Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

Ignition System

|

Lucas write in their Fault Diagnosis Service Manual that "the standard ignition system will quite adequately meet the requirements of a six-cylinder engine at 8000 rpm". You need look no further than the V8 for verification of that which is firing the coil at double the rate of the 4-cylinder i.e. half the coil recharge time so at the red line of 5200rpm (which it very easily revs beyond) it is equivalent to 10400 rpm on the 4-cylinder. So dwell or points closed time on the 4-cylinder is not at all critical and things like dual-point distributors are double the adjustment trouble plus hotter coils for no gain.

Factory Systems

Fixed vs Variable Dwell

After-market Systems

Problems with After-market Systems and the earlier RVI Tach

Coil Current

Programmable

Fault Diagnosis

Factory Systems

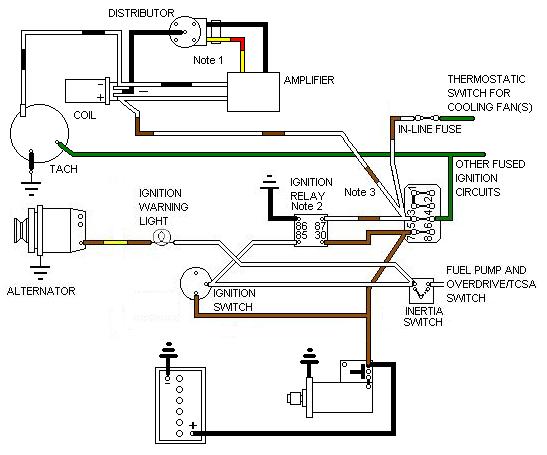

From mid-1974 (i.e. all rubber bumper) North American cars had either the 45DE4 'Opus' electronic ignition (see here for info on the Opus as fitted to Jaguar V12, Aston Martin V8 and Cosworth V8) or the 45DM4 CEI electronic ignition with remote amplifier. They were necessary to meet the emissions requirements of the day, giving consistent results over many thousands of miles (I recall cars of the era having to travel 50k miles with no maintenance other than things like fluids, and having to be in spec at the end), unlike points which deteriorate over distance due to mechanical wear. But with good parts and correct initial setup I find that points easily last 6k to 10k miles without drifting out of the limits for dwell and hence no readjustment (my last 45D4 with their +-5 degrees tolerance for dwell lasted 15k).

The 45DE4 Opus system was very troublesome (it was nick-named 'Opeless') and often replaced with the 45DM4 under the original warranty, I find it amazing that there still seem to be a small number of Opus systems in existence! This Lucas Fault Diagnosis Manual contains some faulting information for the Opus system, but it seems to be for a version that had a separate pickup and amplifier and a different ballast arrangement so may not be that much use. Both factory systems use a (nominally) 6v coil with harness ballast the same as the points operated system on rubber bumper cars for other markets. The Opus system has an additional ballast resistor for the electronic ignition module. Neither of these systems are 'electronic ignition' in the sense of giving a more powerful spark, they are simply 'electronic trigger' systems where the mechanical points are replaced by a magnetic or optical trigger controlling an amplifier, which switches the current in the coil much as mechanical points do. The Opus system has a fixed dwell (unlike the later 45DM4 CEI system) although I believe it is higher than points dwell as it was designed for higher-revving V8 and all V12 engines to give a satisfactory coil recharge time at peak revs, as well as no contact bounce. This has the side-effect that it will cause the coil to run hotter than if points had been used, but as it was only ever used with the 6v coil and external ballast these will still run cooler than a 12v coil with points ignition. See here for information on coil temperature

The 45DM4 CEI system uses more sophisticated electronics in an external module to give 'variable dwell' and did not use the usual rubber bumper ballasted wiring arrangement. The 45DM4 system was used by a large number of manufacturers, albeit with differing physical installation, and the MGB system has been said in the past to be a Delco D1906. At the time of writing the modules may still be available from various sources in China, Google 'DM 1906'. If yours is different physically you can check the other Delco items and other manufacturers e.g. Lucas to see if you can find it. An alternative is NAPA TP45SB (March 2010: Google can't seem to find NAPA) but there has been a suggestion that the 'TP' in the NAPA number denotes Transpo as a source, check the prices of each. However if the fault is in the pickup you have bigger problems replacing it, and you wouldn't want to splash out on a new module only to find it made no difference (see below). Update March 2010: Motaclan/Leacy are showing the AB14 amplifier module (i.e. the DM1906 in a case and with the required leads) as part number BAU1922, at a price of £117, and a 45DM4 distributor for a 1980 California MGB at the same price.

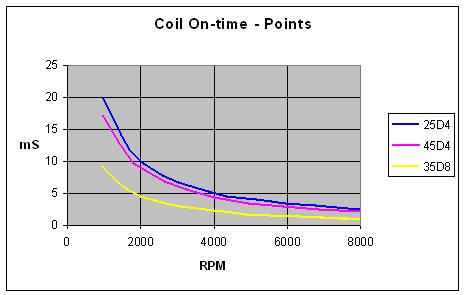

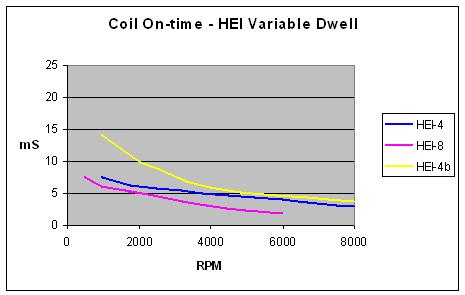

A comparison of points (fixed dwell) and variable dwell electronic systems:

| |

| mS

| 1000 | 20 | 17 | 9 | 1000 | 500 | 7.5

| 2000 | 10 | 9 | 4.5 | 2000 | 1000 | 6

| 4000 | 5 | 4.3 | 2.3 | 4000 | 2000 | 5

| 6000 | 3.4 | 2.9 | 1.5 | 6000 | 3000 | 4

| 8000 | 2.5 | 2.1 | 1.1 | 8000 | 4000 | 3

| 10000 | 2 | 1.7 | 0.9 | 10000 | 5000 | 2.3

| | |||||||||||||||||

Or to put it another way:

On the left are the three points distributors used in the 4-cylinder and V8 MGBs. On the right is the chip that is used in the HEI system of the 45DM4 MGB distributor (and many commercial variable-dwell ignition systems, HEI-4) and if the same chip were used on the V8 (HEI-8). These are 'typical' coil-on figures from the manufacturers spec, but the maximum can be as high as indicated in HEI-4b i.e. significantly higher at lower rpms, and approaching that of points.

Fixed vs Variable Dwell: What is not so obvious from those graphs is that variable dwell delivers a short dwell i.e. coil 'on' time at idle which reduces coil temperature, increasing as the revs increase until at peak revs the dwell is higher than fixed-dwell systems to deliver a stronger spark than fixed dwell.

Points, the original factory 45DE4 electronic system and many after-market electronic replacements use 'fixed dwell' whilst the factory 45DM4 CEI system and various after-market systems use 'variable dwell'. With fixed dwell the relative durations of current flowing and not flowing through the coil are fixed regardless of rpm - about 60% flowing and 40% not flowing which equates to about 30 mS at idle down to 3 ms at 6000 rpm. This is much longer than is needed to 'charge' the coil and get a good spark for the whole of the rev range on a 4-cylinder, and generates waste heat, which is constant regardless of rpm. At very high rpms in excess of 10k the reducing current flow time can start to degrade the HT energy, but this degradation is utterly irrelevant to 4-cylinder MGBs bearing mind the V8 engine has half the coil charge time of a 4-cylinder (twice as many HT pulses per revolution) and is still pulling like a train when it reaches the red line.

By contrast variable dwell varies the relative durations of current flowing and not flowing as the rpm changes, flowing for just long enough - around 5 mS - to fully charge the coil at any rpm, so at low rpm particularly idle the coil runs much cooler. However the difference decreases as the revs increase, and at maximum revs the energising time in variable dwell systems becomes higher than points - at 6000 rpm a 4-cylinder coil is energised for about 4 mS.

Geoff's 77 has an under-cap after-market electronic ignition system. Fitted by the people he bought the car from so he didn't know what type, and I didn't want to disturb things to have a look when I didn't need to so used my volt/dwell meter. Voltage tests showed it to be the type that didn't pass current through the coil until you start cranking, and dwell meter showed it is a variable dwell system, this clearly showing the dwell increasing as the revs are increased:

When installing components under the distributor cap make sure fixing screws are not too long or they can foul the weights and cause a misfire.

From Roger Parker on the MGOC forum in February 2018:

That mirrors my own experiences, in fact I have run points for 15k with no apparent loss of performance or economy, and neither have I ever had a set points or condenser fail in over 60 years. I check them annually but solely by dwell, and have never had to readjust the roadster between replacements. The V8 does need an occasional readjust as firing eight cylinders in one rotation the dwell is half that of the 4-cylinder so changes are more apparent. Despite that there is an adjuster bar on the outside of the distributor so it's simply a matter of turning that with the engine idling with the dwell meter connected. Don't use feeler gauges as they can introduce oil and grease to the contact surfaces. That can be cleaned by drawing a strip of clean paper through them when closed - but don't pull a cut edge through and especially not a torn edge as that can leave insulating fibres behind. Set them up initially on the bench, which is a lot easier especially for the 4-cylinder on RHD cars.

