Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

Cooling System

|

September 2023: A forum post from someone experiencing idle temps at the top of the gauge and wondering if a shroud would help. Before doing that he fitted a 7-blade fan, but then checked the timing and found it to be 0 degrees TDC! Since doing both idle temps are closer to the middle of the gauge and - surprise surprise - performance is better! If you think you have a problem always check the basic stuff first before throwing parts at it.

Gasket sealants - don't use silicone-based as they 'go off' very quickly and on large areas will 'skin' before you can get the surfaces together and not spread out to an even thin coating. Use something non-hardening such as Loctite MR5922, and only a thin smear. Great gobs of it will get extruded out into the works and in the screw holes can rip paper/card/cork gaskets as they are tightened. Overtightening screws can cause covers to warp between adjacent bolt holes and leak more, check they are flat before fitting.

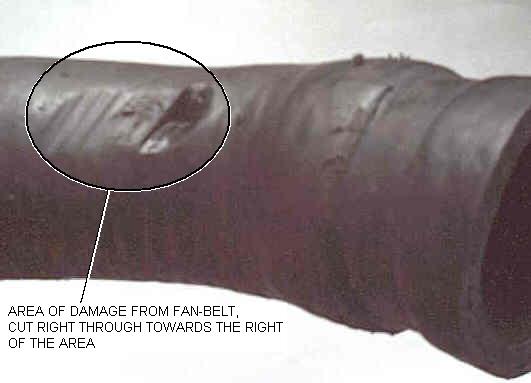

Don Hayter in his 'MGB Story' writes that the radiator was moved forward in 1977 as a result of the American Government Department buying and testing a 1975 MGB. The vehicle was used in a 5mph barrier test which it failed, to such an extent that the engine had moved forward during impact and the fan had damaged the radiator, potentially causing a leak, despite similar factory testing not showing up the problem. Nevertheless they had to do something about it "so moved the radiator forward to the 'C' and V8 position with electric fans, thus obviating the old engine-mounted fan, and we added an engine restraint bar from the gearbox bellhousing bottom to the chassis crossmember for all future cars". He shows a picture of the 77 and later engine bay captioned !MGB engine with radiator moved forward position in order to pass American 5mph barrier test". From the Parts Catalogue Mk1 roadsters had their own restraint rod, GTs and Mk2 cars not having one until Feb 74. So whilst it seems likely that the later restraint rod was as a result of the failed test, that would have been enough to pass future tests, and the radiator wasn't moved forwards until 1977, probably for other reasons.

Clausager also writes that the V8 is of the 'new, more efficient cross-flow type' but this is incorrect. It uses the same arrangement of vertical tubes and top and bottom tanks as both 4-cylinder radiators albeit with a remote expansion tank in place of the larger header tank of the pre-77 4-cylinder. 77 and later MGBs used the same system. (FWIW the Midget 1500 radiator is cross-flow with end tanks rather than top and bottom tanks).

The vast majority of the temp gauge movement range represents 'normal' conditions, not just right over the 'N' of later gauges/middle of the earlier gauges. Anywhere from just outside the 'C' zone to just outside the 'H' zone is 'normal', running nearer to 'C' or the lower end in very cold weather, or nearer to 'H' or the upper end in hot weather and high loads. But if you find the temp gauge reaches the edge of the 'H' zone under conditions of high load it may be time to back-off or stop for a while. Raise the bonnet (put embarrassment to one side) and leave the engine idling to keep the coolant circulating (under extreme conditions heat-soak on switch off could cause a boil and coolant loss), but DO NOT attempt to remove the radiator cap until the engine has cooled significantly or you are likely to explosively boil all the coolant out and scald yourself. Under more normal conditions if you find it barely gets off 'C' or the lower end then the thermostat may be stuck open. Conversely if you find the temp gauge reaches the H zone in other than very hot weather or high loads the thermostat may be stuck closed, or the engine is producing more heat than it should, or the radiator isn't dissipating as much heat as it should, then again it's time to investigate.

It's normal for the temp gauge to fluctuate slightly during warm-up (it varies from car to car) as the coolant gets up to temperature and the system reaches equilibrium due to the characteristics of the thermostat and gauge, but if you find it starts swinging wildly at any time it can indicate a head gasket problem and should be investigated.

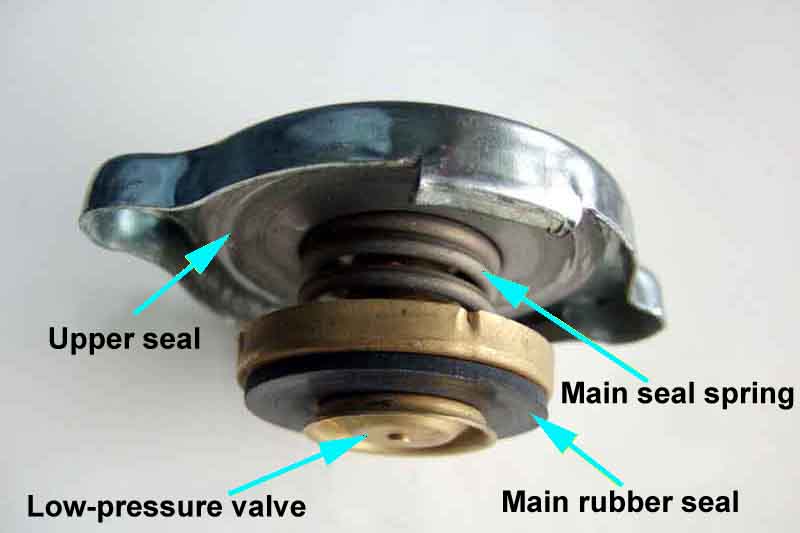

Likewise if you hear hissing from the area of the radiator cap at any time (best heard by getting the engine up to temperature then switching off) a problem is indicated. When starting an engine from cold the coolant warms up, expands, and raises the pressure in the cooling system. Under normal circumstances this will only be a few pounds and well below cap pressure, so nothing escapes from the cap or anywhere else. Then when you switch off the system cools down again and the pressure reduces back to zero. But if the cap is not holding the correct pressure, or the cooling system is being 'pumped-up' by a leaking head gasket or other problem, you will get hissing. If you put the bottom of the overflow pipe in a container with a little water you may see bubbles, but this needs the upper seal on the radiator cap to fully seal to the top of the radiator neck. In either case you may well find the hissing stops after a minute or so, then after a short pause starts hissing again but sounding different. This is air being sucked back in to the cooling system as the system cools and the coolant contracts, to replace that which has been lost, and will suck water up from your container. Fitting a new cap is probably the easiest and cheapest thing to do first, but if it continues with a new cap then you should do a combustion leak check (for a faulty head gasket or cracked head) and pressure check (for other causes) to see just what is happening.

Temperatures

V8 coolant level warning

Never ever mix traditional glycol-based anti-freeze with modern OAT (Organic Acid Technology) fluids or a green crystalline sludge forms blocking coolant passages and causing overheating, which can take a lot of chemical and water flushing to get rid of (Image from John Maguire in Oz). Also see this. Unfortunately coolant manufacturers make life complicated by not sticking to one set of colours for glycol-based and another for OAT-based, made worse by old-style glycol-based now being described as 'Inorganic Additive Technology' or IAT i.e. using a very similar description indeed for something which is completely different. However some manufacturers use 'silicate' for glycol-based which is a bit easier to remember.

Never ever mix traditional glycol-based anti-freeze with modern OAT (Organic Acid Technology) fluids or a green crystalline sludge forms blocking coolant passages and causing overheating, which can take a lot of chemical and water flushing to get rid of (Image from John Maguire in Oz). Also see this. Unfortunately coolant manufacturers make life complicated by not sticking to one set of colours for glycol-based and another for OAT-based, made worse by old-style glycol-based now being described as 'Inorganic Additive Technology' or IAT i.e. using a very similar description indeed for something which is completely different. However some manufacturers use 'silicate' for glycol-based which is a bit easier to remember.

In the early days of OAT the colours could be used to distinguish - blue and green historically being used for glycol based with OAT using pink and orange. However there are now sub-sets of OAT such as HOAT, P-HOAT and Si-HOAT, using orange, yellow, turquoise, pink, blue and purple. As long as you don't switch from glycol to OAT or vice-versa in modern cars you should be fine. But in a car new to you it may not be obvious what is there already, and I'm not aware of any way of distinguishing between them apart from colour. Any 'extended life', or '10 year', or '300,000 change interval' coolant should be avoided as it will be OAT, unless you put it in a completely dry system and only ever top up with the same type.

I'd heard Prestone Max was compatible with any type of coolant but had my doubts as to whether that included glycol-based/IAT as the ad says "... when a complete cooling system flush and fill is performed" which in itself would allow you to switch between types. However it also says "It mixes and works with all antifreeze + coolant colors and formulations including OAT, POAT, HOAT & IAT" i.e. both OAT and IAT types, so if you are unsure what is in there now (but see the next paragraph) it would be the safest thing to use. I'd always recommend getting the concentrate, there's no point in buying 70% water from a shop, unless perhaps you have very 'hard' tap water.

