Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

Steering and Suspension

|

Coming to an MOT test station near you - shaker plates to tear your steering and suspension to pieces.

If ever there was a good reason not to put your classic through an MOT ...

Springs, dampers or shocks/shockers/shock-absorbers? MGBs came out of the factory with springs and dampers. Whilst the term 'shock-absorbers' can be used for coil-over systems where you have a spring and damper in a sub-assembly, it is incorrect to use that term for the MGB damper. It's the spring that absorbs the shock of a bump or pot-hole, so if anything it should be interchangeable with that term and not damper. But once a spring has absorbed a shock it has to give it up again, and the damper is needed to 'damp' that reaction, without it the car will go bounding down the road like a kangaroo.

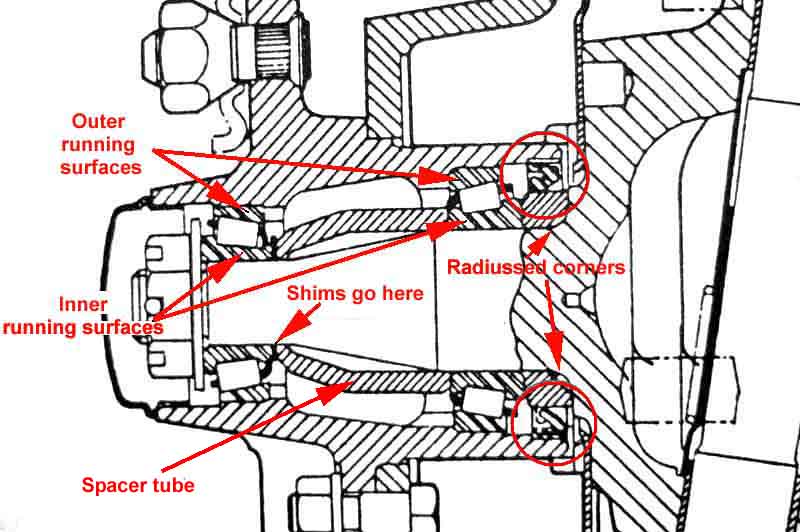

V8s are a one-piece assembly where the rubber bush is bonded to a steel spacer tube to give more positive handling. With these it is important not to tighten the pivot pin castellated nuts until the weight of the car is on its suspension. This is because the outer part of the rubber is a tight fit into the A-arm, the steel tube acts as a spacer and is clamped tight onto the wishbone pivot by the nut and large washers, so the action of the suspension tends to twist the rubber rather than slide it over the spacer. If the castellated nuts are fully tightened with the suspension hanging down then when the car is on its wheels there is already a lot of twist imparted to the rubber, and when the suspension is compressed over a bump the rubber gets twisted even more and can tear.

September 2025: What to replace suspension bushes with in these days of poor quality rubber? Ian Caldwell had a front spring break on his 73 roadster and then had excessive ride height despite fitting what were ostensibly the 'correct' springs, but there is an alternative which gave a great improvement. He replaced the inner A-arm bushes at the same time with standard rubber which collapsed in about 200 miles, then replaced those with Polybush 'comfort' which reputedly replicate the OE rubber and improved things further. Available for both front and rear, select the item then chose 'Comfort' under 'Select an option'. But note:

- Unlike standard V8 A-arm inner bushes Polybush for use here do not appear to have steel sleeves. The only one for the MGB showing a sleeve is the rear spring front eye as originally.

- There have been several complaints about polyurethane bushes squeaking in use even when the grease provided by some manufacturers has been used. Polybush actively discourages the use of grease saying it can cause squeaking as well as attracting grit which can accelerate wear.

- Brown & Gammons in their 'POLYBUSH' fitting instructions talk about a 'crush tube'. It is a spacer not a crush tube and ensures that there is a clearance between the large washers and the sides of the A-arm so that the bush insulates the suspension assembly from the rest of the car. Without that clearance the washers would be clamped up to the A-arm and rotate with them against the pivot pins and nuts causing wear and noise. Despite the use of 'POLYBUSH' in the heading these bushes do not appear to be from the Polybush company as theirs don't seem to have steel sleeves for this application.

Removal and replacement of the of the A-arms can be found in Front Spring Removal. While apart check the lower trunnion thrust washers for wear as this can cause a clonk when braking.

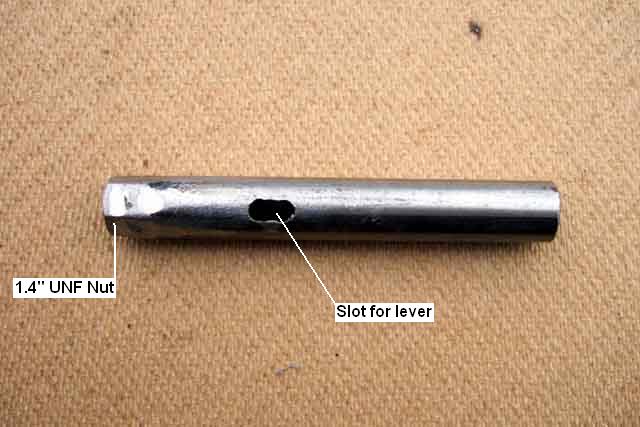

The steel sleeve is quite a snug fit over the pivot pin and can rust to it. In the past I've had to drill through the rubber to part the A-arm from the pivot, then carefully grind through the sleeve before I could chisel it off. The rubber bonds to the A-arm as well requiring more digging-out. Clean up the pivot pin and A-arm hole with a fine file or coarse emery as required to get smooth surfaces. To get the new bush into the A-arm you may well have to smear it with washing-up liquid or Swarfega Original (smooth), then use a vice to press the new bush in. For full seating you may need to use a large socket that will fit over the bush but bear on the A-arm hole on one side, and a small socket that will bear on the sleeve on the other. Smear the pivot pin with copper grease to aid future disassembly and reassemble the A-arms to pivot pin, washers and castellated nut leaving the nuts a turn or two loose as mentioned above. Lower the car onto its wheels, and only then tighten the castellated nuts and fit the split-pins.

It is important to fit castellated nuts NL608041 with flat washer AAA1330 and split-pins GHF504 to hold the A-arm bushes in, which of course needs a hole near the end of the threaded section. Robin Goujah replaced the bushes on his car and found Nylocs, with no threads protruding. He queried it on the MGOC forum and was strongly advised to replace them ... but could find no holes in the pivots. So it looks like the pivots were replaced by incorrect items whilst with a previous owner, and has had to spring for replacements of those as well - AHH4003. Note that Moss Europe do list a Nyloc as an alternative to castellated, in the words of the old seat-belt advert where someone was poised to jump off a building - "Don't Do It".

It is important to fit castellated nuts NL608041 with flat washer AAA1330 and split-pins GHF504 to hold the A-arm bushes in, which of course needs a hole near the end of the threaded section. Robin Goujah replaced the bushes on his car and found Nylocs, with no threads protruding. He queried it on the MGOC forum and was strongly advised to replace them ... but could find no holes in the pivots. So it looks like the pivots were replaced by incorrect items whilst with a previous owner, and has had to spring for replacements of those as well - AHH4003. Note that Moss Europe do list a Nyloc as an alternative to castellated, in the words of the old seat-belt advert where someone was poised to jump off a building - "Don't Do It".

Anti-roll Bars Updated May 2016

Rear bar issues

Some juggling by the factory as to what size front bar was fitted where and when:

| Model | Part No. | Size |

| CB Roadster (Optional to 108038) | AHH7329 | 9/16" |

| CB GT to 315949 | AHH7331 | 5/8" |

| CB V8 | BHH882 | 5/8" |

| CB GT 315950 - on | BHH882 | 5/8" |

| RB Roadster to 76 | None | |

| RB GT to 76 | BHH1217 | 9/16" |

| RB V8 | BHH1217 | 9/16" |

| Roadster & GT 77 on | BHH882 | 5/8" |

Note that the front drop-links are subtly handed! AHH6543 or GZS836 for right-hand and AHH6544 or GZS837 for left, the lower ball joint is angled to match the A-arms.

A rear bar was fitted to both roadster and GT for the 77 model year on, size unknown, the drop link 37H8778 is not handed.

The PO fitted one of the Ron Hopkinson handling kits to the V8 in the shape of the rear bar with telescopic dampers and the uprated front bar. It's said that one has to uprate the front when fitting a rear or it induces oversteer. The front bar is 7/8", I've not measured the rear. However when the factory fitted a rear bar for 77 and later models they reused the CB 5/8" bar so that may well just be marketing. For some time I couldn't really tell whether it was making much of a difference (the PO said it did, but he would say that, wouldn't he?) although the back did feel 'different' to my roadster. But whether that was just because I was comparing a CB roadster with an RB V8 I couldn't really say. Then I drove a friends unmodified CB V8 and I could immediately tell it was the same as my roadster i.e. with more movement at the rear as if the rear axle were moving around or the tyres were squirming. But I still didn't know how much of the difference was down to the ARB and how much to the dampers.

April 2007:

I've had a request from someone who has obtained the RH kit but without instructions and asking for any help I can give on where and how the rear bar mounts. Mine were fitted by the PO so I have no instructions, but I can at least supply some photos and a brief description, click on the thumbnail.

I've had a request from someone who has obtained the RH kit but without instructions and asking for any help I can give on where and how the rear bar mounts. Mine were fitted by the PO so I have no instructions, but I can at least supply some photos and a brief description, click on the thumbnail.

February 2016: Gordon Lewis has kindly supplied me with a scan of the original Ron Hopkinson instructions for front and rear, as he has the same set-up as me.