The Lucas Fault Diagnosis Manual states "the standard ignition system will quite adequately meet the requirements of a six-cylinder engine up to about 8000 rpm". The following table compares the coil on-times between the 4-cylinder 25D4 and 45D4, V8 35D8 points systems and GM HEI variable dwell systems - that module being the core of the factory 45DM4 system as well as many after-market systems.

These figures also show that a dual-point distributor is just adding complexity for no gain - other than a higher temperature coil - as the additional coil on-time simply isn't needed for a good spark at any rpms likely to be found on an MGB engine. And if you think about it its USP is exactly the opposite of a variable dwell system - they can't both be 'right'!

But if you are determined to replace your points system, read on. Aftermarket devices such as the Pertronix Ignitor and Lumenition Magnetronic are similar to the factory systems in that they are electronic triggers and replace the points, and with modern electronics they can be made small enough to fit entirely inside the distributor cap. Lumenition Optronic seems to be much the same except it uses an optical trigger instead of the magnetic of the Magnetronic and requires an external power module. All these systems are the same as points in that they are Inductive Discharge systems, using a 'switch' to break the circuit through the coil and generate the spark. I see claims from the manufacturers that they deliver double the coil voltage and four times the spark energy, but personally I don't see how. They are just a switch, turning coil current on and off, just like points. Spark energy is controlled by coil design and the current flowing through it, so the only way such claims can be accurate is by comparing it with very badly degraded points. Also electronic switches pass LESS current than a decent set of points, which is why the factory used higher energy coils with their electronic systems. On the other hand the cheaper fixed-dwell systems show a higher measured dwell than points, which will cause coils to run hotter.

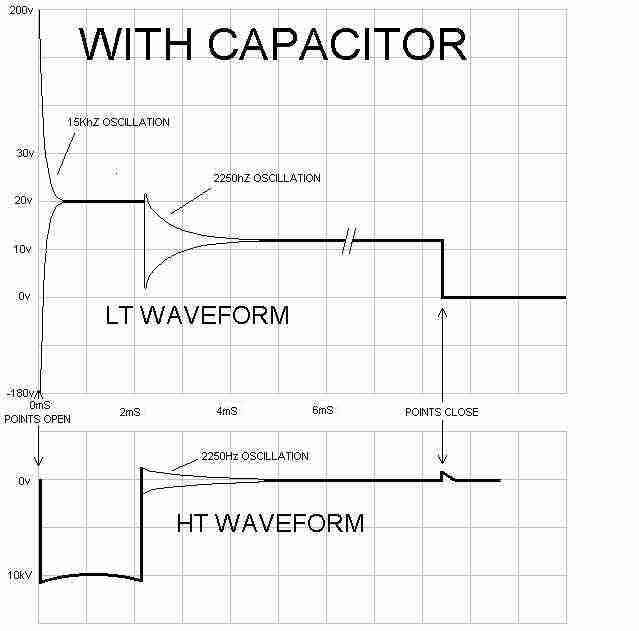

Electronic systems popular in the 70s like Sparkrite were Capacitive Discharge which used an oscillator to charge a capacitor to a high voltage, then discharged the capacitor into the coil to generate the spark. This results in a high voltage at the coil LT terminals, and a dangerously high voltage at the HT terminals, which if open-circuit i.e. not connected to a spark plug could cause injury up to and including death. Whether these much higher energy systems result in anything useful is debatable. IMHO they may make the difference between starting and not starting under the most adverse conditions of weather and poor maintenance, or consistent firing of the much weaker mixtures used in modern engines.

November 2021:

If you have vacuum advance that is continually twisting the 'points' plate back and fore as you alter the throttle. The 25D4 distributor has cloth-braided tinsel conductor wires for the coil and earth wires which are very flexible to cope with this twisting. The 45D4 has a more conventional wire from the condenser leading out of the distributor body to the coil wire but it has more and thinner conductors than the one it connects to, plus a similar earth wire as before, to do the same job. Under-cap systems such as Magnetronic have two wires coming out of the distributor in the same space as the one points wire, and Optronic has three. Whether these are as flexible as the factory wires I don't know, but Ben Columb has had a long-standing intermittent hesitation problem for many months if not years. He'd done all sorts with timing and carbs to no avail, and eventually said the tach was doing strange things at the same time, to which I and others said 'ignition LT'. Eventually he tracked it down to broken conductor strands inside the insulation of one of the Optronic wires, which means a replacement trigger unit at £110, as opposed to a 45D4 condenser at under £10.

If you have vacuum advance that is continually twisting the 'points' plate back and fore as you alter the throttle. The 25D4 distributor has cloth-braided tinsel conductor wires for the coil and earth wires which are very flexible to cope with this twisting. The 45D4 has a more conventional wire from the condenser leading out of the distributor body to the coil wire but it has more and thinner conductors than the one it connects to, plus a similar earth wire as before, to do the same job. Under-cap systems such as Magnetronic have two wires coming out of the distributor in the same space as the one points wire, and Optronic has three. Whether these are as flexible as the factory wires I don't know, but Ben Columb has had a long-standing intermittent hesitation problem for many months if not years. He'd done all sorts with timing and carbs to no avail, and eventually said the tach was doing strange things at the same time, to which I and others said 'ignition LT'. Eventually he tracked it down to broken conductor strands inside the insulation of one of the Optronic wires, which means a replacement trigger unit at £110, as opposed to a 45D4 condenser at under £10.

Often after-market systems cause problems for the electronic tachometer, particularly with the earlier RVI current-triggered type (see here for some suggestions on resolving this). Positive earth cars need to be treated differently as described here. Other down-sides are that when they fail they often do so suddenly and totally, they are difficult or impossible to diagnose or repair other than by substitution, and expensive to replace (see above). By comparison points and condenser are cheap to carry as spares, and easy to diagnose and replace at the roadside. Updated July 2010: A while ago a very much cheaper version of the 'under cap' electronic module from Simon's Best British Classics came to my attention. At around £20 these are about a third or less than the price of the Pertronix, Aldon and Magnetronic versions so it becomes feasible to fit one and carry another as a spare. However on the MG Enthusiasts BBS some people swear by them, and others swear at them after repeat failures. One of these people had two Pertronix fail, another had external unit types fail. Yet another had two from SimonBBC fail, but these were blue (like David Blake's junked item below) whereas current stock appears to be red. However the descriptions for the various types are a bit confusing. Some for the 25D4 say they are for 12v coils and no external ballast, which they all were from the factory anyway, whereas some for the 45D4, which were all ballasted from the factory, don't mention this. And at least one says if used on a ballasted coil it will be damaged, similarly if jump-starting from another car! In various places it says 12v coils must be fitted and the ballast bypassed, but not everywhere. I've contacted the vendor and he informs me that as long as the red wire is taken to a 12v supply, for example the white wire at the fusebox on cars with ballasted ignition, then the module will be fine (See here to confirm whether you have a ballasted or a non-ballasted system, which you really need to do if intending to fit one of these units regardless of how your car might have come out of the factory). It's a pity he can't make this clear on the site. If you do replace your 6v coil and ballast with a 12v coil, then you are throwing away some of the benefits of electronic ignition. Original 12v coils have higher reluctance, which means they need a longer coil recharge time for a given HT spark than 6v coils with a ballast, so you are getting a weaker spark at peak revs. A 12v coil will also run hotter than a 6v coil, unless the ignition module has variable dwell.

The other issue concerns 45D4 distributors, which had two different types of points (and hence points mounting plates) - one sliding (with a pin) and the other non-sliding (no pin). Other vendors supply two different modules depending on the points type, but not this site. Again information from the vendor is that the module is really intended for the non-sliding type, but can be fitted to the other type "if the pin is bent out of the way". Updated November 2010: There is a warning on the site concerning jump starting, recommending that the flat battery is charged either from the other vehicle (or a charger) then the jump-leads removed before attempting to start the car, or the ignition module can be destroyed. This is quite different to the usual jump-start instructions and could take some considerable time to charge the battery enough to start the car. The page also indicates that the unit is not protected against reverse connection, and voltages over 14.2v may damage the module. However the MGB Workshop Manual states that voltages can be as high as 14.7v for an alternator and 15.5v for a dynamo. In the case of the dynamo the voltage regulator is temperature dependant, output voltage increasing as ambient temperature falls, and that 15.5v is at 50F/10C. As temps even in the UK can get quite a bit below that system voltages could be even higher. The instructions also state that the unit cannot be used with a ballasted system - the ballast must be bypassed. One of the suggested ways of doing this is to run a 12v ignition wire direct to the coil +ve, but if you do that without changing the coil to a 12v type the coil will overheat in use. All-in-all quite a few points against use of the system, for all it's cheapness.

Added December 2007: One of the more informative and educational postings to Youtube comparing Pertronix, points and 123. It shows the Pertronix jittering almost as much as points, although that could well be a factor of different amounts of wear on the two old distributors as compared to the new 123, I would have preferred to see the Pertronix and points on the same mechanically refurbished distributor. After replacing the timing chain and gears (obviously not a factor on this distributor machine) on my V8 noticeable jitter beforehand had almost completely disappeared, and that on a distributor with at least 100k on the clock and probably nearer 200k. Note the Pertronix distributor seems to 'advance' in the opposite direction to the points and 123, and the very obvious steps in advance of the 123 as well as its total lack of jitter at higher rpms, although it seems to have significant erratic jitter at lower.

