Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

Wheels and Tyres

|

June 2023: And a second tyre failure, this time on the roadster. Travelled up the M6 for a good two hours at 60 to 65 to a lunch stop on our way to The Pendle Run, then immediately after getting back on the motorways there was a significant vibration. As the previous tyre failure had only been evident at low speed I suspected this was more likely wheel balance, and as it was in the car as whole not the steering wheel it was probably the rears. The other possibility was a weeping near-side damper having lost all its oil so that wheel could be bouncing up and down. That would be difficult to diagnose, and neither easy to sort out immediately so we carried on. No sign of it on the 84 miles of the run, but as soon as we got back on the motorway it started again. Not long after that I could hear a curious rustling noise from the left rear, then very quickly it became obvious a rear tyre had deflated. Fortunately a motorway with a hard shoulder so we stop and get out ... to see hundreds of reinforcing wires sticking out of the tread! Near-side so safer than the off-side, didn't take long to put the spare on and continue, with no vibration. Got two new tyres and the fitters said they had never seen anything like it. These tyres were just under 12 years old, and whilst the recommendation is to change them at 10 years (not that I've ever changed them by age in over 30 years, only wear) they have only done 18k which is equivalent to about two years use on a daily driver when used for commuting, garaged so no subject to UV degradation, so surely this has to be gross premature failure? Nevertheless I probably will go by the ten year recommendation in future.

July 2018: If anyone needs to be convinced how valuable the advice "Listen to your car, it is talking to you" is, this may well do it. I knew the V8 tyres were near the wear bars and had already changed the front pair and a very old spare before a 300 mile trip to the Lake District in July. On the way back in the inevitable stop-start and crawling traffic on the M6 one very hot afternoon I was conscious of a strange slight but regular jiggle, which I put down to the road surface. The Navigator didn't comment, and she is usually very sensitive to unusual sounds, smells, and sensations in any of the cars. Back home on local roads it wasn't apparent, and I forgot about it. Then a couple of weeks later back on the M6 heading south on a 100 miler on another very hot afternoon, it was there again. On our arrival I knew I couldn't ignore it, started checking round and just glanced into the nearside rear arch to see a bulge on the tread. Can't leave that, so went to put the spare on, and was shocked to say the least at what I found. Not only a bulge but a large distortion in the tread, together with canvas and even steel belting showing either side of a deep split, and some of the wires cut through! How close that was to a blow-out at '70' mph on the M6, A14 and A1 I dread to think.

Barrie Robinson asked on the MG List for opinions on how to stop the theft of wire wheels. He got a number of replies both serious and humorous, I have to admit I contributed to the latter. Barrie then summarised these under various headings which made me laugh out loud and with his permission I reproduce his summary:

| The Practical | Put car in lock-up garage |

| The Humorous | Tie an aggressive dog to each wheel, or use one dog with a very long lead |

| The Economical | Get a big enough dog and something for it to chase and save petrol |

| The Comical | Use knock-offs incorrectly labelled "UNDO" |

| The Easiest | Do not anti-seize the wheels so they rust on |

| The Philosophical | Wire wheels are not an easily disposed of item - so not attractive to thieves |

| The Saddest | Current "of-age" thieves would not know how to get them off neither would they know what to use them on. |

Another smile was raised by an aside in a description of how centre-locks work by Wilson McComb attributed to a North American writer. Large diameter wire wheels were an uncommon sight in post-war America, but with a number of early MG T-series cars having been brought back by American Forces personnel after WWII, they were christened 'coffins riding on four harps'.

Stud-mounted e.g. Disc, Rostyle and V8 alloy

Centre-lock

Care needs to be taken with all original types of wheel if having them balanced at modern tyre fitters with computer balancing machines - it is crucial how the wheel is supported on the machine. Modern wheels are relatively high-precision items compared to original MGB wheels, indeed I've heard it said that Rostyle wheels were often neither round nor concentric and they rejected many! Unlike the Dunlop V8 alloys which were (centre hole excepted) very accurate and very strong - the factory apparently never managed to break one in early tests with massive over-loads.

Modern wheels are mounted on computer balancers using the centre hole and a quick-release spinner as this is much quicker to mount and demount than using studs and nuts. All MGB wheels have these centre holes as well, but on disc, Rostyle and V8 alloys the hole was intended simply to clear the hub nut and so its positioning wasn't precise. Mount one of these wheels on its centre hole and the tyre fitter is likely to advise you that it is so out of balance/out of round that is unsafe. Centre-lock wheels have to be mounted on the centre hole of course, but the adapters used are crucial, they need to be held at the same machined surfaces as they on the hub, but these are rarely available. Speaking to the MGOC they told me they had to purchase their own balancing machine and get a suitable adapter made as no-one else was able to do them properly. This Dayton Wire Wheel document on taper angles seems to be saying that their centre-lock wheels manufactured since 1990 have had a fully machined hub and as such will mount correctly on a modern tyre balancing machine using two inside cones of 70 degrees (as measured on screen) as opposed to an inner cone of 60 degrees and an outer of 20 degrees (both stated) that are needed for earlier wheels, and presumably those from other manufacturers.

Personally I reckon on-car balancing would be the answer, for all types of wheel, as was the norm in the 70s and 80s. However tyre places with those machines are now few and far between. Another possibility is the home static (anything that spins the wheel is a 'dynamic' balancer) balancer that uses an air-bubble, but I've read these are a bit hit and miss.

Incidentally 'Rostyle' is actual 'R-O style' abbreviated from 'Rubery-Owen style' after the manufacturer of the wheel.

Stud-mounted: These wheels all have stud holes and if the tyre fitter has a four-stud adapter plate for his balancing machine then ask that it be used. If not then you are better off going somewhere else that does, even to pay extra for balancing only. But I'm still not convinced that is the whole answer, see below for my V8 balance problems.

V8 Balance Problems: From being fine when I first bought the car I started getting problems as soon as I replaced the fronts. They lasted the life of one particular pair of tyres despite repeated rebalancing even with the 4-stud adapter plate (see above), so it was obviously the tyres that were at fault. But along the way I read that the wheel nuts used with the V8 cast-alloy wheels can cause a little imbalance and of a way to avoid it.

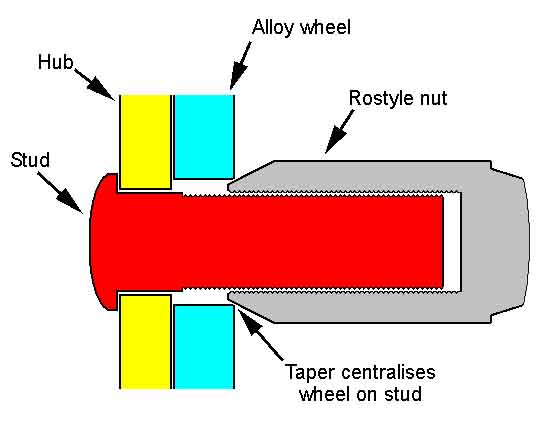

Unlike Rostyles the V8 wheels and nuts do not have the conical seat to aid location. The shank of the nut goes right through the wheel and a flat washer as a shoulder does the clamping, therefore right up until the time the nuts are fully tightened the wheel can move up and down and side to side a little way, which means that when they are fully tightened the wheel can be in one of a small range but infinite number of positions in relation to the hub. Unless the wheel is exactly concentric with the hub some imbalance is inevitable. The recommendation was to use a pair of Rostyle wheel nuts on opposite studs and lightly tighten them. The taper on these nuts, even though it is bearing against a parallel-sided hole, will always locate the wheel in the same position on the hub. The first two V8 nuts are then replaced and tightened, then the Rostyle nuts are removed and the final two V8 nuts replaced and tightened. The Rostyle nuts are a different size 'across the flats' to the V8 nuts, so I welded a strip of metal around the Rostyle nuts to build them up to the same size as the V8 nuts to avoid having to use separate wrenches or spanners for each type. I also mark one hub stud and one hole in each wheel to ensure each wheel goes onto its hub in the same position each time as well as ensuring each wheel goes back onto its own hub (I never rotate my tyres around the car, it leads to premature replacement and all four, or five, wear out together). Since doing that (and junking the dodgy tyres it has to be said) I had no more problems with wheel balance, although after replacing the front tyres again (normal wear) the wobble has come back, and again I have been unable to get rid of it.