August 2018: Kevin Poole has also very kindly supplied me with a scan of the rear fitting template. The distances on the template are critical of course in order to get the holes in the right places, and to that end Kevin has drawn a reference line exactly 4" long on the template before he scanned them. When you print this template you will have to measure the line to confirm the printed template is to the correct scale. With my printer and software the default settings produced a line that was only 3.75" long on A4 paper, but I was able to change a setting from 'Fit to page' to 'Actual size' (or a custom setting of 100%), and that came out correctly. However one side of the drawing is clipped as it is now too big for A4 paper in my printer. But if you orientate the page correctly this clipping can be on the side with the narrow taper near the 'scissors' symbol as indicated by the grey shading here, which won't affect the positioning of the holes. If you can only print out one of the templates like that (there are separate ones for each corner of the spare wheel well) then after using the template on the appropriate side, and having punched holes through to mark the floor for drilling, simply turn it over and bend the 'Lay on boot floor' section the other way. Do not clip the other side or you may lose accuracy.

Front bar issues:

One day in the V8 I noticed a grinding on full lock and it turned out to be the rim of the wheel rubbing on the bar. Checked the other lock and it had plenty of clearance, so I gave an exploratory tap on the bar with a lump hammer and it moved sideways a little bit. So I tapped it some more until the clearances were about equal both sides. Now the standard bar on both the V8 and 4-cylinders cars have clamps which sit just inside the pivots and bushes which bolt up to the front apron and so prevent the bar moving from side to side, but mine doesn't have any. Either the PO never fitted them or the Ron Hopkinson kit never provided them. However this is the first time in 9 years and 65k miles so perhaps I do them an injustice. The right-hand (where the rubbing was) front damper has also started leaking recently and although it still seems to be damping normally maybe that has had an effect too. We shall see and if it rubs again after I have changed the damper I will have to investigate some clamps.

Summer 2006: Still grinding, and by this time Colin Parkinson had emailed me to use a 1" length of hose of the appropriate diameter split up one side, and a worm clip clamped round that. Didn't have any suitable hose, but I did have an old inner tube I had already cut into, so I used a 6" (or so) length of 1" width of that, wrapped round the bar several times, and then clamped. We shall see.

Summer 2007: No further grinding, so it looks like a successful mod.

October 2016: Still no grinding, and although I've just been made aware that Brown & Gammons do clamps for 3/4" bars (and other sizes) at £20 a pair ... strips of rubber/split hose and Jubilee clips appeal to me much more!

May 2014: MOT advisory on slight play in the V8 front anti-roll bar bushes. Checked the lower joint to the A-arms first but that was fine, then tried the joint between the drop-link and the bar proper and found several millimetres! Took it apart to find virtually no bush left, just a couple of slivers of rubber on the tube and socket. As an after-market bar long out of manufacture I'm not going to be able to get spares, but maybe the bush for the standard bar might fit. Email one of the usual suspects but of course no response. In the meantime I thought it was worth experimenting with one side. Found a bit of hose that is a reasonable fit for both the sleeve and socket, and with a bit of Vaseline, a suitable bolt and washers, can squeeze the three together enough to get the U-fitting at the top of the drop-link over the new bush and insert the bolt. So easy I decided to do the other side as well, and several hundred miles later there is still no play in either.

October 2016 Subsequently I see these bushes from Brown & Gammons. As the drop-link is the same for the standard and uprated bar, I'm assuming the bolt and hence the ID if the bush is also the same. An enquiry may elicit a response as to whether the OD is the same.

May 2022: B&G have poly chassis mount rubbers for 7/8" and other bars.

Driving round the block to warm up the oil prior to Vee's service I suddenly started hearing this intermittent loud rattle on the left that seemed towards the rear, that sounded more structural than something loose in the car. My first thought was loose wheel nuts but they were all OK. While the oil was draining I got under the back, poked and prodded but couldn't see or find anything. However as soon as I got under the front to position the jack in preparation for getting the wheels off, I could see the anti-roll bar drop-link had parted company with the bracket on the end of the bar itself! (Interestingly eighteen months later another noise which appeared to be coming from the rear turned out to be a loose front damper). It's going to have to be removed in any event, and I feared the tapered pin would be seized in the A-arm and spring pan as I had experienced before. However that was when I had changed Vee's A-arms because the trunnion holes were ovalled, and as normal I had reassembled with copper-grease so the pin came out with just a tap from a hammer. From the way the link bar had torn away from the bracket and left a shaped hole it was quite easy to see how the two parts had fitted together, so I angle-ground the end of the bar and both faces of the bracket ready for welding.

Driving round the block to warm up the oil prior to Vee's service I suddenly started hearing this intermittent loud rattle on the left that seemed towards the rear, that sounded more structural than something loose in the car. My first thought was loose wheel nuts but they were all OK. While the oil was draining I got under the back, poked and prodded but couldn't see or find anything. However as soon as I got under the front to position the jack in preparation for getting the wheels off, I could see the anti-roll bar drop-link had parted company with the bracket on the end of the bar itself! (Interestingly eighteen months later another noise which appeared to be coming from the rear turned out to be a loose front damper). It's going to have to be removed in any event, and I feared the tapered pin would be seized in the A-arm and spring pan as I had experienced before. However that was when I had changed Vee's A-arms because the trunnion holes were ovalled, and as normal I had reassembled with copper-grease so the pin came out with just a tap from a hammer. From the way the link bar had torn away from the bracket and left a shaped hole it was quite easy to see how the two parts had fitted together, so I angle-ground the end of the bar and both faces of the bracket ready for welding.

I was pondering how best to clamp the two together for welding, but as the alignment of the bar and the bracket is angled, I decided to refit the parts temporarily and tack-weld them in-situ. If the angle was out by even a small amount there would be a constant twisting force on the bush around the pin, as well as the bush in the arm. I placed some pieces of hardboard around the joint to protect surrounding areas from weld splatter, levered the bracket down onto the bar, and applied a couple of welds. They seemed secure to I removed the drop-link and finished the welding and clean-up in the vice, and reinstalled it. While working on this I had noticed that the bush I had replaced in May 2014 showed no signs of wear, so that had been a successful repair.

Would my weld repair hold? If it broke again I would need to replace the drop-link. Initially I thought that as a Ron Hopkinson part spares went NLA years ago, which may mean retro-fitting a standard bar, which would mean removal of the rear bar. But while writing this I realised I had been sent a copy of the instructions, which state that the original drop-links are retained, and so are standard items which does make sense.

June 2016: It did break again, partly down to my welding I suppose, the fact that my welder is more applicable to panels, and the RH front bar is thicker than standard so puts more stress on the drop-links. Ordered Sunday morning it arrived Tuesday morning and only took half an hour to fit, and at £10 didn't break the bank.

October 2017: Checking the near-side damper bolts for tightness (found the off-side were loose and causing a clonk) I found the drop-link broken again! Only 15 months old, but for 12 of those Vee was off the road in restoration, it has only done 1000 miles, 500 of which were some longish trips on good roads. Looked up my records to see it was supplied by Moss, who on their description page today say they are made by the original manufacturer, pull-tested to 3/4 ton.

It's interesting to note that the broken end shows the same minimal weld across barely half the diameter of the end of the bar, with no external signs of welding, so quite possibly a type of spot-weld where the two parts are held together and a very large current passed through the joint, rather than with an arc and adding metal with rod or wire.

It's interesting to note that the broken end shows the same minimal weld across barely half the diameter of the end of the bar, with no external signs of welding, so quite possibly a type of spot-weld where the two parts are held together and a very large current passed through the joint, rather than with an arc and adding metal with rod or wire.

I started looking at replacements again, and find the price varies from less than £7 at Motaclan/Leacy and more than £15 at B&G, so a 100% (from the cheaper item) range. Some of them looked like they may have some weld where the bar joins the bracket, so starting with Motaclan/Leacy I asked them if they could have a look at one of theirs. Always very obliging they did, and after a pause he said "There's no sign of a weld at all!". Even more obliging he said that there might be more than one manufacturer, and would ring round the other suppliers to see what he could find.

In the meantime I contacted Moss and explained the situation, when I bought it and the use it has had etc. Although I couldn't find the invoice I do have a record of the date so gave that, and next day I get an apology saying they will send me a replacement. (Better service than B&G who supplied an incorrect release bearing for the V8 but despite it being unused refused to do anything about it having had it more than 12 months). On arrival that seems to be the same i.e. no signs of weld around the join.

In the meantime I contacted Moss and explained the situation, when I bought it and the use it has had etc. Although I couldn't find the invoice I do have a record of the date so gave that, and next day I get an apology saying they will send me a replacement. (Better service than B&G who supplied an incorrect release bearing for the V8 but despite it being unused refused to do anything about it having had it more than 12 months). On arrival that seems to be the same i.e. no signs of weld around the join.

I have repaired my original again, this time taking more care over the welding. However now I have the FOC replacement I'm going to see about getting it seam-welded where the rod butts up against the bottom of the bracket, so will have what should be a stronger replacement when my repair fails again.