There are alternatives such as 4-Life and Evans Waterless, which on the face of it seem to offer benefits. In the case of 4-Life it is said to indicate a head gasket leak by changing colour, but on a pals car with a cracked head, compression leaking into the coolant (detected by other means) resulting in coolant loss there was no colour change. And someone on the MGOC forum ran exhaust gas through it which also made no change, but it did through combustion leak detector fluid. Evans Waterless amongst other things is said to reduce system pressures and can't boil, but you need to go through a multi-stage flushing process before using it to replace glycol-based fluids. Both can only be topped-up with the same stuff, which you have to carry around with you, and neither guarantee you won't lose fluid e.g. from hose failure, which given the quality of rubber these days is bound to happen at some time. Both are expensive compared to glycol based concentrates, and personally I can't see any good reason to use them - millions of cars have been running for decades with glycol-based perfectly happily. Neither the 4-cylinder even when run in desert states nor the V8 suffers from cooling system problems, unlike some other marques which are prone to problems even in the UK unless everything is perfect. Peter Burgess specifically states that he won't guarantee his work if an engine is run with Evans Waterless, and "In our opinion using coolants other than water with antifreeze/corrosion inhibitor addition as recommended in the original workshop manual can allow the engine to run too hot and cause problems such as sticking valves and piston damage."

References to demonstrate how varied the information out there can be:

Autoblog

Hemmings

Prestone

Fuel&Friction

Something other than plain water is highly desirable if not essential, to prevent corrosion as well as freezing, and the usual product is a glycol-based fluid that has to be diluted with water. A 25% concentration protects down to -12C, and a 33% solution down to -18C, which is probably good enough under most circumstances. However if yours is a daily driver, then although it is unusual to go below -10C in central England, it did get down to -15C in December 2010, and has been as low as -27C (Newport, Shropshire, 1982).

If you are putting anti-freeze into a system that has previously contained plain water - or even if replacing old anti-freeze with fresh, there is a right way and a wrong way of doing it. DO NOT drain the system, and refill it with an already diluted mix, as many web sources advise. There will be a significant amount of water/old coolant left behind which will dilute your mix even further. There is also no point buying four pints of water in each gallon of ready-mix - certainly for me in a 'soft' water area. Calculate how much anti-freeze is required to give the required dilution, add the anti-freeze neat, then top up with clean water, and you will get the correct mix as a minimum - slightly stronger depending on how much was left in the system. The total capacity of the MGB system according to Haynes is:

If you are putting anti-freeze into a system that has previously contained plain water - or even if replacing old anti-freeze with fresh, there is a right way and a wrong way of doing it. DO NOT drain the system, and refill it with an already diluted mix, as many web sources advise. There will be a significant amount of water/old coolant left behind which will dilute your mix even further. There is also no point buying four pints of water in each gallon of ready-mix - certainly for me in a 'soft' water area. Calculate how much anti-freeze is required to give the required dilution, add the anti-freeze neat, then top up with clean water, and you will get the correct mix as a minimum - slightly stronger depending on how much was left in the system. The total capacity of the MGB system according to Haynes is:

- Early models - 9.5 Imperial pints (5.4 Litres, 11.4 US pints)

- 18V engines, GHN5 and GHD5 from model No. 410002 - 11.5 Imperial pints (6.6 Litres, 13.8 US pints)

- 18V engines 1976 to 78 - 10 Imperial pints (5.6 Litres, 12 US pints)

- All models 1978 onwards - 12 Imperial pints (6.8 Litres, 14.4 US pints)

- All plus 0.5 Imperial pints (0.28 Litres, 0.6 US pints) where a heater is fitted.

Looking around on the internet you will see replacement intervals of 30-60k or 12 years or more quoted, however that will be for modern cars. The Workshop Manual recommends replacement at 2-yearly intervals, and checking the specific gravity at each service. There are testers available from the usual sources for a couple of pounds upwards.

Checking Level: For 4-cylinder cars prior to 1977 this is done at the radiator, be very careful removing the cap when the engine is hot as there is a risk of scalding, especially if the temp gauge is close to or in the H zone/212F/100C. Even when it is showing the normal running temperature use a thick cloth over the radiator cap just in case.

Early radiators are known as 'rear fill' where there is a filler tube that projects back from the header tank then up to the cap. Unfortunately you cannot see the tops of the tubes (which is the minimal level for fluid when cold) with the cap removed, and adding coolant until it is visible in the filler neck may mean you lose some from expansion when the engine gets fully up to temperature, making you think you have a leak. For that reason it is preferable to check the level when the engine is still warm - but not when fully hot! - when it should be just visible in the tube. Later radiators are 'top fill' and the tops of the tubes can be seen when the cap is removed. The WSM says the level should be no higher than 1" below the bottom of the filler neck when hot - i.e. lower than that when cold, so care needs to be taken in removing the cap, only do this if the temp gauge is at its normal running temperature, no higher. On my 73 roadster there is 2" between the top of the tubes and the lowest part of the filler neck (it is angled forwards slightly) so only about 1/2" above the tubes when cold or it is likely to push some out when running and you will be continually topping-up.

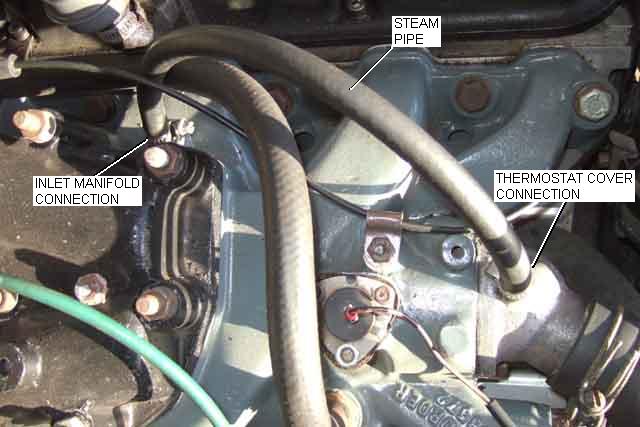

V8s and 4-cylinder cars have a remote expansion tank with a pressure cap, and a filler plug either on the radiator (V8) or thermostat housing (4-cylinder). For checking the level under normal circumstances only the filler cap on the expansion tank needs to be removed, when cold, and the level should be about half-way up. Only if that is empty - listen for gurgling when squeezing the top hose - should you need to remove the filler plug. The design of that system is such that any air in the cooling circuit gets pushed into the expansion tank as the engine warms, together with expanding coolant. When the engine cools it draws coolant back from the expansion tank, replacing any air that was expelled with coolant, which means that the filler plug hole should always have coolant right to the top. Obviously if you find the level in the expansion tank drops significantly from run to run there is a problem which may mean the cooling circuit is not completely full. When draining and refilling these systems the plug will need to be removed and the radiator and engine filled from there, finally topping-up the expansion tank as needed. More on draining and refilling here, and some info on filler plugs here.

Boiling points

Temperature Gradients: Added September 2010

I took the following set of comparative temperatures on the roadster, warming up at a fast idle on a day when the ambient temperature was a cool 9.5C (all temperatures in degrees C):

| 'Inlet' and 'Outlet' are on the header and footer tanks directly opposite the inlet and outlet ports. Note particularly the differential between these two. A large differential here, if your running temps are higher than they should be, can indicate slow flow through the rad. This will allow a lot of heat to be taken out of the coolant that is in the radiator, but not enough heat transfer from the engine to the radiator. This can be seen in the table where the thermostat has just started to open - the head temp only goes up from 90 to 92, the rad inlet jumps from 14 to 55, but the outlet takes longer to start rising at all, and then more gradually anyway. With low circulation the outlet will stay at a relatively low temperature. Low circulation can come from any restriction in the cooling circuit e.g. sludge or thermostat not fully opening, but can also be caused by a problem with the water pump i.e. heavily corroded vanes or even the incorrect pump. A low differential can indicate good flow, but either the engine is generating too much heat (e.g. timing or fuel issues) or the radiator isn't getting rid of it. This latter can be checked by scanning the surface of the rad with an infra-red thermometer looking for spots that are cooler than the surroundings, particularly where cool spots are above hotter areas, but it can also be caused by problems with the fan either of the wrong type, the wrong way round (still flows air through the rad but not as efficiently, or the wrong spacing to the radiator, see the sections on electric and mechanical fans. |

Update July 2013 (phew, what a scorcher):

Quite a few people complain about 'overheating' and ask about installing uprated radiators, and electric fans to cars with mechanical fans. This is very rarely required, especially in the UK. As I say elsewhere these cars run in desert states in standard form without problems and have done so for many years. If your car is running hotter than it should then you need to be considering why, not throwing money and bits at the problem. Firstly, if a car isn't losing coolant, then it isn't overheating. Secondly, anywhere between the upper part of the C zone and the lower part of the H zone (on CNH gauges) is considered 'normal', depending on climate and usage. Consider a car in a temperate climate, pootling along a flat open road, and the temp gauge should be about the middle of it's travel i.e. near the N of CNH gauges.

