the bolt, some supply that type without the special bolt so you have to order it separately, and some have them with the earlier welded bracket which needs a shorter standard bolt.

Originally front over-riders were optional for the UK until 1966, standard elsewhere, although Clausager says it is rare to find a UK car without them. Many changes detailed in Clausager, but basically they were plain chrome until 1970 or 1971 and were the same each side, then had rubber facings and became handed. The all-chrome (AHH6916 front, AHH6489/90 rear) have a welded bracket with nut inside for a standard bolt that comes through from the other side of the mounting 'spring'. Originally the rubber-faced type (BHH377 front, BHH378/9 rear) used a long special bolt with the head under the rubber facing going through the mounting spring with nut screwed on from the other side of that. Some suppliers have these with the long bolt and facing strip already fitted, some a kit of parts including the bolt, some supply that type without the special bolt so you have to order it separately, and some have them with the earlier welded bracket which needs a shorter standard bolt.

Originally most markets had the number-plate lights on the rear over-riders until almost the end of UK chrome-bumper production when they were mounted on the bumper itself directly below the plate. North American spec for 1970 only had half-bumpers with the number-plate lights tucked inside the ends, and for 1974 immediately before rubber bumpers they had large all-rubber 'Sabrina' over-riders. These were mounted further outboard almost directly inline with the bumper irons, both design and position in order to pass early impact tests. Consequently the bumper and its mounting were significantly different, with only one thicker spring going the full width of the car. The over-rider with its underlying metal structure bolted through the bumper to the spring alongside the mounting point of the spring to the bumper iron, and there were three (instead of four) more mounting points for the bumper to the spring - two at the ends as before and one in the middle, using chrome-headed bolts. For this reason this bumper is significantly different to any other full-width bumper and you have to be careful when buying replacements, as one UK chap with a UK car found when buying from a UK vendor.

Lashing brackets: October 2018:

Both chrome and rubber bumper cars were fitted with 'lashing brackets' of various types at various times, used for tying down new cars when exported by sea, sometimes called 'towing eyes'. Early cars from July 62 to November did have a towing eye attached to the front crossmember, deleted at the same time the front lashing brackets were provided.

Both chrome and rubber bumper cars were fitted with 'lashing brackets' of various types at various times, used for tying down new cars when exported by sea, sometimes called 'towing eyes'. Early cars from July 62 to November did have a towing eye attached to the front crossmember, deleted at the same time the front lashing brackets were provided.

Left to their own devices these get dull, rough and greyish with exposure to road dirt and sunlight especially when kept outside facing south as Vee was for several years.

Having tried a couple of products I used to recommend Turtle Black Chrome but it is no longer available. It is quick and easy to apply, brings tired bumpers back to black and shiny, and they stay that way for ages. A subsequent application several months after I got them to a good shine made hardly any difference, they were still so good. It has the same effect on various items of black trim of different materials on my 89 Celica although I only use it on the bumpers on the V8. It is a black almost creamy liquid, and a word of warning, if you get it on paintwork you can only get it off again with car polish, so I slip sheets of paper behind the edges of the bumpers while I am applying it. Turtle Wax Black in a Flash seems to be the current product, or maybe Carplan Black Trim Wax, but I haven't tried either yet.

I had previously tried ArmorAll and sure enough with enough applications left to dry in the sun and then finally polished up you could get them back to black and shiny, but the effects faded very quickly, in fact they seemed to end up rougher and greyer than originally, even when not exposed to sunlight for long periods. Some recommend its use on interior vinyl but others say it dries it out and can cause it to crack in the sun. Having seen the effect on the bumpers I can believe it. About the only thing it is good for is tyres for a show finish, being better than that awful high-gloss tyre paint beloved of second-hand car showrooms. But if you are going to drive the car don't bother, after a few dozen miles the effect has worn off.

Another recommendation I have seen is black boot polish, and whilst I can believe it works I can also believe that it will rub off black on light-coloured clothes even after being polished up. I say this after having had to clean a light-coloured carpet where someone with highly polished shoes had been shuffling their feet.

August 2020: Howard Aris writes:

November 2021: A perennial question, these suggestions on the MGOC forum:

- Autoglym trim and bumper gel. Looks like snot but it's really good stuff. Wipe on, wipe off. The more coats you apply the deeper the shine. After about 5 coats it starts to develop an almost mirror like finish.

- I use Car plan rubber black gel and rub it off after a while then spray Simoniz Back to Black in a aerosol can and just leave it.

- Current winner by a country mile IMO ......Vaseline !

- Black boot polish - Black Beauty was the brand

- I use Meguiars Tyre gel... great on tyre walls so I thought I'd try it on the RBs and it leaves a lovely shine if that's what you're after.

- The best thing to use on those black rubber bumpers? A spanner to take them off!

Mounting:

The front bumpers have four studs screwed into the armature - two each side, with washers, lock-washers and nuts fitted behind the chassis brackets. There are usually several slotted spacer plates fitted between the armature and the brackets to position the bumper as close as possible to the wings without touching, mine have three each side. Unlike the rear bumper the outer corners are unsupported.

The front bumpers have four studs screwed into the armature - two each side, with washers, lock-washers and nuts fitted behind the chassis brackets. There are usually several slotted spacer plates fitted between the armature and the brackets to position the bumper as close as possible to the wings without touching, mine have three each side. Unlike the rear bumper the outer corners are unsupported.

The rear bumper has five studs - two each side one above the other and one centrally in the upper position, the upper three going through into the spare wheel space and the lower two below the floor. In this case the outer corners are supported by one bracket each side. However it is not necessary to unbolt these from the body to remove the bumper, as the bumper has slots which slide off the brackets.

Strip/Refit: February 24 A pal chose to do this as an NOS cover came his way, and it may also be necessary if either your cover is ratty or armature is corroded and you want to mix and match with another. Info from said pal regarding fitting is:

Carpet and mats

Tunnel

Probably the most important decision to be made, even more than quality, is which tunnel shape is needed as the two available are very different. Mk1 cars have a humped tunnel, and Mk2 have a flat (albeit wider) tunnel.

Probably the most important decision to be made, even more than quality, is which tunnel shape is needed as the two available are very different. Mk1 cars have a humped tunnel, and Mk2 have a flat (albeit wider) tunnel.