Why so sure it will fail again? Where I live it is impossible to drive anywhere without going over a series of traffic-calming measures. The full-width tarmac ones are bad enough, but there are a number of the fantastically inappropriately named 'pillows', anywhere between one and five depending where I'm going. These are large rectangular slabs of concrete, one in the middle of each lane, with all four sides sloping straight up to a sharp edge before the flat top. If nothing is coming the other way then I can drive between the pillows, and reduce the effect by half as with the relatively narrow track the wheels are only part-way up the sloping sides, and both wheels go up and down about the same amount. But if there is someone coming the other way I can't do that. Neither can I go straight over the top as the exhaust catches the sharp edge around the flat top in both the MGBs. What makes it worse is that even the entry edge of these stands proud of the tarmac - either the tarmac has sunk a bit or they were never installed low enough in the first place - which makes the problem even worse. So other than waiting until the coast is clear and driving up the middle (and annoying following vehicles), I've been driving with the near-side wheel in the gutter, which means the exhaust clears it. However that tends to push the off-side wheel up and the near-side wheel down, as the rear wheels are still level, which puts the off-side drop-link in compression and the near-side in tension ... i.e. tending to pull it apart! Added to that the PO fitted a Ron Hopkinson rear bar, which apparently necessitates an uprated front bar. So with the uprated front bar there is even more tension on the near-side drop-link, as the bar needs more force to twist it by the same amount. Whilst I can comfortably drive over most of the tarmac full-width strips at nearly 20mph (most of them are in a 20mph zone because of schools) with these pillows especially when I can't drive between them I'm having to creep over them at less than walking-pace, so it's hardly me 'abusing' my suspension. What's really annoying is that some drivers can race over these well in excess of 30mph (20mph zone remember) with impunity, and I've had people overtaking me when I have to slow right down. I complained to the local Council about one of the tarmac strips in the past, as for some reason the rising and falling ramps were only half as long as any of the others, which made them twice as severe and steeper than the guidelines state. They did correct that, so I shall have a go at them about these pillows.

The other possibility is to replace the uprated front bar with an original, which in theory means I would have to remove the rear bar, although when the factory fitted a rear bar they only uprated the front bar from 9/16" to 5/8". However all three times it has broken, effectively meaning no front ARB at all, the only thing I have been aware of on one of the occasions was a noise from the end of the bar hitting the bracket! The other times nothing at all. So for my driving style at least, hardly essential. The original RB V8 item was 9/16" and common to 4-cylinder RB cars, and although it is NLA there might be a possibility of getting a used one.

November 2017: Scanning eBay I find a 5/8" BHH882 bar for sale at £24.95 + £9.95 P&P so go for it. 1/16" thicker than the original RB V8 bar, but these were used on CB V8s, and a full 1/4" less than the existing one. I wonder about the bushes, and there is an ad on the same page for a pair at £5.10 + £1.95 P&P which didn't seem too bad. But when I started looking at the usual suspects they are £1.20 each plus P&P, and I'll see what they are like first (good). No clamps (to stop the bar moving from side to side) shown, and they (21H667 and 668) are NLA (although the 9/16" ones AHH6546 are available). The RH bar never had them but the bodge worked, so I shall just re-bodge the replacement bar. I do wonder whether 1/32" can be shaved off each of the smaller ones though ... I'll also need new mounting bushes, but they also seem to be available - AHH6541 9/16", 1B4526 5/8", and AHH7927 3/4", all of which use the same clamp. Those three do use the same angular clamp, but I had forgotten the RH uses a half-moon clamp! I'll fit the replacement bar using those, but I suspect they will clamp the rubbers too tightly onto the bar and may well squeak, so will get the correct 'straps' BHH2000 in due course. Being a thinner bar I have some hose that will fit with smaller Jubilee clips to prevent the bar moving from side to side, which is neater than the previous bodge using strips of old inner tube.

Getting underneath I did wonder if I would have enough room to manoeuvre the bars out and in over the bottom hose i.e. would there be enough room below the car and to the side, but there was plenty. Getting the new one fitted was a bit of a fiddle. First I couldn't get the bolt through the eye and the repaired drop-link bracket, and had to remove the drop-link to see what was happening. The replacement bar is more bulbous where it sits in the bracket, and was fouling the additional weld going through a hole in the bracket to the end of the bar, filing that down a bit was all that was needed. Next having forgotten the RH pivot bush straps are half-moon shaped whereas the originals are angular, so not a direct fit, I had to use a jack to lift the straps up a bit compressing the rubber to get the bolts started. As the P&P is more than the correct straps, it can wait for a supplier visit. Annoying, as I had already had to order new pivot rubbers and pay a high P&P, buying the two lots together would probably not have cost any more.

Getting underneath I did wonder if I would have enough room to manoeuvre the bars out and in over the bottom hose i.e. would there be enough room below the car and to the side, but there was plenty. Getting the new one fitted was a bit of a fiddle. First I couldn't get the bolt through the eye and the repaired drop-link bracket, and had to remove the drop-link to see what was happening. The replacement bar is more bulbous where it sits in the bracket, and was fouling the additional weld going through a hole in the bracket to the end of the bar, filing that down a bit was all that was needed. Next having forgotten the RH pivot bush straps are half-moon shaped whereas the originals are angular, so not a direct fit, I had to use a jack to lift the straps up a bit compressing the rubber to get the bolts started. As the P&P is more than the correct straps, it can wait for a supplier visit. Annoying, as I had already had to order new pivot rubbers and pay a high P&P, buying the two lots together would probably not have cost any more.

January 2018:

No problems with the RH straps on the factory pivot bushes but a trip to Motaclan/Leacy to get a replacement front damper for Vee (weeping since I started using her again) so took the opportunity to pick up a couple of ARB straps, and some A-arm bushes as one of them has a chunk of rubber sticking out. Damper refitted so easily I decided to replace the ARB straps ... but just doing one took longer than the damper in an awkward space, so I left the other pending better access. The problem is that whereas the RH straps have a slot one side so automatically fit the hole spacing in the chassis rail, the original type just have holes, and these have to be exactly aligned with the chassis rails holes or you can't get the second bolt started. So first step is to offer them up without the bushes in the way, and squeeze them up in a vice to get the correct spacing. Next the straps have to be pushed hard onto the bush, and even the bush compressed a bit, to get the second bolt started as ideally they would be 1/4" longer. Even with the matching bushes and straps they still need to be jacked up into position.

No problems with the RH straps on the factory pivot bushes but a trip to Motaclan/Leacy to get a replacement front damper for Vee (weeping since I started using her again) so took the opportunity to pick up a couple of ARB straps, and some A-arm bushes as one of them has a chunk of rubber sticking out. Damper refitted so easily I decided to replace the ARB straps ... but just doing one took longer than the damper in an awkward space, so I left the other pending better access. The problem is that whereas the RH straps have a slot one side so automatically fit the hole spacing in the chassis rail, the original type just have holes, and these have to be exactly aligned with the chassis rails holes or you can't get the second bolt started. So first step is to offer them up without the bushes in the way, and squeeze them up in a vice to get the correct spacing. Next the straps have to be pushed hard onto the bush, and even the bush compressed a bit, to get the second bolt started as ideally they would be 1/4" longer. Even with the matching bushes and straps they still need to be jacked up into position.

February 2018: I couldn't help laughing when I read this in the latest MGOC magazine:

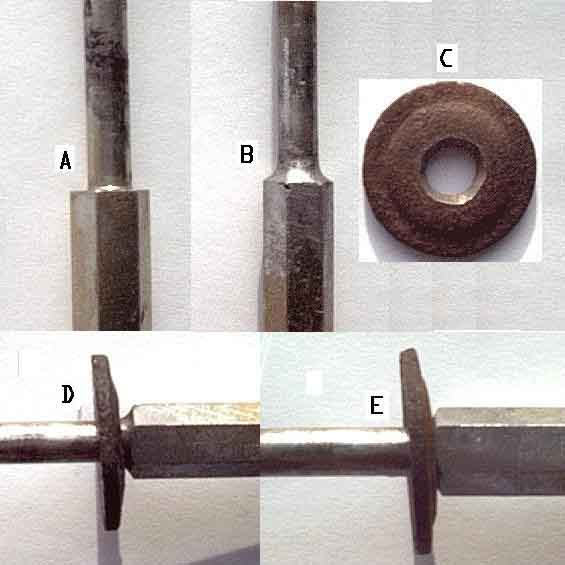

In 2003 or so I became aware of a rattle from the back of the car. When I checked I found that both of the ARB drop-links had snapped where they connect to the bar itself. When I got them off I could see there was a pin on top of the drop-link that goes through a large dished washer, rubber bush, the eye on the bar, another bush and washer and a Nyloc nut holding it all together. The pin had thinned due to corrosion, eventually snapping, click on the picture at the left to enlarge. They had been on the car some eight years and 65k miles of all weathers but even so I thought it was a bit soon for suspension components to corrode and break. However the rear of the car suddenly felt like an unmodified car again, indicating that the improvement came from the ARB and not the telescopic dampers.

In 2003 or so I became aware of a rattle from the back of the car. When I checked I found that both of the ARB drop-links had snapped where they connect to the bar itself. When I got them off I could see there was a pin on top of the drop-link that goes through a large dished washer, rubber bush, the eye on the bar, another bush and washer and a Nyloc nut holding it all together. The pin had thinned due to corrosion, eventually snapping, click on the picture at the left to enlarge. They had been on the car some eight years and 65k miles of all weathers but even so I thought it was a bit soon for suspension components to corrode and break. However the rear of the car suddenly felt like an unmodified car again, indicating that the improvement came from the ARB and not the telescopic dampers.

Ron Hopkinson used to be located in Derby but Moss UK in Derby has taken over the distribution. I ordered a pair of drop links and new nuts, together with two bushes and washers which had been lost, one from each side. The rubber bushes being compressible, and with no instructions, I erred on the side of tightness and when fitting the new parts tightened down the nuts quite a bit. I also daubed the parts in Waxoyl to hopefully reduce any subsequent corrosion. Immediately the rear handling was restored and I went merrily on my way. However about 100 miles down the road I had just done a bit of enthusiastic overtaking when I heard a bump, looked in my rear view mirror, and saw something bounding off into the undergrowth. When I checked underneath sure enough the new pin had snapped but this time I had lost both bushes and washers from that side as it had snapped right at the base of the pin and not part way up as before, see the picture on the left.