Unlike Rostyles the V8 wheels and nuts do not have the conical seat to aid location. The shank of the nut goes right through the wheel and a flat washer as a shoulder does the clamping, therefore right up until the time the nuts are fully tightened the wheel can move up and down and side to side a little way, which means that when they are fully tightened the wheel can be in one of a small range but infinite number of positions in relation to the hub. Unless the wheel is exactly concentric with the hub some imbalance is inevitable. The recommendation was to use a pair of Rostyle wheel nuts on opposite studs and lightly tighten them. The taper on these nuts, even though it is bearing against a parallel-sided hole, will always locate the wheel in the same position on the hub. The first two V8 nuts are then replaced and tightened, then the Rostyle nuts are removed and the final two V8 nuts replaced and tightened. The Rostyle nuts are a different size 'across the flats' to the V8 nuts, so I welded a strip of metal around the Rostyle nuts to build them up to the same size as the V8 nuts to avoid having to use separate wrenches or spanners for each type. I also mark one hub stud and one hole in each wheel to ensure each wheel goes onto its hub in the same position each time as well as ensuring each wheel goes back onto its own hub (I never rotate my tyres around the car, it leads to premature replacement and all four, or five, wear out together). Since doing that (and junking the dodgy tyres it has to be said) I had no more problems with wheel balance, although after replacing the front tyres again (normal wear) the wobble has come back, and again I have been unable to get rid of it.

Update July 2009: It has been quite significant for a long time now, despite repeated rebalancing, more new tyres, and swapping fronts and backs over. It's not a steady vibration, but fades in and out at a regular rate, as if both are out of balance, one is rotating at a slightly different speed to the other, so they are alternately cancelling each other out and adding to each other. Also on a long curve on a motorway one way the rate of fading in and out speeds up, and the other way it slows down, also tending to confirm that both are out of balance. As all four wheels are doing the same it could well be that the so-called balancing machine is actually leaving them all unbalanced by the same amount when the machine says they are balanced. A couple of months ago on one trip it seemed particularly bad, which made me do another Google search, and this time I found a reference to BMTR in Birmingham having a special 'Road Force Measurement' machine, and also Vibration Free in Bicester who are balancing specialists, any rotating machinery, and do have on-car balancing facilities. At the MOT the other week the tester made a verbal observation that the rack is showing some play, which it is in the straight-ahead position, so almost certainly due to this wobble over a long time. I don't want to replace that while I still have the problem, so it really is time to do something about the vibration. £55 (plus the dreaded VAT) per hour for Vibration Free and usually a minimum of 2 hours required for four wheels, as compared to £15 per wheel at BMTR, so that was my first port of call.

I had great hopes of it as they tested the wheels with the existing weights first and both were out, one by a long way, whereas other places have just ripped the old weights off and started from there. They were also mounted on the machine much more securely. Ordinarily places will simply mount them by the centre hole against a cone, but MGB wheels were never made accurately enough for that, pre-dating those machines by several aeons. Some fitters including the one I usually go to have a gadget which holds them by the stud holes, but it consists of a hub with four arms which can be swung out to fit any stud spacing, and I've never been convinced that method is accurate enough. BMTR have a set of circular plates with holes drilled at gradually increasing distances from the centre. Pins are put into these holes that engage with the stud holes in the wheel. Instead of a cone on the back of the wheel there is a cylinder, which fits inside the hole in the wheel with some play and a shoulder that butts up to the back of the wheel. That just supports the back of the wheel same as the hub, whilst the four pins with tapered ends are clamped onto the front of the wheel in the stud holes and do the accurate positioning. This method of mounting is used on all wheels, so obviously the machine manufacturer doesn't think location by the centre hole is a good idea on any wheel! As soon as I drove out of the place I was amazed to find it felt smoother even at low speeds, but then dismissed that as probably wishful thinking. When I was finally able to get on some open road (this place is in the middle of Birmingham frustratingly) I was able to do two or three sprints of 70+ with no wobble - marvellous after all this time. Shan't be totally sure though until I can get on a longer run at those sorts of speeds.

Update May 2010: Will this saga ever end? True enough the balance remained good. But on removing the drivers front on various occasions the very large weight (the only weight) that was on the inside was obviously coming loose, and eventually at the annual service last month I found it was missing altogether, but had noticed no wobble. Thinking it was possible that it had come off on the last outing I took it for a fast run, but on that, and on subsequent longer motorway journeys, the balance was still perfect - very weird! Even weirder had the fronts replaced this week and got them to assess the balance before removing the weights or tyres, and whilst the left font had 10 grams too much on their machine the right front (lost weight remember) was a massive 160 grams out! He couldn't explain why the balance was the same with and without, and I suspect he thought I didn't know what I was talking about, but to be honest I doubt I would believe me either. Had the new tyres balanced as normal, and whilst they are nowhere near as bad as before there seems to be a very slight tremor some times, but not consistently fading in and out as it did originally. On an 80 mile motorway run the only tremor seems to be on concrete surfaces, on new tarmac it is fine. So now that raises questions about the balance machine at the tyre place I have been using for years, as I got these somewhere else.

Incidentally, I noticed that when replacing the wheels the fitter used an air-gun to do up the nuts and only used a torque wrench to check they weren't under torqued. Correct torque is 60 ft lb, and back home I used my torque wrench to loosen a couple on the rears (tightened by myself previously) and they needed about 70 ft lb to undo. One of the fronts got up to 100 ft lb before it started to move, very slowly, needing torque to keep it moving whereas they usually loosen quite quickly, another got up to 120 ft lb and then the torque wrench (bendy bar type) broke! I had to use a breaker bar on the rest, and they were very variable in how much force was required. This place (National Tyre and Autowreck) also use a different method of raising the car - you drive over a short ramp that the wheels straddle, then they place rubber blocks under the body and lift it with those, which I really didn't like. I may take wheels there for tyre replacement in future, but I would never take a car again.

Centre-lock:

Centre-lock wheels must be held by the inner and outer tapers just as they are by the hub and locking-cap or they will not be centralised, with similar comments to mounting studded wheels by the centre hole as above. Modern balance machines usually have a set of tapered adapters of different sizes that are slid onto the balancer machine shaft so as to mount wheels with different sized holes. All the ones I have seen are conical in shape with the contact surface for the wheel on its outer angled surface. These are fine for the inner face of the wheel as it is similar to the hub, but because the quick-release spinner presents a flat surface to the wheel it doesn't hold the outer face of the wheel properly. I've seen them slide another taper onto the shaft and then the quick-release spinner, but this utilises the inside surface of the hole in the wheel and not its taper with the same results as before. Unless your fitter has a taper of the correct type i.e. one with a conical hole then again don't have them balanced. When first fitting chrome wire wheels the last thing I wanted was weights attached, especially to the outside, so opted to try them unbalanced first. Maybe I was just lucky, but I have never had any balance problems.

Centre-lock wheels must be held by the inner and outer tapers just as they are by the hub and locking-cap or they will not be centralised, with similar comments to mounting studded wheels by the centre hole as above. Modern balance machines usually have a set of tapered adapters of different sizes that are slid onto the balancer machine shaft so as to mount wheels with different sized holes. All the ones I have seen are conical in shape with the contact surface for the wheel on its outer angled surface. These are fine for the inner face of the wheel as it is similar to the hub, but because the quick-release spinner presents a flat surface to the wheel it doesn't hold the outer face of the wheel properly. I've seen them slide another taper onto the shaft and then the quick-release spinner, but this utilises the inside surface of the hole in the wheel and not its taper with the same results as before. Unless your fitter has a taper of the correct type i.e. one with a conical hole then again don't have them balanced. When first fitting chrome wire wheels the last thing I wanted was weights attached, especially to the outside, so opted to try them unbalanced first. Maybe I was just lucky, but I have never had any balance problems.

Updated January 2010: Following a discussion on the MG Enthusiasts bulletin board Richard Davidson emailed to anyone who was interested details of an adapter that will mount centre-lock wheels correctly on balancing machines. I'm sure he won't mind if I make his documents available here. He is going to have some made up by a friend with the necessary CNC facilities, making further copies relatively easy to obtain. Unfortunately he lives in South Africa, so postage to places like the UK and North America is likely to be an issue! I'm making enquiries locally to me in the UK about having some made here. However, it occurs to me that maybe only the outer cone that replicates the spinner may be needed, one of the balancer standard cones being adequate for the inner taper. Come to that, maybe an old spinner could have the end machined off to slide onto the balancer shaft. Or even an old hub and spinner modified to clamp the wheel correctly and slide onto the balancer as an assembly.

Updated April 2010:

Son-in-law found me a machinist in Birmingham who quoted me £35 to make an outer cone, and £30 for an inner (collected prices), had one set made and collected them this month. I replaced two rear tyres last year and since then have felt some body vibration at typical wheel imbalance speeds of 65mph and greater. Put these on the fronts and had severe vibration. Took them and the cones to my local tyre place, and first had them assessed using how they would normally mount them (test 1), then with just my outer cone (test 2), then with my inner and outer cones (test 3). A noticeable improvement in run-out using my cones, and more balance weight required, in tests 2 and 3 over test 1. Had them weighted up using my cones, and back on the car they are as right as ninepence (which is more than it cost me to have them done (apart from a bung), which is why I'm reluctant to say who did them in case they get into trouble). Incidentally these are Cooper tyres and one needed 110grams and the other 150grams, which are large amounts. As the first tyres I put on when changing from Rostyles to wires needed no weights, I rather suspect these tyres are the problem instead of my wheels. I need new tyres for the front soon, so it will be interesting to have the wheels checked with the tyres off first, then again with the new tyres on, and I shan't be buying Coopers!