Unfortunately the original 123, despite being a beautifully engineered bit of kit, is designed to a fundamentally flawed concept, and very expensive at £300. The only useful bits on it are the fact that you get a new body i.e. bearings, and a solid-state trigger. But you can get those elsewhere for £45. It's a waste of all that modern technology to simply reproduce the original curves, which were all that could be obtained with the technology available 60 years ago, can only give a rapid increase in advance initially then a slower increase, and at best were only ever an approximation of what the engine really needed. With modern fuels, engines this old and many with modifications, the original curves are even less relevant. One vendor said that he recommended the generic version over the MGB-specific (that were available at the time) as the curves were 'better' for today. Another vendor has said that the curves don't match the specifications anyway, and it needs setting-up on a rolling-road (which he happens to have ...) to get the best out of it! It's like someone designing a new engine with the latest mechanical, ignition and fuelling technologies, but configuring it to deliver 110 ft.lb and 63BHP at 3000rpm, and 27mpg, and charging double the price of a rebuilt original! Far better are programmable systems where you can set the advance rev point by rev point for your specific engine and fuel and store a number of maps, one of which when combined with a new distributor body and electronic trigger is only half the price of the 123. Subsequently a programmable 123/Tune was produced.

August 2019: I have recently discovered that the 123 relatively easily if required, for example if the timing gears or drive gear have been installed incorrectly. Incidentally the same can be done on conventional distributors but can need significant force to drive the roll-pin out. Only an aesthetic nicety really, the original error is still there, and the same thing can be achieved by moving the leads round on the cap by two positions to suit where the rotor points.

September 2020: Brian Wall has contacted me to say that after installing a 123 non-tune version with the curve recommended by the MGOC and following the instructions exactly:

So yet more confirmation that no matter what type of distributor you use, it's all down to experimentation as to what will give the best results, or as Brian says "Suck it and see".

Added January 2008, updated October 2008:

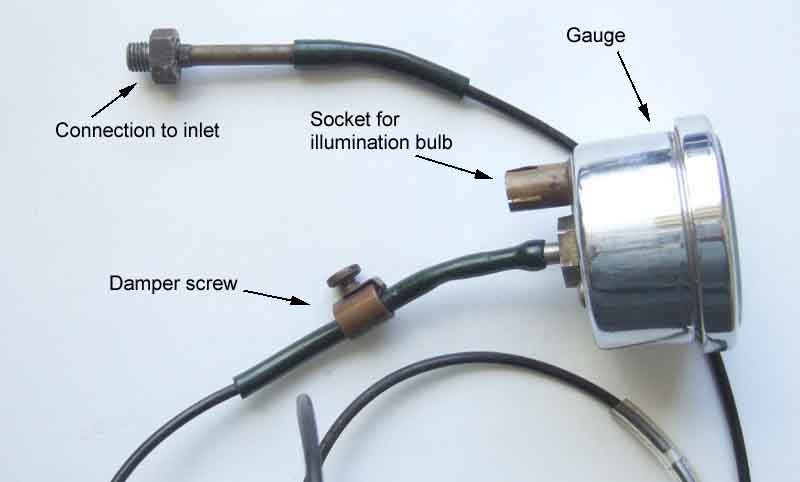

Dave Blake had purchased a distributor on eBay that seems to have been a standard 45D4 but with an electronic trigger (seen here) instead of points. He recounted on the BBS considerable problems trying to get his engine to work properly, eventually resolved when I suggested replacing the trigger with points and a condenser! Dave was going to bin the trigger but kindly sent it to me instead. It is of the same type as Pertronix/Aldon/Magnetronic i.e. magnetic and contained entirely under the cap, but is of a different unspecified manufacture, I tried to find out what without success, but subsequently info from Gary Falkiner indicates that it is also used in a Land Rover conversion kit. It has the same two wires leading out to the coil as the others i.e. one red to the coil +ve and one black to the coil -ve, but the rotor is different on both Dave's and Gary's in that the magnets are integral, the others have a separate magnetic ring that fits over the cam, then a standard rotor goes on the end of the shaft as normal. The separate magnetic ring definitely preferable, as with this integral unit if the rotor should need replacing you would have to get this special one with the magnets, and without knowing the manufacturer whether you would be able to obtain one from eBay is anyone's guess. The alternative would be to scrap the unit and go back to points ... I put Dave's on my bench tester and found that it triggers 30 degrees before points in the same distributor. Whilst this variation could be compensated for from a timing point of view fairly easily by simply twisting the distributor in the clamp, one is left with a change in phasing i.e. the relative positions of rotor and cap contact when the trigger fires. And on my test distributor with a cut-away side I could see that when you start to add vacuum advance, the rotor was moving away from its cap contact, so the spark was having to jump a larger and larger gap. Eventually it would fail to do so, or jump elsewhere, causing erratic HT and misfire when fitted to an engine. Why it is like this is anyone's guess - poor manufacture? Wrong rotor? Who knows? Dave was fortunate in that he was able to retro-fit points and a condenser, it could have had a trigger plate that wasn't compatible. Gary reported that he had to retard the timing by 15 degrees to get back to the same point as before, showing that his phasing was also significantly different to points. Initially it seemed to run well but after a bit of use it was noticeably inconsistent, and kept picking up iron filings on the magnetic collar which may have been affecting things. In the end he went back to points as well!

Dave Blake had purchased a distributor on eBay that seems to have been a standard 45D4 but with an electronic trigger (seen here) instead of points. He recounted on the BBS considerable problems trying to get his engine to work properly, eventually resolved when I suggested replacing the trigger with points and a condenser! Dave was going to bin the trigger but kindly sent it to me instead. It is of the same type as Pertronix/Aldon/Magnetronic i.e. magnetic and contained entirely under the cap, but is of a different unspecified manufacture, I tried to find out what without success, but subsequently info from Gary Falkiner indicates that it is also used in a Land Rover conversion kit. It has the same two wires leading out to the coil as the others i.e. one red to the coil +ve and one black to the coil -ve, but the rotor is different on both Dave's and Gary's in that the magnets are integral, the others have a separate magnetic ring that fits over the cam, then a standard rotor goes on the end of the shaft as normal. The separate magnetic ring definitely preferable, as with this integral unit if the rotor should need replacing you would have to get this special one with the magnets, and without knowing the manufacturer whether you would be able to obtain one from eBay is anyone's guess. The alternative would be to scrap the unit and go back to points ... I put Dave's on my bench tester and found that it triggers 30 degrees before points in the same distributor. Whilst this variation could be compensated for from a timing point of view fairly easily by simply twisting the distributor in the clamp, one is left with a change in phasing i.e. the relative positions of rotor and cap contact when the trigger fires. And on my test distributor with a cut-away side I could see that when you start to add vacuum advance, the rotor was moving away from its cap contact, so the spark was having to jump a larger and larger gap. Eventually it would fail to do so, or jump elsewhere, causing erratic HT and misfire when fitted to an engine. Why it is like this is anyone's guess - poor manufacture? Wrong rotor? Who knows? Dave was fortunate in that he was able to retro-fit points and a condenser, it could have had a trigger plate that wasn't compatible. Gary reported that he had to retard the timing by 15 degrees to get back to the same point as before, showing that his phasing was also significantly different to points. Initially it seemed to run well but after a bit of use it was noticeably inconsistent, and kept picking up iron filings on the magnetic collar which may have been affecting things. In the end he went back to points as well!

Added February 2008:

Another problem that has just come to light when replacing points with one of the 'under cap' systems concerns the condenser fixing screw. As part of installation you remove the condenser as it is no longer required, but the screw has to be refitted to secure the braided earth wire which is still needed with these 'under cap' systems. After installation the engine was run but was giving very poor and erratic results. Eventually the cause was found to be the condenser fixing screw was too long and being hit by the centrifugal advance mechanism. Probably a non-standard screw in this case, but something else to be aware of.

Coil Current: Many moons ago someone, rather smugly I thought, said electronic triggers are better than points as they have zero 'contact' resistance i.e. better than points even if they (the points) only dropped a tenth of a volt. At the time I wondered if he had ever measured the volt-drop across an electronic trigger, because one of the many things I remember from my electronics theory days is that semi-conductors exhibit a forward-bias volt-drop when conducting. This doesn't vary with current as in a conventional resistor, but instead differs according to the semi-conductor junction material. I remembered this as 0.3v for germanium diodes and 0.7v for silicon, pleasingly repeated here. However those are diodes, the switching in these devices will be done by some kind of transistor. Again from my theory days 'Darlington pair' transistors are used to increase switching current capability, and we are talking about 5 to 6 amps for an ignition coil. These have twice the base to emitter volt-drop than single transistors as there are two in series, but there are two parallel paths from the source voltage to the load. Whilst this will double the current that the trigger can safely handle the volt-drop will remain the same as each path is still dropping the same voltage even though the current has halved - Ohm's Law does not apply.

Some systems say they use Hall-Effect devices, which potentially (!) confuses the issue. A Hall Effect device senses a magnetic field and essentially controls a flow of current like a switch. But as they can only handle about 40mA these devices must be in the sensor where there are magnets rotating with the distributor shaft. Other systems use an LED and a photo-cell with a rotating blade like a propeller between them and both types generate an output pulse at the required time. Both are only controlling other electronic components in the modules and it is those components that are doing the actual switching of the the current through the coil, and are almost certainly the more usual silicone devices above.