Ron Hopkinson used to be located in Derby but Moss UK in Derby has taken over the distribution. I ordered a pair of drop links and new nuts, together with two bushes and washers which had been lost, one from each side. The rubber bushes being compressible, and with no instructions, I erred on the side of tightness and when fitting the new parts tightened down the nuts quite a bit. I also daubed the parts in Waxoyl to hopefully reduce any subsequent corrosion. Immediately the rear handling was restored and I went merrily on my way. However about 100 miles down the road I had just done a bit of enthusiastic overtaking when I heard a bump, looked in my rear view mirror, and saw something bounding off into the undergrowth. When I checked underneath sure enough the new pin had snapped but this time I had lost both bushes and washers from that side as it had snapped right at the base of the pin and not part way up as before, see the picture on the left.

I got on the phone to Russ at Moss, who asked me to return the broken drop-link, then he sent me a new pin, bushes and washers at no charge saying he wasn't surprised it had broken given the design of the drop-link with its sharp angle. However after the failure of the new drop-link I had a close look at the ARB and realised there is a significant design weakness in the Ron Hopkinson design as a whole and not just the drop-link. If you look at the factory bars where it joins the drop-links you can see there is a joint that allows the drop-link to swivel back and fore freely, and this is important because as the axle goes up and down the angle between the drop-link and the ARB is continually changing. But with the RH arrangement the only movement that can take place is by distorting the upper rubber bushes which themselves are trying to bend the upper pins of the drop-link back and fore. So this time I made what movement there is as easy as possibly by only tightening the nuts enough to fully engage the nylon on the Nyloc nuts. But even sooner this time it seemed, the drop-link on the right-hand side broke yet again, this time while travelling in a straight line but over some undulations.

Another phone call to Moss and another free drop-link, bushes and washers, but this time they sent yellow poly bushes instead of black rubber. These are much harder than rubber so I would imagine they would break the pins even quicker. Fortunately I had enough rubber bushes left for the top and used the yellow ones on the bottom where there is less bending movement. I decided to try and strengthen the pins by welding and grinding at the base to form a radius instead of a right-angle, you can see the before and after as A and B in the picture on the left. I also cut a chamfer into the base of the bottom washer (C in the picture) so that it sat right at the base of the pin and not up on my weld (D and E before and after). Furthermore I have tried to make the bushes more compliant by shaping the inner hole into a cone rather than the original cylinder, in the hope that this would impart less bending force to the pin. Time will tell, but if one of these breaks again then short of coming up with a completely different joint that allows free pivoting of the drop-link to the bar, I shall have to junk it all.

Another phone call to Moss and another free drop-link, bushes and washers, but this time they sent yellow poly bushes instead of black rubber. These are much harder than rubber so I would imagine they would break the pins even quicker. Fortunately I had enough rubber bushes left for the top and used the yellow ones on the bottom where there is less bending movement. I decided to try and strengthen the pins by welding and grinding at the base to form a radius instead of a right-angle, you can see the before and after as A and B in the picture on the left. I also cut a chamfer into the base of the bottom washer (C in the picture) so that it sat right at the base of the pin and not up on my weld (D and E before and after). Furthermore I have tried to make the bushes more compliant by shaping the inner hole into a cone rather than the original cylinder, in the hope that this would impart less bending force to the pin. Time will tell, but if one of these breaks again then short of coming up with a completely different joint that allows free pivoting of the drop-link to the bar, I shall have to junk it all.

May 2005: Some 18 months and 4k miles later, and prompted by an enquiry from someone else who has had the same failure, they seem to be holding up, and that includes a reasonable amount of using the power and working the suspension. Someone else reported a while ago that they only just nipped up the nuts and have had no problem, but as mentioned above when I did that on the 2nd replacements they broke even sooner than the 1st replacements. An alternative to doing away with a rear ARB altogether might be to fit the factory system recovered off a scrapped car. The joints at the ends of the bar (which freely articulate) could well be worn and loose but I note they are now available again. Another possibility might be to machine the ends of the RH bar to accept the screw-on factory end joints.

February 2018: Gary Roberts and I have been emailing back and fore about the RH kit, and he has found reference to an updated version on the Moss Europe site - Evolution 2 kit EHK101. They are not currently available (and the Moss US part number given does not exist on that site, or this kit) but there are fitting instructions which he forwarded to me. Looking at the drawings and reading the instructions under 'Roll Bar Links' it is evident that rather than the fixing holes for the links - and the studs on the links - both being vertical as on mine, they are now horizontal. This makes them the same as the damper drop-links i.e. relatively free pivots with no bending moment.

Clonk when Braking August 2018

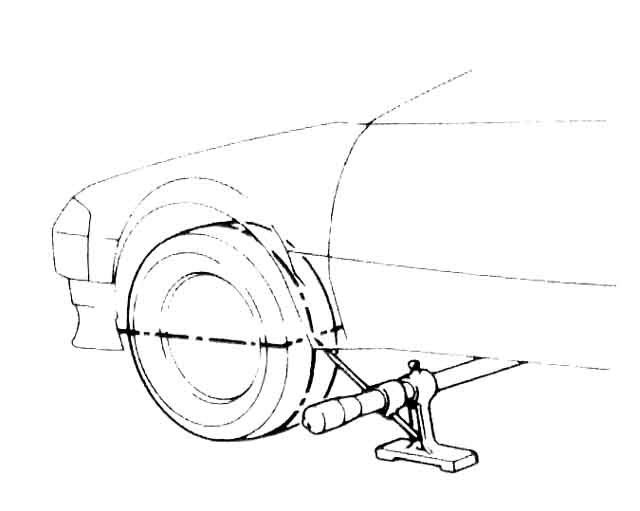

The problem was how to do that while looking round the back of the wheel at the suspension components. I would need a pal, but rather than have him grasp the wheel and heave I decided to make something like the eared spinner 'spanner' which would give more leverage on the wheel and make the job easier. Cut out a template from card held against the spinner and drawn round, marked up some gash board shelving, cut out the shape, and screwed a length of angle iron to it. Applied it to the spinner and sure enough relatively gentle levering reproduced the clonk. While I was at it I thought I'd try the other side ... and the cut-out didn't fit as I had shaped it for the asymmetric spinner on the off-side! No matter, a few minutes later I had a 'universal' spinner spanner, but no clonk from the other side.

The problem was how to do that while looking round the back of the wheel at the suspension components. I would need a pal, but rather than have him grasp the wheel and heave I decided to make something like the eared spinner 'spanner' which would give more leverage on the wheel and make the job easier. Cut out a template from card held against the spinner and drawn round, marked up some gash board shelving, cut out the shape, and screwed a length of angle iron to it. Applied it to the spinner and sure enough relatively gentle levering reproduced the clonk. While I was at it I thought I'd try the other side ... and the cut-out didn't fit as I had shaped it for the asymmetric spinner on the off-side! No matter, a few minutes later I had a 'universal' spinner spanner, but no clonk from the other side.