Son-in-law found me a machinist in Birmingham who quoted me £35 to make an outer cone, and £30 for an inner (collected prices), had one set made and collected them this month. I replaced two rear tyres last year and since then have felt some body vibration at typical wheel imbalance speeds of 65mph and greater. Put these on the fronts and had severe vibration. Took them and the cones to my local tyre place, and first had them assessed using how they would normally mount them (test 1), then with just my outer cone (test 2), then with my inner and outer cones (test 3). A noticeable improvement in run-out using my cones, and more balance weight required, in tests 2 and 3 over test 1. Had them weighted up using my cones, and back on the car they are as right as ninepence (which is more than it cost me to have them done (apart from a bung), which is why I'm reluctant to say who did them in case they get into trouble). Incidentally these are Cooper tyres and one needed 110grams and the other 150grams, which are large amounts. As the first tyres I put on when changing from Rostyles to wires needed no weights, I rather suspect these tyres are the problem instead of my wheels. I need new tyres for the front soon, so it will be interesting to have the wheels checked with the tyres off first, then again with the new tyres on, and I shan't be buying Coopers!

There was no difference between tests 2 and 3, which indicates that the standard cones used on the inside of the wheel is perfectly adequate on its own, hence only the outer cone is required. However offering the standard cone up to the wheel shows that it is contacting the taper right at the inner edge of the taper, i.e. right where the splines start. If there were any damage i.e. burrs in this area then it would hold the wheel incorrectly. By contrast my inner cone contacts the wheel right in the middle of the taper. This inner cone sat exactly square in the wheel, however the outer cone exhibited a slight rock on all five of my wheels. As the axis of the rock stayed with the wheel as I tried the cone in different positions it can only be a slightly warped hub. Perhaps not surprising, it is only a pressing (India Dunlops anyway), this taper is right at the edge and not in the middle as with the inner cone, with spokes close by under significant and variable tension. On the car the spinner is banged up pretty tight which probably helps to overcome this, on a balance machine it won't be as tight. Nevertheless my wheels came up with zero after balancing, and feel perfect on the car, so that is proof enough.

If you want to obtain the cones then I have left the drawings with the machinist for him to use as and when he wishes. He is:

B & M Engineering Services

6 Rowan Court

Crystal Drive

Smethwick

B66 1RB

Tel: 0121 541 1216

October 2018:After finding some play in the steering column UJ which will need replacement - again!, I decide to get the wheel balance checked first. These are Cooper tyres above which - despite originally running the chrome wires with no weights at all, and then just a few grams on subsequent tyre replacements - ended up with 110 grams on one and 150 grams on the other. Checking them first the 110 gram wheel was only about 10 grams out, but the other was 50 and the fitter showed me a wobble at the rim of about 1/4". I said to leave it and I get the wheel checked and trued. But back home I put it on the axle, and with a wire pointer against the recess in the rim (not the outer edge which might not be 'true') the run-out was no more than about +-1mm. I also backed the pads off to allow the hub to rotate completely freely, there was no tendency that I could see for the wheel to continue rotating with just very small pushes in any part of the rotation compared to any other part. So both balance and true-ness would appear to be OK. I know their machine is good as I recently had some fronts fitted by them, tracked as well as balanced, and it felt like a different car. I've always had balance problems with Vee - some quite severe and some less so, the only time it felt like this before was after having them balanced at BMTR on their 'road force' balancing machine. The only thing I can think of is that the wheel wasn't held dead square on their machine using my 'outer cone' adapter. The outer end of that is flat but I'm wondering if really it should have an over-sized centre-hole which can be supported with one of their inner cones. But it hasn't been a problem before.

Self-Tightening? Or not?

Fitting to axle

Balancing

Lubrication

Spline Wear

Grease Caps

Converting to Wires from Rostyle/Disc June 2016

Spinners/Nuts

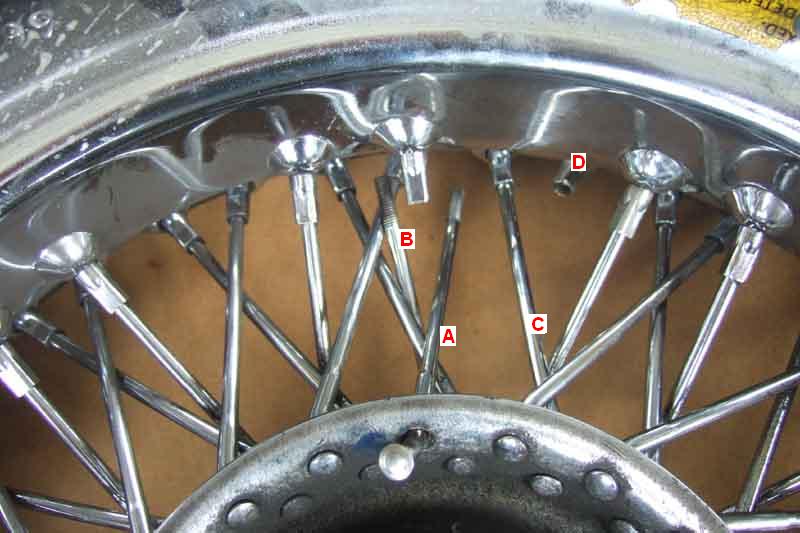

Wire wheels were retained by two-eared spinners in the UK until some time in 1968 when they were replaced by octagonal nuts, other markets changed to octagonal nuts earlier in some cases from the beginning, on safety grounds. This was because the two-eared spinners were seen as a bit like the wheels on Boudicca's chariot! However it's likely that retro-fitters (including myself) prefer the eared spinners. Both types use differently-handed threads on different sides of the car - the MGB uses a right-hand thread on the left-hand side of the car and vice versa for reasons of physics, note that other marques can use the opposite thread because spinner and wheel interface differently. Originally the threads were 12TPI but changed early in 1964 to a coarser 8TPI. For those reasons one must be very careful when fitting hubs to axles - to get them on the correct sides as well as matching threads when replacing components. Hubs may be stamped 'RH' and 'LH', maybe not, the spinners/nuts are marked in the case of MGB components with RIGHT SIDE or LEFT SIDE as appropriate and the word UNDO either side of an arrow pointing in the direction they are turned to be removed. Even clearer on spinners is the design of the ears which are tapered, one side aligned with the centre of the spinner and the other angled off to one side - to remove you apply force to the side aligned with the centre, and to tighten you apply force to the angled side. Yet another recognition method is that with a wheel raised and rotating as if travelling forwards the spinners and nuts should tighten, and that is the case on both sides of the car.

Wire wheels were retained by two-eared spinners in the UK until some time in 1968 when they were replaced by octagonal nuts, other markets changed to octagonal nuts earlier in some cases from the beginning, on safety grounds. This was because the two-eared spinners were seen as a bit like the wheels on Boudicca's chariot! However it's likely that retro-fitters (including myself) prefer the eared spinners. Both types use differently-handed threads on different sides of the car - the MGB uses a right-hand thread on the left-hand side of the car and vice versa for reasons of physics, note that other marques can use the opposite thread because spinner and wheel interface differently. Originally the threads were 12TPI but changed early in 1964 to a coarser 8TPI. For those reasons one must be very careful when fitting hubs to axles - to get them on the correct sides as well as matching threads when replacing components. Hubs may be stamped 'RH' and 'LH', maybe not, the spinners/nuts are marked in the case of MGB components with RIGHT SIDE or LEFT SIDE as appropriate and the word UNDO either side of an arrow pointing in the direction they are turned to be removed. Even clearer on spinners is the design of the ears which are tapered, one side aligned with the centre of the spinner and the other angled off to one side - to remove you apply force to the side aligned with the centre, and to tighten you apply force to the angled side. Yet another recognition method is that with a wheel raised and rotating as if travelling forwards the spinners and nuts should tighten, and that is the case on both sides of the car.

