Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

Heating System

|

There are frequent complaints about the effectiveness of the MGB heater, both in terms of heat output and air output. Whilst the MGB heating system won't be as effective as systems in new cars or even cars 10 years old I have found it perfectly adequate both for heat and air flow and I was using my V8 as a daily driver in all weathers for about 6 years, including one spell of about 2 months when the temperature was well below freezing in the mornings and evenings. During this period the motorway hard-shoulders were littered with modern cars where the owners were scrubbing away at the salt-encrusted windscreens because the washers had frozen up, something the MGB, particularly the V8, will never suffer from! Towards the beginning and end of the run 'season' it can be pretty cool sometimes (we've had snow on the Kimber run before now) so the heater comes into play with the top down, and it is not uncommon for the Navigator's feet to get too warm on full heat. I've taken measurement on both my cars and at an ambient of around 8-10C/46-50F I get just over 60C/140F from the screen vent on the roadster, and slightly below that on the V8, the footwells being a few degrees lower. I think the V8 being lower is partly because of decomposition of the seal that should be around the matrix, as bits of foam have blown out of the vents occasionally. After refurbing the V8 heater I get 58C at the footwell and 51C at the screen vent. I took a series of measurements on the roadster as follows:

| Ambient | 8C | Measuring the heater valve was tricky as it tended to jump about a bit with the digital thermometer being close to HT leads, it seemed to average about 80C. I turned the engine off and measured again and it was 71 over the valve outlet, higher over the valve inlet. Ambient and cabin temperatures were measured with a digital cooker thermometer, engine compartment temperatures with a digital infra-red. Note that the laser spot on these is not the point at which the temperature is measured, that is taken over a much broader area. For small parts the gun must be placed right on the object. |

| Thermostat housing | 83C | |

| Rad header by the inlet | 71C | |

| Rad by the outlet | 29C | |

| Heater valve | 71C | |

| Heater return pipe | 65C | |

| Screen vent | 63C | |

| Footwell vent | 54C |

And in a GT don't forget that opening a 1/4-light or window a smidgen really helps the screen clearing, at least. I know that the MGB can't be compared to the Volkswagen Beetle for airtight-ness but with all the windows closed it is like asking the fan to blow up a balloon.

There are several areas which should be looked at if you have poor heater performance:

- Correct operation of the thermostat

- Adjustment of the heat control valve

- Coolant flow through the heat control valve

- Coolant flow through the matrix (and the rest of the heater coolant circuit including the water pump)

- Air flow through the matrix

- Air flow bypassing the matrix

- Directional control of heated air

- Fan power supply and rotation

- The fresh air vents

- The cold air flap

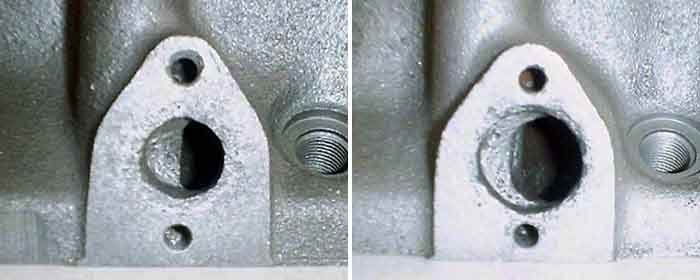

But Roger Parker has said that you can get two cars where all the above are apparently as they should be, but there is still a noticeable difference in heater performance. That still leaves the cylinder head and water pump as possible variables - the cylinder head gained a larger port for the 1972 model year, and there were six different pumps.

February 2022: Someone on the MGOC forum is complaining about poor output from the heater on a 69, and is only getting about 40C from the vents. He has an electric fan which is allowing the temp gauge to read N when running while stationary so the coolant appears to be getting plenty hot enough. With the fan off both the flow and return hoses at the heater are too hot to hold, but with the fan running the one from the valve remains hot whereas the return hose becomes cool enough to hold. That indicates to me that there is flow through the heater circuit when nothing is taking heat out of the matrix, but because the return hose drops (no temps given, mine only shows a 5C drop) there may not be enough flow to replenish what the fan is blowing out i.e. restricted flow. He has flushed the heater and gets good flow on a hose, but there are several other possible causes of a restricted flow. I suggested putting a hose on the return pipe, and another on the valve port and checking the flow through the engine circuit, but he wasn't willing. At the very least he should check the return pipe is clear. He also talked about 'overheating' in the past, which may have led to the fitting of an electric fan, so I wonder if the water pump is not doing everything it should. An interesting test would be to run the engine with a hose on the valve port going into a bucket and another feeding replacement water into the radiator, and comparing the output with engine stopped and engine running. Timing how long each took to deliver say a gallon would show what the pump was doing.

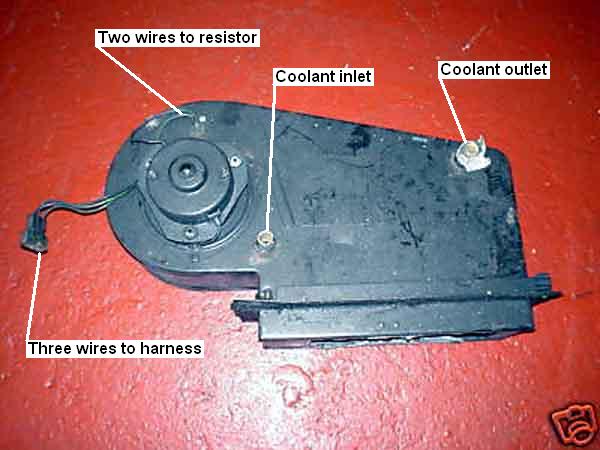

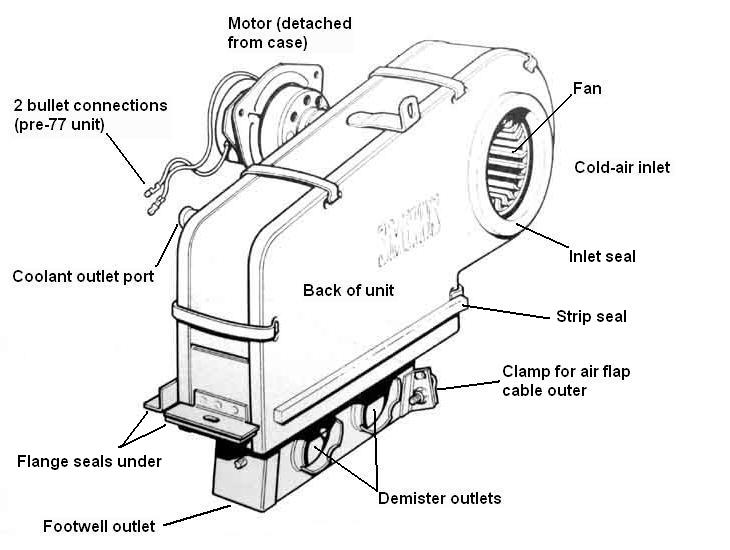

After all that you can start looking at enhancements, but first a description of the heater unit itself, see the accompanying photos and drawings.

Heater Unit:

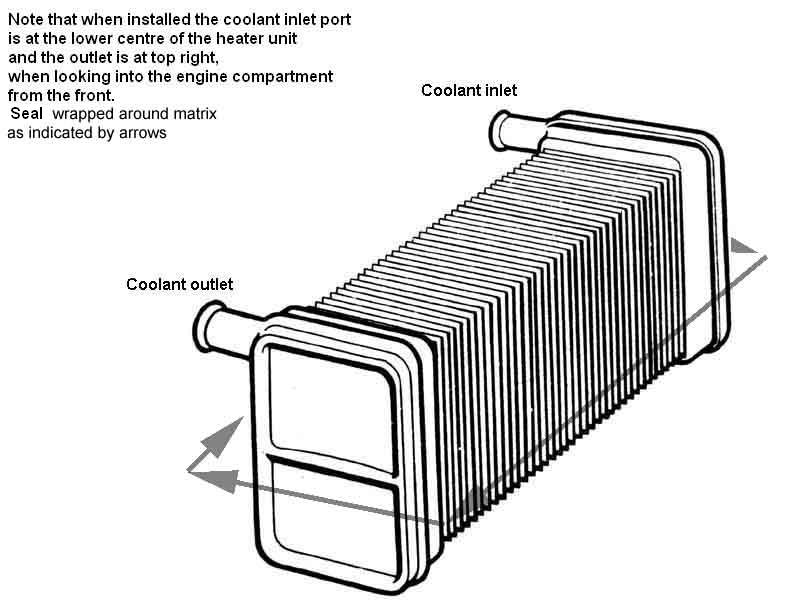

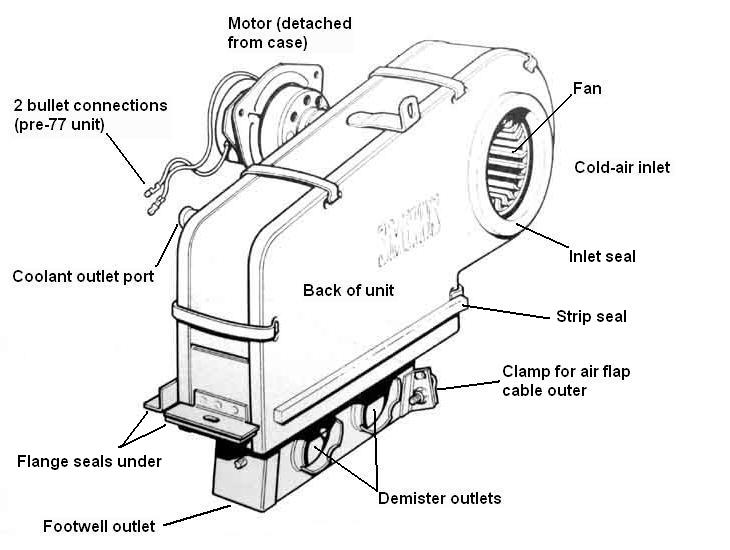

Heater_Removal, and the rubber block on later models

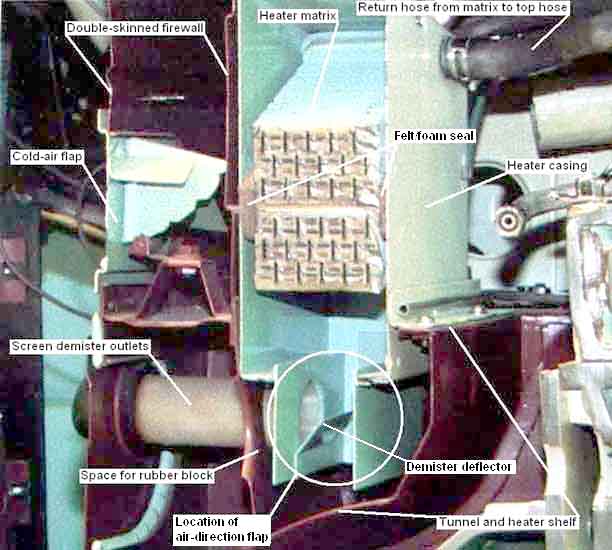

It can be quite confusing to work out just what is going on without dismantling as although the heater is clearly visible in the engine compartment all its workings are hidden away in the depths of the dashboard and the cars structure. What you can see, when looking into the engine compartment from the front, is the back of the motor on the left, a hose connected to the tap on the cylinder head low down near the middle, and another hose at top right connected via a metal pipe to a spur from the bottom hose. Logically, and for the most efficient coolant flow, the inlet would normally be higher than the outlet so natural convection (the temperature of the coolant reduces as the heater transfers heat to the air) aids pumped flow, but in fact it is the reverse i.e. heated coolant comes out of the tap on the cylinder head, into the lower port of the heater, flows upwards through the matrix, and out of the top port to the bottom hose to be circulated through the engine again by the pump. As it would have been quite possible to put the motor on the other side and angle the matrix the other way i.e. a mirror image, so convection aided pumped flow instead of opposing it, I can only assume that they already had the heater unit available in the 'parts bin', quite possibly where the original application had the heat source and return on opposite sides of the engine to the B-series, and had to use that to keep costs down.