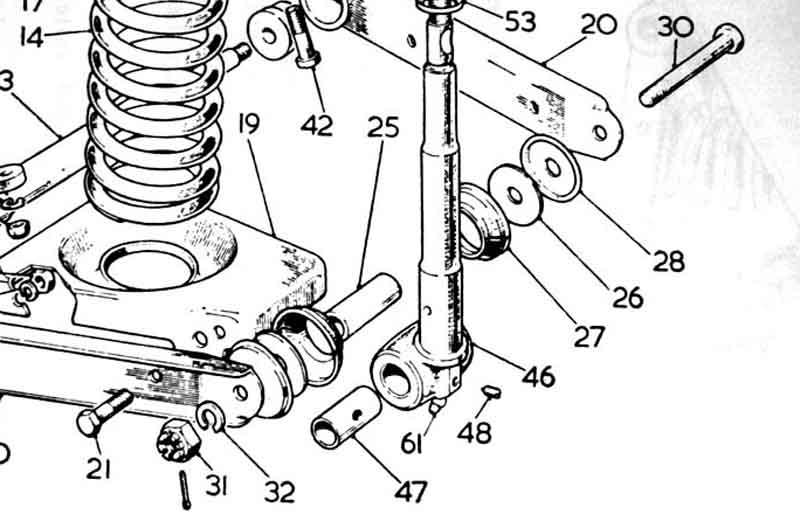

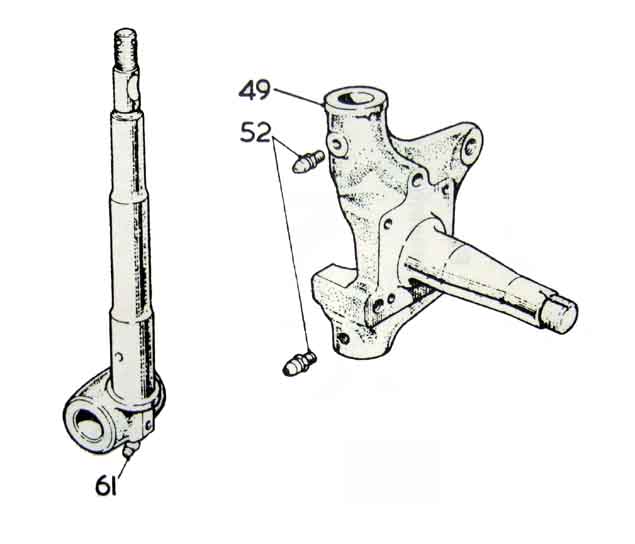

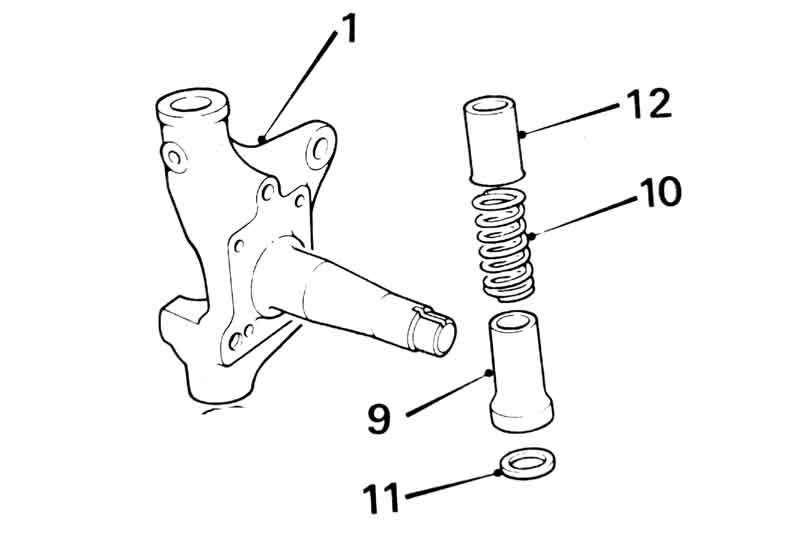

While waiting for said pal to arrive I pondered some more, looking at the drawings of the front suspension assembly to see if I could work out what the source might be, and the main contender was the lower king-pin trunnion sliding back and fore on the distance tube. Pal duly arrived, did the levering, and that's exactly what is happening. The distance tube itself is supposed to be tightly clamped between the thrust washers, but there is a rotation between the king-pin bush and the inner faces of the thrust washers as the suspension moves up and down and the king-pin bush pivots about the distance tube. Grease is supposed to be forced into the lower nipple to the inside of the bush, and then spread outwards to the ends, and the thrust washers, to be retained by the grease seal. With the lower trunnion moving back and fore on the distance tube it could be one of several things:

While waiting for said pal to arrive I pondered some more, looking at the drawings of the front suspension assembly to see if I could work out what the source might be, and the main contender was the lower king-pin trunnion sliding back and fore on the distance tube. Pal duly arrived, did the levering, and that's exactly what is happening. The distance tube itself is supposed to be tightly clamped between the thrust washers, but there is a rotation between the king-pin bush and the inner faces of the thrust washers as the suspension moves up and down and the king-pin bush pivots about the distance tube. Grease is supposed to be forced into the lower nipple to the inside of the bush, and then spread outwards to the ends, and the thrust washers, to be retained by the grease seal. With the lower trunnion moving back and fore on the distance tube it could be one of several things:

- Lower link bolt not tight

- Ends of the bush worn

- Thrust washers at the ends of the distance tube worn

- Anything else?

- New lower trunnion kit? Supposing it's the bush?

- New king-pin bush? That needs reaming

- New king-pin? That means complete strip-down of swivel axle assembly, almost certainly a new upper trunnion kit, and maybe a lower

- Replace the swivel axle wholesale? Expensive, and means re-shimming the hub

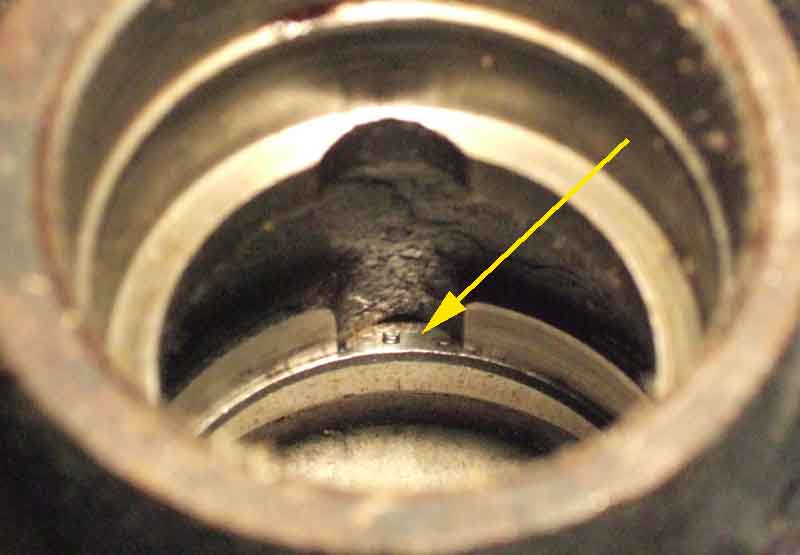

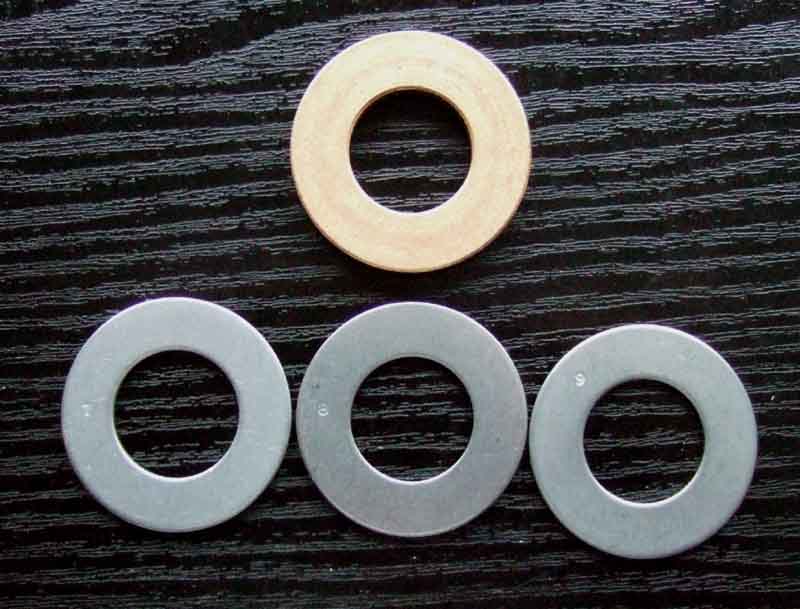

Then cleaning up the thrust washers clearly shows wear marks on the face that has been against the king-pin eye, and they can be felt with a finger-nail. New lower trunnion kit? The rubber grease seals are old but still holding their shape, and it means ordering and waiting for a kit. As there is no wear where the thrust washers bolt up to the distance tube, or to the grease seal support (to be honest I have no idea why the support is there, it's the same size as the thrust washer and flat against it), surely if I just turn each washer round it will present new faces to the king-pin bush? The effect of wear on the (now) back of the thrust washer where it is against the seal support should be negligible. So based on nothing lost if I do that, that is what I do. Pull the trunnion away from the ends of the A-arms, reassemble the seal, seal support and thrust washer against the ends of the distance tube, and slide the trunnion back between the A-arms. Peering through and fine-tuning of the jack height gets the holes aligned to I can get the link bolt back in, and refit the nut. Jack down and heave on the wheel and no clonk. But having been disassembled and reassembled maybe things need time to settle back into position, so take Bee out for a drive. A few miles test braking where I can, and still no clonk, nor some time later on a longer trip!

Then cleaning up the thrust washers clearly shows wear marks on the face that has been against the king-pin eye, and they can be felt with a finger-nail. New lower trunnion kit? The rubber grease seals are old but still holding their shape, and it means ordering and waiting for a kit. As there is no wear where the thrust washers bolt up to the distance tube, or to the grease seal support (to be honest I have no idea why the support is there, it's the same size as the thrust washer and flat against it), surely if I just turn each washer round it will present new faces to the king-pin bush? The effect of wear on the (now) back of the thrust washer where it is against the seal support should be negligible. So based on nothing lost if I do that, that is what I do. Pull the trunnion away from the ends of the A-arms, reassemble the seal, seal support and thrust washer against the ends of the distance tube, and slide the trunnion back between the A-arms. Peering through and fine-tuning of the jack height gets the holes aligned to I can get the link bolt back in, and refit the nut. Jack down and heave on the wheel and no clonk. But having been disassembled and reassembled maybe things need time to settle back into position, so take Bee out for a drive. A few miles test braking where I can, and still no clonk, nor some time later on a longer trip!

The trunnion dust seals may need replacement but beware. If they are reusable then I would as replacements have a reputation for failing in a few months. One person claimed one of the suppliers had neoprene versions, but these expanded in use so didn't retain grease and let dirt in, and needed annual replacement. A year later he was recommending them, and when questioned stated that although they are the same part number they have changed and are now better - Moss Europe AAA1323X, Caveat Emptor!

Flushed with success and as it only took half an hour at most, I decide to tackle Vee as well. Hers is less noticeable, and seems to be coming from the near side. Pulling on the wheel reproduces it, I don't have the equivalent of the 'spinner spanner' for her stud-mounted alloys, but then knowing what I know now I don't need it. Vee has a castellated nut and split-pin which takes a few minutes to fiddle out from behind the brake back-plate, but with the thrust washers out they show similar wear to Bee's, although not to the same extent. But turned round, all refitted, and another test-drive, and no clonk! Doubly chuffed.