The next is whether to get a moulded, or the cheaper flat. Without a doubt the moulded fits better, and flat will almost certainly be of a lower quality, but to be fair with the Mk2 tunnel and the centre arm-rest/cubby the wrinkling that results from a flat carpet is between the tunnel and the seat and only visible if you look for it. I did buy cheap as part of a full repaint and retrim, but that was 32 years and 65k ago wet and dry and they are still as good as new. But then I've always used rubber floor mats in all my cars, which do save the front floor sections from a lot of wear from heels.

The next is whether to get a moulded, or the cheaper flat. Without a doubt the moulded fits better, and flat will almost certainly be of a lower quality, but to be fair with the Mk2 tunnel and the centre arm-rest/cubby the wrinkling that results from a flat carpet is between the tunnel and the seat and only visible if you look for it. I did buy cheap as part of a full repaint and retrim, but that was 32 years and 65k ago wet and dry and they are still as good as new. But then I've always used rubber floor mats in all my cars, which do save the front floor sections from a lot of wear from heels.

There is also a decision on sections for the rear arches. These have a double-curvature and are a real pain to get a neat fit from a flat section even when glued, I had to cut darts. Some kits with the moulded tunnel have these moulded as well as in this GT kit, and some don't.

If you have a 72 and later car with the centre arm-rest and cubby, cut the carpet around the small access panel as well as round the gear lever hole, which means you don't have to pull the tunnel carpet back to access the gearbox switches. Keep a piece to drop on top of the panel when refitting everything. Click the links for more on the reverse light switch, and the overdrive switch.

If you have a 72 and later car with the centre arm-rest and cubby, cut the carpet around the small access panel as well as round the gear lever hole, which means you don't have to pull the tunnel carpet back to access the gearbox switches. Keep a piece to drop on top of the panel when refitting everything. Click the links for more on the reverse light switch, and the overdrive switch.

'Starter Cover' Mat

Aka RHD 'clutch foot rest cover'. A moulded rubber mat that goes over the starter motor bulge in the right-hand footwell, AHH6443 for Mk1 and AHC98 for Mk2.

Aka RHD 'clutch foot rest cover'. A moulded rubber mat that goes over the starter motor bulge in the right-hand footwell, AHH6443 for Mk1 and AHC98 for Mk2.

Boot/Hatch

Two strange pieces of carpet (amongst many) fit immediately in front of each rear light cluster. One flat squarish piece glues to the inside of the rear wing in the space that is bounded by the back of the rear wheel arch, the boot floor,

the rear light cluster, and under the boot lid rim (roadster) or C-post trim (GT). The other is two pieces stitched together such that the natural inclination of the 'hinge' is for the pile-sides to fold together. The wider half lies on the side piece of the boot floor and the narrower half covers the back of the rear light cluster. Both pieces are handed so try them both sides for the best fit.

Two strange pieces of carpet (amongst many) fit immediately in front of each rear light cluster. One flat squarish piece glues to the inside of the rear wing in the space that is bounded by the back of the rear wheel arch, the boot floor,

the rear light cluster, and under the boot lid rim (roadster) or C-post trim (GT). The other is two pieces stitched together such that the natural inclination of the 'hinge' is for the pile-sides to fold together. The wider half lies on the side piece of the boot floor and the narrower half covers the back of the rear light cluster. Both pieces are handed so try them both sides for the best fit.

The narrow part that covers the back of the light cluster is held in position by a plastic trim fastener pushed through the carpet into a bracket, but neither the bracket nor the fastener are shown in the official parts lists I have. The roadster didn't have these brackets so it was always a bit of a puzzle how the 'hinged' pieces were supposed to fit. It wasn't until I got the V8 which happened to have just one of these brackets and fasteners that I realised, and I was able to make three more brackets using the existing one as a pattern. I was able to get suitable fasteners at Halfords from their range of generic trim fasteners at the time. These are black plastic, have a 15mm diameter head, 17mm overall length, 15mm shank length. The shank has serrations and a maximum diameter of about 7mm.

The narrow part that covers the back of the light cluster is held in position by a plastic trim fastener pushed through the carpet into a bracket, but neither the bracket nor the fastener are shown in the official parts lists I have. The roadster didn't have these brackets so it was always a bit of a puzzle how the 'hinged' pieces were supposed to fit. It wasn't until I got the V8 which happened to have just one of these brackets and fasteners that I realised, and I was able to make three more brackets using the existing one as a pattern. I was able to get suitable fasteners at Halfords from their range of generic trim fasteners at the time. These are black plastic, have a 15mm diameter head, 17mm overall length, 15mm shank length. The shank has serrations and a maximum diameter of about 7mm.

I made the brackets out of some bits of body panels I had lying around (Hunts Eighth Law: "If you haven't found a use for something yet, you haven't kept it long enough"). All measurements are approximate but these are taken from the one original bracket I have. It isn't critical, it isn't visible, and I doubt even a concourse judge would be looking at them.

I made the brackets out of some bits of body panels I had lying around (Hunts Eighth Law: "If you haven't found a use for something yet, you haven't kept it long enough"). All measurements are approximate but these are taken from the one original bracket I have. It isn't critical, it isn't visible, and I doubt even a concourse judge would be looking at them.

For each bracket cut a flat strip 19mm wide and 55mm long. Mark a line across the width 15mm from each end, this is where a bend of approximately 40 degrees is made. Mark and centre-punch the centre of each 19mm x 15mm area for the hole to accept the plastic fastener. Get the fasteners and drill a hole of suitable size for them but in my original they are 6.5mm diameter. Finally make the bends so you end up with something like in the picture at the left.

For each bracket cut a flat strip 19mm wide and 55mm long. Mark a line across the width 15mm from each end, this is where a bend of approximately 40 degrees is made. Mark and centre-punch the centre of each 19mm x 15mm area for the hole to accept the plastic fastener. Get the fasteners and drill a hole of suitable size for them but in my original they are 6.5mm diameter. Finally make the bends so you end up with something like in the picture at the left.

The bracket is secured on the top stud for the rear light cluster and held by an additional spring washer and nut. It is angled down and towards the boot/hatch opening,

as shown in the picture on the left. The plastic fastener pushes through the carpet and into the free hole in the bracket.

The bracket is secured on the top stud for the rear light cluster and held by an additional spring washer and nut. It is angled down and towards the boot/hatch opening,

as shown in the picture on the left. The plastic fastener pushes through the carpet and into the free hole in the bracket.