It can be quite confusing to work out just what is going on without dismantling as although the heater is clearly visible in the engine compartment all its workings are hidden away in the depths of the dashboard and the cars structure. What you can see, when looking into the engine compartment from the front, is the back of the motor on the left, a hose connected to the tap on the cylinder head low down near the middle, and another hose at top right connected via a metal pipe to a spur from the bottom hose. Logically, and for the most efficient coolant flow, the inlet would normally be higher than the outlet so natural convection (the temperature of the coolant reduces as the heater transfers heat to the air) aids pumped flow, but in fact it is the reverse i.e. heated coolant comes out of the tap on the cylinder head, into the lower port of the heater, flows upwards through the matrix, and out of the top port to the bottom hose to be circulated through the engine again by the pump. As it would have been quite possible to put the motor on the other side and angle the matrix the other way i.e. a mirror image, so convection aided pumped flow instead of opposing it, I can only assume that they already had the heater unit available in the 'parts bin', quite possibly where the original application had the heat source and return on opposite sides of the engine to the B-series, and had to use that to keep costs down.

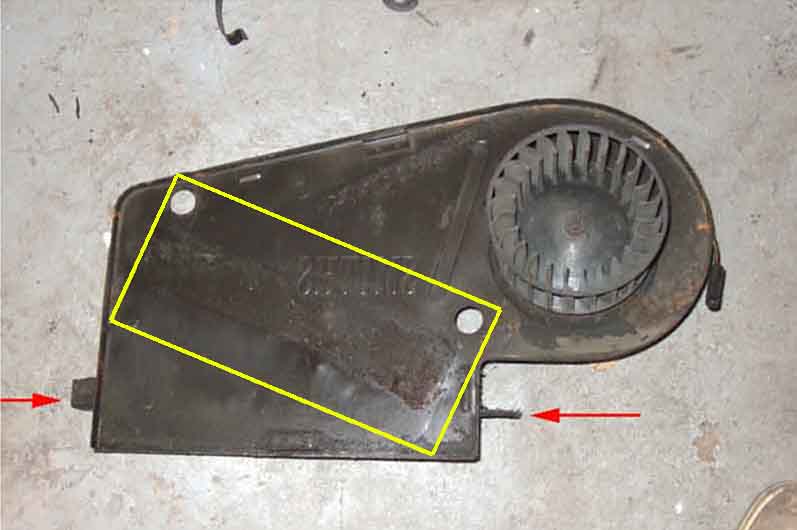

The back of the heater casing butts up against the front of the air-box at the base of the screen, there is a large circular hole connecting the two with the motor impeller sitting in the hole behind a mesh screen (except earlier cars) in the motor casing. Thus when travelling along air pressure at the base of the screen rams air into the heater unit, and when the motor is running the impeller pulls air in from the box.

The back of the heater casing butts up against the front of the air-box at the base of the screen, there is a large circular hole connecting the two with the motor impeller sitting in the hole behind a mesh screen (except earlier cars) in the motor casing. Thus when travelling along air pressure at the base of the screen rams air into the heater unit, and when the motor is running the impeller pulls air in from the box.

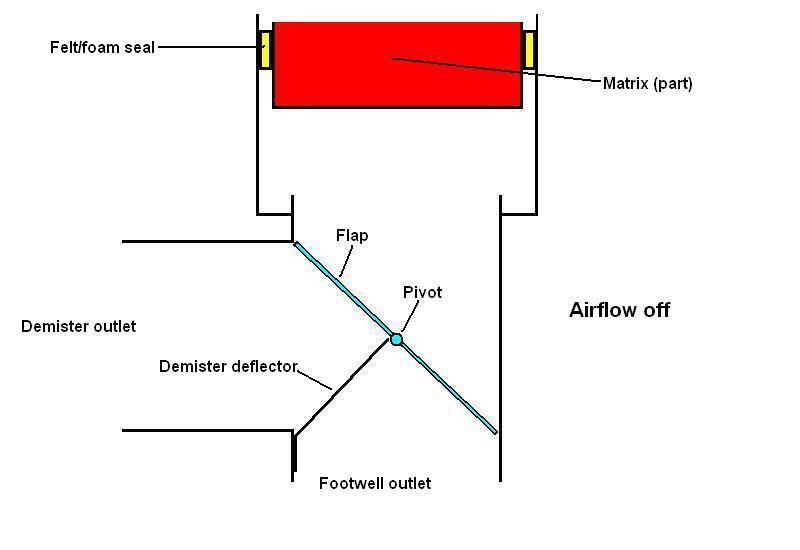

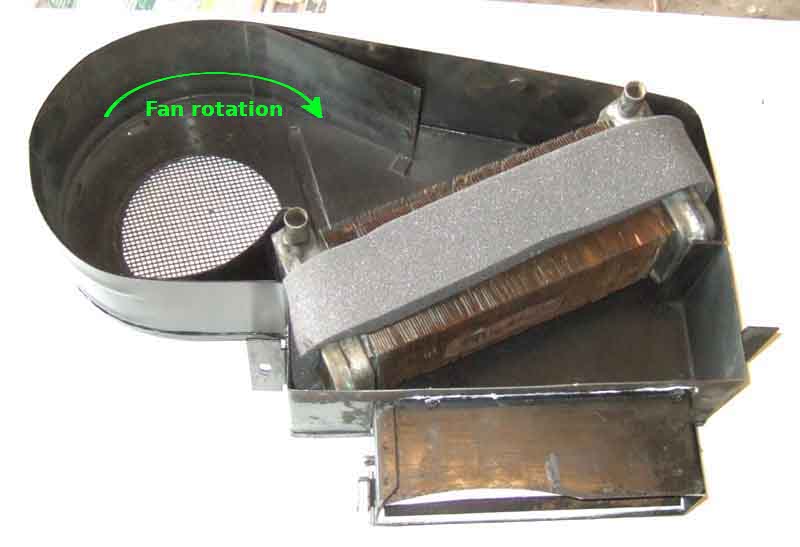

Air is blown downwards through the matrix picking up heat, towards the flap at the base of the unit that controls air distribution. A felt (ideally) or foam strip is wrapped round the ends and sides of the matrix preventing cold air bypassing the matrix, which is one of the several causes of poor heater performance (good air flow but cool), as is anything restricting the air passages in the matrix (poor air flow).

Air is blown downwards through the matrix picking up heat, towards the flap at the base of the unit that controls air distribution. A felt (ideally) or foam strip is wrapped round the ends and sides of the matrix preventing cold air bypassing the matrix, which is one of the several causes of poor heater performance (good air flow but cool), as is anything restricting the air passages in the matrix (poor air flow).

The air-distribution section at the bottom of the heater is buried in the body between two panels and not much can be done with that without removal of the heater unit from the car. Air to the footwells comes out of a large opening at the bottom of the heater unit, above the tunnel, and then travels sideways to exit into the footwells, via plain moveable flaps on early cars and fixed hoods or cowls on later cars, both mounted on the sides of the tunnel. The later fixed cowls are better at directing heat down onto the feet, with the earlier moveable flaps a lot of air will escape sideways and not be directed downwards. Although with the individual closable flaps you could close the passenger one to get more air to the drivers footwell if you wanted. Air for the demisters comes out of two holes on the lower back of the heater unit, pointing towards the back of the car, various tubes and hoses taking this up to the demister vents on the dash.

The air-distribution section at the bottom of the heater is buried in the body between two panels and not much can be done with that without removal of the heater unit from the car. Air to the footwells comes out of a large opening at the bottom of the heater unit, above the tunnel, and then travels sideways to exit into the footwells, via plain moveable flaps on early cars and fixed hoods or cowls on later cars, both mounted on the sides of the tunnel. The later fixed cowls are better at directing heat down onto the feet, with the earlier moveable flaps a lot of air will escape sideways and not be directed downwards. Although with the individual closable flaps you could close the passenger one to get more air to the drivers footwell if you wanted. Air for the demisters comes out of two holes on the lower back of the heater unit, pointing towards the back of the car, various tubes and hoses taking this up to the demister vents on the dash.

There is additional fresh-air (i.e. unheated) ventilation available from the cold-air flap on all models, and the dash vents on the 1972 and later model years.

Some thoughts on heating/ventilation control by Michael Beswick:

Having had many heater valves fail over the years I have a plumbers ball valve type which regulates the water flow pretty well, so started wondering about the air flow. First thing was to shut the flap, and it got all toasty. It started me thinking about the air flow "controls" in addition to the direction knob for "defrost or interior". Most are fairly binary, but all affect the amount of warm air you get from whatever state your heater matrix is in.

I have a couple of pieces of acetate under the grill in front of the windscreen. These can be adjusted to regulate the amount of air that actually enters the heater box. I have the two "Fresh air vents" on the dash: open and whatever goes in the grill comes out of the dash: closed the air flow heads into the heater box. Then the fresh air flap: whatever that entered the grill, was not expelled thru the dash vents can exit at your feet if the flap is open or not if it is closed. (I'm not sure the partially closed positions make all that much difference.) With the grill "half open", the dash vents and the cold air flap shut, it gets really very warm: the final "effect" can then be adjusted with the regular temperature control or by directing part of the air flow up the screen (It's a Roadster!). With the hood up in winter I have used the blower with the dash vents open and the grill closed off to recirculate the cabin air, but never tried adjusting the heating effect using the air controls. Which may just imply I'm a bit thick! I've had the car 15 years......tho it is primarily used in good weather!

The Gaydon cutaway drawings show the air "route" well - right-hand side, and left-hand side, the letter 'A' showing where the dash vents are connected on the later models.