Being a simple chap and far more reliant on practice than theory, there was nothing for it but to measure it - and the results were very interesting. A set of old points, used as removed i.e. the contact faces not cleaned up, gave about 0.5v, so quite a bit. But the electronic trigger (magnetic) gave fully 1v! I also noticed it is a fixed-dwell device just like points, and not variable dwell like the 45DM4 or some after-market triggers. These Reopus FAQs indicates that the original Opus system also gave a 1v drop, and when the MGB changed to the ballasted ignition and 6v coil in rubber bumper cars, and North America got electronic ignition, the UK cars got a coil with nominally 1.5 ohms primary resistance (16C6) whereas North American coils were nominally 1.4 ohms (15C6) precisely so as to offset this reduction in voltage and current. Very late in production in 1980 North American coils were changed again to a 32C5 for which several sources give a nominal primary resistance of 0.8 ohms! By this time they had the 45DM4 distributor and electronic ignition system which is a variable dwell system. Never use this coil with anything other than a variable dwell system or it will grossly overheat as it will be carrying 17 amps instead of about 5 amps. It would be interesting to find the volt-drop in these, as well as other electronic triggers such as Pertronix and Aldon Igniters, and Lumenition Magnetronic.

April 2024: As part of a thread involving possible ignition problems the following fault diagnosis information from Aldon about their electronic ignition system was given:

- Remove the King Lead from the Distributor and Earth to a Cylinder Head Bolt

- Set Volts on Multimeter to 20v Scale

- Red Probe of a Multimeter on the Coil - (Negative)

- Black Probe of Multimeter on the cars earth

- If meter shows "0" Volts Trigger Unit Is Open Circuit

- If Meter shows "1-3v" Module Faulty

- If you get either of the above readings the Trigger Module has failed and a replace is required

- If you get a constant Battery Voltage (12v+) check the wiring and connections of the module to coil.

- If You have None of the above proceed to crank the engine and the Multimeter should read between 1.5v to 12v which indicates the Trigger Module is Switching the Coil Correctly

- Point 9 is the critical thing in determining whether points or electronic ignition give a 'better' HT spark. In an ideal world there would be 0v on the coil -ve with the points or electronic trigger closed and passing current, as that would put the full system voltage across the coil, and hence drive the greatest possible current through it, create the greatest magnetic flux, and hence generate the greatest spark when the points or trigger opened. By saying the multimeter should read between 1.5v and 12v shows that 1.5v is being 'lost' inside the trigger module when it is passing current which reduces the voltage across the coil, hence a lower current, lower magnetic flux, and a lesser HT spark. With a system voltage of 12v across a 3 ohm coil then 4 amps would flow. But if there is only 10.5v across the coil (12v minus 1.5v) then only 3.5 amps will flow. This is why when the factory fitted electronic systems to the MGB they used a lower resistance coil which increased the current and hence the magnetic flux and the spark compensating for the reduced coil current.

A secondary aspect is that usually in a running engine with a working charging system the system voltage is typically 14v not 12v.

- Point 5 indicates that with the meter connected between the coil -ve and a body earth if you see 0v then the trigger unit is open-circuit. The trigger unit is also connected between the coil -ve and earth and so to see 0v the trigger unit would have to be short-circuit, not open-circuit. However you would also see 0v on the coil -ve if the coil itself were open-circuit or the 12v supply to the coil +ve was missing.

The points volt-drop of 0.5v above was measured on a bench test rig with old points so I thought I'd check the V8 with relatively new points, and I was a bit surprised to see almost as much at just under 0.4v, so I decided to dig in a bit further. I was measuring the voltage between the two most accessible points, which was the -ve coil stud and the distributor body. But this includes the points wire spade to coil tag, points wire, connection to points, points themselves, points base to points plate, distributor earth wire, and its connections to the points plate and distributor body. When I started breaking these down the results got very interesting indeed:

| coil stud to points wire spade | 0.03v |

| points wire, coil to points | 0.19v |

| points wire terminal to points spring | 0.03v |

| points | 0.08v |

| points base to distributor body i.e. distributor earth wire | 0.02v |

So the biggest volt-drop by far is in the wire from the coil to the points! That in the points themselves is half that, and ignoring the points the remaining volt-drop is 0.27v, more than three times the volt-drop in the points themselves which is from the wiring and will present no matter what type of trigger is used. Compare the 0.4v total volt-drop with points with the 1.5v drop with the Aldon electronic ignition system, i.e. electronic 'loses' nearly four times more coil current and spark energy than a decent set of points.

Programmable: December 2013 Fairly new to the market are two programmable modules that are inserted between the trigger and the coil - Aldon Amethyst and Accuspark Stealth. A pal has some experience of the former but from the blurb they seem to be similar in that that allow you to develop your own set of curves by specifying the amount of advance at a number of rev points. However it looks like that Amethyst manages the vacuum advance - and boost retard if you have a supercharger - and hence is also mappable, whereas with Stealth vacuum advance remains as before i.e. is fixed by the distributor vacuum capsule. Another difference is that whereas Amethyst is compatible with points or any electronic ignition module, the Stealth information implies that you must have an under-cap electronic trigger. See also this from the Amethyst designer, who did the initial development on a 1967 MGB.

Said pal put an Amethyst on his supercharged MGB and tinkered with the rev points increasing/reducing until he ended up with a 'curve' whereby each rev point was one degree short of causing pinking. He ended up with a very unusual (by mechanical distributor standards) curve, but the whole point of being able to configure your own is that it can be tailored to exactly what your engine and fuel grade require right across the rev range. By comparison a conventional distributor is a relatively crude device, pretty-much only able to have a steeper increase at lower rpms, and a shallower one at higher. The upshot was a noticeably faster car using the 'seat-o-pants' meter.

Subsequently the 123 was upgraded to a programmable version, but it is an 'all or nothing' device in that if fails you are stuffed. If the Aldon or Accuspark modules fail you can bypass them and run the coil directly off your trigger. Both Amethyst and Stealth require you to disable the centrifugal advance on the distributor so bypassing the modules prevents any additional centrifugal advance, which would reduce performance and economy and increase running temperature, but at least it would allow you a 'limp home' mode. Amethyst installation instructions say to set the distributor to your normal static advance, whereas the Stealth instructions imply that you set it to TDC which would hit performance and economy and increase running temperatures even more. However I don't really see why the distributor with Stealth couldn't be set to the static figure just like Amethyst. Bypassing Amethyst would disable vacuum advance as well, but that can be dealt with by simply transferring the vacuum pipe back to the distributor capsule. At the time of writing the 123 is very expensive at £300, the Amethyst significantly cheaper at £200, and the Stealth half the price of the Amethyst at £100, but you have to add the cost of an electronic trigger to the Stealth. Incidentally Accuspark Stealth states "Electronically adjust intial (sic) timing by up to 9 degrees via laptop, no need to adjust distributor with timing light" which doesn't seem correct. Unless you have a crank position sensor to tell the electronics when the piston is at TDC the trigger is the only input, so you still have to initially position the distributor in the block to either to the static figure (Amethyst) or to TDC (Stealth) which can only be done in the normal way i.e. statically with a test-lamp or meter or dynamically with a timing light. Maybe Accuspark mean once you have a running system you can move the whole advance curve by up to 9 degrees rather than having to move each individual point.

Fault Diagnosis October 2015

Misfiring

Cranks but won't start

Weak spark?

Cutting-out - either momentarily i.e. similar to a misfire, or stopping the engine altogether:

If the tach does suddenly drop to zero then look at the ignition warning light (if it has been working normally that is!) as well. If that is glowing then you have lost the voltage supply to the ignition system. In most cases this means a fault in the ignition switch or its wiring, but on 1977 and later cars with ignition relay it can also be caused by the ignition relay and it's wiring.

If the ignition warning light is not glowing, try another ignition powered circuit such as the indicators - you will probably want to be indicating to pull over anyway! If they don't work either, then it's probably going to be a break in the wiring between the ignition switch or relay and the fusebox.

Due to changes over the years and markets the indications of the ignition warning light and indicators can point to different causes, I've tried to summarise these below:

| Year/market | Warning light | Indicators | Likely area |

| 62-64 | on | (no) | brown to ignition switch, ignition switch |

| off | no | white from ignition switch to fusebox | |

| off | yes | white from fusebox to coil etc. | |

| 64-67 Mk1 | on | (no) | brown to ignition switch, ignition switch |

| off | (yes) | white from ignition switch via tach to coil etc. | |

| Mk2 67-72 UK | on | (no) | brown to ignition switch, ignition switch |

| off | (yes) | white from ignition switch via tach to coil etc. | |

| Mk2 67-72 NA | on | (no) | brown via bullet connector to ignition switch, white to bullet connector |

| off | (yes) | white from bullet connector via tach to coil etc. | |

| 73-74 UK | on | (no) | brown to ignition switch, ignition switch |

| off | no | white from ignition switch via bulkhead 4-way bullet connector to fusebox | |

| off | yes | white from fusebox to coil etc. | |

| 73 NA | on | (no) | brown via bullet connector to ignition switch, ignition switch, white from ignition switch to bullet connector |

| off | no | white from ignition switch bullet connector via bulkhead bullet connector to fusebox | |

| off | yes | white from fusebox to coil etc. | |

| 74 NA | on | (no) | brown via ignition switch multi-plug, ignition switch, white via ignition switch multi-plug |

| off | no | white from ignition switch multi-plug via bulkhead bullet connector to fusebox | |

| off | yes | white from fusebox to coil etc. | |

| 74½-76 UK | on | (no) | brown to ignition switch, ignition switch |

| off | no | white from ignition switch via bulkhead 4-way bullet connector to fusebox | |

| off | yes | white from fusebox to coil etc. | |

| on | (no) | brown via ignition switch multi-plug, ignition switch, white via ignition switch multi-plug | |