In the current high temperatures (for the UK) I've been taking some measurements, which may be useful as a comparison if you think you are having problems. On one of several days with an afternoon ambient of 26C, the roadster engine compartment got up to 50C in town traffic after a local run, using a digital thermometer with its probe through one of the holes in the bulkhead shelf. Temp gauge was about an Ns width above its normal position. Rad inlet was 87C, outlet 75C, measured with an infra-red thermometer placed right on the fins. The V8 got up to 58C in town traffic after a motorway run, the rad inlet was 92C, and the outlet was 85C. The temp gauge was in the normal range for when the cooling fans are cutting in and out i.e. between N and about 1/3rd of the way between N and H.

Boiling points by Bob Muenchausen

|

in water at various pressurizations | |||||||

| System Pressure >>> |

|

|

|

|

|

|

|

| Plain Water |

|

|

|

|

|

|

|

| 33% Solution |

|

|

|

|

|

|

|

| 44% Solution |

|

|

|

|

|

|

|

| 50% Solution |

|

|

|

|

|

|

|

| 60% Solution |

|

|

|

|

|

|

|

|

| |||||||

| Pints to add > |

|

|

|

|

|

|

|

| New Freezing Point > |

(8.3%) |

(17%) |

(25%) |

(33%) |

(41%) |

(50%) |

(58%) |

This article is copyright 2000 by Bob Muenchausen and may be reproduced for personal use as long as the copyright and authorship is acknowledged. Please direct any questions to: bobmunch64@yahoo.com.

Draining and Refilling May 2014

Originally rads had a dinky brass tap - later a more functional tap - which probably dates from before anti-freeze when people used to drain the rad each evening in winter and refill with water next morning, although as there is still a significant amount of water remaining in the system it wasn't always proof against block damage. Later rads had a threaded plug, but the problem with those is that unless the threads are lubricated they can seize and you can turn the whole fitting out of the bottom of the rad. Subsequently even that was dropped, presumably as cost-reduction, which means the only way of draining the system is by removing the bottom hose.

Originally rads had a dinky brass tap - later a more functional tap - which probably dates from before anti-freeze when people used to drain the rad each evening in winter and refill with water next morning, although as there is still a significant amount of water remaining in the system it wasn't always proof against block damage. Later rads had a threaded plug, but the problem with those is that unless the threads are lubricated they can seize and you can turn the whole fitting out of the bottom of the rad. Subsequently even that was dropped, presumably as cost-reduction, which means the only way of draining the system is by removing the bottom hose.

That still leaves quite a lot in the block as it will only drain down to the lowest passage which may only be the pump inlet. On 4-cylinder engines this is enough and leaves the coolant level several inches below the top of the block. But it is a problem with V8s as the water pump passages are much higher. Blocks have a drain point as well - on 4-cylinder engines it is just below and to the right of the oil gauge port, originally another tap, subsequently replaced by a plug which is all I have ever seen. Someone wanting to fit a geared starter in place of an inertia unit to an early engine said it either fouled the chassis rail or the drain tap, I suggested he replace the tap with a plug. V8 engines have one each side, relatively central. On mine it is the later more functional tap on the near side, and a plug on the off-side - I discovered why they differ when installing a rebuilt engine to Vee. Having fitted a tap to the off-side as well as the near-side (as I had two available), I found I couldn't fit the exhaust manifold! Fortunately I had just enough room with the engine fitted to remove the tap. I didn't have a plug available as the original was damaged and I couldn't get it out of the old block, but I cut the 'arms' and threaded part off the base that screws into the block - after making sure it was fully tightened - and that sufficed. However, whether you can get anything out of any of the block drains, is another matter altogether. I couldn't from the 4-cylinder or the V8 and this seems very common. Poking in the hole with stiff wire does nothing, and those who have delved into a stripped block say the bottom of the water jacket is choked with something that needs chipping out, probably the original casting sand.

That still leaves quite a lot in the block as it will only drain down to the lowest passage which may only be the pump inlet. On 4-cylinder engines this is enough and leaves the coolant level several inches below the top of the block. But it is a problem with V8s as the water pump passages are much higher. Blocks have a drain point as well - on 4-cylinder engines it is just below and to the right of the oil gauge port, originally another tap, subsequently replaced by a plug which is all I have ever seen. Someone wanting to fit a geared starter in place of an inertia unit to an early engine said it either fouled the chassis rail or the drain tap, I suggested he replace the tap with a plug. V8 engines have one each side, relatively central. On mine it is the later more functional tap on the near side, and a plug on the off-side - I discovered why they differ when installing a rebuilt engine to Vee. Having fitted a tap to the off-side as well as the near-side (as I had two available), I found I couldn't fit the exhaust manifold! Fortunately I had just enough room with the engine fitted to remove the tap. I didn't have a plug available as the original was damaged and I couldn't get it out of the old block, but I cut the 'arms' and threaded part off the base that screws into the block - after making sure it was fully tightened - and that sufficed. However, whether you can get anything out of any of the block drains, is another matter altogether. I couldn't from the 4-cylinder or the V8 and this seems very common. Poking in the hole with stiff wire does nothing, and those who have delved into a stripped block say the bottom of the water jacket is choked with something that needs chipping out, probably the original casting sand.

Cars with mechanical fan: I can't remember ever removing the bottom hose on Bee over the 25 years I've had her until I needed to replace the thermostat, and hadn't appreciated just how awkward it is to get it off the rad. You do not want to completely remove it while under the car as coolant goes everywhere, but you will have to undo the clamp and get the hose moving on the rad port at the very least. Then from above you will need to pull the hose upwards, which means folding it to some extent, and it will probably come off all of a sudden. It's easier to remove it from the pump first, then pull it up, but that means coolant going everywhere twice. With old hoses that have hardened you may have to do it this way anyway. However the bottom hose that came with Bee 25 years ago is still supple and crack-free, which is more than can be said for the other hoses that I've had to replace on both cars over the years. I found the least-messy way of draining Bee was to wedge a sheet of card or similar under the bottom hose connection to the rad, over a bucket. Slacken the hose clip and wiggle the hose or wedge a blunt screwdriver in until coolant starts trickling out, then leave it to drain while you get on with something else.

Cars with electric fans including V8: Much easier as there is more space to get at the hose, and direct it into a container, it's also a straight pull backwards so no folding of the hose required.

When refitting bottom-hoses on the mechanical fan cars and the V8, great care needs to be taken with positioning, as described here.

Refilling has its own considerations and pit-falls. When using glycol-based antifreeze that comes as a concentrate, to get the correct ratio you should add the required quantity of neat glycol to the drained system, then add water to fill the system. Unless the engine and heater are completely dry, as after a strip and rebuild, there will always be some old coolant left behind. If you simply refill with dilute anti-freeze, then whatever is remaining in the engine and heater will dilute it still further. The total capacity seems to have changed several times over the years, see here. How you get on with replacing glycol with ForLife I don't know, but I do know that with Evans waterless you have to go through several flushing cycles first.

For the first start after refilling you can get very different results depending on what thermostat you have, which unless you have changed it will be an unknown quantity. Unless you have a thermostat with one of the self-bleeding functions the thermostat will trap a large volume of air under it until it opens. When this happens the level in the radiator will drop like a stone, so you will have to leave the cap off watching the level, and have a kettle-full of hot water to hand to top-up. When I refilled with a non-bleeding thermostat I only got the required amount of concentrate in, i.e. just under 2 litres, and that brought the level up above the tubes. When the stat started to open and the level dropped I had to add over a litre of hot water to get it above the tubes again. If you have a self-bleeding stat you will be able to put at least 1 litre of cold water in as well as the concentrate to half fill the header tank before starting the engine.

Once the thermostat fully opens it may then drop more slowly as it purges itself, so you can trickle some more water it to keep the level visible. The heater valve should be open, and ideally the nose of the car higher than the rear to aid purging. Check the level again when cold and top-up with plain water, it may need a couple of heat/cool cycles to fully purge itself. After that, any topping-up required should be done with the required dilution, I keep a 2 litre container of ready mixed for this.

Bee has the mid-era top-fill rad so it is easy to see the coolant level, and top up while running. On the earlier rear-fill rads you can't see the tubes so will have to maintain the coolant to just above the bottom of the filler elbow. If done cold this can chuck some out, not so if checked warm, but be careful removing the rad cap if hot. Herb Adler added a catch bottle to his as described here. The remote expansion tank on 77 model year on cars and V8s can't be used to fill the system. 4-cylinder cars have a fill plug on top of the thermostat housing but this is somewhat restricted and it takes ages to get the coolant in. It is recommended that the top hose is disconnected from the thermostat housing, slackened at the radiator, and turned upwards so coolant can be poured in until it comes out of the thermostat elbow. However this will only fill to the bottom of the hose connection on the elbow, so refit the hose and top-off via the fill plug otherwise there will still be quite a bit of air to be purged and backfilled from the expansion tank and may take a couple of goes. V8s have a plug on top of the radiator which makes life easy. But both of these only fill the radiator, there will still be a large amount of air trapped below the stat if that isn't self-bleeding. The V8 fill port can be used to observe the level, and the sudden drop and consequent topping-up with hot water, but I suspect the 4-cylinder thermostat housing fill port could well overflow with hot coolant from pump pressure and flow as the thermostat opens.