Battery 'shelf'

The wheel arch and battery shelf pieces leave the chassis rails exposed, so I cut and glued some additional pieces for a neater appearance.

The wheel arch and battery shelf pieces leave the chassis rails exposed, so I cut and glued some additional pieces for a neater appearance.

Mats:

From inception until the Jubilee of April 1975 had 'PVC coated' (Clausager) rubber floor and sill mats, other models kept them until the start of the 1977 model year. They always matched the main interior trim 'so could be black, red or blue' although the heel mats in front of the seat were always black, regardless of trim colour. Vee still has original black ones under the POs carpet under the seats and on the sills but the front ones were missing when she came to me. Mark Denny sent me these pictures of a pair of rears which seem to be in Autumn Leaf, which was a new trim colour for 1971.

From inception until the Jubilee of April 1975 had 'PVC coated' (Clausager) rubber floor and sill mats, other models kept them until the start of the 1977 model year. They always matched the main interior trim 'so could be black, red or blue' although the heel mats in front of the seat were always black, regardless of trim colour. Vee still has original black ones under the POs carpet under the seats and on the sills but the front ones were missing when she came to me. Mark Denny sent me these pictures of a pair of rears which seem to be in Autumn Leaf, which was a new trim colour for 1971.

Cable and Pipe Routing July 2019

For Mk1 cars all markets used the same main harness, designed to reach right across the car for LHD, turned back on itself behind the dash for RHD. For Mk2 and later cars even though there were separate North American harnesses this was more to do with additional circuitry for that market rather than differences between LHD and RHD, other LHD markets and the UK seem to have continued to use the same 'LHD' harness turned back for RHD cars. It wasn't until the 77 model year that all LHD roadsters conformed to the North American spec, at which point there was a RHD-only harness, a LHD for Canada, and another LHD for America and the rest of the LHD world. The V8 also had an RHD harness as it was never marketed in LHD form, even though seven were built for Federal testing in the USA, which probably had the North American dash, harness and everything else that market required.

For Mk1 cars all markets used the same main harness, designed to reach right across the car for LHD, turned back on itself behind the dash for RHD. For Mk2 and later cars even though there were separate North American harnesses this was more to do with additional circuitry for that market rather than differences between LHD and RHD, other LHD markets and the UK seem to have continued to use the same 'LHD' harness turned back for RHD cars. It wasn't until the 77 model year that all LHD roadsters conformed to the North American spec, at which point there was a RHD-only harness, a LHD for Canada, and another LHD for America and the rest of the LHD world. The V8 also had an RHD harness as it was never marketed in LHD form, even though seven were built for Federal testing in the USA, which probably had the North American dash, harness and everything else that market required.

Tank to pump, and

convenient pictures from Clausager showing how all four 'services' - brake pipe, rear harness, battery cable and fuel pipe (from outside towards the middle) are routed through four small rubber combs (AHH6286) secured with metal straps (AHC60) to studs on the floor pan, plus a larger comb (AHH6284) and strap (AHH6285) where they all pass through a channel in the fixed crossmember. However at some point - probably as the rear harness gained the extra wires for reversing lights (1967), split parking lights (1970), boot/load space light (1971), and GT HRW (1971 or 72) it maybe became too fat to follow that route, and went through a separate hole in the fixed crossmember and P-clips beside the other combs. Another change was on Mk2 cars with the wider tunnel where the inboard stud for the front small comb was lost - a slotted tab was welded to the side of the tunnel and the end of the retainer strap pushed through that, being secured by one stud on the outboard side.

Tank to pump, and

convenient pictures from Clausager showing how all four 'services' - brake pipe, rear harness, battery cable and fuel pipe (from outside towards the middle) are routed through four small rubber combs (AHH6286) secured with metal straps (AHC60) to studs on the floor pan, plus a larger comb (AHH6284) and strap (AHH6285) where they all pass through a channel in the fixed crossmember. However at some point - probably as the rear harness gained the extra wires for reversing lights (1967), split parking lights (1970), boot/load space light (1971), and GT HRW (1971 or 72) it maybe became too fat to follow that route, and went through a separate hole in the fixed crossmember and P-clips beside the other combs. Another change was on Mk2 cars with the wider tunnel where the inboard stud for the front small comb was lost - a slotted tab was welded to the side of the tunnel and the end of the retainer strap pushed through that, being secured by one stud on the outboard side.

December 2020:

Boot/loadspace routing: CB cars have the tail for the fuel tank sender leaving the rear harness in the boot and exiting through a hole by the off-side light cluster to go forwards to the sender. RB cars have it leaving the harness under the floor above the axle and travelling back to the sender.

Boot/loadspace routing: CB cars have the tail for the fuel tank sender leaving the rear harness in the boot and exiting through a hole by the off-side light cluster to go forwards to the sender. RB cars have it leaving the harness under the floor above the axle and travelling back to the sender.

January 2020:

Bulkhead holes and grommets.

Bulkhead holes and grommets.

October 2019:

MGSte writes that the edge clips that attach the harness to the slam-panel are BHA4473, brake line clips are 17H9603 (3/16), and fuel line clips are BMK385 (1/4). Only the last is listed in my Parts Catalogues, but all are listed by the usual suspects.

MGSte writes that the edge clips that attach the harness to the slam-panel are BHA4473, brake line clips are 17H9603 (3/16), and fuel line clips are BMK385 (1/4). Only the last is listed in my Parts Catalogues, but all are listed by the usual suspects.

Cockpit Rail August 2018 - initiated by Dave Farrar

The hood frame and/or tonneau sockets and the trim panel aft of the doors will need to be removed, to remove and refit the cockpit rail. The trim is glued to the moulding. Start at the middle and glue along the curved face, piping uppermost and flush with the back face, and work round to the ends, don't trim at this stage. A warm day or gentle heat will be needed to stretch the vinyl round the back of the moulding in the corners.

The hood frame and/or tonneau sockets and the trim panel aft of the doors will need to be removed, to remove and refit the cockpit rail. The trim is glued to the moulding. Start at the middle and glue along the curved face, piping uppermost and flush with the back face, and work round to the ends, don't trim at this stage. A warm day or gentle heat will be needed to stretch the vinyl round the back of the moulding in the corners.