Flushed with success and as it only took half an hour at most, I decide to tackle Vee as well. Hers is less noticeable, and seems to be coming from the near side. Pulling on the wheel reproduces it, I don't have the equivalent of the 'spinner spanner' for her stud-mounted alloys, but then knowing what I know now I don't need it. Vee has a castellated nut and split-pin which takes a few minutes to fiddle out from behind the brake back-plate, but with the thrust washers out they show similar wear to Bee's, although not to the same extent. But turned round, all refitted, and another test-drive, and no clonk! Doubly chuffed.

Track Rod Ends

Front adjustment

Measurements: A huge variation 'on the road', as it were:

| Axle Type | Wheel Type | Length | Rear Track | Front Track | Note |

| Banjo | Disc | 46.25" | 49.25" (1250mm) | 49" (1244mm) | 1 |

| Wire | 44.5" | 49.25" (1250mm) | 49.25" (1250mm) | 1 | |

| Salisbury/Tube | Rostyle (late) | 48.5" | 1264mm | 1247mm | 2 |

| Wires (late) | 47" | 1250mm | 1244mm | 2 | |

| Dunlop Wires | 47" | 1270mm | 1273mm | 3 | |

| Rostyle (early) | 48.5" | 1252mm | 1235mm | 4 | |

| V8 alloy | 48.5" | 1250mm | 1252mm | 5 | |

| Early Rostyle on V8 | 48.5" | 1252mm | 1254mm | 6 | |

| 72 spoke wires | 47" | 1250mm | 1220mm | 7 | |

| 60 spoke wires | 47" | 1256mm | - | 8 | |

| Minotaur Minilites | 1260mm | - | |||

| 15" alloys | 1278mm | - | 10 | ||

| Aftermarket wires | 1268mm | 1273mm | 11 | ||

| MGC wires | 1267mm | 1287mm | 12 |

- Workshop Manual for G/GA engines

- 1977 LHD Workshop Manual and 1978 Repair Operation Manual. However one would expect the Salisbury Rostyle front track to have increased by the same amount as the rear, i.e. to 1258mm whereas it's only 3mm wider than the Banjo disc wheels, although it's complicated by the change to V8 hubs from the same date. For wires one would expect 1262mm for the rear track and 1256m for the front track given Clausager's comments on pages 95 and 150 about a modified wire wheel from September 76 "BHH2133 instead of AHH6487, new wheel has 9/16" (14.3mm) inset to improve tyre clearance to wheelarch". However I don't understand why the wire wheel would need more clearance in September 76, when the Rostyle wheel had the offset (and hence the clearance) reduced to give a wider track, which the higher ride height of rubber bumper cars would allow for without rubbing. Indications are that the earlier wheel had a 21mm inset i.e. a 6.7mm change per wheel.

- My after-market Dunlops on a standard wire wheel axle and front hubs, i.e. 20mm and 29mm more than the factory figures.

- Early Rostyle estimation based on the above reduction in offset from 28 to 22mm i.e. a 6mm change per wheel.

- My V8 alloys.

- My V8 with 28mm Rostyle wheels.

- Michael Beswick - front 30mm narrower.

- David Corrie.

- Ben Purnell.

- Steve Livesley - RB, 185 tyres. Rubs occasionally two-up.

- Richard Towers - MGB converted to wires

- Richard Towers - MGC with 15" 5.5 wires

June 2020: An article on building a steel-wing Sebring replica in 'Enjoying MG' included the comment that the first time they put the car on wheels they had to hand, the clearance to one arch was 10mm less than the other, which eventually was found to be down to two different wire wheels. That 10mm per wheel, or 20mm difference in the track, is exactly what I have.

In the meantime I've done a measurement between wheel mounting surfaces using my tracking gauge, which comes out at 1320mm.

More information on wheel sizes and offsets/insets here, and on converting from stud wheels to centre-lock here.

Removal

Front Track Alignment

Track Width

May 2017: Following a comment on the MGOC forum I learnt that there have been two types of steering arm and track-rod end. What the Workshop Manual describes as 'early production cars' had a washer under the nut securing the TRE to the steering arm. Later cars had a narrower hole in the arm, the TRE pin was longer, and the nut is deeper, and no washer. The later TREs can be fitted to the early arms, just leave the washer out. The change must have been pretty early as there is only one RHD and one LHD part number for chrome bumper TREs and one (per side) for steering arms in my Parts Catalogues. The catalogue does list five part numbers though:

Dust covers: Damaged dust covers are apparently an MOT failure, and are available separately, but like so many parts these days - rubber in particular - fail very quickly. Someone on one of the fora claimed he had silicone rubber and they are much better but didn't give a source at the time. Googling revealed only one source - an eBay seller in Bulgaria, but the size quoted is much bigger than quoted elsewhere for non-silicone rubber for the MGB and I couldn't find them elsewhere in his 'shop'. Subsequently the poster came back with a link (NLA) to the correct size 13-31-23 from said Bulgarian source.

April 2019:

Finding one of the covers on my RB V8 slightly damaged with the larger retaining spring distorted I took the dust cover off to check the sizing, and find it significantly different: The pin is 11.6mm diameter, the groove in the socket is 30.33 dia, and the depth between the socket groove and the start of the straight section of the pin is 16.6mm. The existing dust cover is very similar to those measurements for the pin and socket groove, and the depth is 18.8mm i.e. 12-31-17. So although the two diameters of the 13-31-23 are fiine the depth is quite a bit more, and the excess material would end up being crushed and maybe not lasting very long. The closest the supplier has is 12-31-21 in 'high quality rubber' but clicking on that displays an error page, and it also looks to be a completely different shape. The next closest is 12-31-22 with the same shape as the existing ones, but is described as 'polyurethane', and priced in American dollars. I am awaiting a response from the supplier. Update: As with so many people these days he seemed incapable of answering several questions asked in one email, saying all types were available. Googling showed up other sources but 'universal', and rubber, so I ordered a pair of the poly ones and will see how I get on. Retaining springs not available, but by disconnecting the TRE from the steering arm I was able to remove the cover and retainer (flat, not round wire as with the smaller retainer), 'straighten' the retainer and refit with one of the replacement covers. Some say they use cable-ties, but even the small ones are quite a bit bigger than the springs. Fine on track-rod gaiters, but on these I'm not so sure.

Finding one of the covers on my RB V8 slightly damaged with the larger retaining spring distorted I took the dust cover off to check the sizing, and find it significantly different: The pin is 11.6mm diameter, the groove in the socket is 30.33 dia, and the depth between the socket groove and the start of the straight section of the pin is 16.6mm. The existing dust cover is very similar to those measurements for the pin and socket groove, and the depth is 18.8mm i.e. 12-31-17. So although the two diameters of the 13-31-23 are fiine the depth is quite a bit more, and the excess material would end up being crushed and maybe not lasting very long. The closest the supplier has is 12-31-21 in 'high quality rubber' but clicking on that displays an error page, and it also looks to be a completely different shape. The next closest is 12-31-22 with the same shape as the existing ones, but is described as 'polyurethane', and priced in American dollars. I am awaiting a response from the supplier. Update: As with so many people these days he seemed incapable of answering several questions asked in one email, saying all types were available. Googling showed up other sources but 'universal', and rubber, so I ordered a pair of the poly ones and will see how I get on. Retaining springs not available, but by disconnecting the TRE from the steering arm I was able to remove the cover and retainer (flat, not round wire as with the smaller retainer), 'straighten' the retainer and refit with one of the replacement covers. Some say they use cable-ties, but even the small ones are quite a bit bigger than the springs. Fine on track-rod gaiters, but on these I'm not so sure.

May 2020:

12 months later still there and no signs of deterioration.

12 months later still there and no signs of deterioration.

Removal:

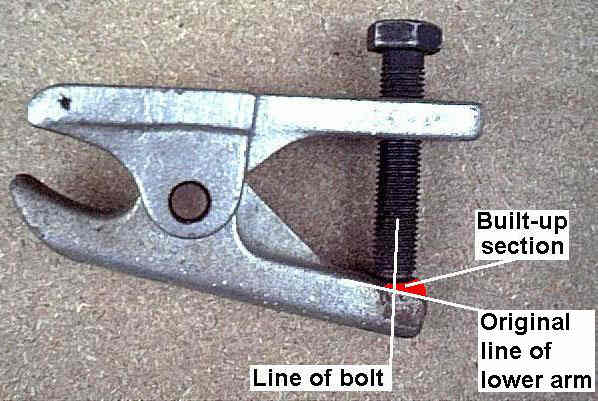

Using wedges and pickle-fork so-called ball-joint splitters I had never been able to disconnect the track-rod end (TRE) from the steering arm without damaging the rubber boots on them i.e. destroying them in the process so unless I was changing them anyway I didn't even try. To replace them you will have to disconnect them from the steering arms of course, but to replace just the gaiter you can either unbolt the steering arm from the swivel axle which is easily done then unscrew the TRE with steering arm from the track-rod, or just unscrew the track-rod from the TRE rather than vice-versa. You may have to remove the tie or clamp on the small end of the gaiter in order to turn the rod without twisting up the gaiter. Eventually I bought a ball joint separator but had to modify it. Now splitting track-rod end tapers is a positive joy.

Using wedges and pickle-fork so-called ball-joint splitters I had never been able to disconnect the track-rod end (TRE) from the steering arm without damaging the rubber boots on them i.e. destroying them in the process so unless I was changing them anyway I didn't even try. To replace them you will have to disconnect them from the steering arms of course, but to replace just the gaiter you can either unbolt the steering arm from the swivel axle which is easily done then unscrew the TRE with steering arm from the track-rod, or just unscrew the track-rod from the TRE rather than vice-versa. You may have to remove the tie or clamp on the small end of the gaiter in order to turn the rod without twisting up the gaiter. Eventually I bought a ball joint separator but had to modify it. Now splitting track-rod end tapers is a positive joy.