| off | no | white from ignition switch multi-plug to fusebox | |

| off | yes | white from fusebox to ignition ballast etc. | |

| 77 UK | on | (no) | brown via ignition switch multi-plug, ignition switch, white via ignition switch multi-plug to ignition relay, ignition relay, white/brown ignition relay to fusebox |

| off | no | fusebox white/brown connections | |

| off | yes | fusebox to ignition ballast etc. | |

| on | (no) | brown via ignition switch multi-plug, ignition switch, white to ignition switch multi-plug | |

| off | no | white from ignition switch multi-plug to ignition relay, ignition relay, ignition relay white/brown to fusebox | |

| off | yes | white/brown from fusebox to ignition ballast etc. | |

| 78-on UK | on | (no) | brown via ignition switch multi-plug, ignition switch, white via ignition switch multi-plug to ignition relay |

| off | (yes) | white/brown from ignition relay to ignition ballast etc. |

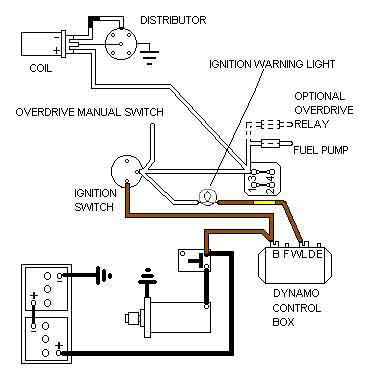

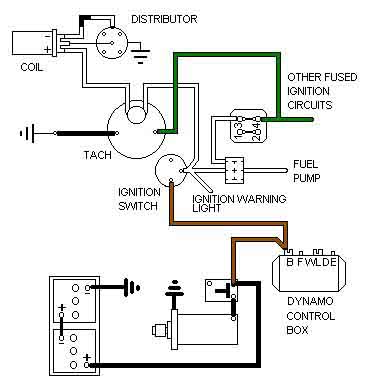

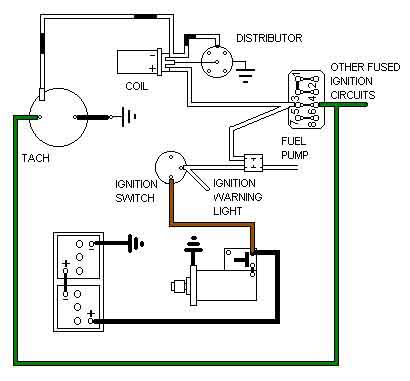

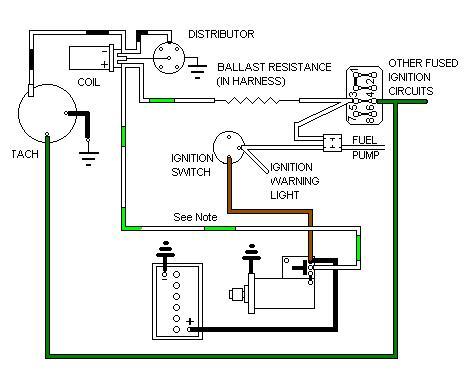

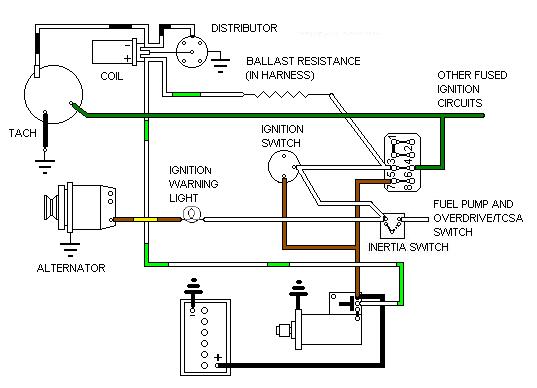

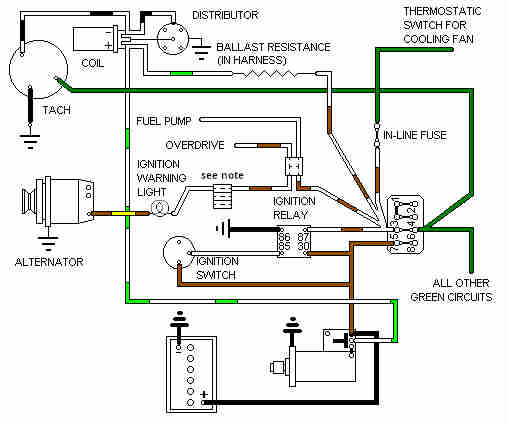

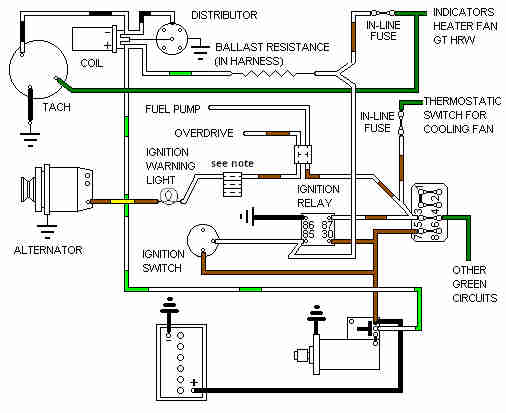

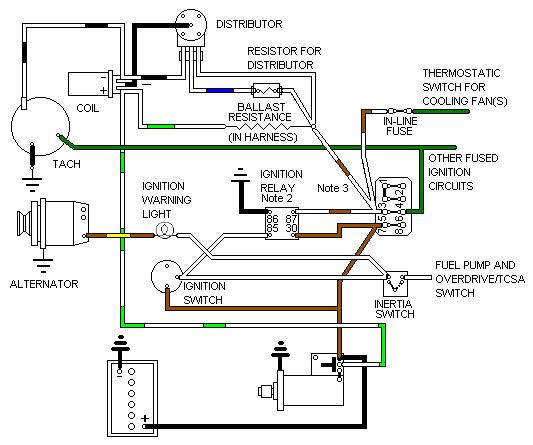

Click on the year and market for the relevant schematic.

Where the 'Indicators' condition is shown in brackets i.e. as (no) or (yes) it means that given the 'Warning light' condition it should always be this way, unless you have more than one fault.

'Coil etc.' and 'ignition ballast etc.' refer to the remainder of the ignition LT circuit i.e. through the ignition ballast (where provided), coil and points or electronic trigger to earth. Where the ignition warning light is extinguished and the indicators etc. still work the problem will lie in this part of the system. As well as disconnections in the wiring between fusebox, ignition ballast, coil and distributor, systems with points and after-market under-cap triggers rely on an earth wire inside the distributor that connects the points or trigger plate to the distributor body. With vacuum advance the points plate is continually being twisted back and fore as you change the throttle position, and this earth wire as well as the points or trigger wires as they pass through the body of the distributor, can fracture the conductors inside the insulation.

June 2016: Systems with an after-market electronic system where the electronics module is external to the distributor such as Lumenition Optronic use three wires from the trigger to the module and one of these is an earth or 'common' wire, so the original earth wire is no longer used. However any of the three wires can suffer from internal fractures due to the points plate twisting with changing vacuum as with the other systems.

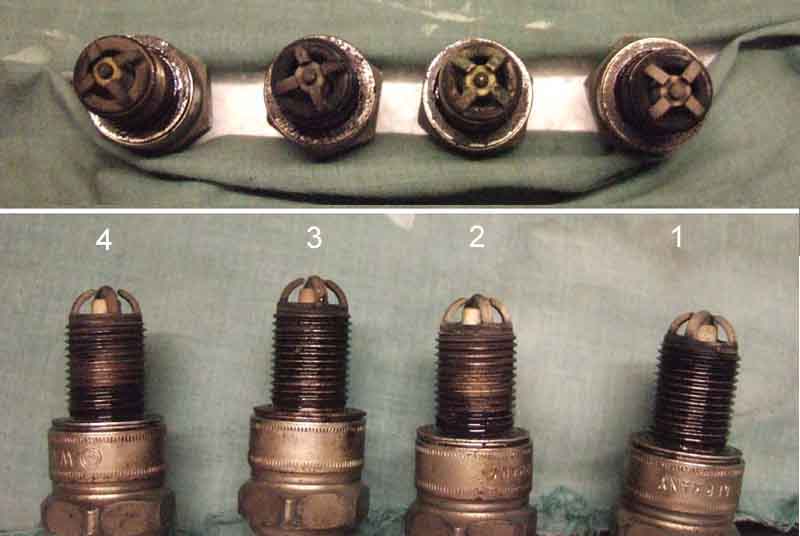

Misfiring: October 2025 Originally MGB coils had riveted spades and over time these can work loose and cause a misfire or cutting-out accompanied by the tach dropping, later coils have threaded studs and nuts and overcome this - at least when your nuts are tight! My 73 roadster had this in 2001 - varying in length but never completely dying and it has cropped up again on the MG Enthusiasts website. From a report of 'tach dropping' Nat found his 1972 (riveted) -ve spade terminal was loose and with an ohmmeter the resistance was at best 4.3 ohms (instead of nominally 3 ohms) but when the spade was wiggled it would rise to about 200 ohms and sometimes infinity. Replacement needed - be sure to measure the resistance between the spades before you fit it. CB MGBs had 3 ohm coils and RB had 1.5 ohms in conjunction with 'ballasted' ignition wiring. Suppliers and even manufacturers do not always have the correct information and previous owners may have changed things. Get the wrong coil for your wiring and you can end up with weak sparking or an overheating coil.