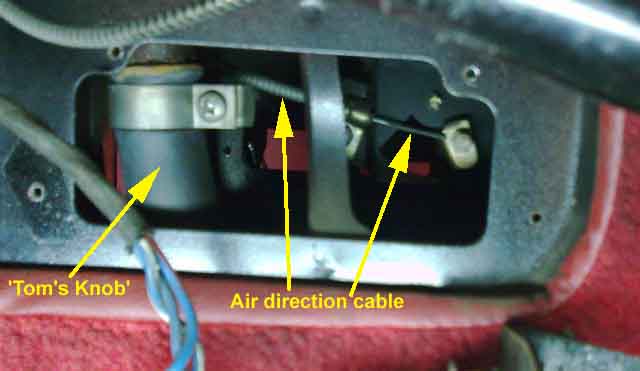

This is the box under the external vent at the bottom of the screen. There is a drain hole at the bottom of the box which has a curiously shaped length of hose connected to it known as "Tom's Knob". It is visible from under the car near the front of the gearbox tunnel at the right hand side, and is a length of about 1" bore hose with a ball-shape at the bottom and a slit below that, secured to a short pipe on the bottom of the air box by a worm clip. The purpose of the ball and slit is to allow water to drain out but stop any engine fumes from being drawn up into the airbox and from there into the cabin. However over many years debris can build up in the bottom of the airbox, particularly if the car is parked under trees, and the vent can get blocked. Usually the first you know about this is that the carpets get wet from the airbox filling up with water and reaching the level of the vents into the cabin.

Click on the thumbnail on the left for a larger image of where this drain can be found and cleared, easier on 72 and later cars. A length of 1/4" dowel (the drain hole is only about 1/2") is ideal for gently probing around the bottom until you find the hole then carefully working through the gunge in the pipe until it comes out of the bottom. That should release any trapped water which will probably be black and gungy, which is why it is always preferable to work from above and avoid getting a face-full or even an arm-full. Then slowly run clean water in from the top from a hose while you work the rod up and down to wash out the accumulated debris until the water runs clear. Some recommend cutting the ball off the end of the hose but since this is probably a once in 30 years or so operation there doesn't seem much point, and it does stop fumes getting into the cabin.

Click on the thumbnail on the left for a larger image of where this drain can be found and cleared, easier on 72 and later cars. A length of 1/4" dowel (the drain hole is only about 1/2") is ideal for gently probing around the bottom until you find the hole then carefully working through the gunge in the pipe until it comes out of the bottom. That should release any trapped water which will probably be black and gungy, which is why it is always preferable to work from above and avoid getting a face-full or even an arm-full. Then slowly run clean water in from the top from a hose while you work the rod up and down to wash out the accumulated debris until the water runs clear. Some recommend cutting the ball off the end of the hose but since this is probably a once in 30 years or so operation there doesn't seem much point, and it does stop fumes getting into the cabin.

If you do need to get at the drain hose for any reason it is fixed to the bottom of the heater box with a worm-clip, which when looking up from underneath seems impossible to get at. However on early cars with the adjustable footwell heater flaps the clip is behind the right-hand flap, and on later cars there is a blanking plug on the side of the tunnel in the right-hand footwell, immediately behind (relative to the front of the car) the heater outlet, giving access to this clip. Be aware that this area has probably never been touched since the car was first assembled, the clip may be rusted, and I have heard of at least one case where leaning on the clip to undo it caused the end of the spigot the hose attaches to, to break off. Incidentally, Pete Thompson has pointed out (January 2011) that the drain should never be left without some kind of hose being attached to it, as the spigot is inside a box section above the tunnel, and the drain hose comes through a hole in the tunnel. This can be seen from the two photos - the access hole for the clip securing the drain hose is level with the heater footwell outlet in one photo, which is clearly above the top of the tunnel in the other. Leaving the spigot without a drain hose will allow water and debris from the air-box to get into the cabin at best, or be trapped and rot out the tunnel at worst.

If you do need to get at the drain hose for any reason it is fixed to the bottom of the heater box with a worm-clip, which when looking up from underneath seems impossible to get at. However on early cars with the adjustable footwell heater flaps the clip is behind the right-hand flap, and on later cars there is a blanking plug on the side of the tunnel in the right-hand footwell, immediately behind (relative to the front of the car) the heater outlet, giving access to this clip. Be aware that this area has probably never been touched since the car was first assembled, the clip may be rusted, and I have heard of at least one case where leaning on the clip to undo it caused the end of the spigot the hose attaches to, to break off. Incidentally, Pete Thompson has pointed out (January 2011) that the drain should never be left without some kind of hose being attached to it, as the spigot is inside a box section above the tunnel, and the drain hose comes through a hole in the tunnel. This can be seen from the two photos - the access hole for the clip securing the drain hose is level with the heater footwell outlet in one photo, which is clearly above the top of the tunnel in the other. Leaving the spigot without a drain hose will allow water and debris from the air-box to get into the cabin at best, or be trapped and rot out the tunnel at worst.

July 2024: John Holland posted his method of refitting the drain hose without the surgery below:

- there's a H shaped hardboard card protecting the demist tubes as they enter the heater. That's where your hand goes.

- the TK tube slides up from the bottom and hold temporarily by virtue of friction, interference fit, or fairies. The jubilee clip can go on top (inside this blind cavity).

- the access to tighten the jubilee clip is through a 30mm diameter hole protected by a plastic push-on cap/grommet (or the larger adjustable footwell vent on pre-72 cars). Make sure that you have planned which way round to fit the jubilee clip. For information for those who don't know, a 7mm socket is the weapon of choice.

- it's well worth while lubricating the TK tube on the inside, swarfega or KY jelly. You can apply brute force as a straight push on the TK from below.

- ….. and rebuild….

November 2015: John Hall from Queensland has posted the following method of reattaching his drain hose when the top section had perished:

(1) Increased access through driver's side by "Dremelling" out the existing access hole - I chose to make it the size of the big rubber bungs in the firewall, as I had a spare.

(2) Removed the clamp from the top of the tube (my tube was sitting loose, having separated from the metal extension to which it was attached).

(3) With the improved driver's side access, used a sharp blade to divide the tube into an upper section (about 1 1/2 inches) which comes away through the top access hole; and the lower section which comes away below the car.

(4) Found a length of heater hose which exactly fits the o/d of the metal stub; fitted it to the stub with new clamp, and left it at about 1 foot long to protrude next to the bellhousing;

(5) Using a copper sleeve, joined the lower section of the original Drain Tube to the new heater hose tube, to preserve the function of the ball-and-split on the end - which I presume is to limit the passage of fumes up into the cabin.

(6) Cleaned up old crud around the hole where the tube passes down to the open air; a bit of rust-converter for good measure; and then replace trim and look forward to a water-flow test at the weekend.

I realise this is not rocket science, but I thought it might be of interest to someone looking at the same issue. Anyone who is about to refit a shiny new dash will be aware that it is folly to fit the dash without first ensuring that no water is entering via the fresh-air vent. Don't ask me how I know this. Kind regards, John.

December 2018:

However after many years of being NLA an alternative design is now available.

However after many years of being NLA an alternative design is now available.

Intake grille

AHH6102, originally secured with spire clips underneath the panel. These have to be prised off carefully to avoid damaging paint, and caught unless you want them to lie in the bottom of the box rusting away, or block the drain. These days there are plastic sockets that push in from above, which make the grille easier to remove ... for both you and a tea-leaf. However when first using these you may have to enlarge the holes slightly to get the sockets in, bear this in mind when sending the car away for painting, making sure the holes are big enough to begin with.

When I repainted Bee 30 years ago I replaced this along with all the other bright trim, but knowing the quality of replacement parts these days it was the only part I replaced on Vee in 2017 as it was showing corrosion. But not unsurprisingly it doesn't fit very well having a different curvature, and I had to reuse four of the old spire clips as the plastic sockets would not hold it down. Bee's replacement fitted just fine, and having kept both old ones they and Bee's new one have the same manufacturers mark on the back and the same curvature. I can't compare that with Vee's new one as I'm unwilling to risk damaging the paint prising the spire clips off, but I have been able to compare the curvatures with a spirit level which does show the new one is way off. There is only one type listed in the Parts Catalogue for all years and all models.

When I repainted Bee 30 years ago I replaced this along with all the other bright trim, but knowing the quality of replacement parts these days it was the only part I replaced on Vee in 2017 as it was showing corrosion. But not unsurprisingly it doesn't fit very well having a different curvature, and I had to reuse four of the old spire clips as the plastic sockets would not hold it down. Bee's replacement fitted just fine, and having kept both old ones they and Bee's new one have the same manufacturers mark on the back and the same curvature. I can't compare that with Vee's new one as I'm unwilling to risk damaging the paint prising the spire clips off, but I have been able to compare the curvatures with a spirit level which does show the new one is way off. There is only one type listed in the Parts Catalogue for all years and all models.

You can get a mesh screen that fits under the bright grille that is said to keep the drain clear, but unless you regularly park in the open near trees it's not worth it. I've only had to clear Bee's hose once in 30 years, shortly after getting her, and the PO did park outside. Also note that the smaller the mesh the more it will restrict air-flow though the heater and into the cabin. As far as fitting goes as above there were originally half-a-dozen spire clips pushed on from below, but these cannot be reused with a mesh as there is no access. This means you will have to use the plastic sockets, but given the incorrect curvature of replacement grilles how secure they will be is questionable. When fitting a mesh put it on the grill first over the pins trimming to size if necessary, then put the grill complete with mesh back on the car.