Nuts are obviously going to need a spanner for removal and tightening - an octagonal one as they have eight flats not six as for most nuts. Some are relatively small that you have to belt with a hammer, others are much bigger giving more leverage but still have an angled face if you need to use a hammer as well. Spinners are completely different of course and there are at least three types or tool: A heavy duty metal bar that engages with the ears and you use leverage, a wooden former that fits over the the whole spinner and you belt with a hammer, and just a hammer to belt the spinner ears with! Both devices for octagonal nuts are metal and I can imagine will damage the chrome over time, as will the large metal implement for eared spinners. The wooden one won't damage the spinners but having used one once on a rear wheel I was concerned about the proximity of the rear wing when I was hitting it. And if you are going to have to hit that with a hammer, you might as well use one on the spinner directly and be well away from the body. Obviously a steel hammer is going to damage them, I bought the MGOC 'lead-faced' hammer with my wire wheels but the 'lead' seemed far too hard to me - one tentative whack confirmed my fears by marking my brand-new chrome spinner. So I had to resort to using a block of wood as a buffer for several years before discovering a Thor 'super plastic' hammer in my local Halfords that has plastic one side and aluminium the other, and in 30 years of use it (the plastic end) hasn't left a single mark on the spinners. Anglo American are agents for Thor hammers, see here for North American stockists. Thor also do the correct (for older MGs) copper and leather hammer but they are more expensive.

Nuts are obviously going to need a spanner for removal and tightening - an octagonal one as they have eight flats not six as for most nuts. Some are relatively small that you have to belt with a hammer, others are much bigger giving more leverage but still have an angled face if you need to use a hammer as well. Spinners are completely different of course and there are at least three types or tool: A heavy duty metal bar that engages with the ears and you use leverage, a wooden former that fits over the the whole spinner and you belt with a hammer, and just a hammer to belt the spinner ears with! Both devices for octagonal nuts are metal and I can imagine will damage the chrome over time, as will the large metal implement for eared spinners. The wooden one won't damage the spinners but having used one once on a rear wheel I was concerned about the proximity of the rear wing when I was hitting it. And if you are going to have to hit that with a hammer, you might as well use one on the spinner directly and be well away from the body. Obviously a steel hammer is going to damage them, I bought the MGOC 'lead-faced' hammer with my wire wheels but the 'lead' seemed far too hard to me - one tentative whack confirmed my fears by marking my brand-new chrome spinner. So I had to resort to using a block of wood as a buffer for several years before discovering a Thor 'super plastic' hammer in my local Halfords that has plastic one side and aluminium the other, and in 30 years of use it (the plastic end) hasn't left a single mark on the spinners. Anglo American are agents for Thor hammers, see here for North American stockists. Thor also do the correct (for older MGs) copper and leather hammer but they are more expensive.

With poor maintenance spinners can seize onto the hubs and the advice is to drive in reverse (see 'self-tightening' immediately below) in a tight circle with the seized spinner on the outside, and for the same reason never tow a centre-lock equipped car backwards for anything more than a few yards with any wheels on the ground.

Self-tightening? Or not? The theory is that centre-lock spinners, or locking-caps, are self-tightening, although some poo-poo it. Certainly the threads are different from side to side - with left-hand threads on the right-hand side of the car and vice-versa. November 2010: This is not the same on all cars, for example the Lotus Elan has the left-hand thread on the left-hand side, because the spinner contacts the inside surface of the wheel hub and not the outside as on the MGB. However there is an error in the logic part way down the link: One contributor writes "I don't fully follow the LH & RH thread thingy because the loads reverse themselves depending upon whether the car is accelerating or braking." The forces involved are not dependant on accelerating or braking, but are simply the weight of the car and the direction it is travelling in, which is the same for both accelerating and decelerating (but not reversing hence the advice above). Definitely mine take more effort to undo than I put in to doing them up, and that is when clean and lubricated and after only a short journey so not seized. I came across a description of the self-locking action on a TR Register web-site, reprinted by permission from Safety Fast (MG Car Club), written by Wilson McComb, which he attributes to The Autocar Handbook of 1918! I reproduce the guts of what he wrote here, I hope none of the aforementioned object:

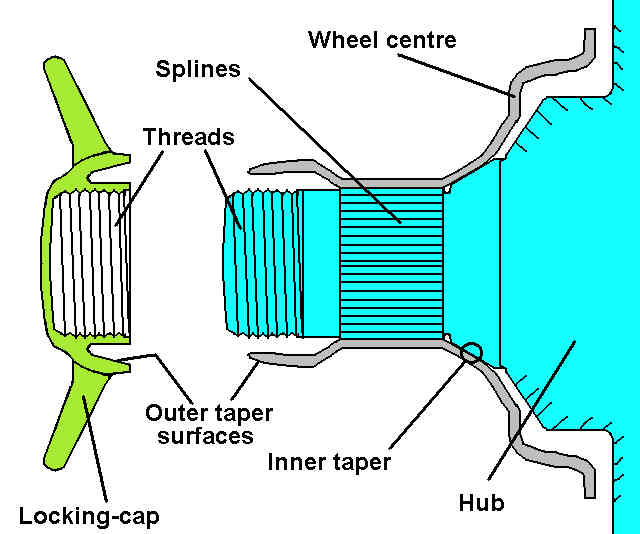

Let us take a closer look at this assembly, referring to the central portion of the wheel as the "wheel centre", which is fitted to the "hub" and fixed in place with a 'locking cap'. The first thing to be appreciated is that the wheel centre does not come into contact with the brake drum. There is, in fact, a clearance of about 1/8" when the wheel is fully home. It is the inner taper of the wheel which comes into contact with the back taper of the hub. Notice the taper which is formed on the outer surface of the wheel centre. This engages with yet another tapered surface formed on the inside of the locking cap. When the wheel is fitted to the hub, and the locking cap screwed on, it is therefore centralised and held between two pairs of tapers.

Let us take a closer look at this assembly, referring to the central portion of the wheel as the "wheel centre", which is fitted to the "hub" and fixed in place with a 'locking cap'. The first thing to be appreciated is that the wheel centre does not come into contact with the brake drum. There is, in fact, a clearance of about 1/8" when the wheel is fully home. It is the inner taper of the wheel which comes into contact with the back taper of the hub. Notice the taper which is formed on the outer surface of the wheel centre. This engages with yet another tapered surface formed on the inside of the locking cap. When the wheel is fitted to the hub, and the locking cap screwed on, it is therefore centralised and held between two pairs of tapers.

The only other contact between hub and wheel centre is provided by the splines, which carry the driving and braking forces. The locking thread, on the hub and cap, is right- handed on the left (near) side of the car and left-handed on the right (off) side. One of the endearing ('enduring'?, although 'endearing' may be rather apt) mysteries of the wire wheel is that the spokes are not, and indeed never can be, in compression. The weight of the stationary car is suspended from those spokes which are uppermost in the wheel when the wheel and locking cap are loosely fitted, therefore, the upper portion of the outer taper is pulled firmly into contact with that of the locking cap taper, and the lower portion of the locking cap thread is in contact with that of the hub.

A slight clearance then exists between the tapers at the bottom, and also between the threads at the top. As the car moves forward, a different portion of the wheel rim takes the weight, and relative movement occurs between wheel centre, locking cap and hub. The effect of this is to tighten the locking cap, and the locking action continues until there is firm contact between the tapers all round when it ceases.

The clearances involved are, of course, minute, but the locking action is nevertheless completely positive and entirely automatic. There are people who deny the very existence of the locking action, and presumably attribute the left and right hand threads to sheer cussedness on the part of the manufacturer. They are, no doubt, the people who bash their locking caps with heavy hammers.

Still don't believe it? See this on mechanical precession from Wikipedia:

Not exactly the same as a wheel, hub and spinner where all three parts normally rotate as an assembly, but it demonstrates what happens when one circle rotates inside the circumference of another without skidding - as the point of contact moves the relative rotational position of the two circles changes. As the spinner tightens the tapered contact surfaces are brought closer and closer into contact until they are clamped together tightly and are fully in contact all the way round. They are then effectively the same circumference so no further precession can take place, and the spinner does not tighten any more. The tricky bit with this animation is that on the MGB the wheel has the smaller circumference and the spinner the larger, which seems counter to the theory. But you can try it yourself with any two circles, and a rubber band and the forefingers of each hand are probably the simplest. Make a mark on the band, put your fore-fingers in and stretch it a bit, rotate one finger about the other, and the mark on the band will rotate in the opposite direction. OK, still not exact but it does show that the outer 'circle' in this case still moves in the opposite direction as the point of contact between the two travels around the two surfaces. Still not convinced? At the end of the day (in fact just after a mile or two ...) centre caps of either type on either side will be tighter than with normal manual tightening.