A similar thing can happen with original spade connectors being a bit loose on the spades, in that case pinching up the connectors a little with a pair of pliers is cheaper than a new coil ...

See also this on incorrectly manufactured points and length of points/condenser screws.

Static tests: With points ignition diagnosis of ignition system faults is relatively easy. With electronic ignition it can be more difficult, usually substitution with another system is the only way, but see below. For static tests a digital meter should be satisfactory as well as an analogue.

- Points: With the ignition on and the points closed (they usually are having switched off a running engine, or cranked with no start) you should have voltage on the coil SW or +ve, and close to 0v on the coil CB or -ve, both with respect to earth. On chrome bumper cars you should have 12v on the coil SW or +ve, but rubber bumper cars originally had a ballast resistance in series with the coil and the effect of this is to reduce the ignition voltage at the coil +ve to about half battery voltage (points closed as said) - as long as you have the correct 6v coil. If you have a 12v coil in series with a ballast resistance you will see about 8v. If you see other voltages there could be a problem with the coil, the ballast, or the wiring connections back towards the ignition switch or relay. If the ballast has been bypassed and you fit a 6v coil then you will burn the points due to excessive current. See here for more information on ballasted ignition and 6v and 12v coils.

If you have 12v on both LT terminals of the coil then the circuit through the points and distributor earth wire is broken. Test the points spring and moving contact, and if that shows an earth then the wire between the points and the coil is broken. If it shows 12v - and the points are closed - then the earth wire inside the distributor is broken.

If you have voltage on the coil SW or +ve and an earth on the coil CB or -ve, then turn the engine by hand until the points open, or hold the points open by hand. You should then see 12v on both terminals of the coil. If you still see 0v on the coil CB or -ve then remove the wiring from the coil CB or -ve. If that terminal now shows 12v then the wire between the coil and points is shorting to earth, this may be from faulty or incorrectly installed points or a short-circuit condenser. If the coil CB or -ve terminal still shows 0v then the coil itself is open-circuit. Another check is to measure the current passing though the coil, which with ignition on and points closed should be nearly 4 amps.

If all that looks correct the coil should be generating HT sparks. Remove the coil lead from the distributor cap and connect it to a plug laying on the block, then manually flicking the points open and closed should show sparks. If not the coil may be faulty, or possibly the condenser is open-circuit. In this latter case the points will be sparking and spitting excessively, to confirm temporarily connect another condenser between the coil CB or -ve and earth. If this reduces the arcing and spitting and you now get the plug sparking then change the condenser. Check the points gap/dwell is correct.

- Electronic ignition

: These vary in that some basically replicate points in that they will be 'closed' and drawing current through the coil as soon as you turn on the ignition, these should show the same voltages on the coil spades as for points. Others do not start drawing current until you start cranking, so until then you will see battery voltage on both spade terminals of the coil on both CB and RB i.e. both non-ballasted and ballasted. Others may initially pass a current through the coil like points, but if the engine is not started for a period it may cut the current off. With these latter two types not allowing current to flow, or turning it off after a few moments, protects the coil from overheating if the ignition is left on without starting the engine for some time. If you completely disconnect the electronic system from the coil you can simulate points by temporarily connecting a condenser between the coil CB or -ve terminal and earth, and connecting an earth to the CB or -ve terminal to simulate the points being closed, and removing it to simulate the points being open. You should get a spark with the coil lead connected to a test plug laying on the block which will confirm everything else is OK and the electronic ignition is almost certainly the problem.

Cranking tests: These can be done with either a voltmeter or a dwell meter (as said above for the voltmeter an analogue instrument is preferable). A dwell meter display in either degrees or percent (%). For the 25D4 a dwell of 60 degrees equates to 67%. For the 45D4 51 degrees equates to 57%. For the 35D8 of the V8 27 degrees equates to 60%.

- Points: If manually operating the points generates HT sparks from a plug connected to the coil, then crank the engine while monitoring the voltage on the coil CB or -ve, and you should see around 5 volts. With a dwell meter you should see about the correct dwell reading if the points gap is correct. On the coil SW or +ve you should see about 10v on all cars but it depends on having a fully charged battery and on rubber bumper cars a working ballast bypass circuit. If you see less than that on a rubber bumper car and battery condition is good the coil boost circuit is probably faulty, although this by itself shouldn't be enough to prevent the engine from starting unless other aspects are poor. However you will need either an analogue meter to see these voltages, or an averaging digital instrument, other digital instruments may have the reading flicking all over the place.

- Electronic ignition: This depends on whether it is a fixed-dwell system like points or variable dwell. With fixed dwell you should see the same as points but dwell can be a little higher and voltage a little lower. With variable dwell you should get a noticeably higher voltage on the coil CB or -ve - between 5v and 10v - but a lower dwell - probably half or less, but it depends on the system. If you see cranking voltage i.e. nominally 10v or a dwell of zero then the trigger is failing to draw current through the coil, which can be confirmed with an ammeter. If you see 0v or 100% dwell, or very nearly so, then the system is drawing current through the coil continuously, which again can be confirmed with an ammeter.

When you have HT at the coil lead then reconnect it to the distributor and refit the cap. Try cranking again, this time with each plug led in turn connected to a plug laying on the block. If none of them spark then the distributor rotor, or possibly the cap is breaking down. If some do and some don't then again it could be the cap, or individual plug leads breaking down, or faulty plugs, swapping plugs between leads should show which. An alternative is to use a timing light and watch the flashes, although bear in mind that a 12v light with inductive pickup may need a separate power supply to work correctly while cranking.

Weak spark? You can use a spark tester connected in series with plug leads or coil lead. There are basic go/no go devices such as the Sealey VS526 (you don't need four of them as in the Laser 2780). However this Gunsons 77077 only needs to be touched onto the outside of the HT lead so easy to move from lead to lead. For interest this type contains a neon bulb instead of an air-gap and there is enough energy round the outside of an HT lead when a plug fires to ionise the neon. However note that there may be enough energy to cause the neon to flash but not to fire the plug. So really it is only a 'no go' type, i.e. only if there is no flash is it telling you anything useful i.e. that plug is not firing. If you are going to buy one you would be better off with the Laser adjustable 5655 at a few quid more which allows you to introduce an additional adjustable gap to see just how far the spark will jump, but if you are lucky you might find a Gunsons Flashtest on eBay for a lot less. You should get at least 1/4", higher with a 'sport' coil, much less indicates weak sparking. All of them only show whether an HT pulse is travelling down the HT lead or not, the plug could be faulty and not firing even when the tester shows HT is present.

You can confirm coil current with a multi-meter. Static coil current should be about 4 amps on both CB 12v and RB ballasted systems. Measure this with the points closed i.e. by inserting the meter between one of the wires and its spade, or by measuring the voltage across the coil and points. Static voltage should be 12v on a CB 12v system, and about 6v on an RB ballasted system. If you see less than that, then measure the voltage between the distributor terminal on the coil and earth when the points are closed. Ideally you would see zero volts, but with 4 amps flowing some voltage drop will occur even in that short wire, the points, and the distributor earth wire. If you see more than a few tenths of a volt then you need to test further to see where it is occurring, i.e. from the points moving contact to earth, and the points fixed contact to earth. If the points are dirty you will see more voltage at the moving contact than at the fixed contact, but you could have losses in more than one place.

See here to test the condenser.

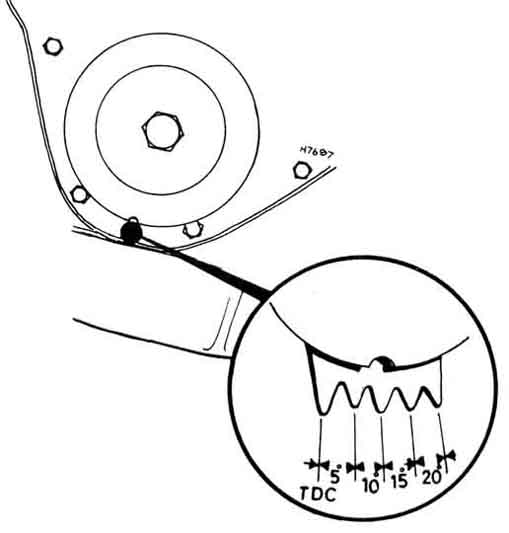

Timing: If all plugs and leads are sparking, then check the static timing. Note this is easy with points, electronic systems may vary and may not be possible. You will have to twist the distributor until you get it running then dynamically time it with a strobe light, or even crank it with the timing light connected and pointing at the crank pulley so you can see how far off it is. 123 distributors seem to have an LED to indicate TDC. Setting this to about 10 degrees Before Top Dead Centre should be enough to start any MGB engine. With the ignition on connect a voltmeter between the coil CB or -ve, and with plugs out turn the engine until the notch on the crank pulley is under the 10 degree pointer on the timing cover. The last pointer the notch passes should be TDC, a smaller pointer immediately before that should be 5 degrees BTDC, and a large pointer immediately before that should be 10 degrees BTDC. With the pulley notch at 10 degrees slacken the distributor clamp bolt or clamp plate bolts and twist the distributor clockwise and anti-clockwise watching the meter switching between 12v and 0v, which is as the points open and close respectively. You should find that as you turn the distributor clockwise the voltage goes to 12v as the points open, and goes to 0v as you turn it anti-clockwise and the points close. If you find it is the other way round then the distributor is 45 degrees out and needs to be turned one way or the other until you get the correct voltage swing. Then with the voltmeter at 0v i.e. points closed, slowly turn the distributor clockwise until the points just open and the voltage goes up to 12v. Tighten the clamp plate bolts - but don't overtighten the bolt on the plate that clamps the distributor body. Make sure the 4-cylinder distributor body flange is flush with the clamp plate when the clamp plate is fully bolted to the block. This ensures the distributor is fully seated into the drive gear, as it can partially seat when 180 degrees out.