The filler plugs on 77 and later 4-cylinder thermostat housings and V8s are ARA2634 with O-ring TRS1418. The plugs were originally plastic, brass are available, but I've not had a problem with the plastic, and a benefit is that I've fitted a probe in the plastic plug to monitor coolant level. One problem I have had though is with the O-ring under the plug, which I found being squeezed out even with what I felt was a 'normal' tightening force. Looking around for something that could be used as a retaining ring, a section out of an old alloy vacuum cleaner nozzle was a perfect fit.

The filler plugs on 77 and later 4-cylinder thermostat housings and V8s are ARA2634 with O-ring TRS1418. The plugs were originally plastic, brass are available, but I've not had a problem with the plastic, and a benefit is that I've fitted a probe in the plastic plug to monitor coolant level. One problem I have had though is with the O-ring under the plug, which I found being squeezed out even with what I felt was a 'normal' tightening force. Looking around for something that could be used as a retaining ring, a section out of an old alloy vacuum cleaner nozzle was a perfect fit.

Motor

Fan blades

Fan fusing

V8 fan cycling

Take the fan load off the battery when cranking

After-market

July 2018:

4-cylinder cars from 1977 had electric fan(s) - one for the UK but two for other markets. It was always powered from an inline fuse under the fusebox with a white/brown one side and green the other. From some time in 1978 UK cars had a second in-line fuse with those colours, but the fan fuse has thicker wires. The thermostatic switch pushes into a seal at the top of the radiator. These were switch URP1126 with seal URP1027, and connection to the switch was via a 2-pin plug with pin connectors. Some have popped out under pressure but it can't be very common. In January 1980 between roadster chassis numbers 509502 (Federal LE, 511250 RHD, 511291 rest of US and Japan) and 512408 (all GTs) the switch was changed to KTP9003, seal KTP9005 and came with a spring-clip KTP9006 to hold it in. This switch uses spade connectors. Clausager writes that the radiator header tank was changed to suit which implies the two are not interchangeable, but suppliers only seem to show one 'standard' part number for the radiator so perhaps not. I don't know whether the later clip fits the earlier switch (the later switch would need a wiring change) but John Pinna has shown how the top hose clip can be positioned behind the switch to hold it in.

4-cylinder cars from 1977 had electric fan(s) - one for the UK but two for other markets. It was always powered from an inline fuse under the fusebox with a white/brown one side and green the other. From some time in 1978 UK cars had a second in-line fuse with those colours, but the fan fuse has thicker wires. The thermostatic switch pushes into a seal at the top of the radiator. These were switch URP1126 with seal URP1027, and connection to the switch was via a 2-pin plug with pin connectors. Some have popped out under pressure but it can't be very common. In January 1980 between roadster chassis numbers 509502 (Federal LE, 511250 RHD, 511291 rest of US and Japan) and 512408 (all GTs) the switch was changed to KTP9003, seal KTP9005 and came with a spring-clip KTP9006 to hold it in. This switch uses spade connectors. Clausager writes that the radiator header tank was changed to suit which implies the two are not interchangeable, but suppliers only seem to show one 'standard' part number for the radiator so perhaps not. I don't know whether the later clip fits the earlier switch (the later switch would need a wiring change) but John Pinna has shown how the top hose clip can be positioned behind the switch to hold it in.

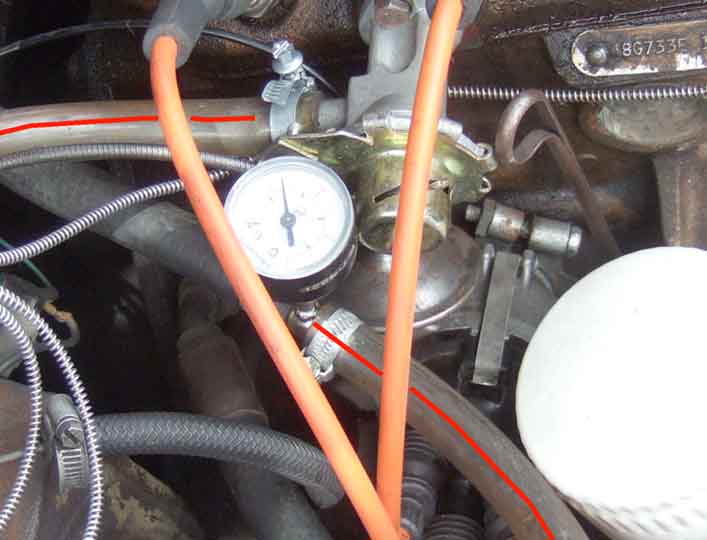

The V8 always had twin cooling fans with a switch in the top of the inlet manifold. This switch (BHA5252 with cork gasket) has a single spade and uses the earth from the inlet manifold to operate a relay to power the fans.

The V8 always had twin cooling fans with a switch in the top of the inlet manifold. This switch (BHA5252 with cork gasket) has a single spade and uses the earth from the inlet manifold to operate a relay to power the fans.

Note: The 1977 LHD Workshop Manual AKM3524 in section 10 Maintenance states that 'the cooling fans on Catalytic Converter equipped cars can operate when the ignition is switched off'. Presumably this would be to reduce heat-soak from the cat affecting the carb, but it isn't depicted in the 1978 LHD wiring diagrams.

Also under 'Radiator cooling fan(s)' it gives the 'light running current (less fan)' as '3 amps (maximum) at 13.5v'. Whether that is per motor or not I don't know, but 13.5v certainly implies the engine is running and the alternator is charging. North America had twin cooling fans like the V8, and I have measured those at 10 amps - both running, fans fitted and engine running. 3 amps for a single motor without fan seems much too high to me, when for the starter motor the loaded current is nearly 8 times more than the unloaded current, but would be pro-rata for both motors running without fans. However in the Cooling section it describes testing a single motor.

My V8 cooling was always a bit marginal in that the temp gauge was higher in hot weather than I would have expected. And although I have a high-efficiency rad (replaced the old one when it had successive leaks, looks the same but has 25% more tubes) which improved matters slightly I was on the lookout for a bit more.

I also decided to investigate the voltages in the fan circuit as they draw a high current and any resistance in wiring and connectors causes a significant volt-drop. I was quite surprised to find I was losing 0.3 volts in various connectors in the brown circuit, 0.8 volts in the relay, and 0.7 volts in the earths - nearly two volts altogether. A PO had added some crimped connectors in the brown circuit and omitted to solder them so I rectified that, the relay was also getting very hot in use so I replaced it, and I added some earths from the fan connectors to terminals bolted between the fan brackets and the bonnet slam panel. Got rid of most of the volt drops (some in the wiring is inevitable) and the fans are now audibly faster and cool quicker.

I have also been looking at the possibilities of fitting some additional puller fans - they would have to be very slim and of a small diameter to clear the water pump. However, after having seen some fans of this type used in pusher mode I am very unimpressed. Despite having a shroud I don't think they are as effective as the factory fans, which really is saying something. The most noticeable difference is just how long the fans continue to spin after the power is switched off, which says to me they aren't pumping very much air, backed up by feeling how much (little) air is pumped through the rads when they are running. They have 'spiral' blades, which one fan manufacturer claims they tried, and promptly dumped them. At a minimum of £60 each I think I'll give them a miss and look further at fitting shrouds to the existing fans.

The latest enhancement was to run a heavy-gauge brown wire from the unused output spade on my alternator direct to the fan relay, which happened to have a second spade on that terminal, and effectively creates a 'ring main' for the brown circuit. This has made another notable improvement in fan speed and rate of cooling, subsequently I shut it in the garage (exhaust piped outside) on a 30 degree day and left it fast-idling to see what happened. The air going into the grill was being recirculated from the engine bay rather than being 'fresh' air at ambient and actually got up to 41 degrees, but still the temp gauge never got more than two-thirds the way from N to H. Travelling through France to LeMans and back in 2002, which was very warm, I was able to keep the needle on Normal at all times even in the hottest conditions. Auxiliary fans/shrouds no longer required.