Update August 2010:A tip when disconnecting the track-rod ends from the steering arms. The nut is usually a Nyloc, and the effect of this is that once the taper is broken you can't turn the nut on the thread without locking the taper again, as the stud just turns in the ball-joint. And if using a screw-type splitter you really need to have a nut on several threads if you are to avoid damaging the end of the stud. The tip is to remove the Nyloc nut, then put a plain nut on until the end of the stud is close to the face of the nut, before using the splitter. As long as the threads are good the plain nut will be much easier to remove once the taper is broken. For replacement the same problem occurs, so screw the plain nut up tight to lock the taper, then replace with the Nyloc nut.

But I digress. Make alignment marks on the track-rod and TRE. Slacken the lock-nut and count how many turns are needed to separate the track rod end from the track rod. If refitting the same TREs then using the same number of turns you should be spot-on, but unless you know your tracking was right before there is no harm in getting it checked, and you know you will be able to slacken and adjust everything before it all seizes up again (and if you reassemble with copper grease it is much less likely to seize-up anyway).

If changing track rod ends and they are basically the same length alignment marks and counting turns will probably get you close enough to drive straight (hopefully!) to an alignment centre, which should be done as there are bound to be dimensional differences between old and new track rod ends. However changing Bee's track-rod ends I found the new ones were quite a bit longer than the old, so no point. I measured the difference as best I could at 6mm, then screwed the lock-nuts back towards the gaiters until there was a 6mm gap to the ends of the old track-rod ends, and removed them.

If changing track rod ends and they are basically the same length alignment marks and counting turns will probably get you close enough to drive straight (hopefully!) to an alignment centre, which should be done as there are bound to be dimensional differences between old and new track rod ends. However changing Bee's track-rod ends I found the new ones were quite a bit longer than the old, so no point. I measured the difference as best I could at 6mm, then screwed the lock-nuts back towards the gaiters until there was a 6mm gap to the ends of the old track-rod ends, and removed them.

The old ones were surprisingly bad given they were only advisories, the worst had lost a large part of its rubber boot, the ball was sloppy in its joint and rusty. The other one had a split boot and was rusty inside, but the ball wasn't as loose. I then screwed the new ones on right up to the lock-nuts. Not happy that I had got the tracking close enough for driving to the alignment place I decided to make an alignment gauge. Having (hopefully) got the tracking close enough for a test drive it was immediately noticeable how smooth the steering was, I had recently been aware of some vibration through the wheel, which wasn't consistent so I didn't think it was wheel balance. Also quieter, as if I had subconsciously noted some rattling, both must have been coming from the worn UJ as well as track-rod ends. I suppose it is a case of not noticing gradual changes in sound and feel over a long time, whereas we should all be aware of sudden changes and either know what they are (as in this case) or investigate them - Nory's "Listen to your car, it is talking to you".

The old ones were surprisingly bad given they were only advisories, the worst had lost a large part of its rubber boot, the ball was sloppy in its joint and rusty. The other one had a split boot and was rusty inside, but the ball wasn't as loose. I then screwed the new ones on right up to the lock-nuts. Not happy that I had got the tracking close enough for driving to the alignment place I decided to make an alignment gauge. Having (hopefully) got the tracking close enough for a test drive it was immediately noticeable how smooth the steering was, I had recently been aware of some vibration through the wheel, which wasn't consistent so I didn't think it was wheel balance. Also quieter, as if I had subconsciously noted some rattling, both must have been coming from the worn UJ as well as track-rod ends. I suppose it is a case of not noticing gradual changes in sound and feel over a long time, whereas we should all be aware of sudden changes and either know what they are (as in this case) or investigate them - Nory's "Listen to your car, it is talking to you".

Just after replacing Bee's I find that Vee's need doing as well, as a result of investigating a clonk when applying and releasing the brakes, which led me to discover a clonk as I turned the steering wheel back and fore with the road wheels on the ground, which felt like it was the track-rod end but could be the rack! But this time the offside at least looks heavily corroded. I buy two more track-rod ends plus lock-nuts as it looks I might have to use an angle-grinder on both. I don't have a spanner that fits, and my mini-Stilsons isn't giving me enough leverage as well as chewing up the nut, so a trip to Halfords with a new nut gets me a 22mm which is a pretty close fit. That gets the nut turning on the track-rod, but the track-rod is stuck fast in the track-rod end. My Stilsons grip the track-rod to some extent, and a large ring-spanner over the end of the handle gives me more leverage, but being round bar eventually it just slips, even having applied Halfords 'shock and oh' releasing fluid ('shock' from the freezing spray as well as the penetrating fluid, 'oh' from the 'oh bugger' when it doesn't make any difference). So nothing for it but to run the angle-grinder along the length of the track-rod end until the tips of the threads just start to appear. Get the Stilsons on the track-rod again, hoping the heat from the angle-grinding might have done the trick, with more freezer spray on the exposed threads, but still no go. So this time I put the Stilsons on the end of the track-rod end, pin still in the steering arm, in such a way that it is trying to peel it open, and finally hear a 'crack'. After that it comes off relatively easily, only took a couple of hours... New and old look to be the same lengths, so count the turns to remove (21) and fit the new one (with copper-grease!). I decide to leave the old nut on, screwed back a bit, plus a new one, thinking that in future the two nuts locked together will give me more purchase to turn the track-rod.

Just after replacing Bee's I find that Vee's need doing as well, as a result of investigating a clonk when applying and releasing the brakes, which led me to discover a clonk as I turned the steering wheel back and fore with the road wheels on the ground, which felt like it was the track-rod end but could be the rack! But this time the offside at least looks heavily corroded. I buy two more track-rod ends plus lock-nuts as it looks I might have to use an angle-grinder on both. I don't have a spanner that fits, and my mini-Stilsons isn't giving me enough leverage as well as chewing up the nut, so a trip to Halfords with a new nut gets me a 22mm which is a pretty close fit. That gets the nut turning on the track-rod, but the track-rod is stuck fast in the track-rod end. My Stilsons grip the track-rod to some extent, and a large ring-spanner over the end of the handle gives me more leverage, but being round bar eventually it just slips, even having applied Halfords 'shock and oh' releasing fluid ('shock' from the freezing spray as well as the penetrating fluid, 'oh' from the 'oh bugger' when it doesn't make any difference). So nothing for it but to run the angle-grinder along the length of the track-rod end until the tips of the threads just start to appear. Get the Stilsons on the track-rod again, hoping the heat from the angle-grinding might have done the trick, with more freezer spray on the exposed threads, but still no go. So this time I put the Stilsons on the end of the track-rod end, pin still in the steering arm, in such a way that it is trying to peel it open, and finally hear a 'crack'. After that it comes off relatively easily, only took a couple of hours... New and old look to be the same lengths, so count the turns to remove (21) and fit the new one (with copper-grease!). I decide to leave the old nut on, screwed back a bit, plus a new one, thinking that in future the two nuts locked together will give me more purchase to turn the track-rod.

When I come to do the second one I don't have much time but put the spanner on the locknut just to see what happens and it moves straight-away. Not only that it is screwing the track-rod out of the track-rod end. So crack the taper to the steering arm, unscrew (18 turns), and screw the new one on. This one already has copper-grease on it, I'd forgotten I had already dealt with that one some years ago when replacing a gaiter. Shows just how effective the grease is, and second nut on the other side obviously not required. This one takes me 10 minutes start to finish! All I have to do now is check and adjust the tracking with my gauge. Well, I say 'all', but having gone from king-pins to track-rod ends and noticing a broken bump-rubber on the way, this time I noticed the A-arms on the left side weren't being held centrally on the bushes on the wishbone pivot, but were both as far back as they could go, the front one up against the face of the pivot and the rear one against the retaining washer. Annoying as I replaced A-arms and bushes a few years ago and they are the correct V8 ones. In theory this might have altered the suspension geometry, which could account for a very slight drift to the left on a flat surface, which implies a difference in castor angle between sides. But the direction the A-arms have moved is rearwards, which would have reduced the castor angle that side, which in theory should cause a drift to the right. So something else to investigate further. Used the alignment gauge again, the kit at my local tyre place should fit the V8 wheels OK as a double-check. But just like Bee it was immediately noticeable how much quieter and smoother the steering had become. After finally getting the wheels balanced correctly I was left with an occasional tremor over some surfaces, which I put down to the slight wear that I know exists in the rack, and the free-play in the column. On a 70 miles run there was absolutely nothing - excellent result.

Front Track Adjustment:

Making an alignment gauge, but first some points about tracking and alignment:

Tracking can be measured in one of two ways - physical measurement of the tyres and wheels, or the amount of scrub. I've never used it but Gunson's Trakrite measures the scrub, or side-slip, by pushing the car forwards with one wheel over the device which consists of two plates, one on top of the other, with ball-bearings between them. Any scrub will tend to push the top plate sideways relative to the bottom plate, and this relative movement is displayed on a scale. You adjust the tracking (both track-rod ends equally remember) to give zero scrub or as close as you can get, my Celica manual for example quotes a maximum of 3mm per meter, or 0.118" in 3.3 feet(!) in either direction. You only have to measure one side, as the grip between the tyre and the ground on the other side will push or pull the tested tyre the whole amount of the scrub for both tyres. Therefore get the tested tyre to zero, and the other should be at zero also (however this from Frost advises doing both sides to confirm). Out of interest the toe on the Celica is +-1mm, i.e. neutral or zero toe, which is quite common for front-wheel drive cars.