Not exactly the same as a wheel, hub and spinner where all three parts normally rotate as an assembly, but it demonstrates what happens when one circle rotates inside the circumference of another without skidding - as the point of contact moves the relative rotational position of the two circles changes. As the spinner tightens the tapered contact surfaces are brought closer and closer into contact until they are clamped together tightly and are fully in contact all the way round. They are then effectively the same circumference so no further precession can take place, and the spinner does not tighten any more. The tricky bit with this animation is that on the MGB the wheel has the smaller circumference and the spinner the larger, which seems counter to the theory. But you can try it yourself with any two circles, and a rubber band and the forefingers of each hand are probably the simplest. Make a mark on the band, put your fore-fingers in and stretch it a bit, rotate one finger about the other, and the mark on the band will rotate in the opposite direction. OK, still not exact but it does show that the outer 'circle' in this case still moves in the opposite direction as the point of contact between the two travels around the two surfaces. Still not convinced? At the end of the day (in fact just after a mile or two ...) centre caps of either type on either side will be tighter than with normal manual tightening.

This effect is nothing to do with a quirk of wire-wheels e.g. their flexibility, it applies equally to alloys which are very rigid. On the other hand I have read that one North American motor manufacturer used left-hand threads on one side of early stud wheels believing that the same principle applies with these too. But the forces involved in a multi-stud mounted wheel do not rotate around the centre-line of each stud and nut but move across them from one stud to the next around the wheel, and relatively small (compared to spinners) nuts on studs are tightened to around 60 ft lb. I think we have been living with right-hand threads on studs and nuts on both sides of the car now to dispose of that theory.

Note that the hub (that part that remains on the axle when the wheel is removed) nuts on the MGB at least are right-hand thread all round the car as they are retained by split-pins.

How tight? McComb in the same document says the earliest instruction he came across was never more than finger-tight. However the looser they are the more the one set of splines is likely to fret against its opposite number, causing wear, and instructions for many years have been to hammer them up then check after 20 miles and retighten if necessary. 'Hammering' means with a copper, hide, lead or similar hammer and not beating the living daylights out of it with a steel sledge-hammer. Manually overtightening could well distort the wheel centre affecting the tightness of the spokes and the 'true' of the wheel, hence causing balance problems. The recheck after 20 miles can only be a belt-and-braces check maybe against having left it finger tight or less when refitting, by then - given the self-tightening action - it will have fully tightened anyway.

Installation to axle: July 2022

Most important is to get the hubs on the correct side of the car! The wheels are retained by threaded spinners or nuts which as explained above have a different handing on opposite sides of the car for reasons of physics - the MGB uses a right-hand thread on the left-hand side of the car and vice versa, note that other marques can use the opposite thread. For that reason one must be very careful when fitting hubs to axles - to get them on the correct sides. They may be stamped 'RH' and 'LH', maybe not. The spinners/nuts are marked in the case of MGB components with RIGHT SIDE or LEFT SIDE as appropriate and the word UNDO either side of an arrow pointing in the direction they are turned to be removed, so it is suggested that you loosely fit a spinner to the hub while it is being offered up to the axle to be absolutely sure.

Most important is to get the hubs on the correct side of the car! The wheels are retained by threaded spinners or nuts which as explained above have a different handing on opposite sides of the car for reasons of physics - the MGB uses a right-hand thread on the left-hand side of the car and vice versa, note that other marques can use the opposite thread. For that reason one must be very careful when fitting hubs to axles - to get them on the correct sides. They may be stamped 'RH' and 'LH', maybe not. The spinners/nuts are marked in the case of MGB components with RIGHT SIDE or LEFT SIDE as appropriate and the word UNDO either side of an arrow pointing in the direction they are turned to be removed, so it is suggested that you loosely fit a spinner to the hub while it is being offered up to the axle to be absolutely sure.

Unlike stud wheel hubs, centre-lock hubs have the hub nut down a long tube so a means to install (and remove) the hub nut split-pin through the hub is required. Both front stub axles and tube-axle half-shafts have two split-pin holes passing through them at about 90 degrees to each other, which means the nuts only have to be tightened beyond the specified torque (70 ft lb for fronts and 150 ft lb rears) about half a castellation to get to the next hole. That means either hole through the axle may be used, but you won't know which one until you have the nut tight, by which time the hub is on the axle. The front hubs rotate on the stub axle so it's just a case of turning the hub to align its access hole to the position you want to install the split-pin, but rear hubs rotate with the half-shaft of course. They should have two access holes - again at about right-angles to one another - for split-pin insertion so you have to position the hub on the half-shaft splines so that BOTH access holes line up with those in the end of the half-shaft, then you can use either split-pin hole via the appropriate access hole once the nut has been tightened.

Lubrication: Essential to avoid the wheel, hub and locking-cap seizing together, with the aforementioned difficulties in the event of a puncture. Splines, locking cap and hub threads to aid self-tightening as well as removal and the surfaces of the tapers. When first fitting new wheels and hubs one probably puts on too much as it fills up the grooves in the splines and the threads, the excess working its way out into the wheel centre. Once on the spoke nipples it will work its way through the wheel centre and along the spokes. I've seen a recommendation to use silver grease so it doesn't show, but in my experience it is the dust and dirt that stick to the grease that you can see on the spokes, and this is always black or very dark brown, making the original colour of the grease immaterial. In 15 years and 40k miles since fitting my wire wheels I didn't have to re-grease the splines or threads, and once I'd cleaned the excess out of the centre of the hub, where the spoke holes are, I very rarely get any up the spokes. Since then (32 years and 70k miles now) I've maybe added fresh grease just once. At each service I just wipe the thinnest smear over the tapers, redistributing what wipes off the area between the taper and the splines with a finger-tip and applying it to the tapers. The tapers should keep dirt out of the splines and threads in normal use, make sure you don't introduce any when removing wheels e.g. by dropping the wheel spinner-side down onto the ground.

Spline wear: Because the splines have some clearance, and even when the centre-cap is fully tightened, it is inevitable that there is very slight rotational movement between wheel centre and hub when repeatedly accelerating (rear wheels only) and braking. Initially this is very slight but each time the one does move relative to the other the faces of the splines are brought together with a bit of an impact. This 'hammering' gradually deforms the splines, making them thinner, which increases: the gap between the faces of the splines; the distance each spline travels when it changes direction; the impact when it finally reaches its opposite number; and the rate of wear. Initially and with lubricated splines, this movement and impact is inaudible, but eventually wear increases to the point of causing an audible 'clonk' (not to be confused with a similar noise from the diff which is caused by worn thrust washers). New splines have a cross section that looks like a triangle with the top cut off. As they wear i.e. the splines get thinner the flat top narrows, until the top of the triangle is pointed again, and the triangle may lean to one side. Further wear will eventually cause the triangle to bend right over and the two sets of splines can wedge on top of one another seizing the wheel to the hub. Alternatively, i.e. under sudden heavy braking, the tops of the splines can be snapped off and then the wheels can rotate independently of the hub, which can be a bit traumatic! I'm told that new hubs have a diameter at the splines of 2.440", fairly worn (sharp point instead of flat top) may be greater than this, stripped splines will be less than this.

The following drawings have been taken from British Wire Wheel. However in my opinion the flat top to an unworn spline is much more evident than shown in their drawings:

Updated July 2010: As stated above there must be some play in the splines or you would never get the wheel on and off without a press or puller. Some spline wear is inevitable as the wheels and hubs get older, and when you start hearing clonks that is when you start keeping an eye on the shape of the splines, and definitely replace both (unfortunately) at the latest when the splines develop a sharp point, if not before. You may find the brake drum is turning slightly with the wheel with the handbrake hard on, and that can come from the shoes moving on the back-plate, which can come from a loose shoe adjuster and also make a noise. Yet another source of clonks can be if the hub is not tight on the half-shaft.

Wire Wheel Conversion: Wire wheels are a bit like Marmite - you either love them or hate them. The reason for loving is the 'classic' appearance, especially chrome wires twinkling in the sun, the reason for hating is the effort needed for a full clean to keep them twinkling. As someone who loves them (chrome) the effort of cleaning (about an hour per wheel two or three times a year, and in-situ was with a hose brush in between) is well worth the end-result. Although some people at the factory said they hated them as an anachronism, they were fitted - both painted and chrome - to some cars as standard, and were always available as an option.