Plug lead orientation: The distributor on the MGB rotates anti-clockwise as you look down on the top of the cap, and the firing order is 1, 3, 4, 2 with the cylinders being counted from the water-pump end to the flywheel end. Start by determining where in the distributor cap No.1 plug lead goes, then count the rest from there. To determine where No.1 goes turn the engine to TDC on the compression stroke of No.1 cylinder, and see where the rotor is pointing. Normally it points to about 2 o'clock, but if the timing gears have been fitted incorrectly, or the distributor shaft has been dismantled and put back together incorrectly the rotor will be 180 degrees out. Also if the 4-cylinder engine distributor drive gear has been inserted to the engine incorrectly the rotor could be in as many positions as there are teeth on the drive gear (eight or nine). The V8 distributor is different in that the drive gear is on the end of the distributor shaft, so more care is needed to refit the V8 distributor to the engine.

It also needs to be borne in mind that on a 4-stroke engine each piston passes through TDC twice for every combustion cycle - once on the compression stroke and once on the exhaust. To set it correctly see here. As long as you fit No.1 plug lead in the cap position that aligns with the rotor position and count the rest from there, the engine should start and run, even if the rotor is not at 2 o'clock. If you want to correct the rotor position then see here.

There is yet another possibility for incorrect timing and that is if the wrong crankshaft pulley has been used, or it is a damped pulley and it has started delaminating - which is where the outer part that carries the timing notch moves in relation to the inner part that is keyed to the crankshaft. To check for this see here.

Even after all that if the engine has been dismantled, reassembled and won't start it could be something fundamental like valve timing or compression.

And my own experiences

Firing order and lead positioning

In the UK at least carbon powder-impregnated string was the standard lead for many years covering the 60s and 70s at least, but the carbon powder moves around and the leads can go high resistance causing ignition problems quite quickly. Then silicone-cored were produced which are much more stable lasting for decades in my experience. It's confusing because many sources also call these 'carbon impregnated', and say they don't last very long, but that is simply not the case in my experience. In more recent years leads have become more 'hi-tech' with an insulating core wrapped with many turns of fine metal wire to give the resistive feature, under silicone-rubber outer layers. These are said to offer better interference suppression which can be important for the electronics on modern vehicles. Beyond that some people produce massively thick HT leads, which is OK if you are running very large plug gaps and very high voltage systems (which have issues for conventional distributors and rotors on cars of our era) plus all sorts of fancy features like capacitors and earthing wires. The common factor in these latter types is their humongous price, and the apparent belief in some have that if they cost that much they must be better. For cars of the MGB era and those ignition systems anything other than basic silicone is a waste of money.

In the UK at least carbon powder-impregnated string was the standard lead for many years covering the 60s and 70s at least, but the carbon powder moves around and the leads can go high resistance causing ignition problems quite quickly. Then silicone-cored were produced which are much more stable lasting for decades in my experience. It's confusing because many sources also call these 'carbon impregnated', and say they don't last very long, but that is simply not the case in my experience. In more recent years leads have become more 'hi-tech' with an insulating core wrapped with many turns of fine metal wire to give the resistive feature, under silicone-rubber outer layers. These are said to offer better interference suppression which can be important for the electronics on modern vehicles. Beyond that some people produce massively thick HT leads, which is OK if you are running very large plug gaps and very high voltage systems (which have issues for conventional distributors and rotors on cars of our era) plus all sorts of fancy features like capacitors and earthing wires. The common factor in these latter types is their humongous price, and the apparent belief in some have that if they cost that much they must be better. For cars of the MGB era and those ignition systems anything other than basic silicone is a waste of money.

There are two basic types of spark plug wires-copper and silicone. The copper wires are great for conducting the high voltage current from the coil to the distributor cap and from the cap to the spark plugs. They have a They have a long life and seldom need replacement. When they do, it is normally due to the insulation of the wire breaking down and causing some of the high voltage to leak. In most cases, they will still conduct electricity, but at a reduced voltage. There is only one real problem with copper wires-they create a minor radio transmitter and produce electrical interference with TVs and radios.

To correct this problem, silicone wires were introduced. These wires have some degree of internal resistance which surpasses the radio/TV interference. The silicone wires became more popular back in the late 60s and early 70s as the car producers began to offer more sophisticated radios. FM was becoming popular with the masses as the stations expanded and cassette and eight track tape players became popular. Prior to this time, people with the very expensive (back then) radio systems had to fit resistors to each individual copper wire to suppress radio interference. With the silicone wires, none of this extra suppression was required. The only drawback to the silicone wires was that they wore out. In the early versions, rather quickly. Today, silicone wires, much changed from the earlier versions are the standard. Unfortunately, they still do not last as long as a good set of copper wires and need to be inspected to see if they are functioning properly.

The first step in inspecting the wires (of both types) is to check to see that they are clean. Dirty build up on the exterior of the insulation may allow some of the current to be lost. It can also speed the breakdown of the insulation leading to current leakage. Examine each wire and, if dirty, clean with either waterless hand cleaner or dish washing detergent. Dry and wipe clean before reinstalling. It is best to remove one wire at a time to prevent mixing them up. Most old hands will be able to install the wires on a bare cap and get them in order with no problems. But, we all make the rare mistake and doing one wire at a time will help to keep the mistakes rare.

The next thing to check is that the ends of the wires are firmly attached to the spark plugs, the distributor cap and the coil. Four cylinder, in line engines are not the smoothest running of beasts and, sometimes, a wire will work its way loose. This is especially a problem at the cap, but Bob and Gil found two wires loose at the spark plugs on two different cars when they were helping me a couple of weeks ago. Always check to see that all connections are properly seated.

The next test requires darkness. You need to start the car with the hood open and run it while looking for blue sparks off the wires or a blue glow surrounding them. This indicates the current is leaking through the insulation and the full current is not being carried to the distributor cap and then to the spark plugs. In really bad cases, this can actually light up the right side of the engine compartment. WARNING: It is dangerous to work around the engine compartment in the dark with the motor running. Put your hands in your pockets when performing this inspection and do not take them out until you are ready to turn off the engine. Running the car in the garage will help to cut down the ambient light, but make sure the door is open to prevent the build up of carbon monoxide.

If you see blue sparks, you need to replace the wires with a good quality set of replacement wires. The ones by Robert Bosch seem to fit the B very well and last well. They are available from BAP and other sources. One problem with the silicone wires is that they do not work well with the screw in, side terminal caps on the Mark I cars. This is not a significant problem. If it is a show car, get the copper wires, which were originally correct for this model. If it is not a show car, the 68-74 distributor cap will fit the distributor and allow you to use silicone wires that push into it. You will also need to install a different coil, one with the push in style terminal, but this would be a good time to install a Lucas Sports Coil anyway, right?

If the car seems to be running well, this is all the testing you need to do. If, however, you seem to have a miss, there is one further test you can run. This requires an ohm meter. An ohm meter measures resistance and is normally a feature found on volt meters. In fact, most volt test meters are actually Volt-Ohm Meters (VOMs). Good quality analogue meters may be had for under $20 at Radio Shack and other sources. Some dwell/tach meters also have a volt and ohm feature. I prefer to have a separate VOM as it allows me to do tuning using both the dwell/tach and the VOM when necessary.

The first thing to do is turn on the meter and set it to ohms or resistance function. Then, touch the two probes together and watch to see the meter's needle swings to zero. This shows that there is zero resistance as it should be. Some of the more expensive meters have a zero function where the probes must be held to zero and the scale adjusted to zero. The less expensive models do not have this feature and it is not needed for this type of work. Having confirmed that the meter is working properly, remove the distributor cap from the car, having disconnected the spark plug wires from the plugs and the coil wire from the coil. A small piece of masking tape on each wire with the number of the cylinder the spark plug wire came off of makes reattaching easy.

Then, take one probe and stick it into the spark plug end of the wire. You can probably insert it between the metal terminal and the boot to hold it in place. Then, you touch the probe to the terminal inside the distributor cap. This tests both the cap and the wire. Make a note of the resistance reading, then check the other plug wires in the same manner. Finally, check the coil wire from the end that goes into the coil to the carbon brush in the top, center of the cap. All of the spark plug wires should have about the same resistance. If one is very much lower or higher than the others, the set may need replacing. If one shows infinite resistance, the set may need replacing. How to determine whether it is a wire or a cap problem?

Simple. Remove the wire showing the infinite or high resistance from the cap and measure it again. If it now shows resistance similar to others, it is a problem with the distributor cap. Firmly seat the wire again into the cap, making sure it is fully engaged and check again. If it still shows a problem, the cap is at fault. If, however, when you test the wire by itself, it shows high or infinite resistance, the wire is bad and the set should be replaced. This is where the “lifetime warranty” pays for itself. Take the wires back and exchange them for another set. I go one step further and keep a spare set of wires on hand and, when I need to exchange them, install the spare set and return the old set in the box.

The final question is how long will the silicone wires last. The best examples may do as long as three to four years. Often, however, the Arizona heat and high under hood temperatures will have them breaking down in two years or so. Testing the wires while doing a tune up only takes a short time. Good wires will give better fuel economy, reduce pollution and not leave you stranded when the car does not start. Time well spent.

This article is copyright 2001 by Les Bengtson and may be reproduced for personal use as long as the copyright and authorship is acknowledged. Please direct any questions to: ragnar@aztec.asu.edu.

My own experiences: In 1973 I bought a new Morris Marina, and ran it for six years. That came with original carbon-string leads of course, and after a few years I started getting ignition problems, checked the resistances and they were all over the place. So I bought a set of silicone-cored from Halfords and had no more problems. When I bought the roadster in 1990 the plug leads were a mixture, so I bought a set of silicone again from Halfords. Many years later one day it wouldn't start, and after some time I found it was because the brass connector at the coil end of the king-lead had some kind of blue coating, that I couldn't scrape off, and seemed to be acting as an insulator, so I bought a new set and since then they have been fine.

When I got the V8 in 1994 again it had a mixture of leads, I enquired of the MGOC and was surprised to discover they had the original carbon string type, even more surprised to discover they were dearer than the silicone equivalents, and bought the silicone. Try as I might and no matter which way round I connect the leads, the best I can end up with is one on the left bank slightly shorter than really it should be, although it is just about OK taking a direct run at the plug. It does however mean that the leads in the combs are not strictly in the correct order. The other problem is that because the distributor is at the top of the engine, and canted sideways, the leads feeding the right bank run closer to the bonnet than the left bank. The original leads had right-angle connectors on all the right-bank leads which keeps them low enough, but the new ones are all straight, turn back on themselves and are pressed up against the bonnet which I don't like. However amongst my many retained bits I have four right-angle connectors, the leads push into those, and they push onto the cap so all is hunky-dory. And after (currently) 29 years and 100k+ miles they still look and work as good as new.

When I got the V8 in 1994 again it had a mixture of leads, I enquired of the MGOC and was surprised to discover they had the original carbon string type, even more surprised to discover they were dearer than the silicone equivalents, and bought the silicone. Try as I might and no matter which way round I connect the leads, the best I can end up with is one on the left bank slightly shorter than really it should be, although it is just about OK taking a direct run at the plug. It does however mean that the leads in the combs are not strictly in the correct order. The other problem is that because the distributor is at the top of the engine, and canted sideways, the leads feeding the right bank run closer to the bonnet than the left bank. The original leads had right-angle connectors on all the right-bank leads which keeps them low enough, but the new ones are all straight, turn back on themselves and are pressed up against the bonnet which I don't like. However amongst my many retained bits I have four right-angle connectors, the leads push into those, and they push onto the cap so all is hunky-dory. And after (currently) 29 years and 100k+ miles they still look and work as good as new.

However in September 2018 someone was asking about resistance of plugs and leads and whether they could be causing a misfire on cold starts, so I did some research into lead resistance. Various Google sources indicated about 6k to 8k per foot, and checking one of Bee's and Vee's longest one out of interest that proved to be the case. But checking Vee's coil lead i.e. the shortest it was 80k! As there is no sign of running problems at the very least it indicates that resistances as high as this are not necessarily going to cause a problem. I do need to replace it, but checking the other leads they are all in the range of 10k to 23k and vary hugely in length so they seem OK. Whilst you can get a set for £17, you can also pay up to £100. But after the problem with one lead being a bit shorter than ideal, and not having the correct right-angle connectors for the right bank, I'm in no rush to change all of them unless I have to, and have had a single lead made to order. In the meantime I've modified the 'old' roadster No.4 lead (8k) which is only slightly shorter than the V8 coil lead and fitted that, and when the new lead arrived I opted to carry the removed V8 lead just in case of problems. Incidentally, I had the new lead made the same as the old i.e. with straight connectors each end. Right-angle connectors were available at no extra cost, and it was only afterwards I realised that not only do they result in a better fit for the coil lead, but looking at various sets for the V8 that seems to be how it should be! Oh well.

V8:

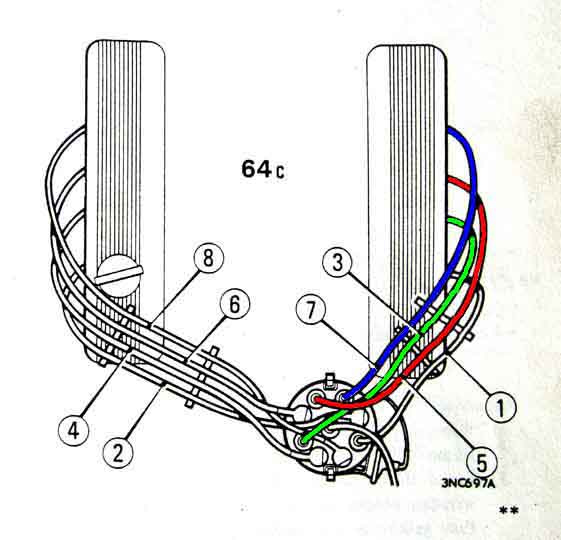

The other thing to be aware of on the V8 is that cylinders 5 and 7 are next to each other in the firing sequence as well as being next to each other on the engine, and at the back so the leads are quite long and run parallel to each other. The factory seems concerned that the firing of 5 could induce enough voltage into lead 7 to initiate premature firing of that cylinder, so show the two leads 5 (red) and 7 (blue) being separated in the combs by lead 3 (green), as shown here.

The other thing to be aware of on the V8 is that cylinders 5 and 7 are next to each other in the firing sequence as well as being next to each other on the engine, and at the back so the leads are quite long and run parallel to each other. The factory seems concerned that the firing of 5 could induce enough voltage into lead 7 to initiate premature firing of that cylinder, so show the two leads 5 (red) and 7 (blue) being separated in the combs by lead 3 (green), as shown here.

Ignition Switch Removal

Ignition/Steering Lock

North American 'Key in' Warning

Ignition Keys

Types used:

| May 62 - Nov 67 | Mk1 | When no steering lock provided | 13H337 | Spades on switch

| Nov 67 - Dec 70 | Mk2 | When no steering lock provided | 13H926 | Spades on switch

| Dec 70 - Feb 72 | 230617-275645 | Not North America | BHA5709 | Use BMK2259 | Combined lock and switch

| Feb 72 - Sep 74 | 275646-361000 | As above | BHA5215 | 37H7708 | Use BMK2259 | Spades on switch

| May 62 - Sep 74 | 101-361000 | As above | BMK2259 | 37H5934 | Spades on switch

| Sep 74 - end | 360301-on | As above | BHM7056 | BHA5398 | Note 1 | Lock with switch, multi-plug

| V8 | 18G8905 | Note 2 | Lock with switch, bullets

|

| May 62 - Aug 68 | 101-152454 | Sweden, Germany, Finland (Oct 67), Austria (Jan 68) | 13H4180 | 27H6237 | BMK2259 | Spades on switch

| Aug 68 - Dec 70 | 152455-231338 | Above plus France (Sep 69) | 13H4862 | 27H6237 | Use BMK2259 | Spades on switch

| Aug 68 - Dec 70 | 152455-231338 | As above | 13H4862 | 27H6237 | BMK2259 | Spades on switch

| Nov 67 - Sep 69 | 138401-187840 | North America | BHA4715 | 37H4114 | Lock and switch NLA

| Sep 69 - Aug 71 | 187211-258000 | North America, Sweden (Dec 70) | BHA5050 | BHA5056 | Alternatives | Lock and switch NLA

| Aug 71 - Aug 72 | 258001-296000 | As above | 18G8906 | Combined lock and switch

| Sep 69 - Aug 71 | 187211-258000 | As above | 18G8901 | BHA5070 | Lock and switch NLA

| Aug 71 - Aug 72 | 258001-296000 | As above | 18G8905 | BHA5070 | Lock with switch, bullets

| Aug 72 - Aug 73 | 294251-324942 | As above | 18G8984 | BHA5128 | Bullets on wires

| Aug 73 - Aug 73 | 324943-325855 | As above | 18G9064 | BHA5288 | Lock and switch NLA

| Aug 73 - Aug 73 | 325856-328800 | As above | 18G9118 | BHA5288 | Lock with switch, multi-plug

| Aug 73 - Jun 76 | 328110-410000 | As above | 18G9119 | BHA5292 | Multi-plug

| Jun 76 - end | 410001-on | As above | 18G9119 | BHA5069 | Multi-plug

| | ||||||||||||||||||||||||||||

Note 1: Switch no longer available, use BHA5292. This is the North American switch with extra grey and purple/pink wires, the original switch may have the grey but not the purple/pink. The remaining four wires should connect directly to the same colour wires in the main harness, but double-check before plugging in. The grey and purple/pink should not have corresponding wires in the other half of the multi-plug.

Note 2: Prices for replacement lock with switch for the V8 varies from £31 to £120! If only the switch has failed it may be worth trying BHA5292 as they can be had for little more than a tenner, and if it fits it saves having to cut off the lock which cannot be done by drilling up from below like it can with the earlier side-entry locks. You would need to cut off the multi-plug, discard the grey and purple/pink wires, and solder bullets to the remaining brown, white/green, white and white/red wires.

Dash type is easy with just the usual locking ring. When associated with a steering lock the switch seems to be held in the lock body with a small screw, the type and position of which varies depending on the type of lock.

Dash type is easy with just the usual locking ring. When associated with a steering lock the switch seems to be held in the lock body with a small screw, the type and position of which varies depending on the type of lock.

Ignition Theory See also these pages from Tjellvar Harbom in Sweden and this document from Frodo Irrxsom in Norway (must be those long winter nights ...)