As well as describing measuring side-slip or scrub the Celica manual has a detailed description of how to measure the physical amount of toe. Basically you mark the middle of tread, in line with the centre of the axle, on the front or the back of the tyre, and measure the distance between the two marks, which is most easily done with two pointers on a connecting bar resting on the ground. Then roll the car half a revolution, so the marks on the tyres are now on the other side but back in line with the axle centre-line again, and again measure the distance between the two marks. If you carefully move your pointers from the first (reference) position to the second (comparison) position, and line up one pointer with its mark, you can directly measure the total toe between the other mark and its pointer. If you take the reference measurement at the back then roll the car forward to make the comparison, or vice-versa, so the marks aren't scrubbed off on the ground. If adjustment is required this method obviously needs you to move the gauge between the back and the front of the tyres several times, making small adjustments to the pointers each time, and being careful not to knock the pointers when moving from the reference side to the comparison side, in addition to rolling the car back and fore several times (which applies to both methods). The side-slip method will certainly be easier, but at a cost of typically £75 as opposed to perhaps nothing if you have a long enough broom-handle and some thin rod, considerably more expensive for something that may only be used once per year at most.

As well as describing measuring side-slip or scrub the Celica manual has a detailed description of how to measure the physical amount of toe. Basically you mark the middle of tread, in line with the centre of the axle, on the front or the back of the tyre, and measure the distance between the two marks, which is most easily done with two pointers on a connecting bar resting on the ground. Then roll the car half a revolution, so the marks on the tyres are now on the other side but back in line with the axle centre-line again, and again measure the distance between the two marks. If you carefully move your pointers from the first (reference) position to the second (comparison) position, and line up one pointer with its mark, you can directly measure the total toe between the other mark and its pointer. If you take the reference measurement at the back then roll the car forward to make the comparison, or vice-versa, so the marks aren't scrubbed off on the ground. If adjustment is required this method obviously needs you to move the gauge between the back and the front of the tyres several times, making small adjustments to the pointers each time, and being careful not to knock the pointers when moving from the reference side to the comparison side, in addition to rolling the car back and fore several times (which applies to both methods). The side-slip method will certainly be easier, but at a cost of typically £75 as opposed to perhaps nothing if you have a long enough broom-handle and some thin rod, considerably more expensive for something that may only be used once per year at most.

Having recently had a major clear-out of garage and shed I didn't really have the makings without butchering a garden tool or two, so for a few quid I bought some square tubing, threaded rod and nuts from B&Q. I measured the distance between the centre of the treads on each wheel, and this gave me the nominal spacing of the pointers. I also measured the ZS, which is quite a bit wider, and made the bar just long enough to take the pointers at this spacing, in case I ever needed to do that car as well. I drilled hole through the tubing (at the MGB spacing) to take the threaded rod, then overdrilled the bottom hole to allow a cap-nut to pass through which would be on the bottom of each rod. A butterfly nut further up the thread, above the tubing, clamps the rod in position. The rod rises vertically from the tubing and is then bent forwards to meet the mark on the tyre, it's overall length being such that the pointer touches the centre-line of the axle. I subsequently noticed that Moss have a similar gauge at about £50 so quite a bit cheaper than a Trakrite, but not as cheap as mine! However the instructions on the ordering page simply to measure between the outer sidewalls at the front of the tyre, then compare that with the backs. That would require the tyres to be perfectly mounted on the wheels, with no run-out. At the very least the car should be rolled back and fore half a turn so you are comparing the same point on the sidewalls, as I am doing with the centre of the tread.

Having recently had a major clear-out of garage and shed I didn't really have the makings without butchering a garden tool or two, so for a few quid I bought some square tubing, threaded rod and nuts from B&Q. I measured the distance between the centre of the treads on each wheel, and this gave me the nominal spacing of the pointers. I also measured the ZS, which is quite a bit wider, and made the bar just long enough to take the pointers at this spacing, in case I ever needed to do that car as well. I drilled hole through the tubing (at the MGB spacing) to take the threaded rod, then overdrilled the bottom hole to allow a cap-nut to pass through which would be on the bottom of each rod. A butterfly nut further up the thread, above the tubing, clamps the rod in position. The rod rises vertically from the tubing and is then bent forwards to meet the mark on the tyre, it's overall length being such that the pointer touches the centre-line of the axle. I subsequently noticed that Moss have a similar gauge at about £50 so quite a bit cheaper than a Trakrite, but not as cheap as mine! However the instructions on the ordering page simply to measure between the outer sidewalls at the front of the tyre, then compare that with the backs. That would require the tyres to be perfectly mounted on the wheels, with no run-out. At the very least the car should be rolled back and fore half a turn so you are comparing the same point on the sidewalls, as I am doing with the centre of the tread.

Subsequently took the car to my local tyre place for a tracking check to find their stuff would not fit over/round the spinners, also my next local place. The fronts could be turned so that with the ears at an angle the laser unit fitted round them, but at the back it is a single central vertical bar and even the body of the spinner sticks out too far for that. Good job I got them (hopefully) close with my home-made gauge, looks like I have a 20 mile drive to the next nearest place with kit that should cope with them. One week later... Some nice weather at long last so a trip through the countryside to a place with screw-in adapters that hold the gizmos further out from the wheel hence clearing the spinner. Tracking is a shade under 2mm toe in, so given that the spec calls for 1.5 to 2.3mm I call that a result! Even more of a result is that checking is free, only adjustment costs!!

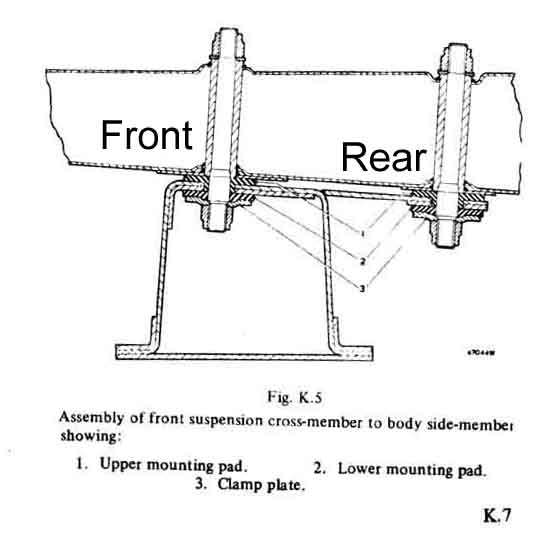

Front Crossmember November 2018

Three types over the life of the MGB - originally AHH6195 on all chrome bumper 4-cylinder cars, then BHH803 on all V8s and RHD rubber bumper 4-cylinder cars, and BHH804 on LHD rubber bumper 4-cylinder cars. The RB versions have a thick spacer under the chassis rails to give the higher front ride height on these cars. The RB rack mounting brackets are also different, and in one case at least angles the rack relative to the crossmember making one end higher than the other ... or does it?

Three types over the life of the MGB - originally AHH6195 on all chrome bumper 4-cylinder cars, then BHH803 on all V8s and RHD rubber bumper 4-cylinder cars, and BHH804 on LHD rubber bumper 4-cylinder cars. The RB versions have a thick spacer under the chassis rails to give the higher front ride height on these cars. The RB rack mounting brackets are also different, and in one case at least angles the rack relative to the crossmember making one end higher than the other ... or does it?

The mounting pads also changed for the later versions. Originally four AHH6205 for the uppers with a collar round the bolt hole projecting down into the crossmember, and four AHH6206 for the lowers which were flat. On rubber bumper cars the front lower pads were replaced with collared pads as there is now space for the collar to project up into the crossmember as well as the upper ones projecting down. The rears are unchanged. For that reason it would appear that all V8s would have lipped pads upper and lower at the front as they had the rubber bumper crossmember throughout, but this isn't shown in the Parts Catalogue or on suppliers websites. The Leyland Parts Catalogue for 1977 and later gives the amended quantities, but whether the change only dated from that point, or whether it was on all rubber bumpers and V8s and simply missed out of the earlier catalogue isn't known. Only Moss Europe (AHH6205SPKC for CB and AHH6205SPKR for RB) and British Parts Northwest (AHH6205/6P for CB and AHH6205/6LP for RB) seem to give a logically correct change point for the quantities with their poly kits.

The mounting pads also changed for the later versions. Originally four AHH6205 for the uppers with a collar round the bolt hole projecting down into the crossmember, and four AHH6206 for the lowers which were flat. On rubber bumper cars the front lower pads were replaced with collared pads as there is now space for the collar to project up into the crossmember as well as the upper ones projecting down. The rears are unchanged. For that reason it would appear that all V8s would have lipped pads upper and lower at the front as they had the rubber bumper crossmember throughout, but this isn't shown in the Parts Catalogue or on suppliers websites. The Leyland Parts Catalogue for 1977 and later gives the amended quantities, but whether the change only dated from that point, or whether it was on all rubber bumpers and V8s and simply missed out of the earlier catalogue isn't known. Only Moss Europe (AHH6205SPKC for CB and AHH6205SPKR for RB) and British Parts Northwest (AHH6205/6P for CB and AHH6205/6LP for RB) seem to give a logically correct change point for the quantities with their poly kits.

Castor Angle: July 2023 According to the Workshop Manual this is set at a nominal 7 degrees between 5 degrees and 7.25 degrees, however Don Hayter in his 'MGB Story' writes on page 40 that during the development of the MGB this was "originally designed to give 7 degrees of castor angle, but eventually changed to 4 degrees after testing for optimum steering effort". Curious - a development change that never made it into production for some reason - cost? Or just forgotten?