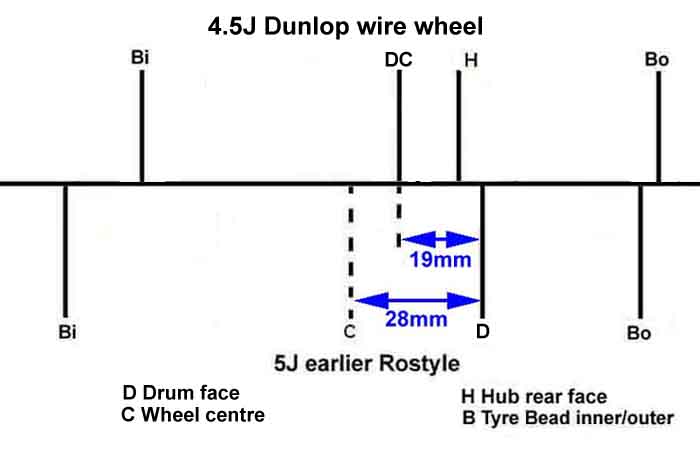

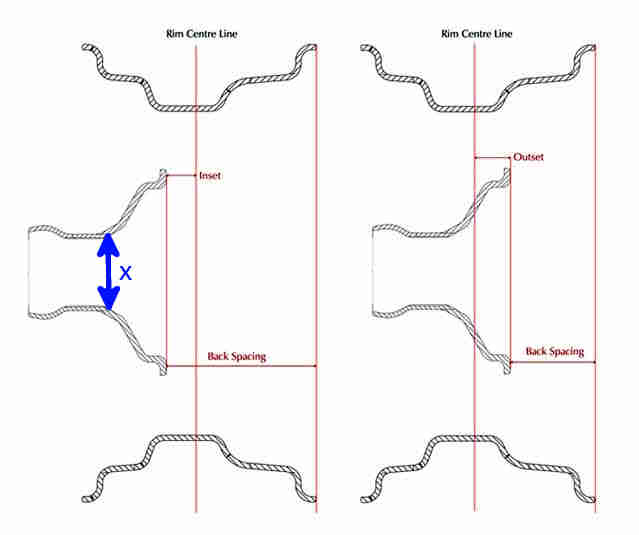

I'm specifically talking about wire wheels here even though other styles such as Minilite and other centre-lock alloys are available as after-market items. Although the process for converting to both types is basically the same, there are special considerations affecting wire wheels that don't apply to the 'solid' centre-lock wheels and this is due to the different 'offsets' on wire wheels to 'solid' wheels. The upshot is that due to their design and construction the mounting face of wire wheels is much closer to the centre of the wheel than for solid wheels, which usually have a 'positive' offset which moves the mounting face closer to the outer face of the wheel. What this means is that for a given axle, the track with wire wheels will be significantly more than with solid wheels such as disc, Rostyle or LE/Jubilee/V8 alloys. "So what", you might say, but given that on chrome bumper cars the tyres are tucked up inside the arches, and the only lateral axle location is performed by the leaf springs, on cornering the body tends to move across the axle towards the outside of the bend, and as it does so the arch lip on the inside of the bend is very likely to rub on the sidewall of the tyre. It's true that at the same time the arch on the inside of the bend tends to rise relative to the tyre, but with a standard chrome bumper ride height it's not enough to clear the tyre. For that reason MGB wire wheel axles are almost 2" shorter than stud wheel axles, giving more clearance to the arches, both banjo and Salisbury. There are special conversion hubs for standard axles that bring the wheels in a bit, but there are also two offsets of wheel - later factory wheels and aftermarket being positioned further out, and with those you can still get rubbing with the correct wire wheel axles, even more so with conversion hubs on standard axles.

This only affects chrome bumper cars - or lowered rubber bumper. On unlowered rubber bumper cars the arch is clear of the tyre to start with, and that clearance increases during cornering. Also it also only affects wire wheels, as 'solid' centre-lock after-market wheels would presumably be obtained with a suitable offset.

But conversion is quite popular, and replacing the axle is quite a large and expensive undertaking (and the job is already pretty expensive anyway). You could fit standard wire-wheel hubs to a stud wheel axle (only with the Salisbury axle, on the banjo the half-shafts and other components differ as well), but with chrome bumper cars the tyres would rub very badly. For that reason there are conversion kits available for existing axles, which consist of specially machined rear hubs - to replace the original stud wheel hubs. These allow the wheels to sit a little closer together, compared to standard wire-wheel hubs on a stud wheel axle. However it's only about 1/4" - 1/2" closer each side, and given that the axle is nearly 1" wider each side, this still leaves the wheels sticking out more than they would on a pukka wire wheel axle. And the upshot of that is that you can still get rubbing, in some cases severe. It's exacerbated by later wheels having less inset that sets them further out (wider track) than originals and they seem to be the only ones available new. The first time I went out in mine after the conversion I swung round a corner and was shocked by the graunching noise, and the marks it left on the tyre, and it was even worse when touring two-up fully laden, even though I cut the arch flange back to about half its depth. Something Had To Be Done, as I was concerned that it would fail the MOT. Subsequently I lost the oil from the axle and it started whining badly, so I took the opportunity to swap it for a pukka wire-wheel axle. But they still rub, although nowhere near as badly - only if I corner a bit hard when when touring fully laden.

But conversion is quite popular, and replacing the axle is quite a large and expensive undertaking (and the job is already pretty expensive anyway). You could fit standard wire-wheel hubs to a stud wheel axle (only with the Salisbury axle, on the banjo the half-shafts and other components differ as well), but with chrome bumper cars the tyres would rub very badly. For that reason there are conversion kits available for existing axles, which consist of specially machined rear hubs - to replace the original stud wheel hubs. These allow the wheels to sit a little closer together, compared to standard wire-wheel hubs on a stud wheel axle. However it's only about 1/4" - 1/2" closer each side, and given that the axle is nearly 1" wider each side, this still leaves the wheels sticking out more than they would on a pukka wire wheel axle. And the upshot of that is that you can still get rubbing, in some cases severe. It's exacerbated by later wheels having less inset that sets them further out (wider track) than originals and they seem to be the only ones available new. The first time I went out in mine after the conversion I swung round a corner and was shocked by the graunching noise, and the marks it left on the tyre, and it was even worse when touring two-up fully laden, even though I cut the arch flange back to about half its depth. Something Had To Be Done, as I was concerned that it would fail the MOT. Subsequently I lost the oil from the axle and it started whining badly, so I took the opportunity to swap it for a pukka wire-wheel axle. But they still rub, although nowhere near as badly - only if I corner a bit hard when when touring fully laden.

Something to note when fitting conversion (or indeed standard) hubs to a tube-type axle is the need to line up the split-pin access holes in the hub with those in the half-shafts before fitting the nut.

There is another aspect of MGB construction that makes this lack of clearance worse on one side than the other. For some reason the clearance between the tyre and the arch on the left is almost always less than that on the right, both left and right-hand drive, and the reason has never been fully explained. Some think the axle is the problem and cut off and reweld the spring mounting points, but I've done a full longitudinal, horizontal and diagonal alignment check and my rear axle is in line with the front wheels, so moving the mounting points would simply make the car crab - not good - and I've seen the same offset when a non-MG axle was used in a V8 conversion. Also on my car the left rear arch bulges out round the wheel slightly, which in theory should increase the clearance to the tyre, making the smaller clearance even more strange. You may be able to get a more even clearance by supporting the body, slackening the U-bolts, levering the axle to the right and holding it there while retightening the U-bolts. Some people have described using a baseball bat to 'roll' the flange on the left-hand arch upwards, almost completely back on itself, however this will create a dirt and moisture trap.

In an effort to control the rubbing I fitted new rear springs which made no difference, then rubber bumper roadster rear springs, which did lift the rear of the car enough for the arches to clear the tyres. But over some surfaces the ride was very choppy and unpleasant, so I decided to fit a pukka wire wheel axle, and refit the correct springs. I found one at a small parts supplier that was from a dismantled car. The CW&P was bad but I had the axle rebuilt including new bearings through Clive Wheatley in 1998, who had a stock of good 4-cylinder CW&Ps removed from axles that had been modified with V8 units as part of his V8 conversion business. This also needs a replacement handbrake cable because of the shorter axle. Another thing to bear in mind regarding the brakes is that Mk2 roadsters have smaller wheel cylinders than GTs, which have locating pins in different positions on each type, and consequently the back-plate being drilled slightly differently. This needs to be borne in mind if the replacement axle comes with back-plates and you decide to refurb them so the axle change becomes a simple swap, rather than having down-time while you refurb the originals.

The axle swap was successful ... until I fitted 175 tyres at the rear in place of 165s (when I couldn't get 165s). They now rub again, but only very slightly and occasionally, so I can live with it, but will go back to 165s in the future if possible. So in conclusion I can't recommend the conversion kits with after-market wire wheels for a CB such as mine at least, you try them at your own risk. If factory wheels (or other) have a greater inset and give the narrower track then they will probably be OK. Really I need to fit the conversion hubs to this wire-wheel axle which would bring these wheels further in and have the outer face of the tyres the same distance from the arches as originally, but I sold them on when I swapped the axle! The same considerations apply to centre-lock alloys, which can have many different offsets.

More info on wheel sizes and offsets/insets, wheel track , and axle length.