Fan fusing October 2017

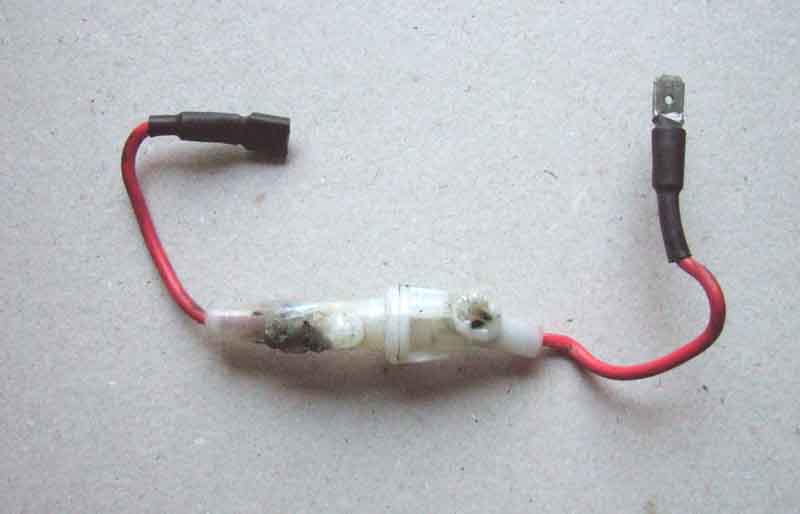

The wiring diagrams show 4-cylinder cars electric fans having their own in-line fuse under the fusebox - white/brown to green, one of two for RHD cars from 1978 on. However somewhere I've seen reference to a thermal cut-out rather than a fuse for North America, and this eBay offering from Oz shows just such a device with stud connections. The part number quoted is of the form typically used by Moss US, but Googling that throws up no other references. However Googling variations of the description came up with this forum post that shows two cars with the thermal device, albeit with spade connections.

The wiring diagrams show 4-cylinder cars electric fans having their own in-line fuse under the fusebox - white/brown to green, one of two for RHD cars from 1978 on. However somewhere I've seen reference to a thermal cut-out rather than a fuse for North America, and this eBay offering from Oz shows just such a device with stud connections. The part number quoted is of the form typically used by Moss US, but Googling that throws up no other references. However Googling variations of the description came up with this forum post that shows two cars with the thermal device, albeit with spade connections.

V8s originally used the main green fuse in the fusebox. There is a fan relay, but it is a three-terminal device which results in both relay and fan current coming from the main green circuit. But so does HRW current and all the ignition powered stuff, which meant that without an ignition relay you could easily have more than 20 amps flowing through the ignition switch and the green-circuit fuse in the fusebox. Vee, and I have seen it on another example so it may have been a retrospective factory mod, has a four-terminal relay with the fan supply coming from a tee off the brown circuit at the fusebox. So only the relay current comes off the fused green circuit, the fan load is direct off the brown, so not fused!

I wasn't happy with that, especially after I boosted the current-carrying capacity of the circuit which significantly boosted fan performance, so I added an in-line fuse, with male and female spades on the fuseholder wires to make it 'plug compatible' with the existing wiring and relay and easily reversible. Originally a 'recycled' blade-type fuseholder with rubber cover I happened to have in my stock of bits with a 15A fuse (Halfords only had 6A in standard glass-type available). But with contacts that were less than perfect I discovered that the plastic body of the fuse had melted in normal use, so 18 months ago I got some 20A in-line fuse holders with fuses and wired one of those in.

I wasn't happy with that, especially after I boosted the current-carrying capacity of the circuit which significantly boosted fan performance, so I added an in-line fuse, with male and female spades on the fuseholder wires to make it 'plug compatible' with the existing wiring and relay and easily reversible. Originally a 'recycled' blade-type fuseholder with rubber cover I happened to have in my stock of bits with a 15A fuse (Halfords only had 6A in standard glass-type available). But with contacts that were less than perfect I discovered that the plastic body of the fuse had melted in normal use, so 18 months ago I got some 20A in-line fuse holders with fuses and wired one of those in.

That showed no heat damage after several months, but shortly after her restoration, in a busy car-park looking for a space I noticed the fan tell-tale was on, but I couldn't hear the fans. Fortunately I soon found a space, and could get the bonnet up - to find a melted fuse-holder! Unplugged it and tapped the wire directly onto the relay, and one fan burst into life but the other didn't, which made me think it had seized - which happened to the other fan many years ago. However when I removed the wire I noticed the non-moving fan moved slightly, and looking closer saw that my emergency bonnet release cord had somehow got onto the radiator side of one of the blades and was stopping it spinning. Moved that out of the way, reconnected the fan wire, and both fans burst into life, with the stalled one apparently working normally. That started me thinking. I've had this cord in place for years, and this hasn't happened before, and I couldn't really see that the action of the fan could suck the cord over the blade anyway. The only alternative is that I inadvertently ended up with it on the wrong side when I refitted it. But that would mean that fan had been stalled for 500 miles of running-in, over a dozen or so trips, with plenty of fan operation in traffic, and especially when I left it idling for quite a long time after first replacing running-in oil with 20W/50 to check the effect on oil pressure, and I'm sure I would have noticed if only one of the fans was running then. So, a mystery that will probably never be solved.

That showed no heat damage after several months, but shortly after her restoration, in a busy car-park looking for a space I noticed the fan tell-tale was on, but I couldn't hear the fans. Fortunately I soon found a space, and could get the bonnet up - to find a melted fuse-holder! Unplugged it and tapped the wire directly onto the relay, and one fan burst into life but the other didn't, which made me think it had seized - which happened to the other fan many years ago. However when I removed the wire I noticed the non-moving fan moved slightly, and looking closer saw that my emergency bonnet release cord had somehow got onto the radiator side of one of the blades and was stopping it spinning. Moved that out of the way, reconnected the fan wire, and both fans burst into life, with the stalled one apparently working normally. That started me thinking. I've had this cord in place for years, and this hasn't happened before, and I couldn't really see that the action of the fan could suck the cord over the blade anyway. The only alternative is that I inadvertently ended up with it on the wrong side when I refitted it. But that would mean that fan had been stalled for 500 miles of running-in, over a dozen or so trips, with plenty of fan operation in traffic, and especially when I left it idling for quite a long time after first replacing running-in oil with 20W/50 to check the effect on oil pressure, and I'm sure I would have noticed if only one of the fans was running then. So, a mystery that will probably never be solved.

It all started me thinking about current, and whether I should fit a fuse that would blow in the event of a stalled fan. Measured the current with both fans running with a stopped engine (12v) and it was very nearly 10 amps. Stalled one of them and it went way over 10 amps, but as my meter only reads to 10 amps I was none the wiser. So took the grille off and unplugged one of the fans, and measured the other at 5.5 amps running (that's higher than half the current from two fans, but is down to how inevitable connection and wiring resistances interact with voltage, current and heat, and especially how electric motor current varies with voltage and speed of rotation, all too complex to go into here). Checked the current with the remaining fan stalled, and it was still over 10 amps. Measured the resistance at 0.8 ohms for each motor, which means a stalled motor will take 15 amps at 12v and 18 amps at a charging voltage of 14.5v! Add to that more than 5 amps from the remaining motor still running, and you get well over 20 amps i.e. more than the rating of the fuse and the fuseholder. That's theoretical, as again we are into the realm of how current, heat, and resistance interact and the greater the current you try to draw the more the resistance goes up which tends to limit the current. Looking at the fuse holder the damage has occurred where the terminals on the ends of the wires were in contact with the ends of the fuse. Which shows they were the point of greatest resistance, and hence where volt-drops were occurring, and consequently heat. Both fuse and holder were 'new', so should have been clean. The wires themselves were undamaged, as was the fuse, albeit with the strip discoloured so close to melting, until the pressure of the internal spring pushed the ends of the softened fuseholder apart, which broke the contact. Now I don't know what the 'blow' rating of these fuses is, but going by the OE fuses which are 17A rated 35A blow, you could be talking close to 40 amps for a 20 amp fuse, so both fans would have to stall to reach that, which hopefully would never happen. I could use a 10 amp rated, 20 amp blow fuse, but that could be marginal for both the normal 10 amp or so running current, as well as for 20 amps or so for one fan stalled. It would also cut power to both fans. I could fuse the fans individually at 5 amps each, but that is still going to be marginal for both running and stalled current, and would mean messing about with the wiring in order to have the fuses behind the radiator panel to avoid the worst of the weather.

All-in-all, I think I will settle for simply replacing this 20 amp fuse and holder, and making sure the bonnet release cord can't get tangled up in the fan. The old fuse acted as a 'thermal protection device' by disconnecting the power, even though it was sacrificed in the process. So for what should be a very rare occurrence I'll accept the possibility that it might happen again. If it does, it's only a couple of minutes to remove the grille and disconnect a seized fan, then bypass the fuse as before, and one fan will be enough for anything but the hottest weather.

All-in-all, I think I will settle for simply replacing this 20 amp fuse and holder, and making sure the bonnet release cord can't get tangled up in the fan. The old fuse acted as a 'thermal protection device' by disconnecting the power, even though it was sacrificed in the process. So for what should be a very rare occurrence I'll accept the possibility that it might happen again. If it does, it's only a couple of minutes to remove the grille and disconnect a seized fan, then bypass the fuse as before, and one fan will be enough for anything but the hottest weather.