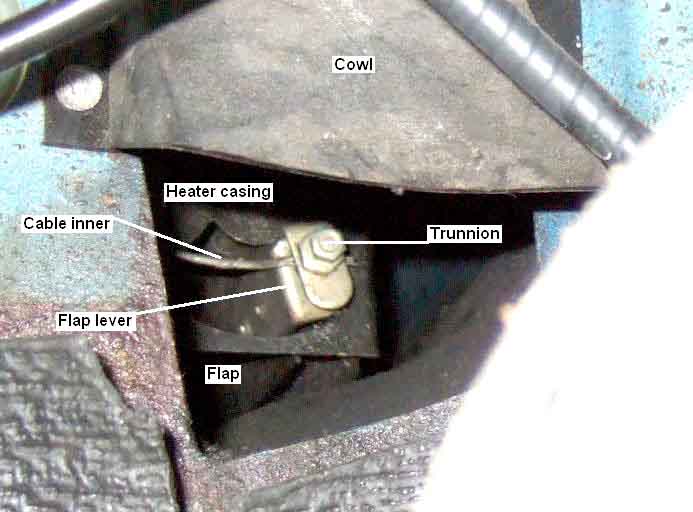

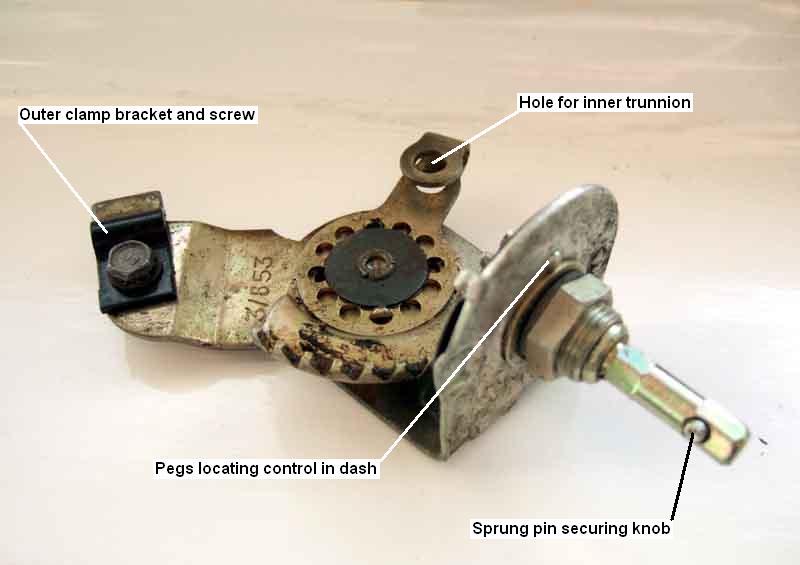

Air Direction Cable

This is controlled by one of the two knobs on the dashboard - the one that says 'Screen', 'Interior' and 'Off'. This moves a cable which controls an airflap at the bottom of the heater box inside the car to direct the air to either the screen vents, the footwell vents, or block it off altogether. Note that early cars had a door on the footwell vents and if this is closed it will block off the air no matter how the heat and direction controls are set. By removing the footwell vents and standing on your head in the footwell you should be able to see the air flap moving as the control is turned. If not maybe the cable has become detached from one end or the other. Removing and replacing the heater is reckoned to be the worst ever job on the MGB (but comprehensively described on this Chicagoland MG Club page) and refitting the direction control cable has to be done at a particular time. If yours doesn't work then maybe a PO got the heater box back in forgetting to refit the cable and couldn't face getting it out again. Another problem is that there should be felt strips glued to the flap and these can become detached blocking the airways. If the flap moves and the strips are in place but the air direction does not line up with the knob markings it could just be the relatively (!) simple job of adjusting the cable in the clamps on the dashboard control. But there were several sets of knobs and controls over the years if yours works backwards a PO may have fitted the wrong one.

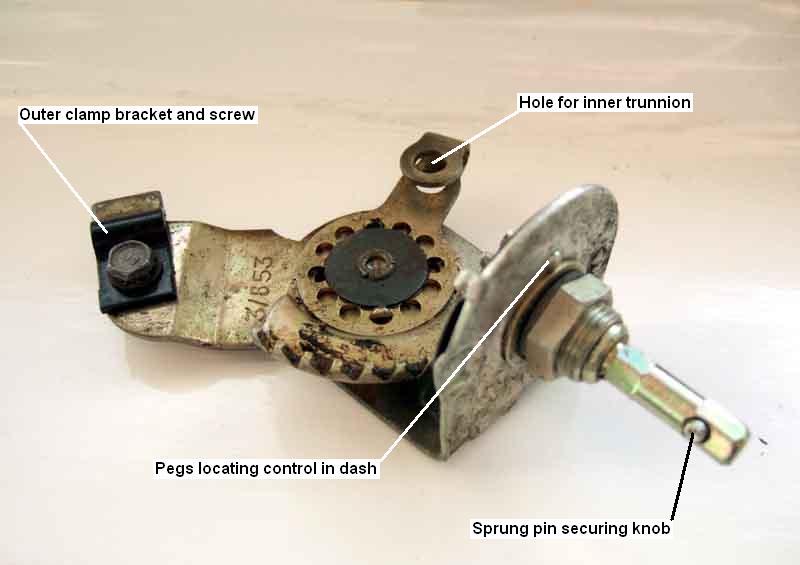

As well as different mechanisms for air and heat there are also different ones for RHD and LHD dash-mounted, 4-cylinder and V8, and for various export markets - no less than 11 different types, plus 10 different knobs, and whilst later models had common knobs there were 4 different dials that went behind them! The controls have two locating pegs that fit into holes on the dash, each control can fit in one of two positions 180 degrees apart, so check that the legends on the control knobs align correctly with the datum pip in the dash above each knob also. Convention seems to be that the heat control goes above (dash-mounted) or to the left (console-mounted) of the direction control, on UK dashes at least. This is probably quite important as you will see the flats and location holes in the dash are different between the two. When the controls were moved to the centre console they became the same for both RHD and LHD for obvious reasons, before that when on the dash - firstly on the right for the LHD tin dash, then either side of the column on the padded dash, they had to be different as the cables went off in different directions.

The direction flap is situated in the large opening at the bottom of the heater unit, running across the car, pivoting horizontally. The ends of this can just about be seen and felt through the footwell vents. In the Off position the top half is tilted towards the back of the car so it covers the angled plates that direct air into the demister ports, so blocking those off, and the bottom half is tilted towards the front of the car, so blocking the footwell vents off as well. In the middle Interior position the flap is straight up and down. Both the interior and demister outlets are uncovered, but as there is more resistance to flow up to the screen the bulk of the air comes out of the footwell vents, although some comes out of the demister vents as well. On Demist the flap is tilted so that it completely blocks off the footwell exit, so all air is directed through the demister ports.

The direction flap is situated in the large opening at the bottom of the heater unit, running across the car, pivoting horizontally. The ends of this can just about be seen and felt through the footwell vents. In the Off position the top half is tilted towards the back of the car so it covers the angled plates that direct air into the demister ports, so blocking those off, and the bottom half is tilted towards the front of the car, so blocking the footwell vents off as well. In the middle Interior position the flap is straight up and down. Both the interior and demister outlets are uncovered, but as there is more resistance to flow up to the screen the bulk of the air comes out of the footwell vents, although some comes out of the demister vents as well. On Demist the flap is tilted so that it completely blocks off the footwell exit, so all air is directed through the demister ports.

Whilst airflow to the footwells comes direct from the heater box, that to the screen vents goes via flexible tubes coming off the back (i.e. the cabin side) of the air box high up behind the centre of the dash and going to the slotted vents under the screen. If footwell air is OK but little or nothing is getting to the screen, particularly one side only,

check these tubes are in place and not split. Note that in November 1970 the screen vents were changed to include baffles that improved the distribution of air across the screen and hence demisting.

Whilst airflow to the footwells comes direct from the heater box, that to the screen vents goes via flexible tubes coming off the back (i.e. the cabin side) of the air box high up behind the centre of the dash and going to the slotted vents under the screen. If footwell air is OK but little or nothing is getting to the screen, particularly one side only,

check these tubes are in place and not split. Note that in November 1970 the screen vents were changed to include baffles that improved the distribution of air across the screen and hence demisting.

Effectiveness of both the Off and Demist positions is aided by felt strips glued to the edges of the flap to give a good obstruction to airflow without rattling. These felt strips can come unglued which not only prevents complete closure from a missing strip, but the dislodged strip can block normal movement of the flap, and block airflow to both demister ports and footwell.

Effectiveness of both the Off and Demist positions is aided by felt strips glued to the edges of the flap to give a good obstruction to airflow without rattling. These felt strips can come unglued which not only prevents complete closure from a missing strip, but the dislodged strip can block normal movement of the flap, and block airflow to both demister ports and footwell.

With the heater out you can detach the air-direction channel from the main case which makes it easier to clean and replace the felt.

With the heater out you can detach the air-direction channel from the main case which makes it easier to clean and replace the felt.

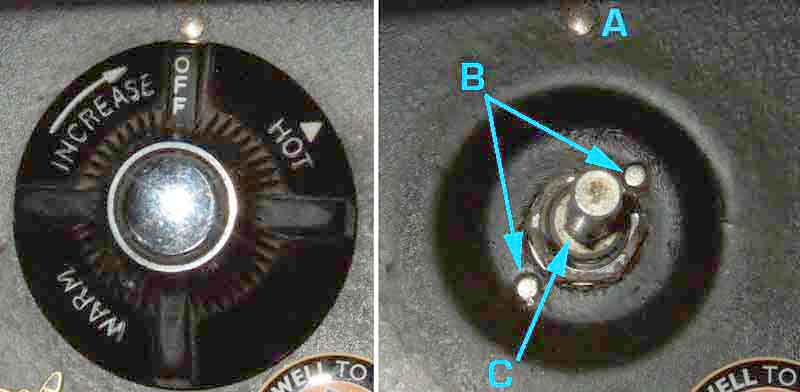

Getting at the control can be a fiddle. First you have to remove the knob. Somewhere on the shaft of the knob you should see a hole or depression that looks like it might contain a grub-screw. It doesn't, it is a spring-loaded pin on the control shaft. Depressing it while pulling on the knob should get it off but some knobs have been known to seize on the control shaft. With the knob off remove the nut and withdraw (that all encompassing term) the control from the rear of the dashboard or console. The UK dash-mounted ones are much easier to remove than the console mounted in my experience, can't speak for the American padded dash.

Getting at the control can be a fiddle. First you have to remove the knob. Somewhere on the shaft of the knob you should see a hole or depression that looks like it might contain a grub-screw. It doesn't, it is a spring-loaded pin on the control shaft. Depressing it while pulling on the knob should get it off but some knobs have been known to seize on the control shaft. With the knob off remove the nut and withdraw (that all encompassing term) the control from the rear of the dashboard or console. The UK dash-mounted ones are much easier to remove than the console mounted in my experience, can't speak for the American padded dash.