Slot the studs into the channel through the cut-outs, and fit the end-plates into the channel such that the exposed part is flush with the back of the moulding. Only then trim the vinyl to the ends of the end-plates as this goes under the trim panel aft of the doors.

Slot the studs into the channel through the cut-outs, and fit the end-plates into the channel such that the exposed part is flush with the back of the moulding. Only then trim the vinyl to the ends of the end-plates as this goes under the trim panel aft of the doors.

There are nine holes around the edge of the cockpit, through which go the threaded part of the studs, then plain washer, spring washer and nut fitted. This is a bit of a fiddle as they are accessed from below inside the cabin, and you need dextrous fingers to get the washers on and the nuts started. A 2BA spanner is best for tightening the nuts in the limited space available, don't over-tighten and strip the threads.

There are nine holes around the edge of the cockpit, through which go the threaded part of the studs, then plain washer, spring washer and nut fitted. This is a bit of a fiddle as they are accessed from below inside the cabin, and you need dextrous fingers to get the washers on and the nuts started. A 2BA spanner is best for tightening the nuts in the limited space available, don't over-tighten and strip the threads.

Dashtop and Crash-roll

Mounting

Gauges

Glovebox

Heating and Ventilation

Horns

Ignition Switch

Lighting

Radio

Screen Washers

Wipers

Originally metal painted in black wrinkle-finish, RHD changed to plastic for the 1977 year on. North American Mk2 were completely different but became similar from the start of 1973 with central air-vents and regaining a glovebox albeit in plastic, changing to a different plastic type for the 77 year on.

Dashtop and Crash-Roll A vinyl sheet is glued to the metal dashtop panel on roadsters, with the front edge tucked under the screen frame seal, and the rear edge behind the crash-roll on the dash. GTs have the vinyl glued to a 'hardboard' panel, with the front edge tucked back under the panel instead of the screen seal, but the rear edge is behind the crash-roll as on roadsters. Heater vents sit on top of the vinyl with studs through to the underside of the metal panel. Various suppliers show vinyl for recovering both the dash top and the crash-roll as part number AHH7597.

The ply backing for the crash-roll can get pretty flimsy after many years and the studs pull out. My original was breaking up, and anyway it looked a fiddle to recover as a staple-gun would be needed man enough to staple through the vinyl and the piping into the ply, because of that I opted to replace mine complete. Originally BHH947 now AKE5155 from several suppliers and seems to come with the vinyl for the dash-top i.e. in place of AHH7597, the quality of vinyl wasn't so good being less textured than the original. Secured to a flange on the dashtop with eight nuts FNZ103, spring washers LWZ203 and plain washers PWZ103. One 'Push-on fix plug' is listed under the crash-roll parts in the Leyland Catalogue but this seems to relate to the blanking plug and spire clip fitted in place of the dash-mounted overdrive switch when OD is not provided.

The ply backing for the crash-roll can get pretty flimsy after many years and the studs pull out. My original was breaking up, and anyway it looked a fiddle to recover as a staple-gun would be needed man enough to staple through the vinyl and the piping into the ply, because of that I opted to replace mine complete. Originally BHH947 now AKE5155 from several suppliers and seems to come with the vinyl for the dash-top i.e. in place of AHH7597, the quality of vinyl wasn't so good being less textured than the original. Secured to a flange on the dashtop with eight nuts FNZ103, spring washers LWZ203 and plain washers PWZ103. One 'Push-on fix plug' is listed under the crash-roll parts in the Leyland Catalogue but this seems to relate to the blanking plug and spire clip fitted in place of the dash-mounted overdrive switch when OD is not provided.

Mounting July 2023

Brendan Hussey asked me about this as fitting his dashboard as per photos on an MGOC Forum thread he just could not get it to fit neatly. The dash has brackets that fit over studs under the scuttle, and there is an additional plate AHH6293 (NLA but may be available from breakers if lost) for each one. The dashboard brackets are purely used for location, it's the plates that give the required support. The MGOC forum post described these plates as 'spacers' (other fora stated that they went somewhere else altogether) and showed them between the dashboard brackets and underside of the scuttle i.e. going on the studs first, but that is incorrect. They go on afterwards, under the dash brackets, and clamp those to the underside of the scuttle.

Brendan Hussey asked me about this as fitting his dashboard as per photos on an MGOC Forum thread he just could not get it to fit neatly. The dash has brackets that fit over studs under the scuttle, and there is an additional plate AHH6293 (NLA but may be available from breakers if lost) for each one. The dashboard brackets are purely used for location, it's the plates that give the required support. The MGOC forum post described these plates as 'spacers' (other fora stated that they went somewhere else altogether) and showed them between the dashboard brackets and underside of the scuttle i.e. going on the studs first, but that is incorrect. They go on afterwards, under the dash brackets, and clamp those to the underside of the scuttle.

| Car | Overall Length | Overall Width | Overall Height |

| CB Roadster | 12' 9.2" | 4' 11.9" | 4' 1.4" |

| CB V8 | 12' 10.7" | 5' 0" | 4' 2" |

| RB GT | 13' 2.25" | 5' 1.75" | 4' 3" |

I'd not really thought about the width differences until I got copies of the 1977 and 78 Leyland Workshop and Repair Operation manuals where the width is given as 4 ft 11 and 15/16 inches or 1523mm, i.e. 4' 11.9" which is the same as the CB roadster in the earlier manuals. I'd put the difference between CB and RB down to the bumpers, but in fact the widest part of the car is between the doors. Then I realised that my door mirrors add another inch per side, and wing mirrors would possibly add even more. I measured my V8, including door mirrors, at 5ft 2 and 3/4in, or just over 2 3/4" more than the 77 and 78 manuals, and an inch more than the earlier Workshop Manual.

Drinks Bottle Holder Added September 2009

The Navigator likes to keep a small bottle of water with her, but it keeps rolling under her seat so she has been nagging me to install a holder of some kind. Hadn't given it a lot of thought, but while I was rooting through my box of old MG bits for something else I came across a broken windscreen washer bottle holder that I had replaced when I first had Bee 20 years ago. The frame between the two mounting holes had broken away, but I realised it would make an ideal 'holster' for the small water bottles she uses.

The Navigator likes to keep a small bottle of water with her, but it keeps rolling under her seat so she has been nagging me to install a holder of some kind. Hadn't given it a lot of thought, but while I was rooting through my box of old MG bits for something else I came across a broken windscreen washer bottle holder that I had replaced when I first had Bee 20 years ago. The frame between the two mounting holes had broken away, but I realised it would make an ideal 'holster' for the small water bottles she uses.