July 2023:

Just messing about and happened to turn the manual switch on - and no fans! Straight to the fuse and the holder has heat damage again, can't get it open to see if the fuse has blown or not. Had a 200-miler in 30C weather less than two weeks ago and no sign of a problem then, and when bypassed both fans running - another mystery. This time I opt to replace it with a 30A Mini blade fuse holder (with LED to show a blown or disconnected fuse at a glance) which I shall use with a 10A fuse. Although the fans take a little over 10 amps the fusing current is twice the rated current so I'm hoping that will be enough, if not I'll up it to 15A. So much for theory and testing with the engine off, the first time they came on with the engine running the fuse blew even though I'd measured the current at slightly less than 10A at 12v. At 14v it would be about 17% higher i.e. 15A which should still be in the 20A fusing range, maybe the higher start-up current makes the difference. So I've ordered some 15A mini-blades and in the meantime used a spare 12v Planet 20A in-line glass fuse holder with a standard 17/35 fuse.

Just messing about and happened to turn the manual switch on - and no fans! Straight to the fuse and the holder has heat damage again, can't get it open to see if the fuse has blown or not. Had a 200-miler in 30C weather less than two weeks ago and no sign of a problem then, and when bypassed both fans running - another mystery. This time I opt to replace it with a 30A Mini blade fuse holder (with LED to show a blown or disconnected fuse at a glance) which I shall use with a 10A fuse. Although the fans take a little over 10 amps the fusing current is twice the rated current so I'm hoping that will be enough, if not I'll up it to 15A. So much for theory and testing with the engine off, the first time they came on with the engine running the fuse blew even though I'd measured the current at slightly less than 10A at 12v. At 14v it would be about 17% higher i.e. 15A which should still be in the 20A fusing range, maybe the higher start-up current makes the difference. So I've ordered some 15A mini-blades and in the meantime used a spare 12v Planet 20A in-line glass fuse holder with a standard 17/35 fuse.

But it all led to an in-depth investigation of these fuse holders and fuses.

V8 fan cycling

My 'Otter' switch (so-called because it switches on the fans when the water gets 'otter) was getting a bit 'late' (the normal switch-on point is about mid-way between 'N' and the red, or 90C/194F degrees F) and erratic so I bought a replacement (BHA5252) from SU Burlen. This is a copy that actually switches on slightly earlier than the original which is no bad thing in itself, and also has the side-effect that hot oil pressure after idling for a while with the fans cycling on and off is noticeably higher. However it has a much higher hysteresis than the original, which means that once switched on the temp has to fall further before they switch off again, i.e. the fans run for much longer than they used to. At least, most of the time it does. Very occasionally, when I am stuck in traffic, it will cycle on and off much more frequently such that the temp gauge only varies slightly at a point between N and H. Why, I have no idea, but there it is, and I wish it were like this all the time. At the time of writing (February 2011) I see Brown & Gammons also have the switch, it's quite a bit more expensive than Burlen, but if it is an original Otter I would opt for that one. There may also be other sources.

My 'Otter' switch (so-called because it switches on the fans when the water gets 'otter) was getting a bit 'late' (the normal switch-on point is about mid-way between 'N' and the red, or 90C/194F degrees F) and erratic so I bought a replacement (BHA5252) from SU Burlen. This is a copy that actually switches on slightly earlier than the original which is no bad thing in itself, and also has the side-effect that hot oil pressure after idling for a while with the fans cycling on and off is noticeably higher. However it has a much higher hysteresis than the original, which means that once switched on the temp has to fall further before they switch off again, i.e. the fans run for much longer than they used to. At least, most of the time it does. Very occasionally, when I am stuck in traffic, it will cycle on and off much more frequently such that the temp gauge only varies slightly at a point between N and H. Why, I have no idea, but there it is, and I wish it were like this all the time. At the time of writing (February 2011) I see Brown & Gammons also have the switch, it's quite a bit more expensive than Burlen, but if it is an original Otter I would opt for that one. There may also be other sources.

Researching these I found references to Otter switches of this physical appearance being used to turn on a choke warning light i.e. to prompt the driver to push the choke home after a cold start. Logic dictates that these must close at a lot lower temperature than the MGB V8 temp of 90C, probably the stat temp at the highest and maybe lower if it was to be any use, so care needed if looking at an alternative item to specifically BHA5252 which a couple of places do show. However one source has a description of 'SOVY OTTER SWITCH Choke warning light. NEW. Jaguar. MGB GT V8.' but it can't be suitable for both applications, as an MGB fan switch it wouldn't put a Jaguar warning light on until 90c, when Jag stats are either 74C or 82C.

October 2024: I'm sure we had some pretty warm weather last year but the fan seemed to be going on and off as normal, and this year the summer was nothing to shout about anyway so despite having bought a couple of alternatives I've not done anything with them. But another option I heard about is this one from the MGOC which replaces the switch with an electronic sensor and external module. They say it turns the fans on at 90C and off at 87C, which is a tighter band than some of the modern sensors (but not as close as the Intermotor 50373 although that one didn't fit the threaded plate despite being quoted as the correct size!) but expensive at £125 compared to between £5 and £10 for the conventional type.

August 2022: The present hot weather would have been an ideal opportunity for testing but a damaged disc in my spine meant I could only get in the Golf, and only that with difficulty, for a couple of weeks. When I could get out it was morning so not as hot as later on, got the engine fully up to temp and pulled over to let it idle. Fan came on just as the needle was about to clear the top right-hand corner of the N, got back underway and it went off again when covering the bottom right-hand corner, and continued to drop to the lower side of the N. Tried again with the same result, then about an hour later trying to get round various road closures for a half-marathon and quite a bit of traffic it came on and went off several times in the same positions. So so-far so-good, although a bit higher wouldn't hurt. I'll leave it as it is for the time being but look into higher ranges. Bank Holiday weekend sees a 200 miler - quite warm on the Friday, fan cycling on and off in synch with the temp gauge and only in traffic, so again so-far so-good.

June 2022: A 100-miler M6/A14 on a pretty hot Friday saw the fans come on shortly after getting on the M6 and staying on for the rest of the journey even though the temp gauge was below the N, despite relatively light traffic, and that was despite going on and off in the urban journey to get on the motorway. Never done that before, in hotter weather, but it did strike me that she had been running on 99 E5 since the previous August. That doesn't seem a logical cause since it makes her run smoother and more economically, so time to investigate an alternative switch. I'd seen elsewhere a more modern switch screwed into an adapter that fitted the V8 inlet manifold, and found this from Fosseway Performance. However the only switch they do turns on at 85C and off at 78C which is too low for the V8 where the stat is 82C - once on it would likely never turn off except perhaps in very cold weather. They told me the adapter thread was M16 (thread size) x 1.5 (fine pitch) and if I could find a switch that suited better they could supply just the adapter and gasket. I embarked on a search for switches that turn on closer to the original at 90C but will turn off by the time it has dropped to the stat temp of 82C. Intermotor make loads with various temps and threads and connections so patient research is needed to find 50373 which is stated as having an on of 92C and an off of 87C. This one has a single spade, some have two spades but Fosseway will supply a link cable to go from under one of the adapter fixing screws to the 2nd terminal. Others have a more modern 1 or 2-pin connector which would need you to make your own arrangements. Also this has normally open contacts as per the Otter whereas many more modern switches are normally closed (fail safe in terms of connections) and would need a different relay arrangement. I could have got an On temp closer to the original but then the Off temp would be closer to the stat temp. As it screws in to the adapter and only cost £7 it's worth a try and I have the option of trying others with different temp ranges without needing a new gasket each time.

But nothing is straightforward and getting the adapter after the switch they don't fit together! Any number of sites say 50373 is M16 x 1.5 i.e. the adapter thread, and it says 50373 on the box, but only '92' (the On temp) on the switch itself so in theory it could be anything. I'm no expert on threads but charts show male M16 threads as having a major diameter of between 15.732mm and 15.968mm, the switch Fosseway use measures 15.8mm which fits with that. Their adapter (female thread) measures 14.38mm tapering to 14.5mm between the peaks and an M16 female thread minor diameter (troughs) is 13.980mm to 14.344mm which also fits. However the switch measures 16.1mm tapering to 16.9mm at the peaks so appears to be an M17 as external threads of those can range from 16.732 to 16.974. I've ordered a couple of M16 and M17 x 1.5 nuts and bolts to test both switch and adapter, and I'll see where that gets us. And as expected an M16 bolt fits the adapter but the so-called 'M16 switch' just about engages one thread of an M16 nut and slides into an M18 nut, so it's basically M17 not M16. The problem is these switches are made to fit specific vehicles, calling it M16 (or whatever) is just something suppliers have tagged on. This may be an incorrect switch in a correctly labelled box, but I can't find any M17 Intermotor switches listed. In which case all the switches described as M16 may be M17, which would be really odd, not to say bloody annoying.