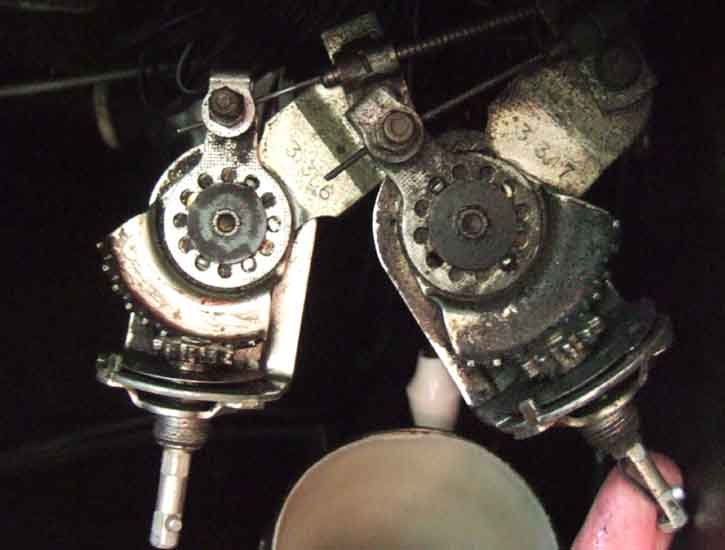

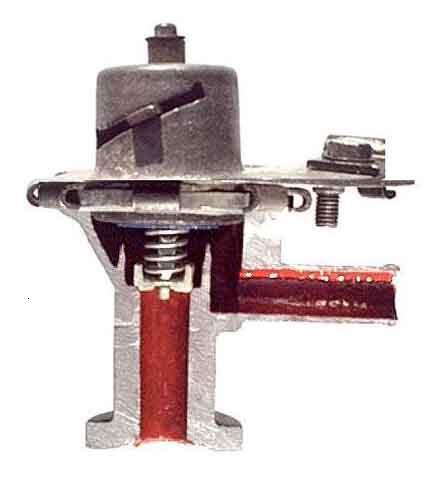

With the control in your hand you should see the outer of the cable is clamped to a fixed arm by a curved bracket secured with a screw, and the inner attaches to the moving part with a 'trunnion' that fits in a hole on the end of the lever. This 'trunnion' is also used at the other end of both cables i.e. at the air flap and the heat valve. I have seen two types of cable - a spiral-wound outer (both like this on my 73 roadster), and a later type with plastic outer sheath with embedded longitudinal wires (on the heat control of my V8, the earlier type on the air control). Both types for the heat control use a solid wire inner, but the spiral outer type for the air control both use stranded cable. This is rather odd as both work on a push/pull principle i.e. it has to be pushed one way and pulled the other, it is not like the accelerator cable which the pedal pulls but returns under the action of springs on the carb. I believe the later type of outer came about because with the earlier spiral-wound outer if the other end is stiff then pushing on the wire just causes the spirals to open up like a spring instead of moving the valve or air flap, which was what was happening with the water valve on the roadster when fully shut. The later sheath does not do this and so you can get greater force on the inner when pushing. But although My V8 has this later sheath and was not expanding when the control was pushing on the wire, the valve was so stiff that when it pulled on the wire it was pulling the sheath through the clamp, which required some ingenuity to fix (see below).

With the control in your hand you should see the outer of the cable is clamped to a fixed arm by a curved bracket secured with a screw, and the inner attaches to the moving part with a 'trunnion' that fits in a hole on the end of the lever. This 'trunnion' is also used at the other end of both cables i.e. at the air flap and the heat valve. I have seen two types of cable - a spiral-wound outer (both like this on my 73 roadster), and a later type with plastic outer sheath with embedded longitudinal wires (on the heat control of my V8, the earlier type on the air control). Both types for the heat control use a solid wire inner, but the spiral outer type for the air control both use stranded cable. This is rather odd as both work on a push/pull principle i.e. it has to be pushed one way and pulled the other, it is not like the accelerator cable which the pedal pulls but returns under the action of springs on the carb. I believe the later type of outer came about because with the earlier spiral-wound outer if the other end is stiff then pushing on the wire just causes the spirals to open up like a spring instead of moving the valve or air flap, which was what was happening with the water valve on the roadster when fully shut. The later sheath does not do this and so you can get greater force on the inner when pushing. But although My V8 has this later sheath and was not expanding when the control was pushing on the wire, the valve was so stiff that when it pulled on the wire it was pulling the sheath through the clamp, which required some ingenuity to fix (see below).

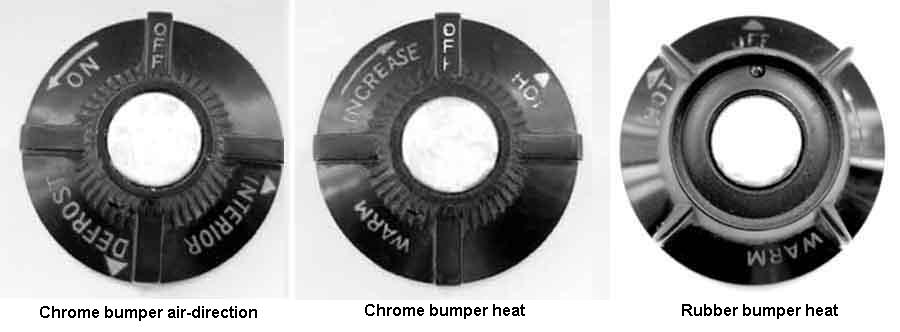

Note that there are different control mechanisms installed to the dash for heat and air direction, so if you remove both remember to label them or check the 'logic' of them before going to the bother of reconnecting the cables and installing them. Chrome bumper cars have both controls of the same design i.e. sheath and inner clamps in the same basic positions, albeit at slightly different angles to the spindle. Unfortunately this give rise to the illogical heat control where you have to turn it clockwise for heat, whereas you turn the air control anti-clockwise for air, which is the more logical direction (think of most sink/basin taps). This is because the heat valve works the other way round to the air flap i.e. it has to be pushed for heat, whereas the air flap has to be pulled for air. On rubber bumper cars the heat control has the positions of the sheath and inner clamps reversed, as well as them being at different angles to the spindle, and this gives it the more logical 'anti-clockwise for heat' action.

Note that there are different control mechanisms installed to the dash for heat and air direction, so if you remove both remember to label them or check the 'logic' of them before going to the bother of reconnecting the cables and installing them. Chrome bumper cars have both controls of the same design i.e. sheath and inner clamps in the same basic positions, albeit at slightly different angles to the spindle. Unfortunately this give rise to the illogical heat control where you have to turn it clockwise for heat, whereas you turn the air control anti-clockwise for air, which is the more logical direction (think of most sink/basin taps). This is because the heat valve works the other way round to the air flap i.e. it has to be pushed for heat, whereas the air flap has to be pulled for air. On rubber bumper cars the heat control has the positions of the sheath and inner clamps reversed, as well as them being at different angles to the spindle, and this gives it the more logical 'anti-clockwise for heat' action.

The cable that controls the flap attaches to the right-hand end of the flap, and uses the same kind of trunnion for the inner and curved clamp on the outer as for the heater tap and dash controls, see below. Before the

The cable that controls the flap attaches to the right-hand end of the flap, and uses the same kind of trunnion for the inner and curved clamp on the outer as for the heater tap and dash controls, see below. Before the Originally the cable had a stranded inner in a wound steel outer AHC185 (NLA, said to have been replaced by AHC752 heat control on the MGC), replaced by BHA4337, which only seems to be available from one supplier in America, with a 'steel casing', described as being 37" long which is the length of the heat control cable. In August 71 the air direction cable changed to BHH1229 (again only shown as available from one supplier in America), and in November 72 to BHH1230 (multiple suppliers) to be the same as the new V8, both these having a plastic-covered nylon sheath with four longitudinal reinforcing wires and are 24" long. However Vee built in May 75 has a steel outer with stranded inner cable. A solid inner for air direction would seem to make more sense, but as some of them have to be fitted to the heater unit before it is fitted to the car, and has to be wedged into the bulkhead slot, it's possible a solid inner may kink making it stiff. In any event the flap should move very freely so stranded is not a problem. BHH678 and BHH679 are mentioned by some suppliers, are steel, probably have a solid core, but are intended for the water valve as they are much longer at 117cm/43" and 97cm/38" respectively. Note that some sources interchange the steel and plastic types in images, the lengths may vary, and the inners are not specified.

There should be a lever in the left-hand footwell by the right knee of any occupant for both RHD and LHD cars. It opens a large flap behind the console which opens the bottom of the airbox and lets cold air in directly from the air box. It is only effective when the car is moving, not when the fan is on, and even if the heater is going full-blast makes the cabin jolly cold if it is either open or the seal is defective! The lever is said to click the flap into three positions, one of them being closed, but both my 73 roadster and 75 V8 have an extra 'notch' on the lever quadrant giving a third, even wider open position, albeit needing a bigger tug and a longer movement of the lever to get to it. If this flap is open or leaking it will easily defeat the attempts of the heater to warm the cabin on a cold day. There should be a gasket round the edge of the flap to seal to the aperture, this makes the flap close with a 'thunk' rather than a 'clang'.

There should be a lever in the left-hand footwell by the right knee of any occupant for both RHD and LHD cars. It opens a large flap behind the console which opens the bottom of the airbox and lets cold air in directly from the air box. It is only effective when the car is moving, not when the fan is on, and even if the heater is going full-blast makes the cabin jolly cold if it is either open or the seal is defective! The lever is said to click the flap into three positions, one of them being closed, but both my 73 roadster and 75 V8 have an extra 'notch' on the lever quadrant giving a third, even wider open position, albeit needing a bigger tug and a longer movement of the lever to get to it. If this flap is open or leaking it will easily defeat the attempts of the heater to warm the cabin on a cold day. There should be a gasket round the edge of the flap to seal to the aperture, this makes the flap close with a 'thunk' rather than a 'clang'.

Note that if the air intake in front of the screen is blocked off then opening the fresh-air flap will convert the heating system from a fresh-air one into a recirculating one (Stephen Strange), and opening the later dash vents will do the same. In theory this will allow the cabin to get progressively warmer as the air recirculates through the matrix, but air-flow will be totally dependant on the electric fan and not the forward motion, and it is the latter that is far more powerful at pushing air through the matrix, offset by fresh air having to find its way out of the cabin before more heated air can come in. But the MGB was never 'air-tight', unlike the VW Beetle which reputedly will float.

Updated December 2008:

Just spotted this on page 62 of Clausager, which clearly shows the control quadrant having four notches. The flap is closed so the spring catch is in the first notch, there are three more notches giving three open positions. It also seems to show the 2nd open position having a bigger notch than the others, which means it would take more of a pull on the handle to move it from that one to the final one, which is exactly how mine is.

Just spotted this on page 62 of Clausager, which clearly shows the control quadrant having four notches. The flap is closed so the spring catch is in the first notch, there are three more notches giving three open positions. It also seems to show the 2nd open position having a bigger notch than the others, which means it would take more of a pull on the handle to move it from that one to the final one, which is exactly how mine is.

Updated December 2009:

Herb Adler has sent me this photo of a mod he has made to the detent to make it easier to move the flap. It consists of a coil spring on the bolt, which is easier to compress and allows the whole detent to move downwards, rather than having to spring the actual detent itself between notches. I suspect the spring that carries the roller is slotted so that it can be adjusted such that as the roller drops into the 'closed' notch it can pull the flap against the aperture to give a good seal.

Herb Adler has sent me this photo of a mod he has made to the detent to make it easier to move the flap. It consists of a coil spring on the bolt, which is easier to compress and allows the whole detent to move downwards, rather than having to spring the actual detent itself between notches. I suspect the spring that carries the roller is slotted so that it can be adjusted such that as the roller drops into the 'closed' notch it can pull the flap against the aperture to give a good seal.

February 2013:

There are vanes on the back of the cold air flap to direct air into the footwells.

There are vanes on the back of the cold air flap to direct air into the footwells.