My first thought was to mount it above the sill in the footwell somehow, but that would probably have meant screwing through the trim panel which I didn't want to do. Then I investigated hanging it from the square-section bracing tube behind the bottom edge of the dash. Possible, but it would have to hang several inches down and not swing about. Looked along the tube towards the centre console to see the two brackets for the LHD steering column, which were a definite possibility, but again the holster would need to be lower and not swing about. Then my eye fell on the lower screw in the side of the centre console, and Bingo, the ideal location.

Repaired the frame by welding a strip between the two broken holes, and re-drilling the top one, did a test fit and it looked fine. However the water bottles are quite a bit smaller diameter than the washer bottle and if at an angle in the holster would fall through the frame. Started pondering welding more strips around the bottom, but then I seemed to remember I had replaced the water bottle as well when I replaced the frame because it was holed and leaking. Another root through the box of bits and Lo and Behold! Cut the top off the washer bottle to just below the top of the frame, perfect. Then it was just a matter of stripping and painting the frame, and installing.

October 2017:

I say 'perfect' - and I'd done the same to Vee - but being against the tunnel the bottle did get a bit warm in hot weather. When Vee had been restored the passengers side trim panel had been removed to replace the front wing, and when I came to refit it I realised that - unlike Bee - there is a trim-screw half-way up the edge by the door. That makes a convenient mounting point, although it rather forces the height and angle the holder has to be positioned at. That proved just fine, so I moved Bee's across as well.

I say 'perfect' - and I'd done the same to Vee - but being against the tunnel the bottle did get a bit warm in hot weather. When Vee had been restored the passengers side trim panel had been removed to replace the front wing, and when I came to refit it I realised that - unlike Bee - there is a trim-screw half-way up the edge by the door. That makes a convenient mounting point, although it rather forces the height and angle the holder has to be positioned at. That proved just fine, so I moved Bee's across as well.

Front Valance January 2022

LE models had an additional rubber 'scoop' spoiler on top of the standard metal valance below the bumpers and this may suffer from the same problem. The ST spoiler adds significantly to cooling on RB models with the under-slung oil cooler, and particularly the deeper radiator on V8s and 77 and later 4-cylinder cars, as described here. The LE spoiler may offer the same benefits.

Glovebox June 2019

Fittings: The fibre-board 'box' is available (AHH6338 for RHD and AHH6339 for LHD) from the usual suspects. The brackets that support the back of the box (HZA545 and HZA543) are NLA but can be fabricated quite easily. Two parts originally, but I'd say not much more than a simple 'L' bracket performing both functions is needed.

Fittings: The fibre-board 'box' is available (AHH6338 for RHD and AHH6339 for LHD) from the usual suspects. The brackets that support the back of the box (HZA545 and HZA543) are NLA but can be fabricated quite easily. Two parts originally, but I'd say not much more than a simple 'L' bracket performing both functions is needed.

What to do when you lose the key: The Heritage Certificates for Bee and Vee give the key numbers - one for the ignition and one for the doors, boot/tailgate and glovebox. It's quite likely that the external locks have been changed at some point, much less so the glovebox, and the likes of Moss and Brown & Gammons plus other BL model parts houses sell replacement FS keys. Failing that you could drill out the lock and replace that (£15), or maybe even remove or destroy (and replace - £25) the fibre-board glovebox itself to get at the back of the lock. A 9/16" socket fits the screw that hold the tongue onto the barrel on Bee and Vee, and with that removed the lid should fall open.

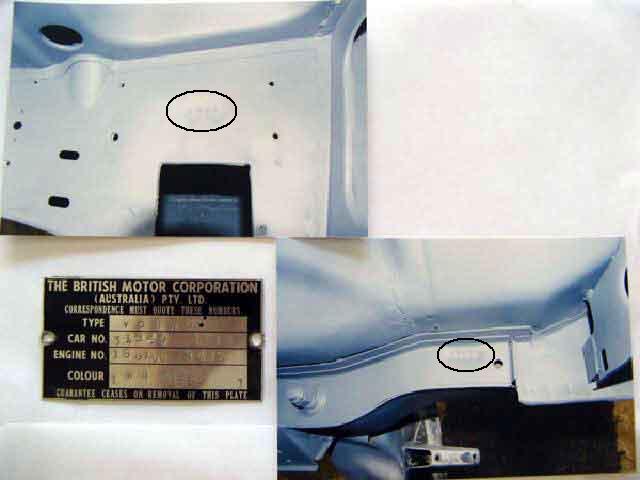

But I hate destroying things if there is another way, which is to remove the five screws holding the lid to the dash, then slide it to the left as far as it will go, tilt the left side down and the lock tongue should come out of the slot in the dash panel. The images also show how the fibre-board 'box' is attached to the dash panel.

But I hate destroying things if there is another way, which is to remove the five screws holding the lid to the dash, then slide it to the left as far as it will go, tilt the left side down and the lock tongue should come out of the slot in the dash panel. The images also show how the fibre-board 'box' is attached to the dash panel.

And failing that, the lock is a very simple three-tumbler affair that should be quite easy to pick - I managed it in a couple of minutes.

And failing that, the lock is a very simple three-tumbler affair that should be quite easy to pick - I managed it in a couple of minutes.

And finally, if you only have one key now, get another and hide it in the car where you can get at it without any keys!

GT C-post Liners November 2014

When I bought Vee 20 years ago come January bodily she was in very good condition, and apart from one thing the interior was also good - patinated but very original. The exception was the C-post liners, where the nuts on the back of the tail-gate spring stays had been allowed to gouge the vinyl of the C-post liners. Really annoying, as all it took was a little force to bend the pivots in towards each other a little bit so they cleared the liners. That left what to do about the liners. Never in a rush to do things (it took me 18 years to replace the plastic covers on the tail-gate struts ...) I decided now was the time, so as I had built up a list of things I wanted to do on both cars over winter I went on a shopping trip to Motaclan/Leacy's.