But nothing is straightforward and getting the adapter after the switch they don't fit together! Any number of sites say 50373 is M16 x 1.5 i.e. the adapter thread, and it says 50373 on the box, but only '92' (the On temp) on the switch itself so in theory it could be anything. I'm no expert on threads but charts show male M16 threads as having a major diameter of between 15.732mm and 15.968mm, the switch Fosseway use measures 15.8mm which fits with that. Their adapter (female thread) measures 14.38mm tapering to 14.5mm between the peaks and an M16 female thread minor diameter (troughs) is 13.980mm to 14.344mm which also fits. However the switch measures 16.1mm tapering to 16.9mm at the peaks so appears to be an M17 as external threads of those can range from 16.732 to 16.974. I've ordered a couple of M16 and M17 x 1.5 nuts and bolts to test both switch and adapter, and I'll see where that gets us. And as expected an M16 bolt fits the adapter but the so-called 'M16 switch' just about engages one thread of an M16 nut and slides into an M18 nut, so it's basically M17 not M16. The problem is these switches are made to fit specific vehicles, calling it M16 (or whatever) is just something suppliers have tagged on. This may be an incorrect switch in a correctly labelled box, but I can't find any M17 Intermotor switches listed. In which case all the switches described as M16 may be M17, which would be really odd, not to say bloody annoying.

The other problem is that being a V8 the switch is in the engine cooling circuit not the radiator cooling circuit, so even if the thermostat is partially closed it's still 'seeing' full engine heat. When they are in the radiator that could well be significantly cooler than the engine which would turn the switch off. I'm wondering now if I need to try an after-market 4-cylinder electric fan arrangement with the switch in an adapter that fits between two halves of the top hose, or probe in the end of the top hose, but once the stat has started opening is that always going to be seeing coolant at the same temperature? Or a probe in the radiator fins. The 77 and later 4-cylinder switch is right next to the top hose connection, so is that always going to be seeing coolant at the same temperature as in the engine as well? If I go down that route I'll try the other end of the rad.

Report back and they send me a returns label and they will refund on receipt (get a Proof of Posting from the PO!) and order another from somewhere else in case the first one was the wrong item in the right box, and it is just the same. Report back and they say they will refund me and I can keep it, Googling 'Intermotor' comes up with SMP Europe who seem to be a manufacturer of various brands including Intermotor, explain the situation and ask if they can suggest a solution. They come up with four Intermotor switches which they say are all M16 x 1.5 and switching between 92C and 87C (the range I want) - but one of them is the one I have been having problems with. Two use a 17mm spanner, one 22mm and one 24mm (the one I have tried twice) and looking at pictures of the 17mm ones the thread does seem to be slightly smaller than the hex. So I ask very nicely if they can measure the thread diameter for me, and they come back with 15.8mm for one and 15.9mm for the other, so we are in with a chance! Another complication is that modern cars have changed over to normally closed switches (for several sensors) presumably as a fail-safe whereby they can detect if the circuit has become disconnected and warn the driver. I could use one of those but would have to change the relay for one with a normally closed contact, and that relay would be operated all the time the ignition was except when the fans were running. Feasible with a modern Bosch relay, but I'd rather avoid it. Of the two that seem to be the right size one is a normally closed (50163) and one a normally open - 50416, so order one of those. It has some kind of single-pole connector rather than an open spade, but I'm sure I can get round that. At least they are getting cheaper - the first one was £7, the second £5.50 and this one £3.70!

And it fits! This has a plain thread with a fibre gasket, whereas the other ones I have been trying have been tapered threads. Obviously they won't screw all the way down and don't have a gasket, but if they don't even start in an M16 socket I don't see how they can be classed as an M16, unless it's something to do with being tapered. Info online is that females for tapered males can be tapered or plain, but the only charts for tapered threads I can find only give one dimension for M16 and that is 16mm. Fair enough if that is the middle of the thread i.e. starts less than 16mm and ends bigger than 16mm, but the tapered switches I've had run from 16.1mm to 16.9mm.

Suspended it in water with a digital oven thermometer probe on The Navigator's induction hob (permission obtained) and it closes at 91 and opens at 85 with an audible click (heated and cooled twice)so pretty close to spec, a couple of ohms when closed but that's not an issue as it's only operating a relay. Next job is to fit it.

Not a trivial task, not least unscrewing the existing three fixings, which haven't been touched for decades since one of them stripped its thread in the inlet manifold and I had it tapped to the next size up for a stud and nut, which means that hole in the current switch and the new adapter has to be drilled out. Were I doing it again I'd bond a stud with the correct thread into the hole, as I did with the heater valve. Fortunately the nut came undone easily and the other two screws came out relatively easily. Put a smear of non-setting sealant on one side of the gasket adapter and fit them over the stud. One of the screws goes in fine but the other one is off-centre, didn't happen with the previous switch so maybe this adapter isn't quite right, but the sealant has to be cleaned off the adapter and the other two holes drilled out slightly as well, until I can get both screws in, then re-smear the adapter with sealant. The nut and the two screws all tighten up as they should, so fit the switch to the adapter and the harness wire to the switch. Test drive another day as it's getting near tea-time.

Not a trivial task, not least unscrewing the existing three fixings, which haven't been touched for decades since one of them stripped its thread in the inlet manifold and I had it tapped to the next size up for a stud and nut, which means that hole in the current switch and the new adapter has to be drilled out. Were I doing it again I'd bond a stud with the correct thread into the hole, as I did with the heater valve. Fortunately the nut came undone easily and the other two screws came out relatively easily. Put a smear of non-setting sealant on one side of the gasket adapter and fit them over the stud. One of the screws goes in fine but the other one is off-centre, didn't happen with the previous switch so maybe this adapter isn't quite right, but the sealant has to be cleaned off the adapter and the other two holes drilled out slightly as well, until I can get both screws in, then re-smear the adapter with sealant. The nut and the two screws all tighten up as they should, so fit the switch to the adapter and the harness wire to the switch. Test drive another day as it's getting near tea-time.

Next day showery, so while waiting for the weather I test the previous switch exactly the same as I did the new one - and find it goes on as the temperature is rising through 95 degrees towards 96, and goes off as it is falling through 95 degrees to 94! So not only does this switch have a higher temperature but it also has a much smaller hysteresis, and if that wasn't enough it registers zero ohms as opposed to the couple of ohms of the new one!! At that rate it's going to be even worse than the previous switch, and the erratic and delayed switching off must be something to do with the temperature of the coolant and inlet manifold around it and not the switch. Which is odd given that the sensor for the temp gauge is only a couple of inches away, and that shows about 95 coming on and about 80 before it goes off. I'll have to try it for a while, but if it's worse this exercise will have been a complete waste of time and money. And it is. The fan comes on just as the needle is clearing the right-hand vertical of the 'N', and goes off again just as it is clearing the left-hand vertical. So less hysteresis than the Otter-type but way too low.

As it now takes a screw-in switch I do have the option of trying one with a higher range, but as the WSM supplement quotes the switch setting as 90C and the Burlen seems to be 95, I don't want to go much higher. Intermotor 50455 (parallel M16 x 1.5 normally open) is 95 on 90 off, can't find one but Facet equivalent 7.5057 at £17. Two spades so I'll have to pick up an external earth somewhere but that's easy enough. But after the first run it looked like there was a bit of coolant round the seal at the base of the switch. Tightened it another fraction of a turn, and after the next run it looked like there was a bit more! After that slackening or tightening it was no better. The problem is that the seal is a rubber O-ring, and the base of the adapter it butts up against is very narrow, so it just expands and goes down the sides, just like on the radiator filler plug all those years ago. The previous switch had a fibre gasket which didn't leak, so I tried to get that off for re-use but that has split into two rings for the same reason. So I wrapped a few turns of PTFE tape round the threads and it still leaked. Wrapped a few more and at last it seems to have sealed.

As it now takes a screw-in switch I do have the option of trying one with a higher range, but as the WSM supplement quotes the switch setting as 90C and the Burlen seems to be 95, I don't want to go much higher. Intermotor 50455 (parallel M16 x 1.5 normally open) is 95 on 90 off, can't find one but Facet equivalent 7.5057 at £17. Two spades so I'll have to pick up an external earth somewhere but that's easy enough. But after the first run it looked like there was a bit of coolant round the seal at the base of the switch. Tightened it another fraction of a turn, and after the next run it looked like there was a bit more! After that slackening or tightening it was no better. The problem is that the seal is a rubber O-ring, and the base of the adapter it butts up against is very narrow, so it just expands and goes down the sides, just like on the radiator filler plug all those years ago. The previous switch had a fibre gasket which didn't leak, so I tried to get that off for re-use but that has split into two rings for the same reason. So I wrapped a few turns of PTFE tape round the threads and it still leaked. Wrapped a few more and at last it seems to have sealed.

The other option is a sensor that fits in the radiator fins, about the only one I can find is this Merlin Motorsport, but I'll see how the new switch goes. This is getting expensive!

July 2018: In the current heat-wave it is coming on and staying on in traffic until we get moving again, even though the temp gauge is below N. I suspect the engine compartment is so hot when standing that heat is travelling down into the switch and keeping it on, even though the coolant temp would normally have turned it off.