May 2023:

Nigel Mumford wrote to me seeking help with his cold-air flap. He had someone work on his screen washers and he thinks they pulled on the cold-air flap handle to open the bonnet ... and broke it somehow! However after several emails back and fore he couldn't get any pictures of the position of the handle, so I'm not entirely sure that was the problem anyway. I did wonder whether they had managed to pull the handle past the third notch on the flap quadrant, which would prevent the flap from being close unless somehow you could press the roller detent down to allow the edge of the quadrant to pass over it. I sent Nigel the pictures in the link to see if that helped, however he subsequently wrote to say all it needed was a good push back. As written above my flaps need a noticeably harder tug on the levers to get them from the 2nd open position to the 3rd, which is why some have declared that the flap only has two open positions, and it also needs a harder push to close if from the 3rd open position to the 2nd.

Nigel Mumford wrote to me seeking help with his cold-air flap. He had someone work on his screen washers and he thinks they pulled on the cold-air flap handle to open the bonnet ... and broke it somehow! However after several emails back and fore he couldn't get any pictures of the position of the handle, so I'm not entirely sure that was the problem anyway. I did wonder whether they had managed to pull the handle past the third notch on the flap quadrant, which would prevent the flap from being close unless somehow you could press the roller detent down to allow the edge of the quadrant to pass over it. I sent Nigel the pictures in the link to see if that helped, however he subsequently wrote to say all it needed was a good push back. As written above my flaps need a noticeably harder tug on the levers to get them from the 2nd open position to the 3rd, which is why some have declared that the flap only has two open positions, and it also needs a harder push to close if from the 3rd open position to the 2nd.

Coolant Return Pipe Added July 2009.

This pipe (AHH9498) for Mk2 cars comes with mounting brackets attached for the rocker cover studs and connects to the bottom hose that includes the heater return tee (GRH498). The earlier plain pipe (AHH5435) for Mk1 cars has no mounting brackets and connects to elbow ACH5031 via hose GRH105 and connection AMK8847, which is fitted between two straight hoses GRH305 (same as the top hose) and FMK8859. Clausager shows this pipe as sitting low down beside the rocker cover rather than on top as for the later pipe, with no visible mounting clips. But some suppliers show the same mounting clips as for the HS carb fuel hose supports being used with this pipe, which would put it on top of the rocker cover. That being the case the hose between the pipe and the elbow connection would need to be longer, but at least it would be supported. Without clips only the hoses position the pipe unless it has some attachment to blanking plugs on the inlet manifold. And in that position it would probably have to be disconnected to get the rocker cover off, with the later mounting position the pipe can be lifted off the rocker cover studs while still attached to heater and bottom hose.

The heater controls have been described as 'wonderfully illogical' in the past, and this is because with the chrome bumper controls you have to turn the air direction control anti-clockwise to turn it on which is fine, but the heat control has to be turned clockwise. Not only is that illogical from a tap point of view, which normally has to be turned anti-clockwise to turn it on, but doubly so as it is also the reverse to the air direction control. However this only seems to have been for 4-cylinder cars that used BHA4326, according to the Parts Catalogue CB V8s used BHA4334 with the more logical arrangement. Rubber bumper cars had knobs of a different style, and on these the heat control direction has been reversed to make it the same as the air direction control i.e. anti-clockwise to turn then both on. Up to the 77 model year they used BHH1687, and from the 77 year on the knobs changed again to a coloured and illuminated style positioned on the centre console. These had a common knob BHH1866, with separate surrounds for heat (BHH1870) and air (BHH1873).

The heater controls have been described as 'wonderfully illogical' in the past, and this is because with the chrome bumper controls you have to turn the air direction control anti-clockwise to turn it on which is fine, but the heat control has to be turned clockwise. Not only is that illogical from a tap point of view, which normally has to be turned anti-clockwise to turn it on, but doubly so as it is also the reverse to the air direction control. However this only seems to have been for 4-cylinder cars that used BHA4326, according to the Parts Catalogue CB V8s used BHA4334 with the more logical arrangement. Rubber bumper cars had knobs of a different style, and on these the heat control direction has been reversed to make it the same as the air direction control i.e. anti-clockwise to turn then both on. Up to the 77 model year they used BHH1687, and from the 77 year on the knobs changed again to a coloured and illuminated style positioned on the centre console. These had a common knob BHH1866, with separate surrounds for heat (BHH1870) and air (BHH1873).

August 2018: The CB heat (both 4-cylinder and V8) and air controls are available, as are the illuminated controls for the 77 and later console installation, but not the earlier RB controls.

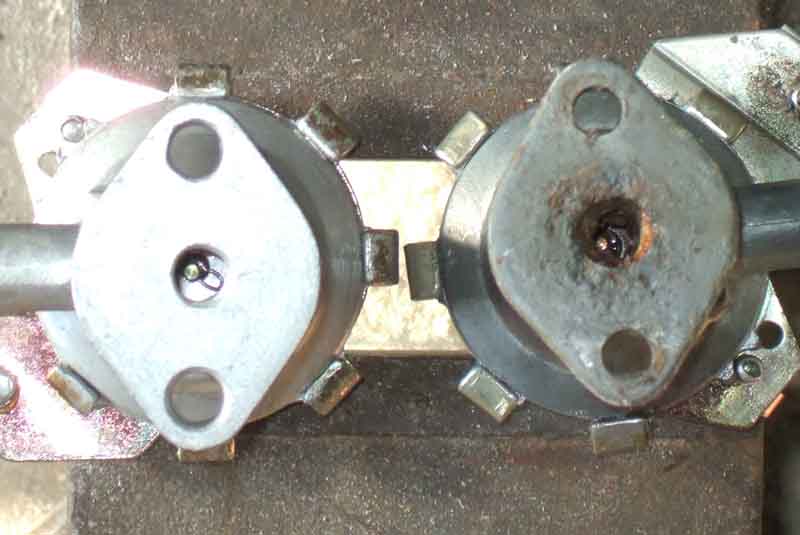

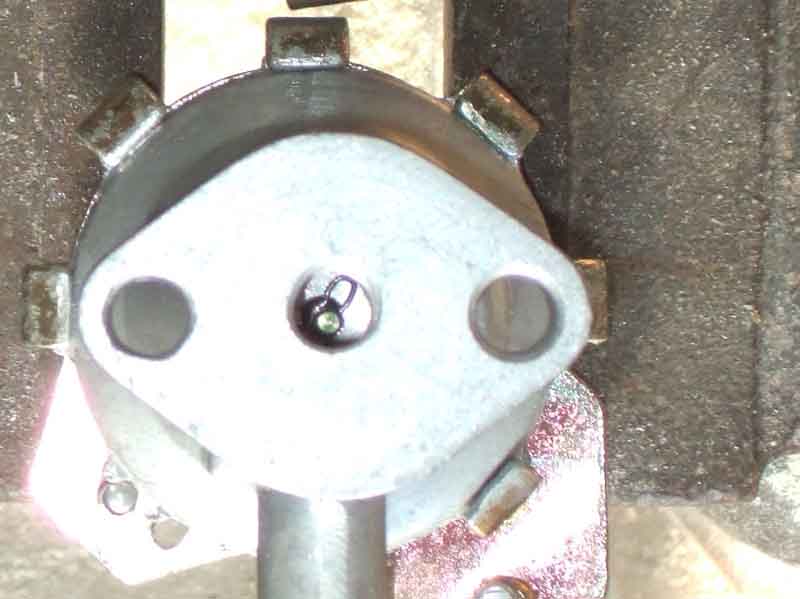

Two aspects to the heat control valve - adjustment of the cable operating it and coolant flow through it. I'll cover the cable first, or you can skip straight to coolant flow.

The heat control, unlike the air flow control, uses a cable with a solid inner to operate a lever on the valve. Even if the valve operates smoothly and easily there is lost motion in the control, cable and valve, but the control and valve both seem to have the same amount of movement on the levers. Therefore you can adjust the cable so that at one extremity the valve is fully shut, or adjust it so that at the other extremity the valve is fully open. You cannot adjust things so that the control will move the valve from fully open to fully shut, so which one do you opt for? I suggest that unless you have an additional on/off tap to shut things off completely in the summer you go for the 'fully off' option. In any case in the UK at least you are quite likely to sometimes want the heat on in summer, and sometimes want it off in winter! Even not being able to fully open the valve on either of my cars I still get air temps of around 140F/60C coming out the heater and that is with an ambient of about 50F/10C which I find quite adequate and usually have to turn down after a while.

Getting at the control can be a fiddle. First you have to remove the knob. Somewhere on the shaft of the knob you should see a hole or depression that looks like it might contain a grub-screw. It doesn't, it is a spring-loaded pin on the control shaft. Depressing it while pulling on the knob should get it off but some knobs have been known to seize on the control shaft. With the knob off remove the nut and withdraw (that all encompassing term) the control from the rear of the dashboard or console. The UK dash-mounted ones are much easier to remove than the console mounted in my experience, can't speak for the American padded dash.

Getting at the control can be a fiddle. First you have to remove the knob. Somewhere on the shaft of the knob you should see a hole or depression that looks like it might contain a grub-screw. It doesn't, it is a spring-loaded pin on the control shaft. Depressing it while pulling on the knob should get it off but some knobs have been known to seize on the control shaft. With the knob off remove the nut and withdraw (that all encompassing term) the control from the rear of the dashboard or console. The UK dash-mounted ones are much easier to remove than the console mounted in my experience, can't speak for the American padded dash.

November 2015:

As well as the heat control being constructed differently between chrome bumper and rubber bumper they are positioned differently in the dash.

As well as the heat control being constructed differently between chrome bumper and rubber bumper they are positioned differently in the dash.

With the control in your hand you should see the outer of the cable is clamped to a fixed arm by a curved bracket secured with a screw, and the inner attaches to the moving part with a 'trunnion' that fits in a hole on the end of the lever. This 'trunnion' is also used at the other end of both cables i.e. at the air flap and the heat valve. I have seen two types of cable - a spiral-wound outer (both like this on my 73 roadster), and a later type with plastic outer sheath with embedded longitudinal wires (on the heat control of my V8, the earlier type on the air control). Both types for the heat control use a solid wire inner, but the spiral outer type for the air control both use stranded cable. This is rather odd as both work on a push/pull principle i.e. it has to be pushed one way and pulled the other, it is not like the accelerator cable which the pedal pulls but returns under the action of springs on the carb. I believe the later type of outer came about because with the earlier spiral-wound outer if the other end is stiff then pushing on the wire just causes the spirals to open up like a spring instead of moving the valve or air flap, which was what was happening with the water valve on the roadster when fully shut. The later sheath does not do this and so you can get greater force on the inner when pushing. But although My V8 has this later sheath and was not expanding when the control was pushing on the wire, the valve was so stiff that when it pulled on the wire it was pulling the sheath through the clamp, which required some ingenuity to fix (see below).