When I bought Vee 20 years ago come January bodily she was in very good condition, and apart from one thing the interior was also good - patinated but very original. The exception was the C-post liners, where the nuts on the back of the tail-gate spring stays had been allowed to gouge the vinyl of the C-post liners. Really annoying, as all it took was a little force to bend the pivots in towards each other a little bit so they cleared the liners. That left what to do about the liners. Never in a rush to do things (it took me 18 years to replace the plastic covers on the tail-gate struts ...) I decided now was the time, so as I had built up a list of things I wanted to do on both cars over winter I went on a shopping trip to Motaclan/Leacy's.

There are two colours - cream and grey, and looking at mine I couldn't tell for sure what I had, but I managed to get a sample of each, to find I had grey. Removing the old is pretty straightforward - one screw with cup washer at the very top, two screws for the rear window latch, three screws for the rear shoulder rail that has to be slid forwards, and five spring clips. On the first side all five of these came out easily, but on the other (only started when the first had been finished) one snapped, and another fell out and hid. The old boards were quite significantly warped, but otherwise in pretty good condition.

There are two colours - cream and grey, and looking at mine I couldn't tell for sure what I had, but I managed to get a sample of each, to find I had grey. Removing the old is pretty straightforward - one screw with cup washer at the very top, two screws for the rear window latch, three screws for the rear shoulder rail that has to be slid forwards, and five spring clips. On the first side all five of these came out easily, but on the other (only started when the first had been finished) one snapped, and another fell out and hid. The old boards were quite significantly warped, but otherwise in pretty good condition.

Comparing old and new it is apparent that the size and shape is slightly different, and the foam padding is probably only a quarter as thick on the new. The spring clips lower into holes in the back-board and slide on, and on the old were all orientated in the same direction. The holes in the new boards are slightly smaller than the clips, so the open end needs to be slotted in, then a screwdriver used to open up the end so it can be slid onto the board. I orientated them the same way as on the old boards. I made sure I had clean hands before handling the boards. I was using various tools from time to time during the fitting process, and whilst they are generally 'clean' my hands still get a little grubby from using them, so I kept a man-size wet-wipe handy to use when handling the liners after tools.

Comparing old and new it is apparent that the size and shape is slightly different, and the foam padding is probably only a quarter as thick on the new. The spring clips lower into holes in the back-board and slide on, and on the old were all orientated in the same direction. The holes in the new boards are slightly smaller than the clips, so the open end needs to be slotted in, then a screwdriver used to open up the end so it can be slid onto the board. I orientated them the same way as on the old boards. I made sure I had clean hands before handling the boards. I was using various tools from time to time during the fitting process, and whilst they are generally 'clean' my hands still get a little grubby from using them, so I kept a man-size wet-wipe handy to use when handling the liners after tools.

Care is needed as the board has to be slid behind the bracket on the hatch opening for the spring stay. The rear edge of the upper half then has to be twisted so that it can sit on top of the rear padded section above the hatch, as will be seen from the witness marks of the old liner, so this is part of the reason for the warping in the old boards. Using the cut-out in the liner that goes round the stay bracket as a guide I peer behind the board to find the lower two clips are nowhere near the holes. I can't move them with my fingers behind the board, so the liner has to come off again to adjust first one then the other of the lower clips, and there are three more to align!

At this point I realise the new liner is showing the effects of being fitted, removed and refitted behind the stay bracket, so wrap the bracket in masking tape to protect the liner. The upper three clips are more awkward to align - I'm either having to peer down from the edge of the hatch opening through a narrow gap, or outwards from inside the load space, to get a glimpse of the ends of the clips in relation to the holes. I'm also having to push at least one of the lower clips into its hole and unclip it again each time I tweak the upper clips as that is the only way to get a consistent position of the liner relative to the body. There is some up and down flexibility of the whole board, but you have to be aware that the top fixing screw is very near the edge, and in practice the liner has to be pushed up pretty-well as far as it will go. Eventually I get all five lined up, but a couple of the upper three are now sitting in the hole rather than being slid onto the board, and pressing them into the holes in the body is leaving the square imprint of the base of the clip in the vinyl - hopefully that will vanish in time. It's obvious the positioning of the holes in the new liners is perhaps 1/2" different in various directions compared to the old.

At this point I realise the new liner is showing the effects of being fitted, removed and refitted behind the stay bracket, so wrap the bracket in masking tape to protect the liner. The upper three clips are more awkward to align - I'm either having to peer down from the edge of the hatch opening through a narrow gap, or outwards from inside the load space, to get a glimpse of the ends of the clips in relation to the holes. I'm also having to push at least one of the lower clips into its hole and unclip it again each time I tweak the upper clips as that is the only way to get a consistent position of the liner relative to the body. There is some up and down flexibility of the whole board, but you have to be aware that the top fixing screw is very near the edge, and in practice the liner has to be pushed up pretty-well as far as it will go. Eventually I get all five lined up, but a couple of the upper three are now sitting in the hole rather than being slid onto the board, and pressing them into the holes in the body is leaving the square imprint of the base of the clip in the vinyl - hopefully that will vanish in time. It's obvious the positioning of the holes in the new liners is perhaps 1/2" different in various directions compared to the old.

There are no holes in the new liners for the top screw or the rear window latch screws, so how you get particularly the former in the right place as there is very little room for error, only a cup-washer? The latch is easier as there is a rectangular plate with two holes, which will give quite a bit of room for manoeuvre. Funnily enough pal Terry had asked me the same question when fitting his early front door liners, which are screwed to the door in the same way, and after a little thought I suggested screwing a self-tapper out from the back, then pressing the board against the sharp point will leave a mark which he could feel and use as a drilling reference. Terry did that, but a couple of them were not accessible from the back, so he took it one stage further and cut the head off, and screwed the shank in from the front, which still left the point sticking out to make the mark. Can't get a screw in from the back, so off with it's head. However it's so near the edge and mixed up with folds on the vinyl and staples that I can't see the mark, so use a blob of pant on the end of the screw instead. For the latch holes position not being critical I use the old liner as a template ... but when I get the liner clipped into position and with the top screw in, despite angling the screw in all directions I can't find the holes. Also even with the screws through the liner only and not through the latch, they are too short for me to be able to see the tip in relation to the hole in the body, to know how far to move the hole. However the screws I had removed from the shoulder rail are about 1 1/2" long, and with those through the liner I can see they are about 1/4" out! Never mind, the latch will cover a multitude of sins, and I can redrill with the liner in-situ. The next problem is that the new liner is about an inch or so away from the body panel, and has to be pressed in very firmly, with a screw through the latch and the liner, wiggling it around to find the hole. Screwing it in enough to bite is proving very difficult, so again I use one of the longer screws to find the hole and pull the liner in to the panel, then put one of the correct screws in the other hole and tighten, then I can remove the long screw and replace it with the other correct screw. Phew, that was a struggle, given the position and having to clamber in and out of the load space all the time, and took about one and a half hours. Still, it's kept me warm in what otherwise would have been a chilly garage.

The second side is much the same, except I opt to mark one of the holes for the latch with the painted screw stub same as for the top, then use the old liner and that hole as a template for drilling the second hole. With one broken and one missing clip I only have three, so opt to use them in the bottom two holes and the middle of the upper three, as the latch and the top screw prove to be plenty good enough for holding it in place. With that and familiarity that one only takes half the time. Step back to appraise my handiwork, looking in from the drivers door to examine it from that angle as well, and immediately espy the errant spring clip sitting on the wheelarch right in front of the seat belt reel, so completely hidden when looking in from the load space. Oh well, I'll keep it in a safe place.

Then when I lower the hatch to make sure the stay nuts are going to be well clear of the new liners, I suddenly realise that edge-on they are nowhere in sight! As well as being thicker, the old liners sat on the side of the flange around the opening, whereas the new ones are behind the flange. If there was any contact now it would be with the flange before the liners.

Then when I lower the hatch to make sure the stay nuts are going to be well clear of the new liners, I suddenly realise that edge-on they are nowhere in sight! As well as being thicker, the old liners sat on the side of the flange around the opening, whereas the new ones are behind the flange. If there was any contact now it would be with the flange before the liners.

One of the things that put me off replacing them for so long was whether they would look like a diamond in a goat's bottom i.e. make the rest of the trim look really shabby. But I could see from the colour samples that they weren't that bad, and whilst the new liners are cleaner and brighter it's not showing the rest up too badly.

One of the things that put me off replacing them for so long was whether they would look like a diamond in a goat's bottom i.e. make the rest of the trim look really shabby. But I could see from the colour samples that they weren't that bad, and whilst the new liners are cleaner and brighter it's not showing the rest up too badly.

February 2018:

Tom Brearley asked on the MGOC forum about a chunk of foam he found wedged up inside the C-pillar, wondering if it was supposed to be there. It is - but the picture he posted showed his C-post trim with a screw right where the gouges had been on mine. It's a 74 model, but he couldn't say whether the screw was original or not. Clausager shows a 73 and an 80 without it, and my 75 V8 doesn't have it, so it looks as if a PO has added it - either to protect the panel, or because they had removed and had trouble refitting the panel just with the clips! It certainly pushes the panel back out of the way of the pivot on the hatch stays, Vee came to me with them both ripped.

Tom Brearley asked on the MGOC forum about a chunk of foam he found wedged up inside the C-pillar, wondering if it was supposed to be there. It is - but the picture he posted showed his C-post trim with a screw right where the gouges had been on mine. It's a 74 model, but he couldn't say whether the screw was original or not. Clausager shows a 73 and an 80 without it, and my 75 V8 doesn't have it, so it looks as if a PO has added it - either to protect the panel, or because they had removed and had trouble refitting the panel just with the clips! It certainly pushes the panel back out of the way of the pivot on the hatch stays, Vee came to me with them both ripped.

GT Headlining Added October 2009

The main headlining on my V8 is not much more than compressed orange fluff about an inch thick - known as 'the biscuit' - with a layer of card between that and the visible vinyl covering. It slides about on the cant rails and is self-supporting. When stripping Vee the mechanic said to be very careful moving it around as they can crack, although whether that was because mine has a glass sunroof so the amount of headliner at the sides is very narrow, or whether that applies to all, I didn't enquire at the time.

The main headlining on my V8 is not much more than compressed orange fluff about an inch thick - known as 'the biscuit' - with a layer of card between that and the visible vinyl covering. It slides about on the cant rails and is self-supporting. When stripping Vee the mechanic said to be very careful moving it around as they can crack, although whether that was because mine has a glass sunroof so the amount of headliner at the sides is very narrow, or whether that applies to all, I didn't enquire at the time.

The Leyland Parts Catalogue shows drawings and part numbers for five parts - the main board, the front and rear header rails, and the left and right cant rails. The drawings appear to show that the front header and cant rails are of a similar size and pre-formed type to the rear header, for all eras of GT. I wasn't able to find any reference to the front and side rails from any source, new or used, via Google, and only one to the rear section.

The Leyland Parts Catalogue shows drawings and part numbers for five parts - the main board, the front and rear header rails, and the left and right cant rails. The drawings appear to show that the front header and cant rails are of a similar size and pre-formed type to the rear header, for all eras of GT. I wasn't able to find any reference to the front and side rails from any source, new or used, via Google, and only one to the rear section.

Cutting a panel from sheet is definitely feasible for the main board, recovering kits are available at the rather shocking price of £40-£60. The only other possibility seemed to be breakers and abandoned projects. In jest my pal suggested I take mine out and have a look at it, and was horrified when I said I had already decided to do just that! I then remembered the sun-roof and realised I wouldn't be able to remove the main section to use as a template, but at least I could remove the rear section and have a look around.

To do that the C-post trim panel really needs to be removed, which involves removing the screws from the rear window catch and another screw right at the top. I then discovered five spring-clips which need careful levering if they are not to rip the hardboard. The plastic covering on the trim panel had pressure bonded to that around the rear window, but peeled apart without ripping with a bit of careful pulling.

To do that the C-post trim panel really needs to be removed, which involves removing the screws from the rear window catch and another screw right at the top. I then discovered five spring-clips which need careful levering if they are not to rip the hardboard. The plastic covering on the trim panel had pressure bonded to that around the rear window, but peeled apart without ripping with a bit of careful pulling.

The rear header is a pre-formed, padded and vinyl covered panel attached with two screws through the load-space light plus four spring clips. There appear to be two holes at the ends of this rail for more clips, but only four are shown in the Parts Catalogue and the top of the C-post trim panels support them anyway.

The rear header is a pre-formed, padded and vinyl covered panel attached with two screws through the load-space light plus four spring clips. There appear to be two holes at the ends of this rail for more clips, but only four are shown in the Parts Catalogue and the top of the C-post trim panels support them anyway.

With the header rail removed it became apparent that far from my 75 V8 cant rails being rigid pre-formed they are covered with the same adhesive vinyl as the main headlining stuck to the structural members of the roof. The front header rail is the same, as the rear-view mirror screws into it with short screws, the edges of the holes being at earth potential when tested with an ohmmeter, i.e. part of the body.

With the header rail removed it became apparent that far from my 75 V8 cant rails being rigid pre-formed they are covered with the same adhesive vinyl as the main headlining stuck to the structural members of the roof. The front header rail is the same, as the rear-view mirror screws into it with short screws, the edges of the holes being at earth potential when tested with an ohmmeter, i.e. part of the body.

However Geoff's 78 cant rails are pre-formed plastic, with the frame underneath visible through the mounting hole for the swivelling sun-visors, which use a screw through the mount into a spire clip in a hole in the frame.

However Geoff's 78 cant rails are pre-formed plastic, with the frame underneath visible through the mounting hole for the swivelling sun-visors, which use a screw through the mount into a spire clip in a hole in the frame.

The front and side rails form a 'shelf' running round the roof that the main headlining sits on. A pal managed to get a set of old side and front pieces, which amazingly someone had been able to peel off the body without ripping. Comparing these to the strips in the recovering kit reveals the new pieces to be extremely thin and flimsy by comparison, even taking into account that the originals will have hardened over time and have a coating of glue on them. However I suspect the originals were heat-formed to fit round the box-sections to make attachment easier, and the ends of the front section have stepped ends (also heat-formed) for the ends of the side pieces to sit on, to make a smooth transition from the one to the other.

I'd always imagined that the main board just pushes in from the rear above this shelf, the rear panel covering the back edge. The back edge on mine is tucked into a metal recess which is part of the body structure, that may be as a result of having slid back a bit when the sun-roof was fitted, and would need prising forwards and down for removal. As far as cutting a panel to fit goes you wouldn't want to go the full width available above the shelf as I felt various protrusions i.e. reductions in width at various points. Neither would you want to cover less than half the width of the shelf, because if the panel moved over in use it could leave a visible gap, so maybe covering 2/3 or 3/4 of the shelf is the way to go. The amount of board that is 'hidden' above the shelf is surprising - 2" to 2.5" at the sides and just over 3" at the front! However the mechanic stripping Vee said when it is slid fully to one side the other edge drops off the shelf, so it can be removed and replaced through the hatch opening when tilted. But I'm pretty sure I measured the maximum available width at 43", and the visible width at 38", which means the headlining would have to be a maximum of 38" or it wouldn't fit as suggested without bowing, which he warned against.

I'd always imagined that the main board just pushes in from the rear above this shelf, the rear panel covering the back edge. The back edge on mine is tucked into a metal recess which is part of the body structure, that may be as a result of having slid back a bit when the sun-roof was fitted, and would need prising forwards and down for removal. As far as cutting a panel to fit goes you wouldn't want to go the full width available above the shelf as I felt various protrusions i.e. reductions in width at various points. Neither would you want to cover less than half the width of the shelf, because if the panel moved over in use it could leave a visible gap, so maybe covering 2/3 or 3/4 of the shelf is the way to go. The amount of board that is 'hidden' above the shelf is surprising - 2" to 2.5" at the sides and just over 3" at the front! However the mechanic stripping Vee said when it is slid fully to one side the other edge drops off the shelf, so it can be removed and replaced through the hatch opening when tilted. But I'm pretty sure I measured the maximum available width at 43", and the visible width at 38", which means the headlining would have to be a maximum of 38" or it wouldn't fit as suggested without bowing, which he warned against.

The maximum size of the tailgate opening at the top is 39", and at the bottom is 41.25". As can be seen above the maximum width available for the board is 43", so some bowing of a board this wide would be required to get it in. Even with a suggested width of 41" it would still have to fed in from quite low down or bowed along its length, and because the highest point of the tailgate opening is lower than the shelf the board would have to be bowed from front to back at the same time. The other issue relates to the upward curvature of the roof. To follow this curve either the board has to have a 'natural' curve produced by steaming or damping and then drying in a mould, or it has to be slightly wider than the maximum available so that the board can then be forced to curve upwards. But that would require a precisely cut board - too wide and it wouldn't go in even bowed up, too narrow and it will flop down again. I don't actually know whether it is a natural bow in the board or a precise width that forces it to bow up, as I say at the beginning my V8 has a glass-panel sunroof the surround of which holds mine up against the roof as well as preventing removal without interference to the sunroof which I'm not prepared to do at this point.

GT Load-space and Rear Seat Back

Luggage cover

There is a large flat area above the spare wheel and tools which gives a reasonable load space, especially with the rear seat back folded down which extends the flat area. With the additional carpet it is also neat in appearance while empty. Originally there was a two-piece hinged board, with a short section that screwed to the body, and a larger section that hinged up. Simple hinges (AHH 7527) were used here as well as on the seat back, and were screwed to the short section.

There is a large flat area above the spare wheel and tools which gives a reasonable load space, especially with the rear seat back folded down which extends the flat area. With the additional carpet it is also neat in appearance while empty. Originally there was a two-piece hinged board, with a short section that screwed to the body, and a larger section that hinged up. Simple hinges (AHH 7527) were used here as well as on the seat back, and were screwed to the short section.

Then in October 1973 the board changed to a one-piece, with more complex hinges (BHH 976, no longer available) that provided the pivot for both the seat back and the board. If needing to reproduce this type of hinge, note that although the pivot and the plates that screw to the board and the seat-back are above the board, additional sections are needed to go down past the edge of the board, then turn at right-angles underneath it to be attached to the body.

Then in October 1973 the board changed to a one-piece, with more complex hinges (BHH 976, no longer available) that provided the pivot for both the seat back and the board. If needing to reproduce this type of hinge, note that although the pivot and the plates that screw to the board and the seat-back are above the board, additional sections are needed to go down past the edge of the board, then turn at right-angles underneath it to be attached to the body.

Accessing the spare wheel and tool area:

After getting the V8 I very soon tired of supporting the spare-wheel cover on the top of my head when getting tools out of the space underneath - I blame it for my hair-loss ... With the cover raised I noticed that the toggles that fasten it down are very close to the hatch struts and realised how simple it would be to fabricate a simple hook to hold it up. In the end I just formed a piece of stiff wire into a suitable shape and Hey Presto! Click on the thumbnails for a full-sized image.