It's not an issue at the front, the lateral locating of the front wheels relative to the body is much more positive than with the leaf springs at the rear, and the arches being clear of the tyres (to cope with steering!) will never rub anyway. If you chose to go the conversion kit route the kits available these days contain simple conversion hubs which bolt onto the wheel studs (which may need shortening to clear the wheel) of the standard hub, but you will need a method of locking the hub while tightening the nuts (similar to locking the gearbox output shaft to remove/tighten the flange nut). When I did mine these weren't available, one had to obtain a pair of standard hubs. Second-hand it is wise to replace the bearings, so the end-float has to be set-up, and you will need the correct grease caps with the threaded stud. Using the conversion hubs you could get away with the original grease caps, but would need to remove the hub extensions in order to remove the grease caps for any reason. The big benefit of these front conversion hubs is that it makes life much easier if ever you need to remove the hub and reset the end-float e.g. for replacement wheel bearings, compared to working down the long tube of standard wire-wheel hubs. You would almost certainly need to swap the front hubs if replacing the axle with a pukka wire-wheel one as I can't imagine the front conversion hubs are available on their own.

With Dunlop wires at least you will need inner tubes (although some more expensive brands may claim to seal the spokes). Some people say that you need special tubed tyres to run tubes, or imperfections and knobbles on the inside of the tyre will puncture the tube, but I haven't had that in 27 years and several sets and brands of tyres. However I have found they exhibit a very slow air loss and can benefit from slight over-inflation, more info here.

But bear in mind it won't be repairable afterwards.

September 2017: Yet another puncture on the ZS, this time in a tyre barely a month old, from a massive hand-tightening clamp like something off a bike carrier or roof rack! Halfords manager said it trumped anything he'd seen before.

Spare Wheel December 2019

GT Wheel Cover

Someone on the MGOC forum wondered if he could use a 14" Rostyle in place of a 15" Minilite in the event of a puncture. On the face of it 'no' based on the MOT Manual - "Defect (b) Tyres on the same axle or on twin wheels are different sizes - Major". The DVSA Categorisation of vehicle defects Section 5 Part 2 (p185) seems to confirm that with "One tyre is of a different nominal size or aspect ratio from those on the same axle (see notes 3 and 4) - Delayed Prohibition". The 'delay' is from 3 to 10 days depending on whether it is safety-critical or not and how many defects there are, I suspect tyres would be considered 'safety-critical'. Space-saver spares were raised, and note 3 in that document says "Manufacturer supplied ‘temporary use' spares (‘Space-Savers') are acceptable" - 'Manufacturer supplied' perhaps being the critical point. Dave Birkby came up with the following from the Construction and Use Section 27 Paragraph 3 - "Paragraph (1)(a) does not prohibit the use on a road of a passenger vehicle (not being a bus) by reason only of the fact that a wheel of the vehicle is fitted with a temporary use spare tyre, unless the vehicle is driven at a speed exceeding 50 mph." which doesn't specify 'Manufacturer supplied'. So a grey area perhaps open to interpretation. One solicitors web page states "the law requires that all tyres on a motor vehicle (including the spare) have a minimum depth of tread ... " but that seems to be a one-off, it would be a bit harsh on someone carrying four slicks for track use. As the original poster's question was definitely not a 'manufacturer supplied space-saver spare wheel', it's the age-old question - what would your insurance company say about it if a claim was made?

Clamps:

Note that even though the disc wheel clamps are NLA it's distinctly possible that the wheels can be stored upside-down like the V8 wheels to give more storage space inside the wheel, and use the short V8 clamp, as can Rostyle wheels. However, despite being the shortest the V8 ones seem to be the most expensive for some reason, so any of the others could be shortened and re-threaded to suit.

The V8 clamp is short as the wheel is stored upside-down as said above (and incidentally means the hole in the cover board for wheel centres of other wheels isn't needed). The wire wheel clamp is long as the centre of the hub protrudes so has to be stored with the outer face upwards, as does the LE wheel and its clamp is even longer. The disc wheel clamp is longer than the V8 but shorter than the others, and this wheel could also be stored upside-down as the widest part is the tyre. The Rostyle clamp is long like for the wire wheel, and early versions do have the centre of the wheel protruding past the rim slightly, but only by a few mm. In fact this wheel can be stored upside-down as the boss in the boot floor fits inside the wheel centre with a clearance, the V8 clamp fits perfectly and again gives additional storage space as can be seen in the pictures. I've not been able to try the later Rostyle with the narrower offset and slightly wider track where the wheel centre does not protrude past the tyre. No problem with the wheel centre clearing the boot floor boss, the clamping face is a few mm higher off the boot floor, but given how many free threads there were with the earlier wheel I have no doubt the V8 clamp would work with this wheel also. Why no-one twigged out the outset that the disc and Rostyle wheels could be stored upside down and so use a shorter (and hence cheaper?) clamp and offer a bit more storage space, I have no idea. Much less why - when they started fitting the V8 (and Jubilee) wheels upside down - they didn't realise they could do the same with Rostyles using the V8 clamp which by reducing the number of types and increasing the quantity in theory would also reduce costs. However the short V8 clamp is as much as £30 when the longer Rostyle clamp is £15 and the even longer clamp for the LE can be had for £12, all from the same supplier, I have no idea why!

The V8 clamp is short as the wheel is stored upside-down as said above (and incidentally means the hole in the cover board for wheel centres of other wheels isn't needed). The wire wheel clamp is long as the centre of the hub protrudes so has to be stored with the outer face upwards, as does the LE wheel and its clamp is even longer. The disc wheel clamp is longer than the V8 but shorter than the others, and this wheel could also be stored upside-down as the widest part is the tyre. The Rostyle clamp is long like for the wire wheel, and early versions do have the centre of the wheel protruding past the rim slightly, but only by a few mm. In fact this wheel can be stored upside-down as the boss in the boot floor fits inside the wheel centre with a clearance, the V8 clamp fits perfectly and again gives additional storage space as can be seen in the pictures. I've not been able to try the later Rostyle with the narrower offset and slightly wider track where the wheel centre does not protrude past the tyre. No problem with the wheel centre clearing the boot floor boss, the clamping face is a few mm higher off the boot floor, but given how many free threads there were with the earlier wheel I have no doubt the V8 clamp would work with this wheel also. Why no-one twigged out the outset that the disc and Rostyle wheels could be stored upside down and so use a shorter (and hence cheaper?) clamp and offer a bit more storage space, I have no idea. Much less why - when they started fitting the V8 (and Jubilee) wheels upside down - they didn't realise they could do the same with Rostyles using the V8 clamp which by reducing the number of types and increasing the quantity in theory would also reduce costs. However the short V8 clamp is as much as £30 when the longer Rostyle clamp is £15 and the even longer clamp for the LE can be had for £12, all from the same supplier, I have no idea why!

Bee came to me without a spare clamp for when she had Rostyles, then 30 years ago I converted to wires and ran clamp-less for quite a long time, but could hear the wheel bouncing in the boot from time to time. Eventually I investigated them but as at the time of writing they are £20 from a decent supplier I decided to see what I could do from sundry bits. Found an old Ron Hopkinson rear ARB drop link with one end sheared off, and welded the threaded part of a bolt that fitted the boot floor to the end of that. After that it was just a case of making a top part with 'wings' to screw it on and off, and a plastic protector between it and the wheel, both from materiel I had lying around, and attaching them to the other end of the shaft. The wheel-cover carpet section sits on top of the clamp, and luggage sits on top of that, so I was careful to make that end of the clamp smooth so as not to wear through the carpet.

Bee came to me without a spare clamp for when she had Rostyles, then 30 years ago I converted to wires and ran clamp-less for quite a long time, but could hear the wheel bouncing in the boot from time to time. Eventually I investigated them but as at the time of writing they are £20 from a decent supplier I decided to see what I could do from sundry bits. Found an old Ron Hopkinson rear ARB drop link with one end sheared off, and welded the threaded part of a bolt that fitted the boot floor to the end of that. After that it was just a case of making a top part with 'wings' to screw it on and off, and a plastic protector between it and the wheel, both from materiel I had lying around, and attaching them to the other end of the shaft. The wheel-cover carpet section sits on top of the clamp, and luggage sits on top of that, so I was careful to make that end of the clamp smooth so as not to wear through the carpet.

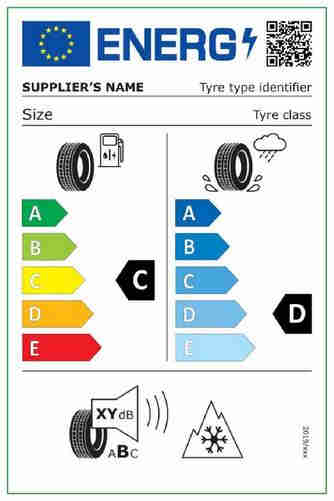

Decoding the tyre wall. For modern tyres you will typically see (on the ZS for example) '205/45 R17 88W' where 205 is the width of the tyre in millimetres, 45 is the aspect ratio or height of the tyre sidewall as a percentage of the width (in this case 45% of 205mm), 'R' is Radial construction, '17' is the diameter of the tyre's inner rim in inches, '88' is the Load Capacity (in this case 560kg), and 'W' is the Speed symbol indicating the max. speed for the tyre at full load (in this case 150mph).