With the control in your hand you should see the outer of the cable is clamped to a fixed arm by a curved bracket secured with a screw, and the inner attaches to the moving part with a 'trunnion' that fits in a hole on the end of the lever. This 'trunnion' is also used at the other end of both cables i.e. at the air flap and the heat valve. I have seen two types of cable - a spiral-wound outer (both like this on my 73 roadster), and a later type with plastic outer sheath with embedded longitudinal wires (on the heat control of my V8, the earlier type on the air control). Both types for the heat control use a solid wire inner, but the spiral outer type for the air control both use stranded cable. This is rather odd as both work on a push/pull principle i.e. it has to be pushed one way and pulled the other, it is not like the accelerator cable which the pedal pulls but returns under the action of springs on the carb. I believe the later type of outer came about because with the earlier spiral-wound outer if the other end is stiff then pushing on the wire just causes the spirals to open up like a spring instead of moving the valve or air flap, which was what was happening with the water valve on the roadster when fully shut. The later sheath does not do this and so you can get greater force on the inner when pushing. But although My V8 has this later sheath and was not expanding when the control was pushing on the wire, the valve was so stiff that when it pulled on the wire it was pulling the sheath through the clamp, which required some ingenuity to fix (see below).

Note that there are different control mechanisms installed to the dash for heat and air direction, so if you remove both remember to label them or check the 'logic' of them before going to the bother of reconnecting the cables and installing them. Chrome bumper cars have both controls of the same design i.e. sheath and inner clamps in the same basic positions, albeit at slightly different angles to the spindle. Unfortunately this give rise to the illogical heat control where you have to turn it clockwise for heat, whereas you turn the air control anti-clockwise for air, which is the more logical direction (think of most sink/basin taps). This is because the heat valve works the other way round to the air flap i.e. it has to be pushed for heat, whereas the air flap has to be pulled for air. On rubber bumper cars the heat control has the positions of the sheath and inner clamps reversed, as well as them being at different angles to the spindle, and this gives it the more logical 'anti-clockwise for heat' action.

Periodically I have to lubricate both heat controls as they get stiff after several years use. I started off using copper grease and working that in, but that seemed to get sticky after a while so I reverted to a light oil such as 3-In-One which does seem better. It only takes literally a couple of minutes to get the heat control out and the same to put it back, even leaving the air direction control in place, so no big deal.

As well as different mechanisms for air and heat there are also different ones for RHD and LHD dash-mounted, 4-cylinder and V8, and for various export markets - no less than 11 different types, plus 10 different knobs, and whilst later models had common knobs there were 4 different dials that went behind them! The controls have two locating pegs that fit into holes on the dash, each control can fit in one of two positions 180 degrees apart, so check that the legends on the control knobs align correctly with the datum pip in the dash above each knob also. Convention seems to be that the heat control goes above (dash-mounted) or to the left (console-mounted) of the direction control, on UK dashes at least. This is probably quite important as you will see the flats and location holes in the dash are different between the two. When the controls were moved to the centre console they became the same for both RHD and LHD for obvious reasons, before that when on the dash - firstly on the right for the LHD tin dash, then either side of the column on the padded dash, they had to be different as the cables went off in different directions.

Centre Console Controls April 2018

From 77-on the heater controls were fitted in the centre console, which makes removing and refitting the console more of a challenge than normal. Also due to the way the graduated surround for the knobs is attached to the console the securing nuts for controls themselves are recessed making them more difficult to get at than with the dash controls.

From 77-on the heater controls were fitted in the centre console, which makes removing and refitting the console more of a challenge than normal. Also due to the way the graduated surround for the knobs is attached to the console the securing nuts for controls themselves are recessed making them more difficult to get at than with the dash controls.

Originally the 'OFF' legend was at the top and the arrows on the knobs vertical when both the heat valve and the air direction flap were closed. But John Maguire in Australia found the standard cable routing was a bit tortuous resulting in stiff controls and has made some changes.

Originally the 'OFF' legend was at the top and the arrows on the knobs vertical when both the heat valve and the air direction flap were closed. But John Maguire in Australia found the standard cable routing was a bit tortuous resulting in stiff controls and has made some changes.

Changing the heat cable on Geoff's 1977 - with no radio installed - I was able to unscrew the control fixing nut and fish the control out through the radio slot which made the job much easier. The fixing nuts are deeply recessed - unlike when dash-mounted - so need a deep socket or a box-spanner. Having neither to hand I used a conventional socket but couldn't fit a socket wrench or extension bar as the spindle was in the way, but fortunately gripping the socket with a Mole wrench did the job. Refitting - with the stiff cable - you have to position the location studs on the control in the holes in the console and hold it there while finally tightening the nut to get the correct range of movement of the knob against the dial. I was gobsmacked to find the valve had the full range of travel instead of the usual 2/3rds that I and others have always found to be the norm!

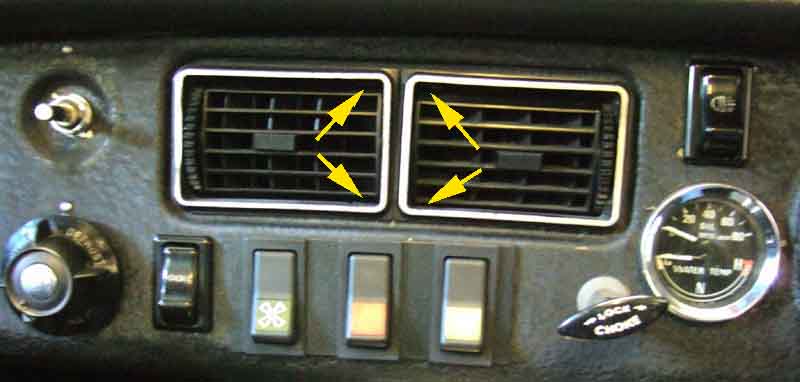

For the 1972 model year two fresh-air vents were fitted to the centre of the dash controllable for both air volume and direction. Rather pointless in the roadster except perhaps in a tropical rainstorm, but they do make the GT more comfortable. The air for these comes straight from the external air box bypassing the matrix so the air is not heated. Like the cold air flap if you have these fresh-air vents open at the same time as the heater is on you will find the cold air from the vents wins easily. As with the cold-air flap if the air intake in front of the screen is blocked off then opening these vents will convert the heating system from a fresh-air one into a recirculating one. In theory this will allow the cabin to get progressively warmer as the air recirculates through the matrix, but air-flow will be totally dependant on the electric fan and not the forward motion, and it is the latter that is far more powerful at pushing air through the matrix, offset by fresh air having to find its way out of the cabin before more heated air can come in. But the MGB was never 'air-tight', unlike the VW Beetle which reputedly will float!

For the 1972 model year two fresh-air vents were fitted to the centre of the dash controllable for both air volume and direction. Rather pointless in the roadster except perhaps in a tropical rainstorm, but they do make the GT more comfortable. The air for these comes straight from the external air box bypassing the matrix so the air is not heated. Like the cold air flap if you have these fresh-air vents open at the same time as the heater is on you will find the cold air from the vents wins easily. As with the cold-air flap if the air intake in front of the screen is blocked off then opening these vents will convert the heating system from a fresh-air one into a recirculating one. In theory this will allow the cabin to get progressively warmer as the air recirculates through the matrix, but air-flow will be totally dependant on the electric fan and not the forward motion, and it is the latter that is far more powerful at pushing air through the matrix, offset by fresh air having to find its way out of the cabin before more heated air can come in. But the MGB was never 'air-tight', unlike the VW Beetle which reputedly will float!

November 2016:

Ray Longsheds writes asking if I had any knowledge of a packing piece between the two dash vents, which is described as an 'anti-rattle' measure in the Workshop Manual. His weren't rattling, but one of them tends to work its way out of the dash and he wondered if the packing would prevent it. I've not found any packing as shown in the manual in either of my cars, but the V8 does have some thin strips of card glued to the back of the flange on three sides. I can see they would make the locking tabs a tighter fit against the back of the dash panel, and so have the same effect. Any packing between the vents would need to total at least 8mm i.e. 4mm each side to protrude past the flanges, but whether that would also prevent them coming loose as well as rattling remains to be seen. Ray replicated what I have and reports that it has worked a treat.

Ray Longsheds writes asking if I had any knowledge of a packing piece between the two dash vents, which is described as an 'anti-rattle' measure in the Workshop Manual. His weren't rattling, but one of them tends to work its way out of the dash and he wondered if the packing would prevent it. I've not found any packing as shown in the manual in either of my cars, but the V8 does have some thin strips of card glued to the back of the flange on three sides. I can see they would make the locking tabs a tighter fit against the back of the dash panel, and so have the same effect. Any packing between the vents would need to total at least 8mm i.e. 4mm each side to protrude past the flanges, but whether that would also prevent them coming loose as well as rattling remains to be seen. Ray replicated what I have and reports that it has worked a treat.

All models have a 'warm air' vent in each footwell on the side of where the heater box is located, above the tunnel and behind the dash or console. Originally the vent had an adjustable flap, possibly to direct more air to the drivers footwell if the passengers seat were unoccupied (or you didn't like them). I don't think it was anything to do with directing air to the screen demisters as these cars had the air direction control knob anyway.

All models have a 'warm air' vent in each footwell on the side of where the heater box is located, above the tunnel and behind the dash or console. Originally the vent had an adjustable flap, possibly to direct more air to the drivers footwell if the passengers seat were unoccupied (or you didn't like them). I don't think it was anything to do with directing air to the screen demisters as these cars had the air direction control knob anyway.

In August 1970 (Car No. 219001) these adjustable doors were replaced by a fixed hood. Said by Clausager to be 'improved', it possibly did so by having sides and so directing more air downwards onto the feet instead of 'leaking' away from the sides of the flap, but I'm sure there was an element of cost-reduction as well!

In August 1970 (Car No. 219001) these adjustable doors were replaced by a fixed hood. Said by Clausager to be 'improved', it possibly did so by having sides and so directing more air downwards onto the feet instead of 'leaking' away from the sides of the flap, but I'm sure there was an element of cost-reduction as well!

Heater Removal December 2015

However I question the later comment on the above web site about the slot for the air direction control cable. This quotes Haynes as indicating that 1977 models gained a dedicated slot for the cable, replacing the earlier 'egg-shaped' arrangement that encompassed both the right-hand demister vent and the cable. The early arrangement makes it impossible for the heater to be fitted with the cable attached without severely kinking it, which means the cable has to be fitted afterwards - bad enough with the original demister tube arrangement and footwell vent, worse with the smaller fixed vents, impossible with the rubber block. The dedicated slot makes it possible to fit the heater with the cable already attached, but it was provided much earlier than 1977. My 73 roadster and 75 V8 have it, as does a chrome bumper shell that could be as early as 1971, all pictured by clicking the thumbnail to the left. As Clausager indicates the demister tubes changed in August 1970 for the 1971 model year at the same time as the tunnel changes (and probably the footwell vent change), I suspect they all occurred as a package.