September 2017: Following Vee's body restoration and engine rebuild one interesting change is how consistent the fan cycling has become. For 24 years - with very few exceptions - it hasn't cut in until about 4 o'clock on the temp gauge (higher still with the original Otter switch), staying on until it gets back down to N i.e. very long on and off times. On rare exceptions it would cut in at barely 5 o'clock, and cut out again barely any lower, i.e. as per a modern car. Once it started doing that it would continue, but once underway again, or switching off and a restart, it would be back to the usual cycling with very long on and off times. Now, every time, it's been cutting-in at about 5:30, and out again without the gauge noticeably moving. Timing it - out of interest - following the first oil change, after it had done a dozen cycles or more it was off for 25 seconds every time, with the on times slowly increasing 40, 45, 50 seconds, without the gauge noticeably moving. Why this change in behaviour? It's the same inlet manifold and the switch wasn't touched during the rebuild; that manifold had been on and off several times before; and the coolant drained and refilled several times. Before I did occasionally have to top-up the expansion tank, but since filling with anti-freeze and allowing a couple of heat/cool cycles to fully purge, the level doesn't seem to be dropping over the 500 miles. Maybe a tiny leak was allowing air to get round the switch, I doubt we shall ever know.

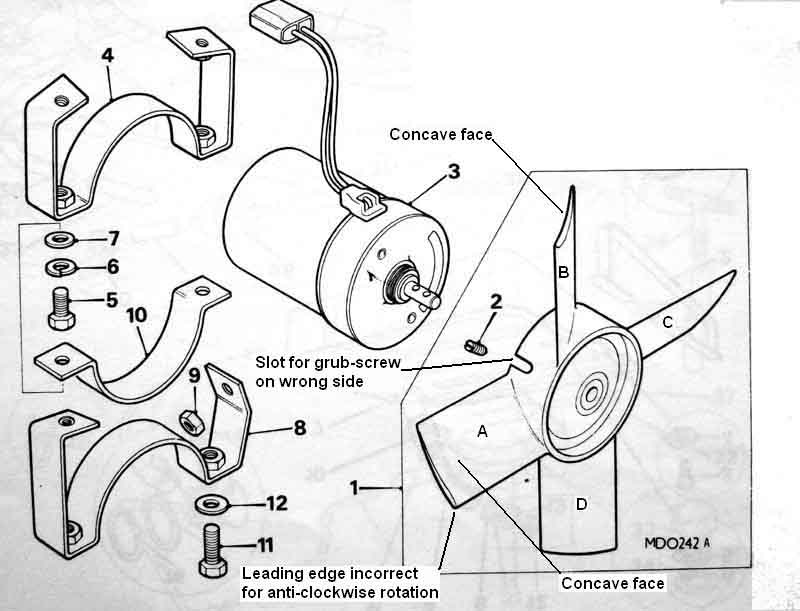

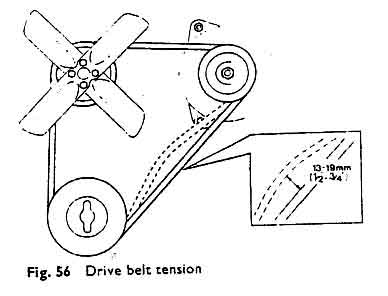

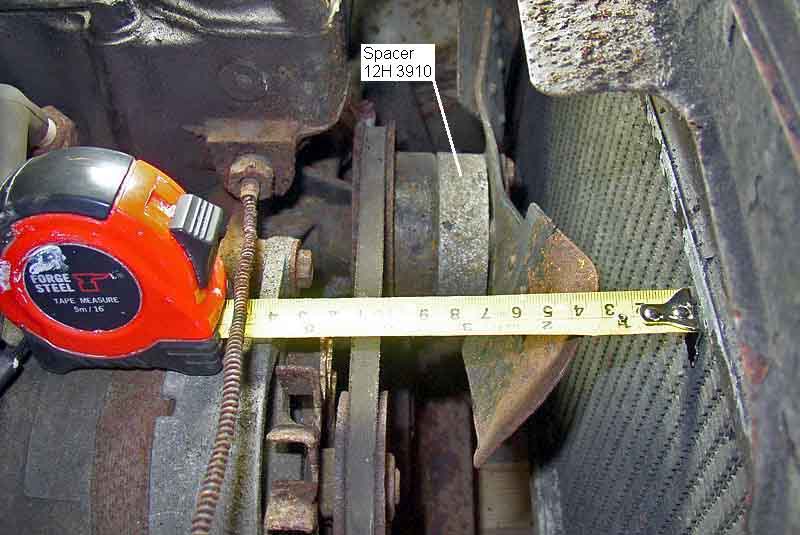

Motor: Important:

- The motor shaft has two indentations for the grub screw so the blades can be fitted either way round according to the application. For both 4-cylinder and V8 the one closer to the end of the shaft is used, with the grub-screw on the radiator side of the blades, and the end of the shaft almost flush with the end of the boss on the fan.

- Replacement motors are generic and at the time of writing do not have the 2-pin connector, so the old one will have to be cut off and the wires joined to the motor wires (twist, solder and heat-shrink). These motors are polarity-sensitive so must be connected the right way round or the fan will suck instead of blow (and reversing the blades will not correct that ...). The one I fitted for a pal had a white wire and a black wire and connecting white to green/black from the harness and black to black the motor spun in the correct direction - anti-clockwise when looking from the back of the motor.

- The upper part of the motor bracket must be positioned the right way round on the underside of the slam panel or the blades will not be square to the radiator.

Ideally if having to remove the motor you will remove the fan first, then the motor can be removed from the front of the car. Ideally. With a faulty motor on the V8 many years ago I could never get the grub-screw undone, and on a pal's 78 although the screw came undone easily the blades would not shift on the spindle, despite PlusGas and being left. In both cases the motor had to be removed complete with blades - which isn't easy. Both halves of the mounting bracket have to be removed, and the oil cooler hose is in the way for two of those screws, then the motor with blades has to be tilted with the blades turned to a certain position, and one of the cooler hoses pushed over the top of the blade at the top and front, then it can be removed and the stuck fan addressed. Note that to remove the additional motor for North America motor with is fan may need the radiator to be removed as the vertical member below the slam panel is offset to that side and there is less space.

To remove the blades from the motor I used a Workmate with the motor hanging down between the jaws and the edges of the fan boss resting on them, and used a drift on the end of the shaft. It took quite a bit of hammering all the way until the end of the shaft finally cleared the boss. Fortunately the blades were a better fit on the spindle of the new motor ... but of course I didn't fit it until I had replaced the mounting bracket and slotted in the motor, tightening the upper part to the underside of the slam panel (this must go the right way round or the blades will not be square to the radiator) but leaving the motor clamp bolts loose to fit the blades.

The motor spindle has to be pushed into the motor boss as there is not enough room to the rad to do it the other way round. Position both the grub-screw (having greased its threads before fitting to the fan boss) and the shaft indentations uppermost so you can see them as you slide the shaft in, then when the end of the shaft is at the end of the fan boss plus a tiny bit more, start tightening the grub-screw. Being pointed it should locate the hole in the shaft and you will probably feel the two being pulled into their final position.

Nip up the bracket bolts clamping the motor, then spin the blades before final tightening as one or more may come slightly higher than the lower edge of the header tank, and that will limit how close to the rad core the blades can be positioned. A little clearance should be enough, then tighten the clamping bolts on the bracket.

Fan blades: October 2008

Unlike mechanical fans which can only turn one way with the engine (clockwise when viewed from the front of the car), electric fans will usually change direction according to how the motor is connected, these are motors that have a permanent magnet stator. If you should have a motor with a wound stator reversing the polarity to the motor as a whole will have no effect. Starter motors are like this, and early heater fan motors were the same, but all motors you are likely to find for cooling fan applications will almost certainly have the potential (ho ho) to run backwards. So the first thing to do with a new fan motor, or if you have cooling problems, is to check which way the air is blowing when the fan is running. The factory fan should rotate anti-clockwise (i.e. opposite to the mechanical fans) when viewed from the front of the car to push air through the radiator. Note that turning the blades over on the motor spindle will not affect air direction, only changing the motor polarity will. However as with mechanical fans the blades are 'handed' which means they move air more effectively one way round than the other, and this is where turning the blades over may be required. An old fan from my V8 has an arrow on one side of the boss of the blades showing the direction is should spin. This is on the side facing the motor so you have to squint down the gap between motor and fan boss to see it. If you can't see an arrow, or other marking indicating direction (one person has reported that his fan has 'B' on one side for 'Blow' and 'S' on the other for 'Suck' but that may just be BS ...) you will have to look at the tips of the blades. These should resemble a wing profile, and have be relatively blunt on one edge and tapered on the other. Just like an aircraft wing the blunt edge is the leading edge, and the tapered the trailing. See the accompanying photos (click thumbnail) for examples of the direction arrow and profile.