Originally radial tyres for the 4-cylinder would have been marked '155SR14' for the roadster, '165SR14' for the 4-cylinder GT and '175HR14' for the V8. '155/165/175' is the width of the tyre in millimetres, 'S' and 'H' are the speed rating (113MPH and 130MPH respectively), 'R' signifies Radial construction, and '14' is the rim diameter in inches. No aspect ratio is given as most tyres were 80s, i.e. the sidewall height is 80% of the tread width. 80 profile tyres aren't commonly available these days, so it is quite normal to see 70 or 75 profile tyres used with an increased tread width to keep speedo accuracy. No load rating given either. Modern tyres, for the V8 for example, will be marked '185/70 R14 H88' i.e. 185mm tread width, 70 profile, radial construction, 14" rims, H speed rated, 88 load rated.

It's interesting to note that with the change from crossply to radial the tread width units changed from Imperial to metric, even though it was long before general metrification in the UK. This may well have been to give a clearer indication of construction than a simple code letter, as crossply and radial must never be mixed on the same axle, nor can their be radials on the front with crossplies on the rear. However the rim diameter continues to be in inches, because there are few exact, round number conversions between metric and Imperial, and the rim diameter needs to be to very close tolerances or you won't get it on, it will leak, or even worse come off the rim, and there is little point in specifying tyres for a 14" wheel as '355.6mm' just so as you can use metric units. Why do UK wheels continue to have rim diameter in inches when they could be metric? Probably because tyre manufacturers for the UK market would then have to produce tyres in both Imperial and metric, with only tiny differences between some of them.

Speed ratings:

"P" For cars with a speed capability not exceeding 150 Km/h (94 MPH)

"Q" For cars with a speed capability not exceeding 160 Km/h (100 MPH)

"R" For cars with a speed capability not exceeding 170 Km/h (106 MPH)

"S" For cars with a speed capability not exceeding 180 Km/h (113 MPH)

"T" For cars with a speed capability not exceeding 190 Km/h (119 MPH)

"U" For cars with a speed capability not exceeding 200 Km/h (125 MPH)

"H" For cars with a speed capability not exceeding 210 Km/h (130 MPH)

"V" For cars with a speed capability not exceeding 240 Km/h (150 MPH)

"W" For cars having speed capability not exceeding 270 Km/h (170 MPH)

"Y" For cars having speed capability not exceeding 300 Km/h (190 MPH)

"VR" For cars having speed capability over 210 Km/h (130 MPH)

"ZR" For cars with a speed capability over 240 Km/h (150 MPH)

"ZR+W" Tyres marked with both designations for cars with speed capability over 240 Km/h but not exceeding 270 Km/h (168 MPH)

"ZR+Y" Tyres marked with both designations for cars with speed capability over 240 Km/h but not exceeding 300 Km/h (186 MPH)

Load ratings:

| Load Index | Load in kg | Load Index | Load in kg | Load Index | Load in kg |

| 62 | 265 | 84 | 500 | 106 | 950 |

| 63 | 272 | 85 | 515 | 107 | 975 |

| 64 | 280 | 86 | 530 | 108 | 1000 |

| 65 | 290 | 87 | 545 | 109 | 1030 |

| 66 | 300 | 88 | 560 | 110 | 1060 |

| 67 | 307 | 89 | 580 | 111 | 1090 |

| 68 | 315 | 90 | 600 | 112 | 1120 |

| 69 | 325 | 91 | 615 | 113 | 1150 |

| 70 | 335 | 92 | 630 | 114 | 1180 |

| 71 | 345 | 93 | 650 | 115 | 1215 |

| 72 | 355 | 94 | 670 | 116 | 1250 |

| 73 | 365 | 95 | 690 | 117 | 1285 |

| 74 | 375 | 96 | 710 | 118 | 1320 |

| 75 | 387 | 97 | 730 | 119 | 1360 |

| 76 | 400 | 98 | 750 | 120 | 1400 |

| 77 | 412 | 99 | 775 | 121 | 1450 |

| 78 | 425 | 100 | 800 | 122 | 1500 |

| 79 | 437 | 101 | 825 | 123 | 1550 |

| 80 | 450 | 102 | 850 | 124 | 1600 |

| 81 | 462 | 103 | 875 | 125 | 1650 |

| 82 | 475 | 104 | 900 | 126 | 1700 |

| 83 | 487 | 105 | 925 |

For years I've felt I'm the only MGB owner in the world that uses the manufacturers pressures of 21psi front and 24 rear for 'normal' use. The discussion cropped up again last week when a new owner complained of a poor quality ride. As well as questions of 'What are you used to?' and vehicle condition, once again I chipped in with the manufacturers figures, had those dismissed as being for cross-ply tyres (they aren't, the pressures for cross-ply tyres are lower than that at 18 front and rear for 'normal' use) and others as usual saying they should be in the 30psi range. But it did occur to me that my old Celica, my Son's BMW, and my new ZS all do have pressures in that area for normal use, so I decided to make mine 28 front and 32 rear prior to the Daffodil Run this year. It was immediately apparent how much harsher the rise had become, and going over larger bumps the suspension was crashing whereas previously even bottoming the suspension was done quietly albeit with a bit of a jar, so mine are going back to what they were before. A couple of days later the original poser of the question writes back:

Those figures are for the roadster, for completeness 4-cylinder GT figures are 20 or 21 front (cross-ply or radial) 24 rear, V8 21 front and 25 rear. At maximum weight increase the rear pressures by 2psi, and for sustained high-speeds increase front and rear by about 6psi.

MGC: June 2022 The MGC had poor handling when using factory figures as the engine was so heavy (didn't they drive it themselves?) and were subsequently increased. Quite a bit of info online, with fora saying they should be around 30psi, with some saying the rear lower and some the same. Longstone say 34 front and 30 rear. As ever, experiment with those and see what suits best.

Rolling Radius

The original tyres for the roadster were 5.60-14 (crossply) or 155-14 (radial) as an option. The first number is the tread width - 5.60 inches in the case of the crossply, 155mm for the radial, even though 5.6" converts to 142mm! '14' is the wheel diameter at the tyre bead. When the GT was introduced its tyres were 165-14. At the time the sidewall height (which is the major factor in rolling radius) wasn't specified, but was always '80', which represents 80% of the tread width. It was the same for both 155 roadster tyres and 165 GT tyres, which means the GT has a slightly higher rolling radius, which will have a small effect on speedo reading. Wheel width was something else altogether, at 4" for roadster disc wheels, 5" for GT disc wheels, but 4.5" for wire wheels on both! It's this difference (in disc wheels) that accounts for the different tread widths. When Rostyles replaced disc wheels both models used 5". The alloy wheels used on some special models late on were also 5", but had 185 width tyres, with 70 profile instead of 80, and RV8s used a 65 profile! Confused? You have every right to be. Speedo reading isn't as much as an issue as you might think, as most markets accept speedos that fit into a band where they don't under-read, but can over-read (i.e. show you are going faster than you really are) by up to 10%. 5mm increase in the width for the same profile results in about an extra half inch (in typical MGB tyres) of radius, which equates to about 2%, so well inside the 10%. Germany was the exception and required more accurate speedos on Mk1 cars, so GTs had a different speedo to roadsters to cope with the wider tyre with the same profile and hence the larger rolling radius, with a lower turns per mile - 640 as opposed to 660mm (which is actually turns per kilometre not turns per mile). Speedo operation is governed by a number of factors including tyre rolling radius, axle ratio, speedo drive gears in the gearbox, as well as the gearing inside the speedo.

As well as width, profile and wheel size speed rating is also important. Neither the Leyland Workshop Manual nor Haynes specify a speed rating for the 4-cylinder cars, but Clausager states it was SR. However today the 'R' seems to have been dropped and the rating is just 'S' which is good for up to 112mph, comfortably over what a standard car should be able to achieve. However the MGOC seems to only be offering MGB tyres in T and H ratings, T is rated up to 118mph and H is 130mph. They also offer them in 15", which is the MGC diameter, which should definitely have H rated. Originally V8 tyres were specced as 'HR' ('H' in today's parlance) which is good for up to 130mph, which doesn't give much leeway. Of course any increase in performance that even reaches these figures, let alone exceeds it, means that the appropriate higher rating must be fitted. Beware those websites that show speed ratings with column graphs, as well as being pointless and taking up far more screen space they are confusing if not downright inaccurate as they appear to show each rating as having a lower speed than they actually have. You are better-off with a simple table from the likes of BlackCircles.com or the RAC.