However I question the later comment on the above web site about the slot for the air direction control cable. This quotes Haynes as indicating that 1977 models gained a dedicated slot for the cable, replacing the earlier 'egg-shaped' arrangement that encompassed both the right-hand demister vent and the cable. The early arrangement makes it impossible for the heater to be fitted with the cable attached without severely kinking it, which means the cable has to be fitted afterwards - bad enough with the original demister tube arrangement and footwell vent, worse with the smaller fixed vents, impossible with the rubber block. The dedicated slot makes it possible to fit the heater with the cable already attached, but it was provided much earlier than 1977. My 73 roadster and 75 V8 have it, as does a chrome bumper shell that could be as early as 1971, all pictured by clicking the thumbnail to the left. As Clausager indicates the demister tubes changed in August 1970 for the 1971 model year at the same time as the tunnel changes (and probably the footwell vent change), I suspect they all occurred as a package.

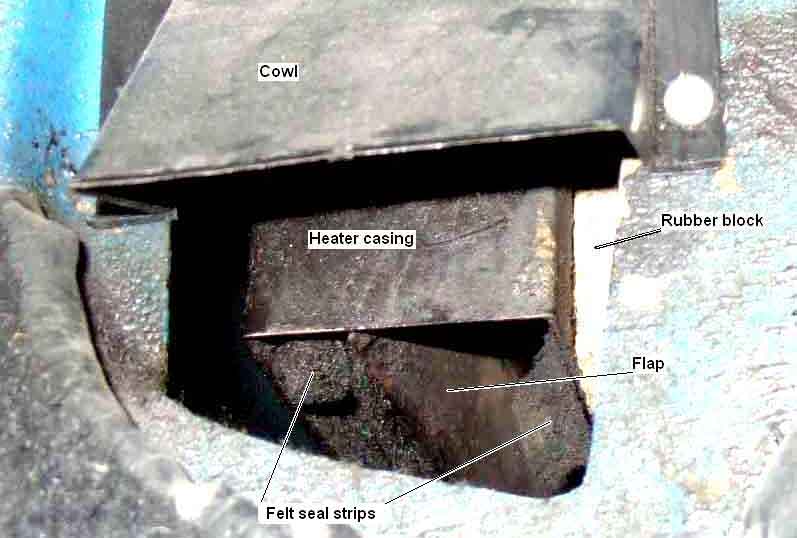

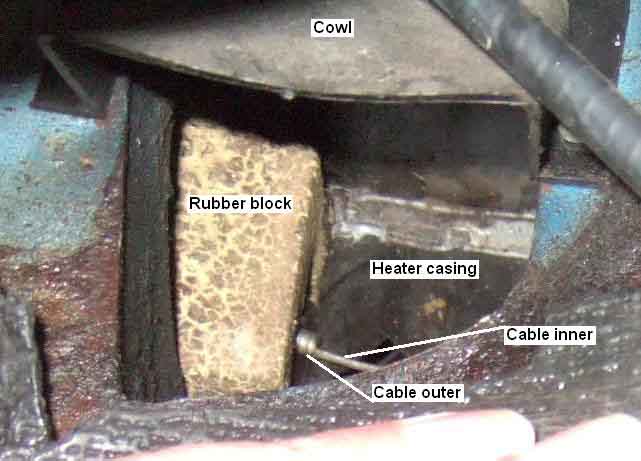

Rubber Block:

As said above probably for the 1971 model year with the other heater changes a rubber block was fitted between the heater unit and the cabin bulkhead which was a bit of a double-edged sword as it made some things easier (factory installation) but some more difficult (subsequent removal and refitting)! The block can be seen from various positions so you can see what you are dealing with before you start trying to remove the heater:

- Behind the separate slot for the air-direction control cable beside the right-hand screen-vent bulkhead aperture as viewed through the radio slot (if radio not fitted).

- Edges of the rubber block visible as viewed through the right-hand footwell vent and the left-hand footwell vent.

February 2017: I removed Vee's heater along with the rest of the stuff on the bulkhead as part of a restoration. I pondered long and hard over this, as there is such a lot to remove. The decision was finally made after checking all the pedal box, servo and heater fasteners could be reached and removed, then doing a test-lever under the flange of the heater. It started moving straight away, then suddenly came free with a sound of something coming unstuck, so I decided to go for it. Removed the washer bottle cradle, pedal box and servo first, then removed the clips on the demister tubes and pulled the tubes back into the cabin, and disconnected the air-direction cable from the dash control. After that I found I could just lift it by hand, tilting it forwards to clear the surround, and out it came! However that was with the engine out which gave me a place to stand and space to wield a long enough lever.

Refitting:

Two distinct processes depending on whether you have the earlier bulkhead with the egg-shaped hole, or the later with the separate tall slot. The later arrangement allows the heater unit to be refitted with the cable already attached. But if you have the earlier then you can't get the heater unit back in with the cable attached without significant kinking. If you also have the large adjustable footwell vent, then with that removed you may just have enough room to attach the cable once the heater unit has been refitted. But it's probably much easier to cut a slot from the side of the egg-shaped hole up to where the top of the later separate slot was, and fit the heater unit with the cable already attached.

Two distinct processes depending on whether you have the earlier bulkhead with the egg-shaped hole, or the later with the separate tall slot. The later arrangement allows the heater unit to be refitted with the cable already attached. But if you have the earlier then you can't get the heater unit back in with the cable attached without significant kinking. If you also have the large adjustable footwell vent, then with that removed you may just have enough room to attach the cable once the heater unit has been refitted. But it's probably much easier to cut a slot from the side of the egg-shaped hole up to where the top of the later separate slot was, and fit the heater unit with the cable already attached.

April 2017:

December 2019: Vee's

Vee's

Vee's restoration has progressed to fitting-out the engine-bay. I was able to trim the rear face of the rubber block over most of the thicker part, leaving the area round the vent holes at full thickness, with a craft knife. On fitting as suspected the bottom of the heater was 1/4" forward of the cavity. With an unmodified block you would have to compress the whole of the upper thick part 1/4" to get it in, but trimming as I did meant much less compression was required. Then having lubricated it and the back of the cavity with Swarfega I managed to get the right-hand corner of the heater wedged in, then pressing down (one body) and wiggling got the rest in and all the way down. It certainly helped being able to stand in the engine bay, without that you may have to rig-up some method of standing over the engine.

Vee's restoration has progressed to fitting-out the engine-bay. I was able to trim the rear face of the rubber block over most of the thicker part, leaving the area round the vent holes at full thickness, with a craft knife. On fitting as suspected the bottom of the heater was 1/4" forward of the cavity. With an unmodified block you would have to compress the whole of the upper thick part 1/4" to get it in, but trimming as I did meant much less compression was required. Then having lubricated it and the back of the cavity with Swarfega I managed to get the right-hand corner of the heater wedged in, then pressing down (one body) and wiggling got the rest in and all the way down. It certainly helped being able to stand in the engine bay, without that you may have to rig-up some method of standing over the engine.

Brian Wall of the Exeter MG Owners Club writes that he approached this job with some trepidation. Having stuck the block to the heater air-flap box and left it to fully cure he inserted the bottom of the heater in the shelf hole, angled it forwards, then liberally sprayed the back of the block with WD40 and the heater slipped into place easily and was connected up easily. He goes on to say that they did subsequently need to remove it again to replace the cable, but it came out easily as well. He wrote subsequently to say that the heater had to come out twice more - once when the new cables were found to be too long (there are at least seven different part numbers around, check against the old before fitting!) and again because the air flap lever was fouling the side of the rubber block, so the block had to be trimmed - check for good operation of the air-flap before installing to the bulkhead.

A common problem is water flow through the matrix being reduced due to a build-up of rust 'silt' over many years. This can usually be cleared by repeatedly reverse and forward flushing the matrix until water flows clear. In severe cases you may have to add a flushing compound and leave it to 'soak' before flushing with clean water again. This can be done in-situ with hoses on both flow and return pipes to avoid dowsing the rest of the engine bay in rusty water. If you do get bright orange silt coming out of the heater matrix it might be as well to similarly flush the block (with a cold engine!) and radiator to aid cooling.

A common problem is water flow through the matrix being reduced due to a build-up of rust 'silt' over many years. This can usually be cleared by repeatedly reverse and forward flushing the matrix until water flows clear. In severe cases you may have to add a flushing compound and leave it to 'soak' before flushing with clean water again. This can be done in-situ with hoses on both flow and return pipes to avoid dowsing the rest of the engine bay in rusty water. If you do get bright orange silt coming out of the heater matrix it might be as well to similarly flush the block (with a cold engine!) and radiator to aid cooling.

Updated January 2007 Of course anything that restricts coolant flow in the heater circuit will have the same effect and this includes the metal return pipe running across the top of the rocker cover (thanks David Witham for mentioning this) and hoses as well as the matrix.

Similarly the air passages in the matrix could be blocked with leaf litter. Mk2 cars had a mesh over the matrix inlet (not the air-box inlet, which is an aftermarket modification) to reduce the chance of this happening. If the matrix is blocked and compressed air from inside the cabin doesn't improve things removing it and poking the passages clear (trying not to puncture the water passages - test before refitting) or fitting a new matrix.

A third possibility is the airflow bypassing the matrix, and hence not passing through it and picking up heat,

because the seal around it has decomposed. Ashley Hinton, manufacturer of the heater system components using the original Smiths tooling, supplies a felt seal 17H 1797, rather than the foam seal that all the other suppliers seem to have, as felt stands up to the heat much better. Makes sense. Not much you can do about this seal short of complete removal and dismantling, although it may just be possible to lever the heater cover back with the heater unit in-situ and wedge more in.

A third possibility is the airflow bypassing the matrix, and hence not passing through it and picking up heat,

because the seal around it has decomposed. Ashley Hinton, manufacturer of the heater system components using the original Smiths tooling, supplies a felt seal 17H 1797, rather than the foam seal that all the other suppliers seem to have, as felt stands up to the heat much better. Makes sense. Not much you can do about this seal short of complete removal and dismantling, although it may just be possible to lever the heater cover back with the heater unit in-situ and wedge more in.

The matrix can corrode through or split, leading to water on the carpet or dropping on the ground from by the air vent drain tube. In the case of the former you may get the sweet smell of antifreeze in the cabin and condensation forming on the screen above the air vents, as well as loss of coolant at the radiator.

It's said in various places that you can modify the cover to allow removal of the matrix with the heater unit in-situ. The cover extends down into the slot in the bulkhead shelf by an inch or more, but even if you bend the cover forwards to clear the matrix ports there is a flange at the bottom of the cover that goes under the main case and prevents the cover being lifted out.

It's said in various places that you can modify the cover to allow removal of the matrix with the heater unit in-situ. The cover extends down into the slot in the bulkhead shelf by an inch or more, but even if you bend the cover forwards to clear the matrix ports there is a flange at the bottom of the cover that goes under the main case and prevents the cover being lifted out.

March 2017: